Production method of regenerated cellulose fiber and cotton blended colored yarns

A technology of regenerated cellulose and production method, applied in the field of yarn production, can solve the problems of inability to go to market, large waste and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

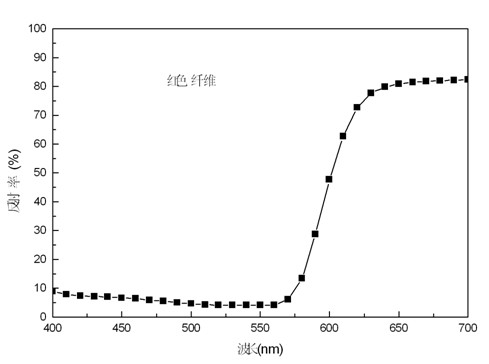

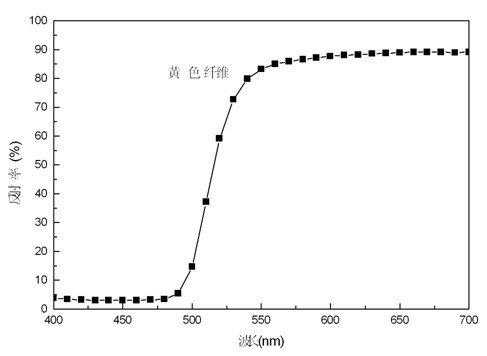

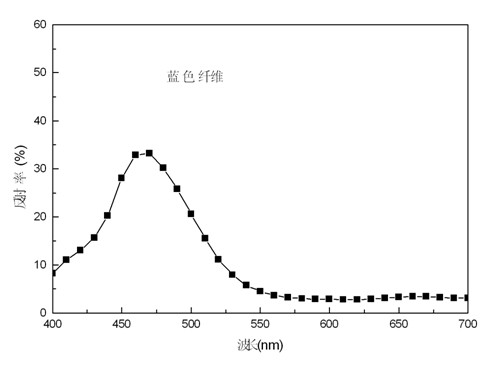

Image

Examples

Embodiment 1

[0060] According to the ratio of red: yellow: natural color cotton: black = 1:1:7.8:0.2, the fiber distribution and color matching are carried out, and the cotton distribution and its weighing equipment are used to quantitatively feed the A104 type flat carding machine; the carding machine is carded and clustered Finally, it becomes a sliver with a certain mixing degree, and the fixed weight is 20g / 5m. The draw frame chooses the second draw frame, and the fixed weight of the cooked sliver is 20g / 5m. The cooked sliver is drafted 8 times on the roving frame to obtain a roving, and the fixed weight is 5g / 10m. The roving is drafted 27 times on the spinning frame to obtain a spun yarn with a fineness of 18.5tex (32 English counts).

Embodiment 2

[0062] According to the ratio of red: blue: natural color cotton: black = 1:1:7:1, the fiber distribution and color matching are carried out, and the cotton distribution and its weighing equipment are used to quantitatively feed the A104 type flat carding machine; the carding machine is carded, After bundling, it becomes a sliver with a certain mixing degree, and the fixed weight is 20g / 5m. The draw frame chooses the second draw frame, and the fixed weight of the cooked sliver is 20g / 5m. The cooked slivers are spun yarns with a fineness of 50tex (13 English counts) on the rotor spinning machine.

Embodiment 3

[0064] According to the ratio of yellow: blue: natural color cotton: black = 3:2:4:1, the fiber distribution and color matching are carried out, and the cotton distribution and its weighing equipment are used to quantitatively feed the A104 type flat carding machine; the carding machine is carded, After bundling, it becomes a sliver with a certain mixing degree, and the fixed weight is 20g / 5m. The draw frame chooses the second draw frame, and the fixed weight of the cooked sliver is 20g / 5m. The cooked slivers are spun yarns with a fineness of 50tex (13 English counts) on the rotor spinning machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com