Biological cement reinforced roadbed on under-consolidation silt blowing foundation and construction method of roadbed

A biological and ground-based technology, applied in infrastructure engineering, construction, soil protection, etc., can solve problems such as consolidation, insufficient stability of bearing capacity, shorten construction period, reduce moisture content, etc., and achieve energy recycling, Improve the ability to control post-construction deformation and reduce the effect of bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not constitute a conflict with each other.

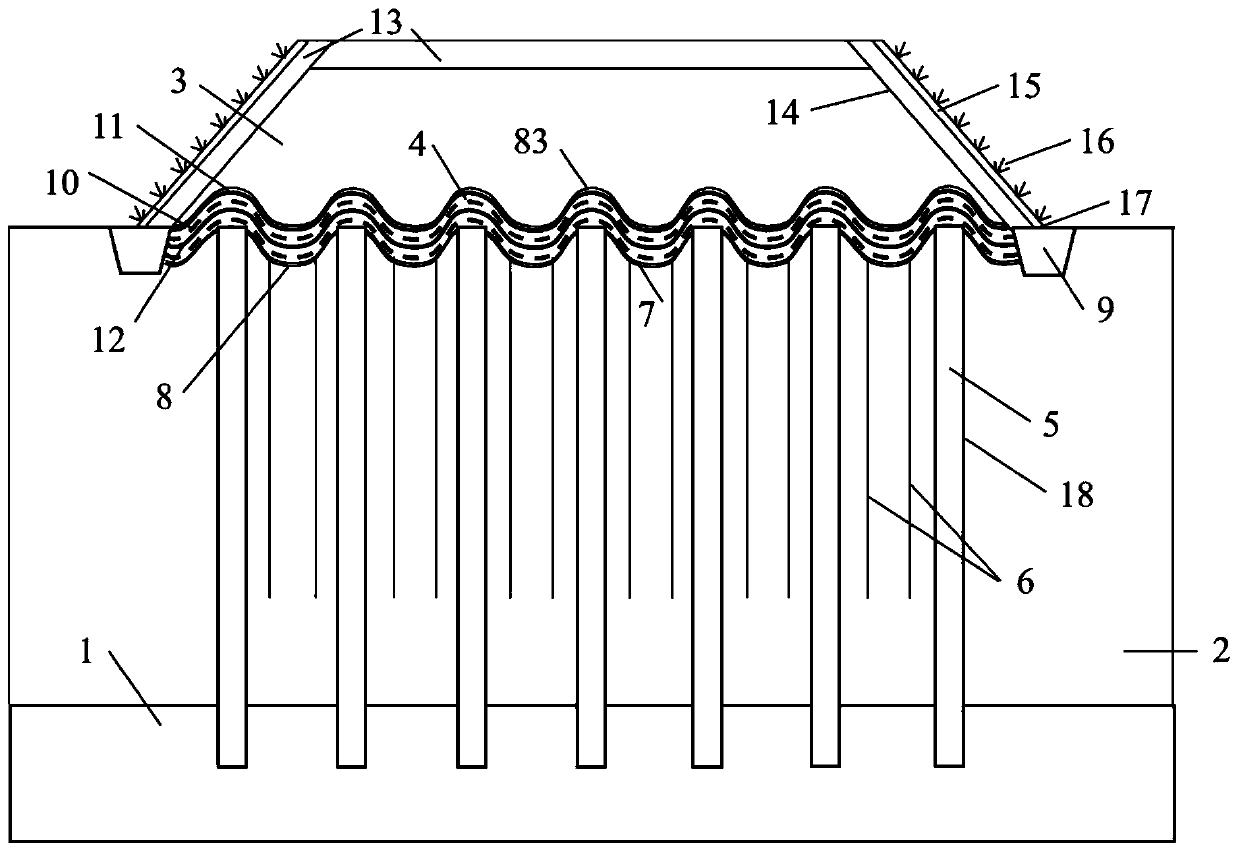

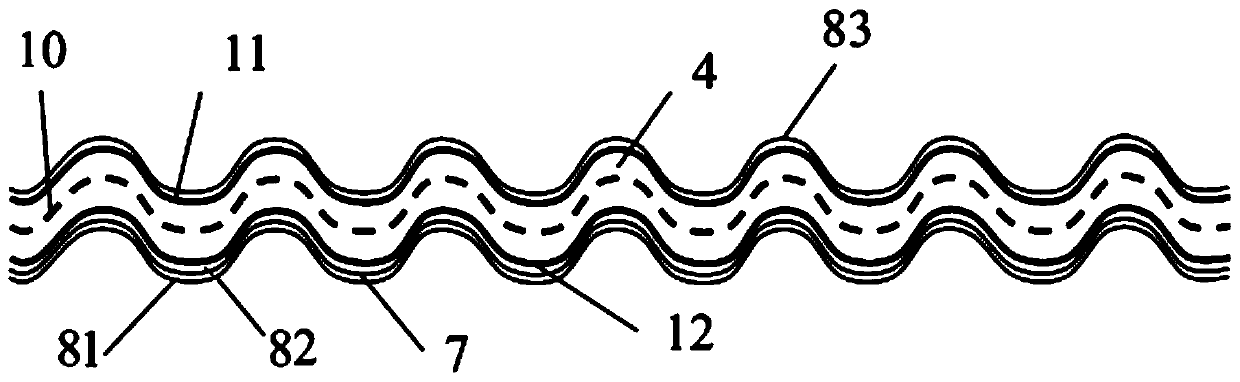

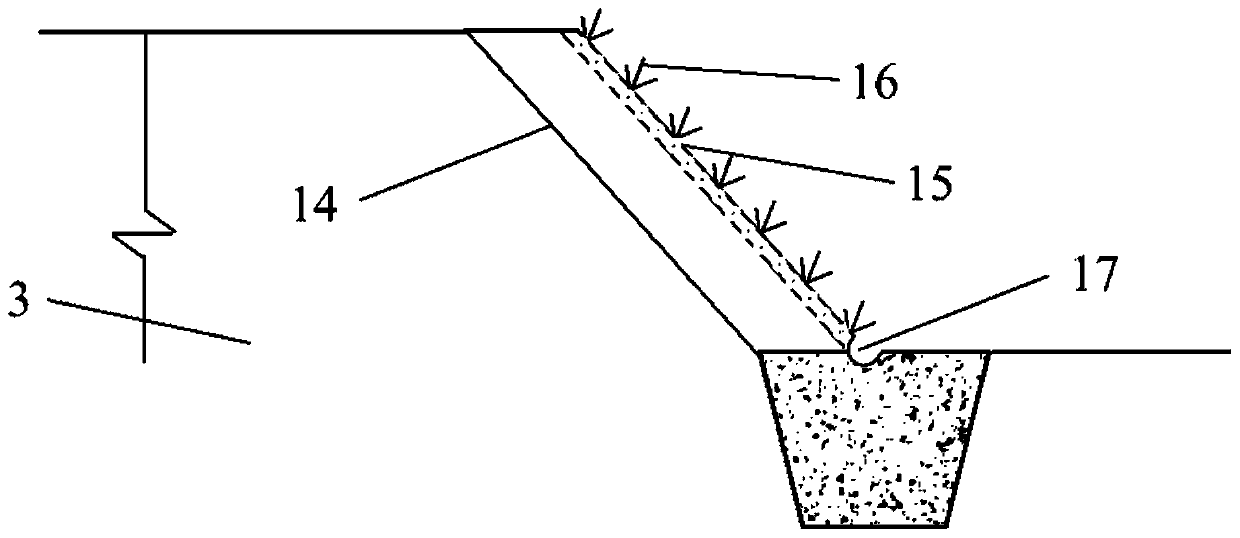

[0043] A bio-cement reinforced subgrade on an under-consolidated dredging foundation, such as figure 1 As shown, it includes the underlying bearing layer 1, the underconsolidated silt blowing foundation 2, the embankment 3, the biological waterproof layer 13, the cultivation soil layer 15, the slope protection vegetation 16, and the embankment 3 and the underconsolidated silt blowing foundation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com