Patents

Literature

43results about How to "Smooth surface quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

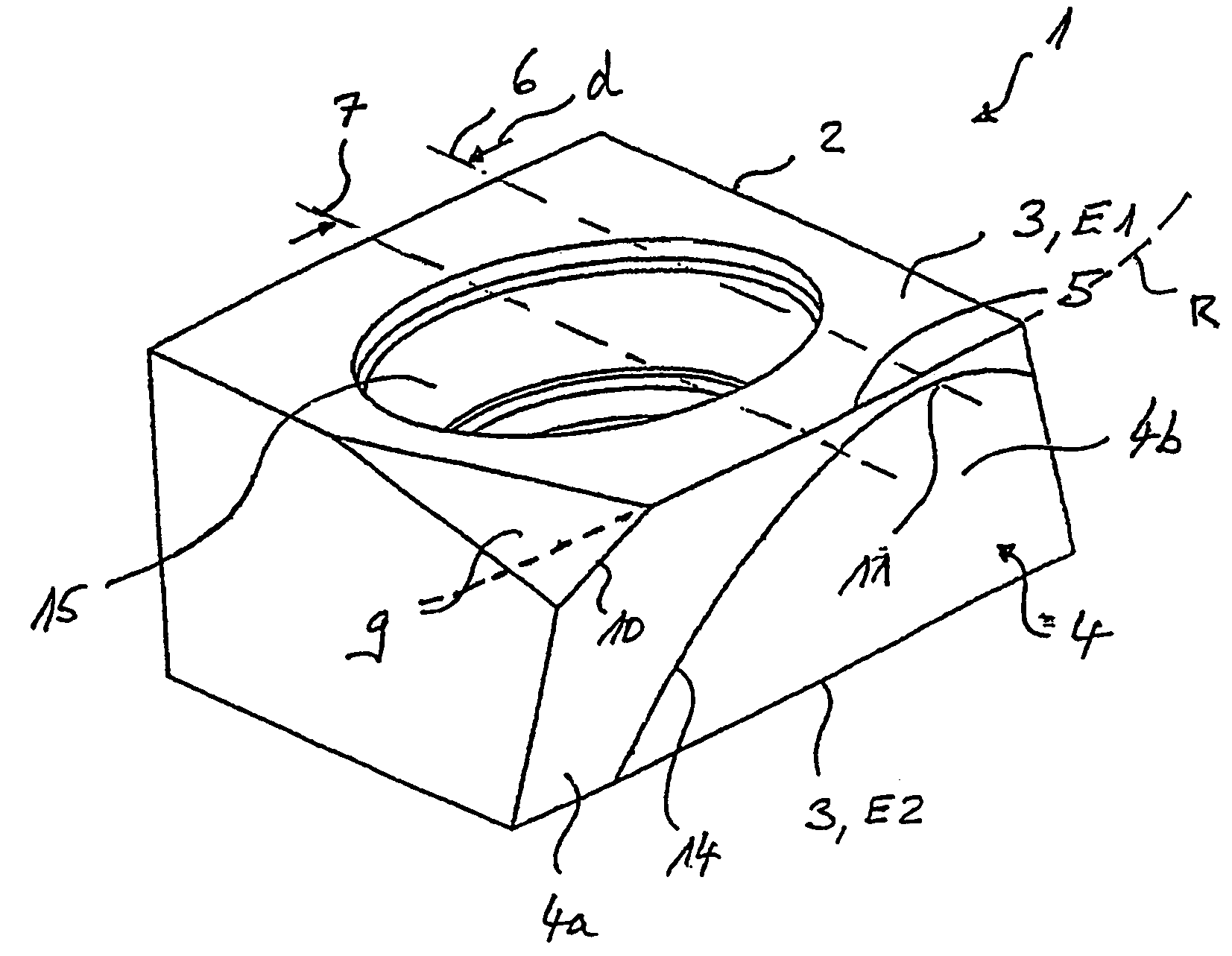

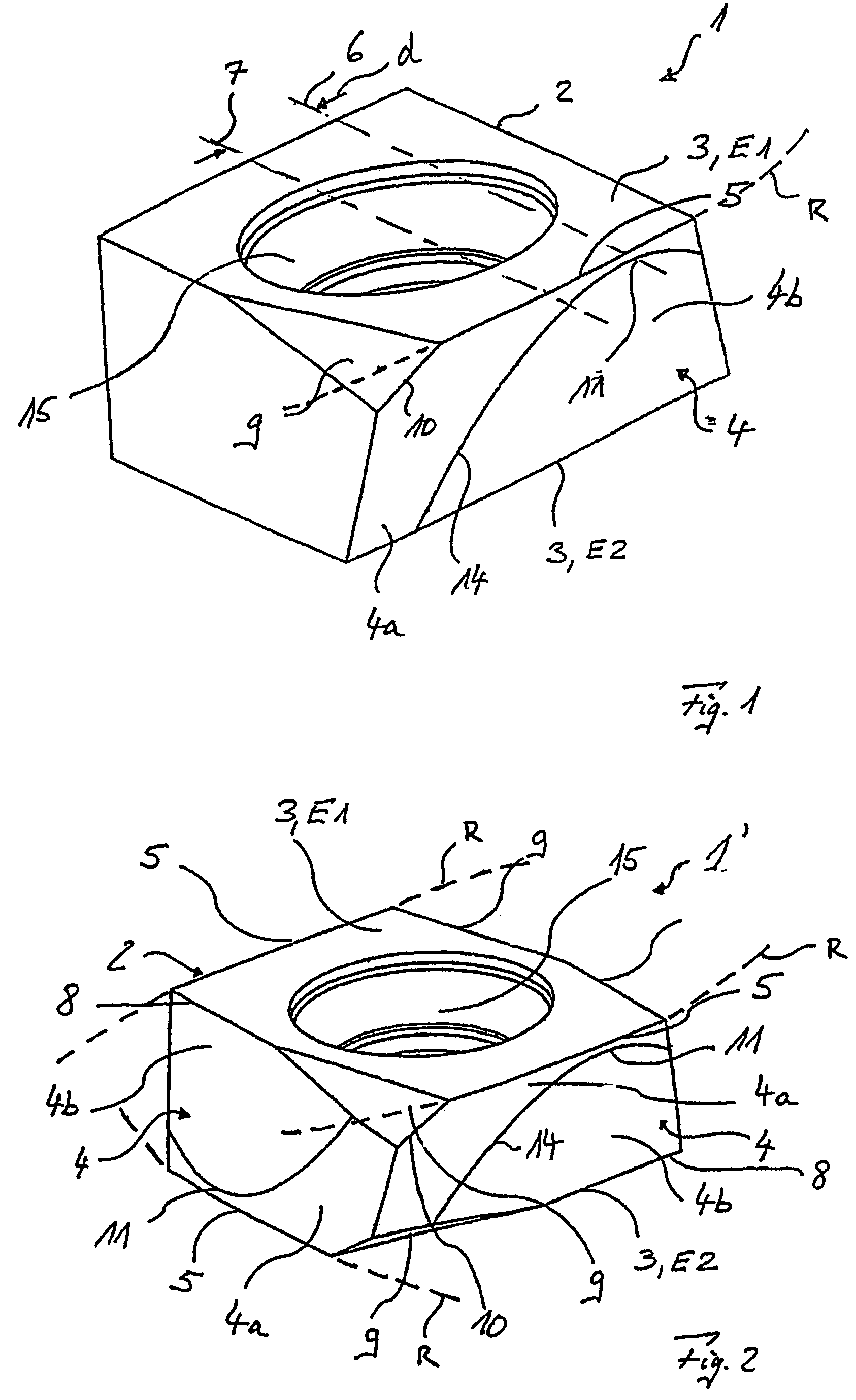

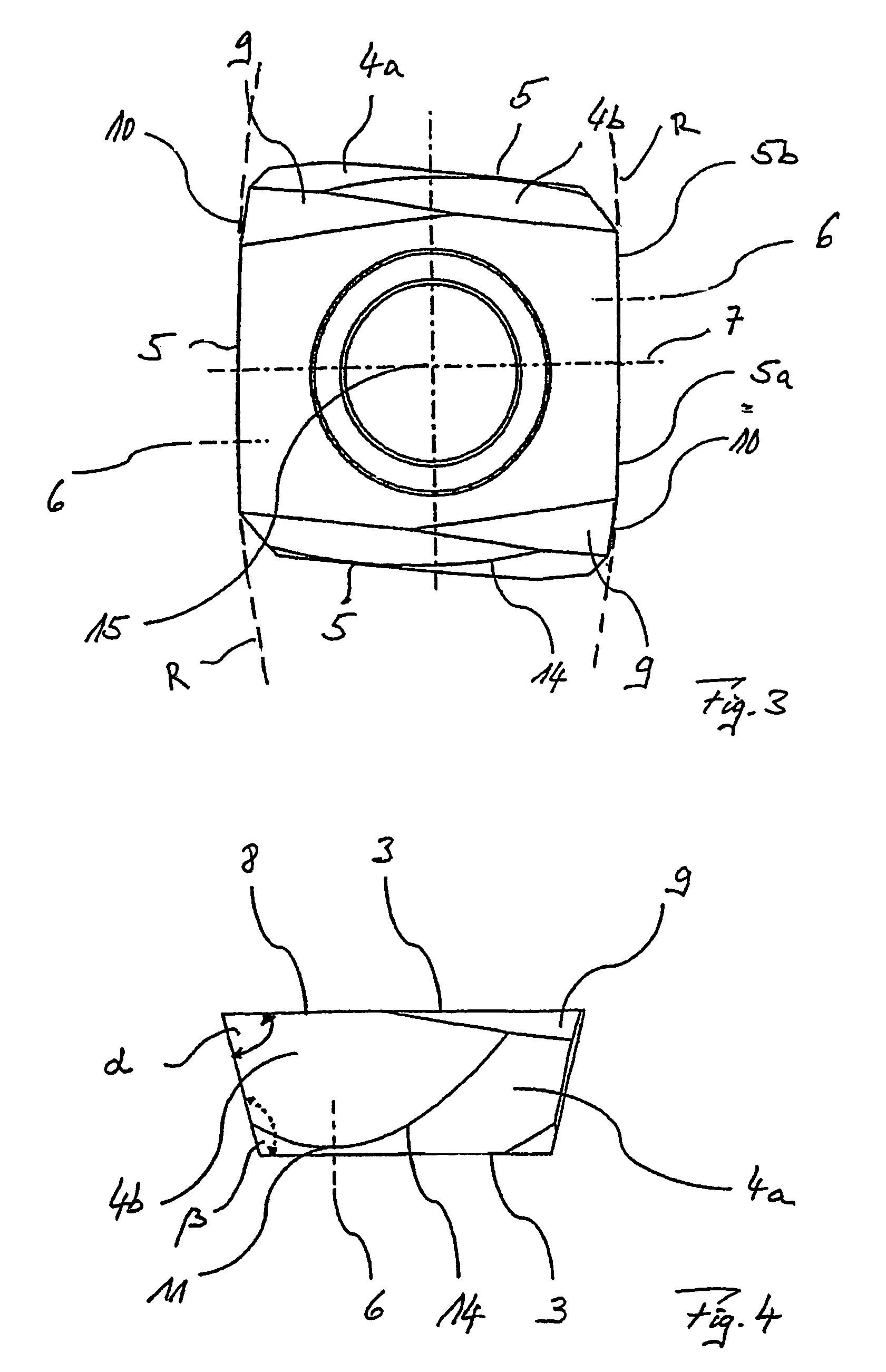

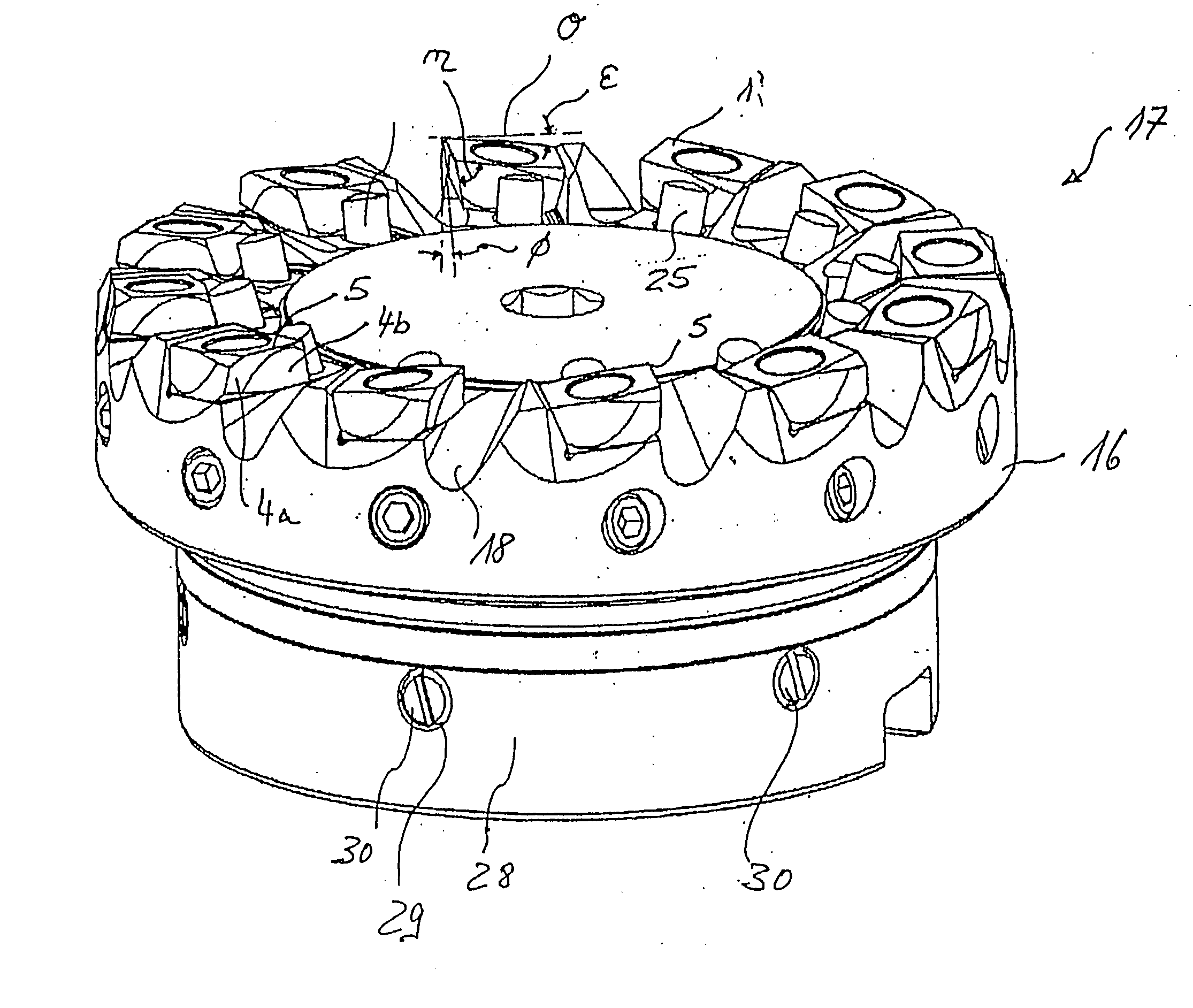

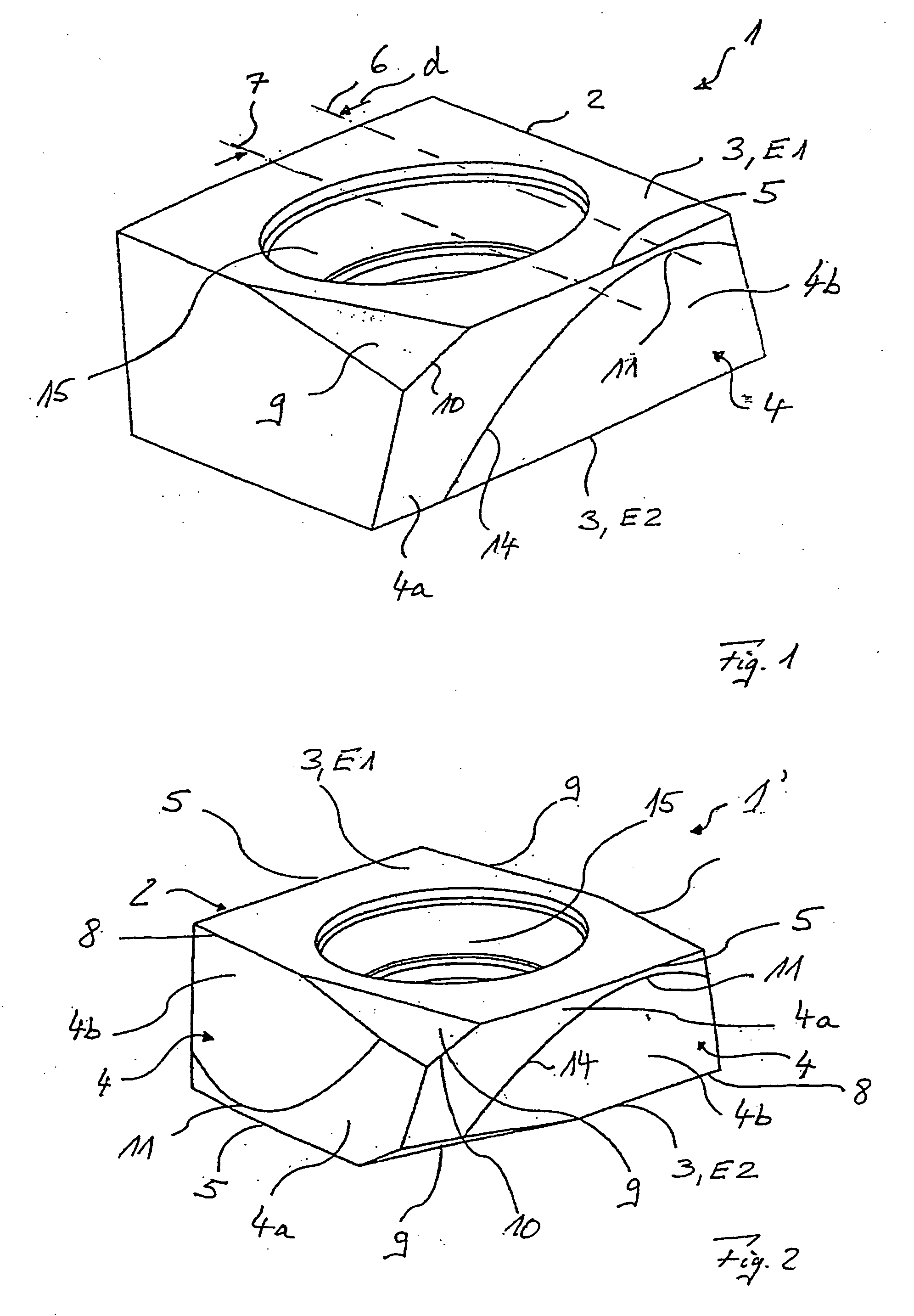

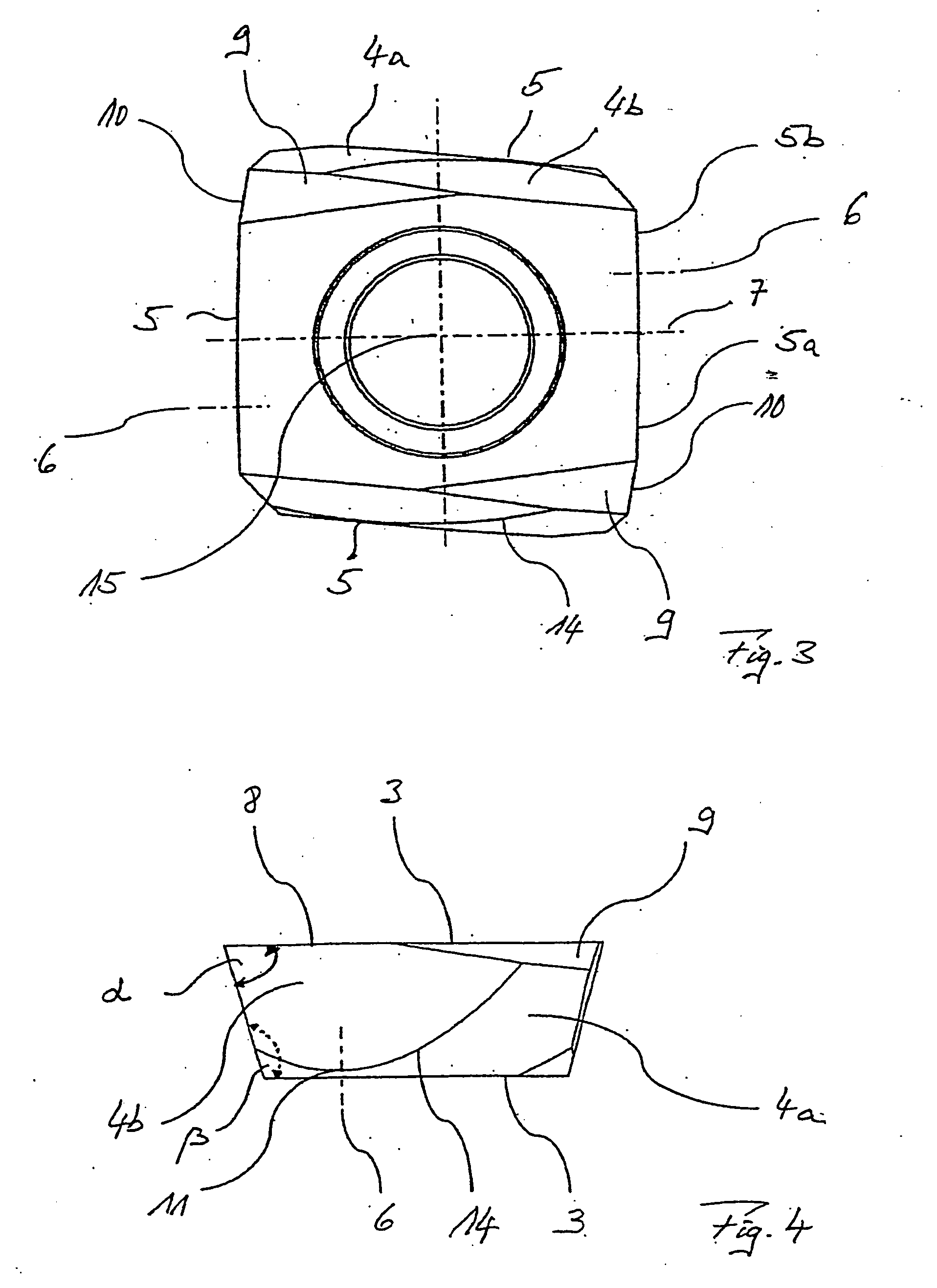

Cutting insert and milling cutter with such a cutting insert

InactiveUS7168512B2Quality improvementSmooth surface qualityDrill bitsConstructionsMilling cutterAcute angle

Owner:KENNAMETAL INC

Cutting insert and milling cutter with such a cutting insert

InactiveUS20050023044A1High surface finishIncrease radiusDrill bitsMilling cuttersAcute angleEngineering

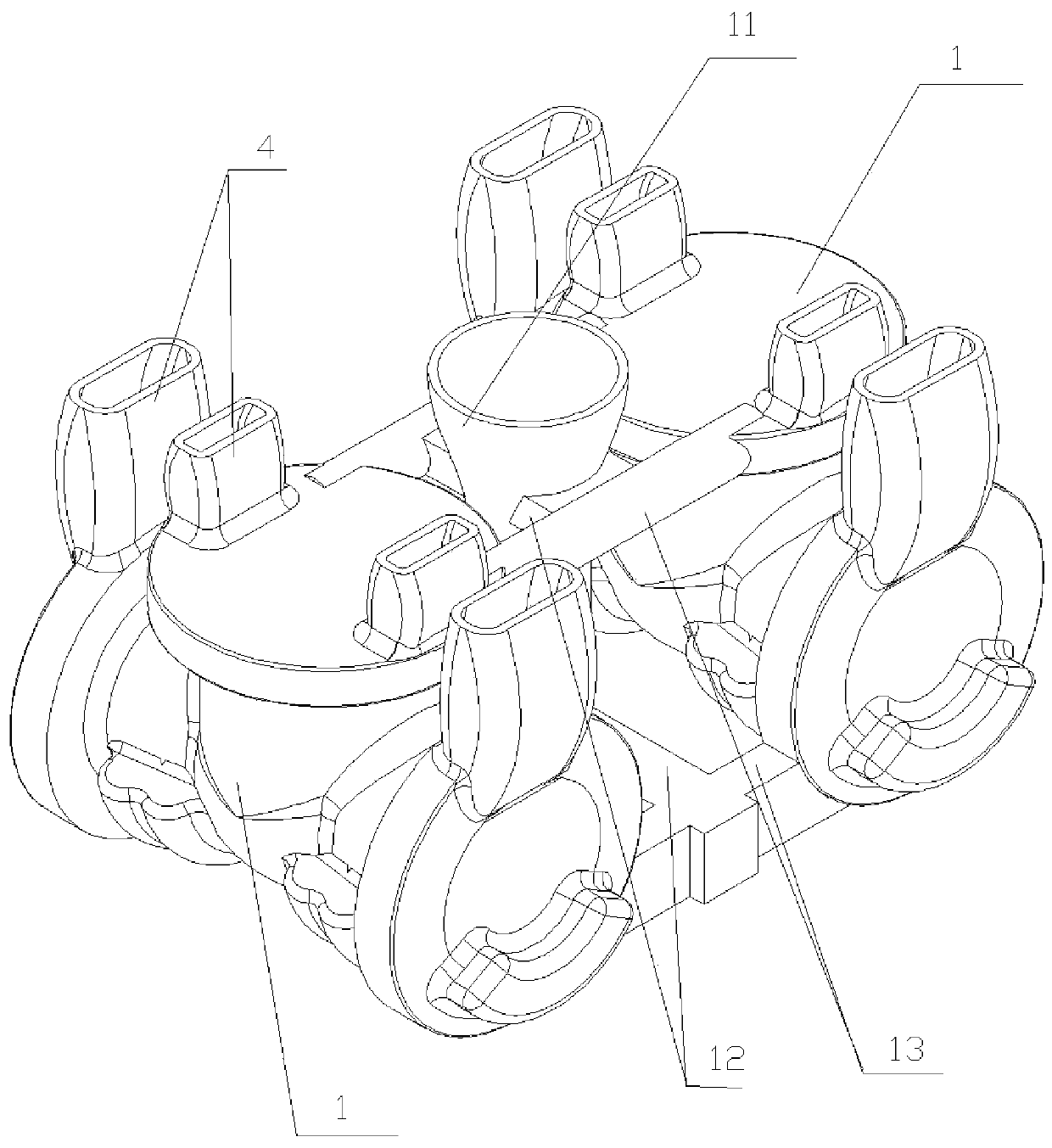

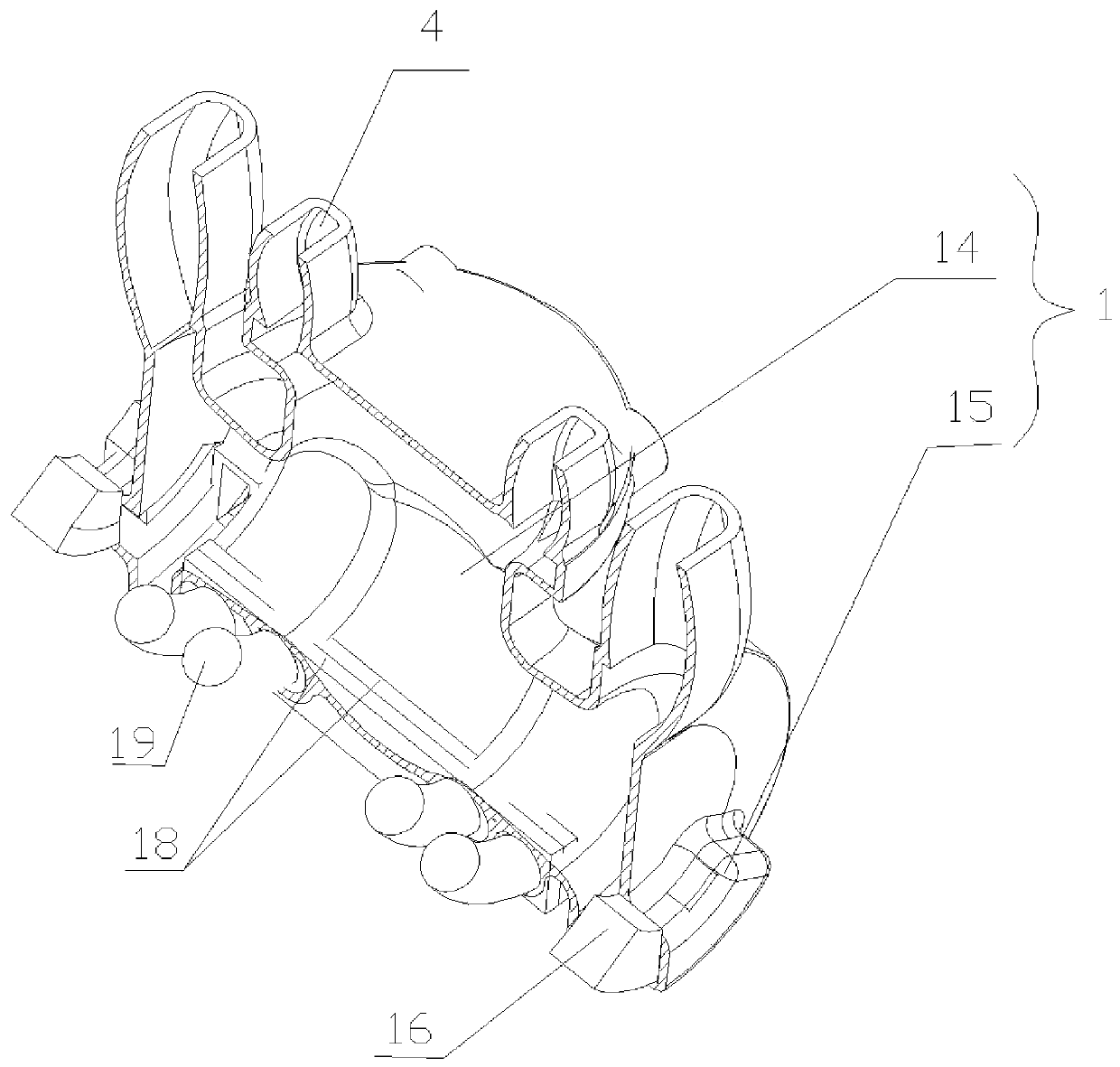

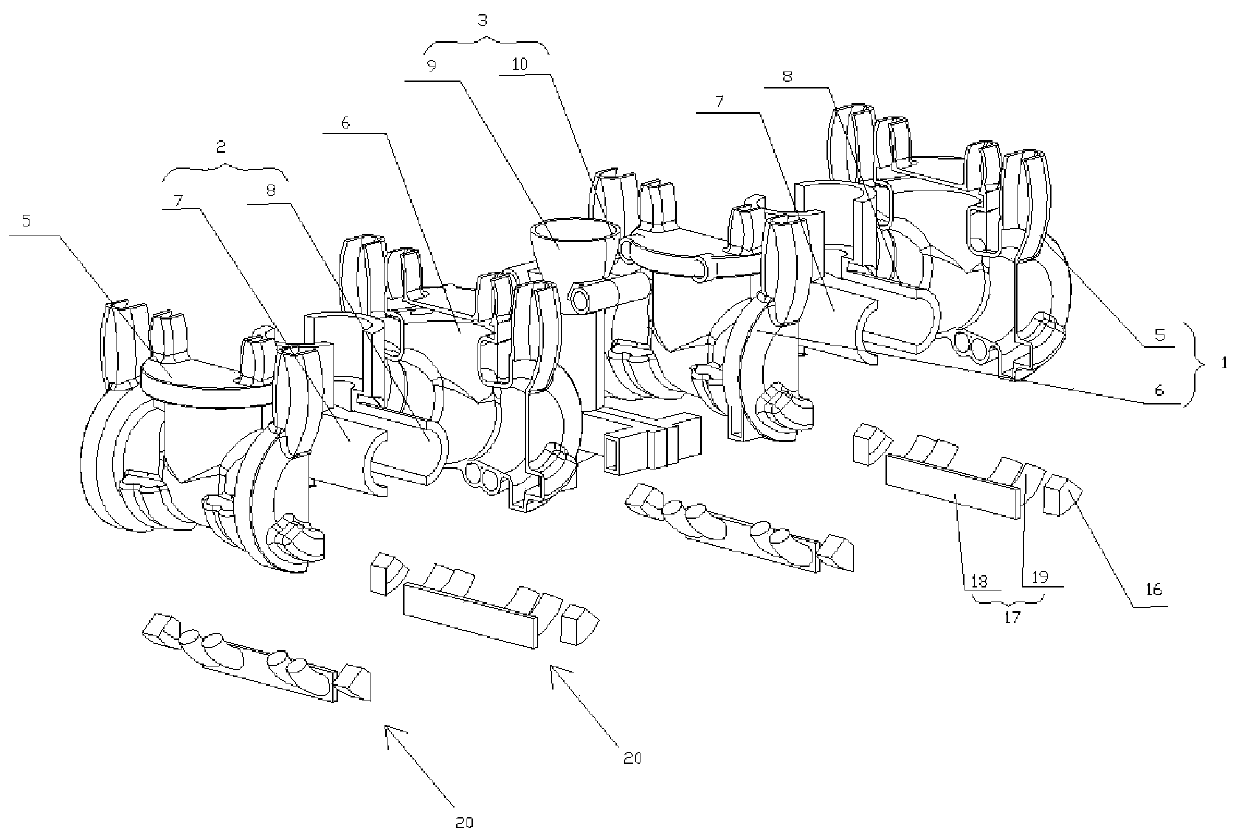

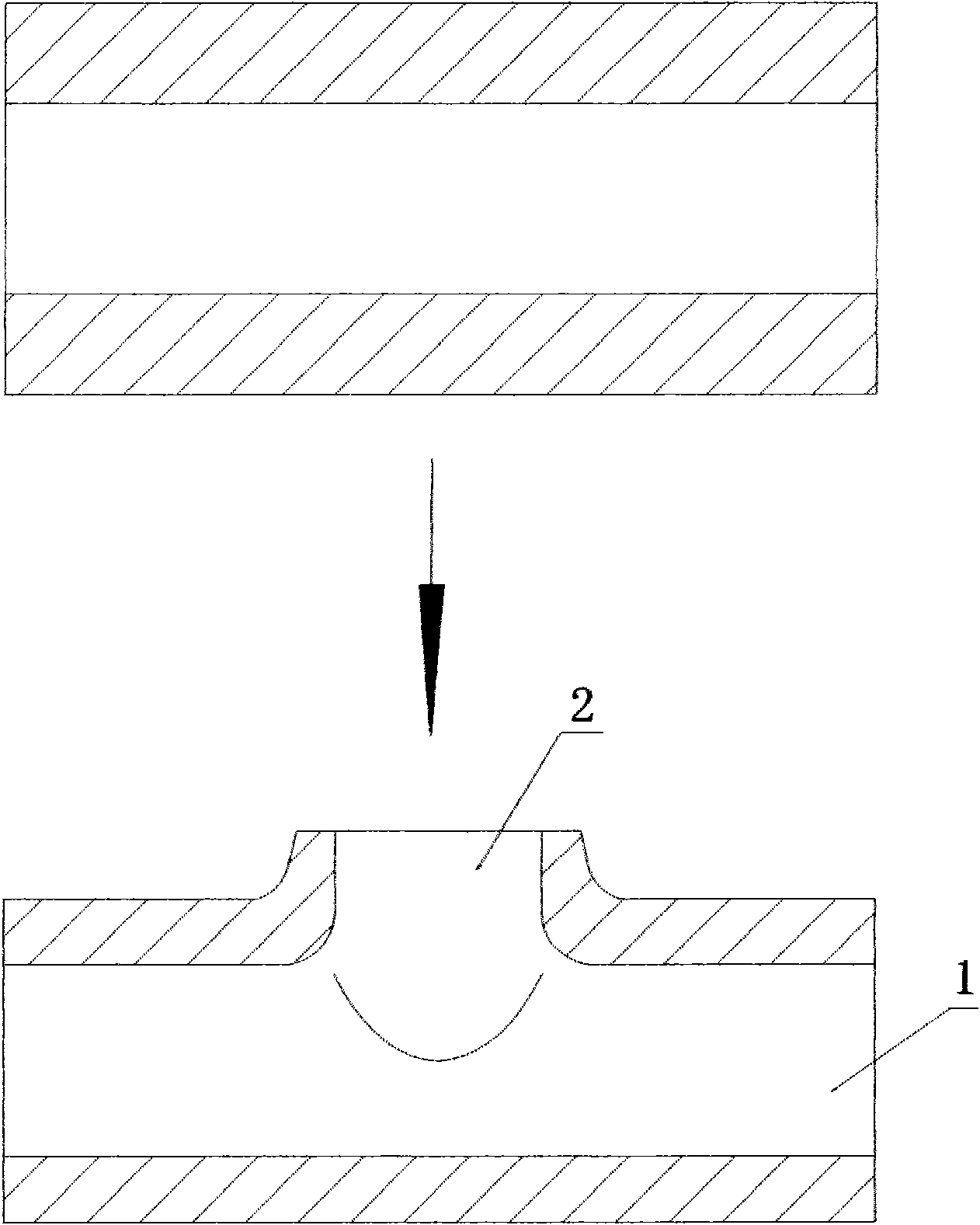

A cutting insert 1, 1′, comprising opposite insert planes E1, E2 of a base 2 of one base area 3 wherein a conical surface section 4a of a lateral face 4 and the base area 3 facing the same form an acute angle alpha while forming a cutting edge 5, while a planar surface section 4b of the same lateral face 4 forms an obtuse angle beta with the opposite base area 3. The cone axis 6 of the conical surface area 4a lying in the insert plane E1, E2 runs off-set in parallel to the center insert axis 7 lying in the same insert plane E1, E2 while forming an off-center arcuate profile of the cutting edge 5. A milling cutter 17 comprising a number of such cutting inserts 1, 1′ is characterized in that a cutting insert 1, 1′ preferably disposed on the periphery of the center line M of a tool support 16 is off-set from the center line M by an angle phi equal to 5±3 degrees. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KENNAMETAL INC

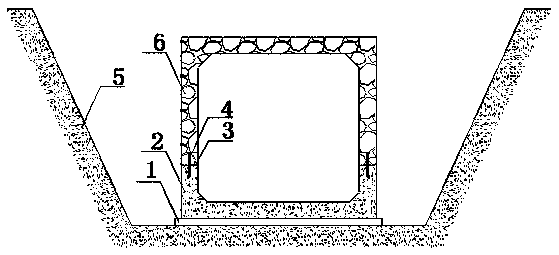

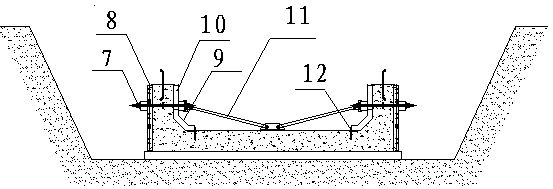

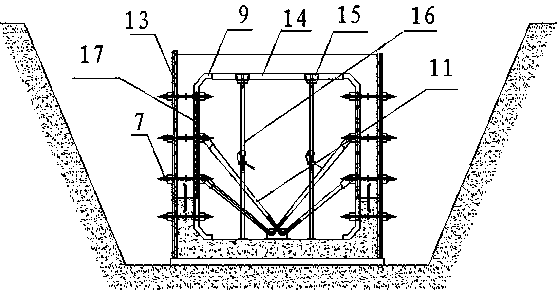

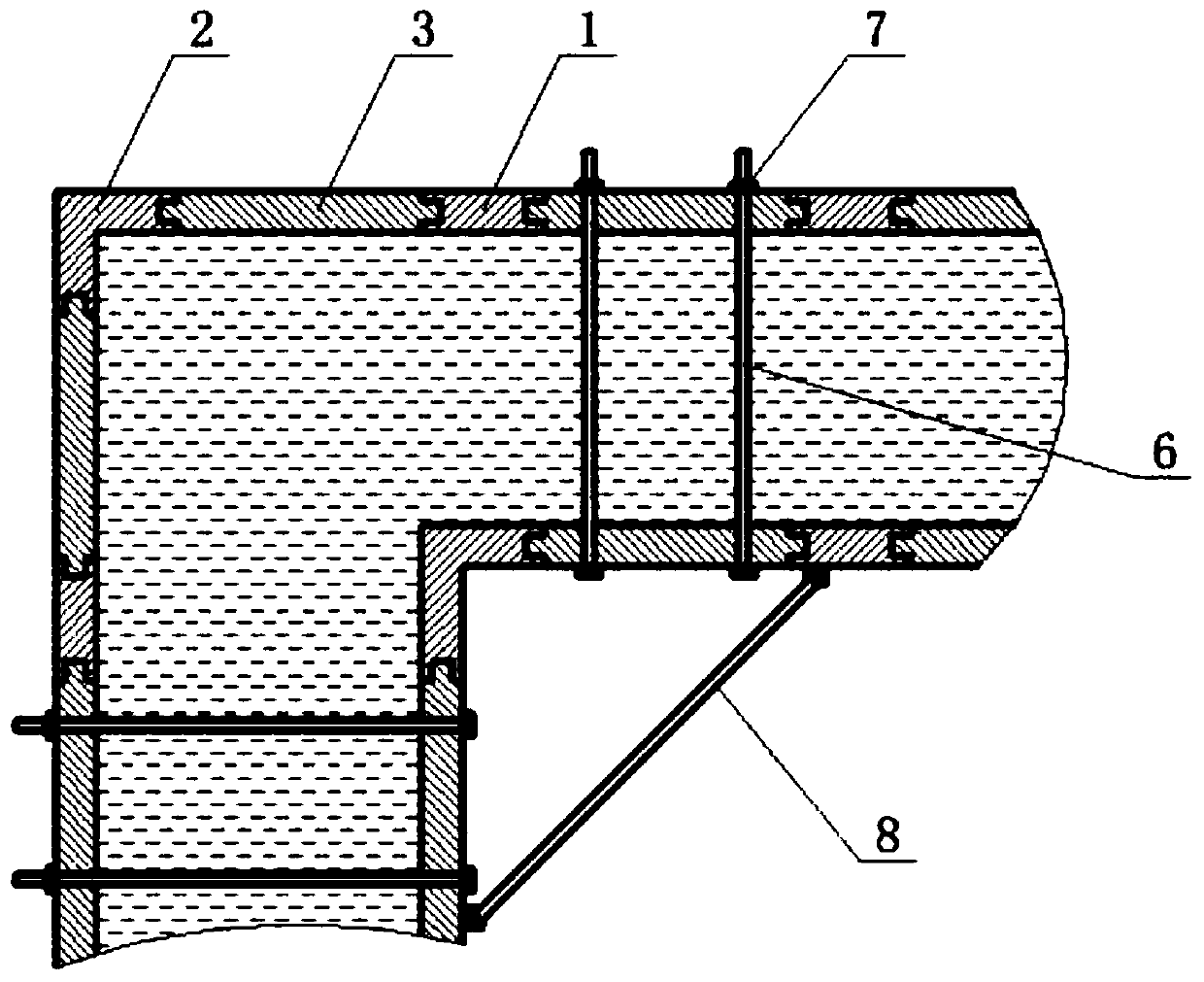

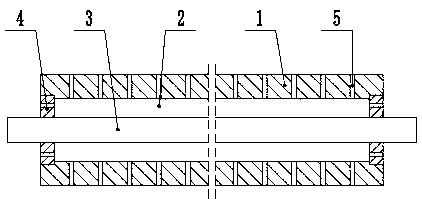

Continuous construction method for aluminum alloy template for comprehensive pipe rack

ActiveCN108914965AFast constructionShorten the construction periodArtificial islandsUnderwater structuresMaterials scienceAluminium alloy

The invention relates to underground comprehensive pipe rack construction, in particular to a continuous construction method for an aluminum alloy template for a comprehensive pipe rack. The continuous construction method comprises the following steps that A, first-time pouring construction of a first-section comprehensive pipe rack body is conducted; B, second-time pouring construction of the first-section comprehensive pipe rack body and first-time pouring construction of a second-section comprehensive pipe rack body are conducted at the same time; C, form removal of the first-section comprehensive pipe rack body is conducted; D, second-time pouring construction of the second-section comprehensive pipe rack body is conducted; and F, first-time pouring construction of a third-section comprehensive pipe rack body is conducted. According to the continuous construction method, the continuous cyclic work is achieved, rapid turnover construction is achieved, the construction speed is increased, the construction period is shortened, construction materials are saved, and the construction environment is safer and more environment-friendly. Meanwhile, a concrete structure formed through the continuous construction method is flat and smooth in surface quality, the requirements of facing and bare concrete are met, secondary plastering is not needed, and the construction cost is saved.

Owner:22MCC GRP PRECISION FORGING

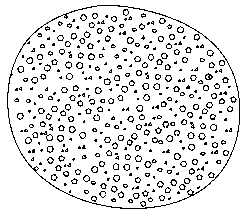

Aluminium magnesium ferroalloy for molten steel deoxidization desulfuration and alloying and preparation method thereof

The present invention discloses one kind of Al-Mg-Fe alloy for deoxidizing and desulfurizing molten steel. The Al-Mg-Fe alloy is produced through special pressure working, rather than smelting in a common induction furnace. It is one kind of energy-saving high purity alloy with alloy recovering rate as high as 100 %, no pollution and capacity of lowering steel deoxidizing and desulfurizing cost. It is suitable for deoxidizing and desulfurizing molten steel for making different steel products.

Owner:赵宇

Electroslag remelting process of nickel-based superalloy

InactiveCN110724826ASmooth surface qualityHigh yieldIncreasing energy efficiencyFurnace typesSlagSuperalloy

Owner:JINGYE STEEL CO LTD

Cold-rolled strip for new energy battery aluminum-plastic film aluminum foil, and preparing method of cold-rolled strip

ActiveCN109694963AUniform fine dispersionGood rollabilitySecondary cellsJackets/cases materialsFiltrationNew energy

The invention belongs to the technical field of aluminum alloy materials, and particularly relates to a cold-rolled strip for a new energy battery aluminum-plastic film aluminum foil, and a preparingmethod of the cold-rolled strip. An aluminum ingot is subjected to semi-continuous casting after smelting and refining, heat-insulation still standing and refining, multi-pass degassing and multi-stage filtration; the cast ingot is subjected to heat-insulation homogenization heat treatment after being subjected to sawing and face-milling; the cast ingot is taken out of a furnace, subjected to hotrolling, then subjected to cold rolling, cleaning and intermediate annealing; and finally cold rolling is conducted, and a cold-rolled strip blank for the aluminum-plastic film aluminum foil is obtained after edge cutting. The cold-rolled strip has the clean surface and internal texture and has no thick and big mesophase compounds, no pinhole is generated after rolling is conducted till the thickness of the aluminum foil for an aluminum-plastic film reaches 20 to 40 [mu]m, and the use demands of the aluminum-plastic film in the aspects of the barrier property, the cold stamping forming property, puncture resistance, chemical stability and insulativity are met.

Owner:中铝东南材料院(福建)科技有限公司 +1

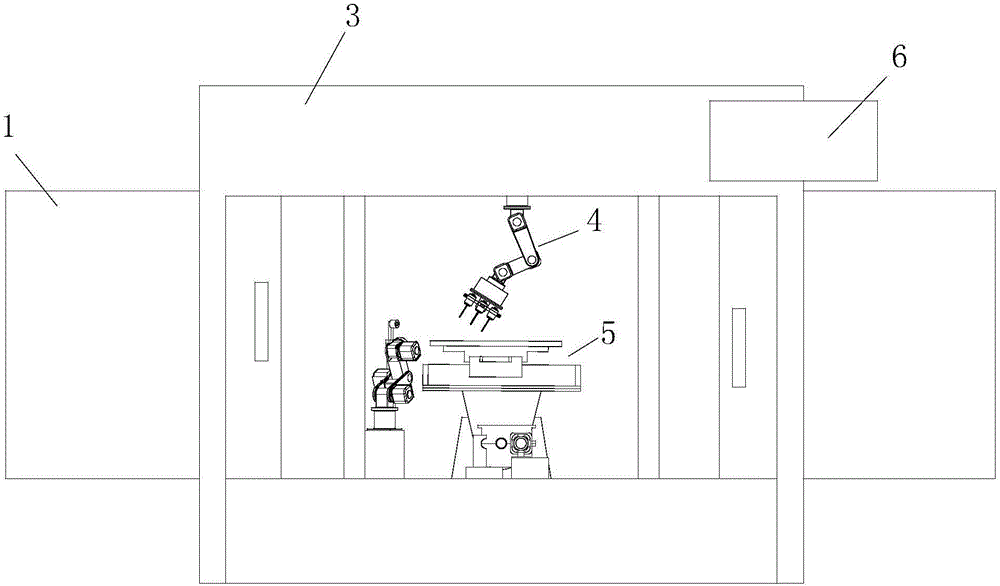

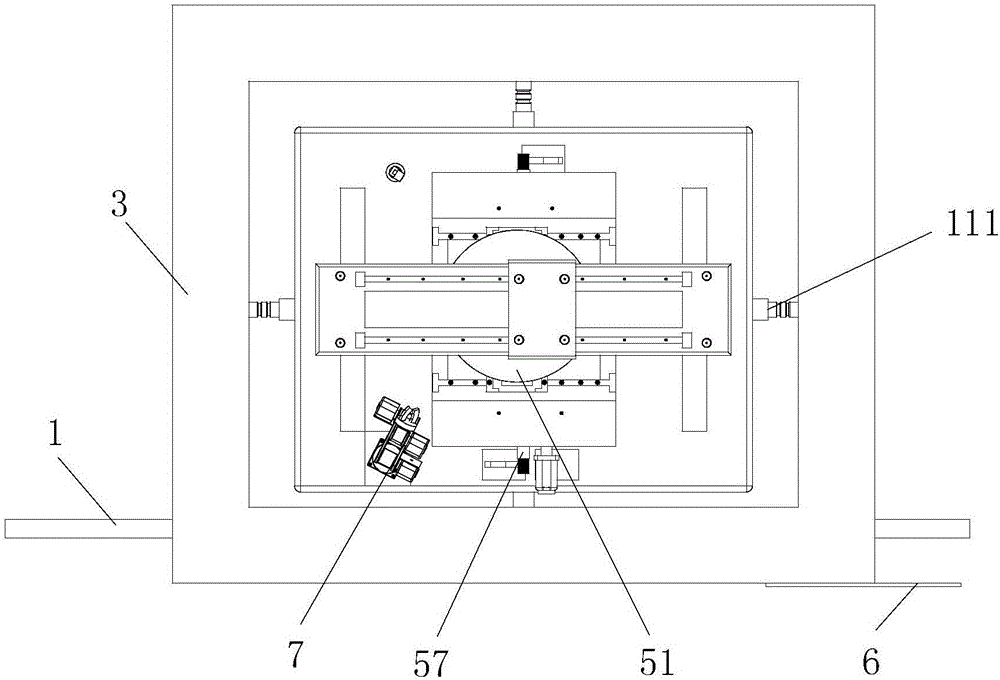

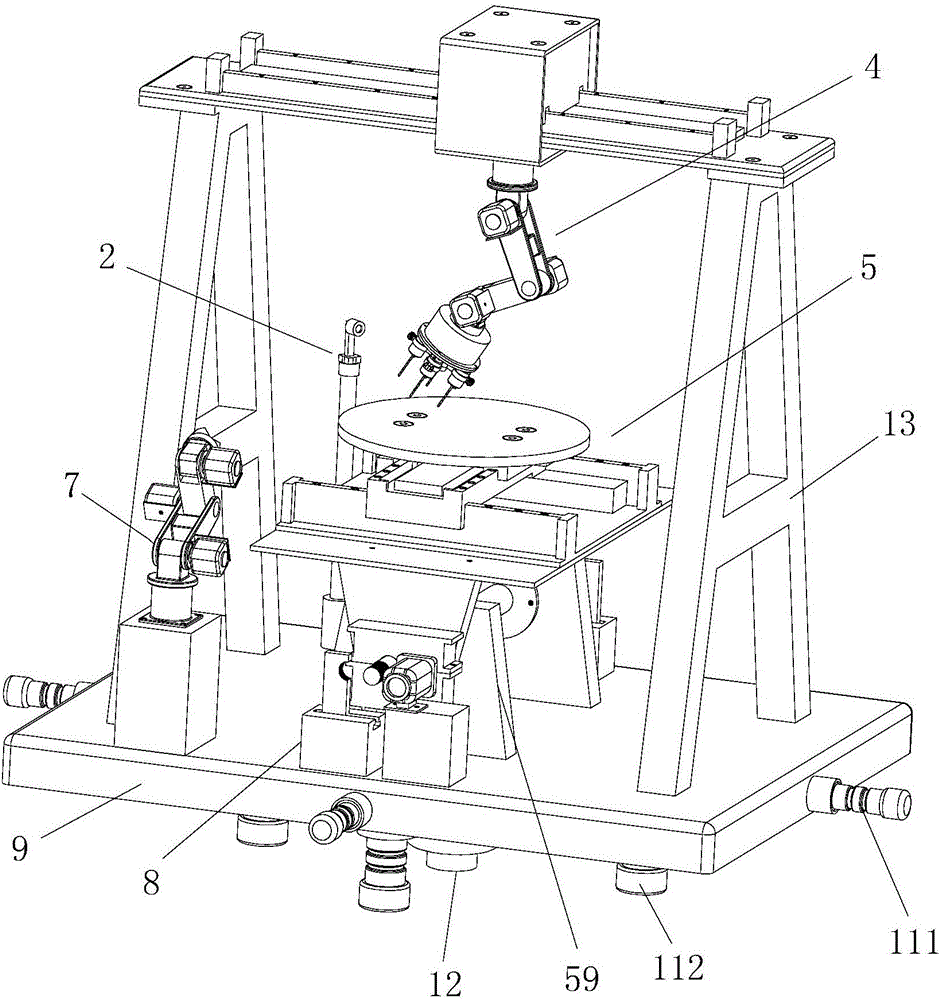

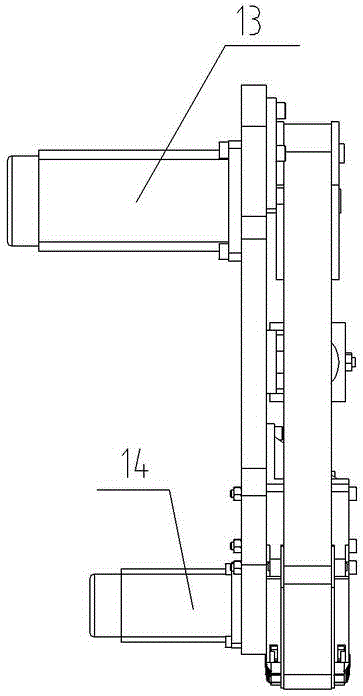

Micronano-sized micro hole machining tool

ActiveCN106807975ARealize precise machiningImprove finished product qualityDrilling/boring measurement devicesMeasurement/indication equipmentsCollection analysisControl system

The invention discloses a micronano-sized micro hole machining tool. The micronano-sized micro hole machining tool comprises a machining tool base, a cutting device, a multi-degree-of-freedom workbench system, a micronano microscope video system and a control system. The multi-degree-of-freedom workbench system is arranged on the machining tool base and comprises a workbench and a workbench driving device. The cutting device is arranged above the workbench. The micronano microscope video system is arranged on the machining tool base and located at one side of the multi-degree-of-freedom workbench system. The micronano microscope video system is used for performing image collection analysis on the machining process of workpieces on the workbench and transmitting collection analysis data to the control system. According to the micronano-sized micro hole machining tool, the micronano microscope video system is used for performing image collection analysis on the machining process of the workpieces on the workbench and transmitting the collection analysis data to the control system in time, the control system gives out control instructions to the cutting device and the multi-degree-of-freedom workbench system according to the collected workpiece machining information, and hence machining precision and finished product quality are improved.

Owner:SHANDONG UNIV OF SCI & TECH

Precoated sand casting process of cast steel valve

InactiveCN109940127AAccelerate solidificationEliminate shrinkage, shrinkage, etc.Foundry mouldsFurnace typesSand castingMolten steel

The invention relates to a precoated sand casting process of a cast steel valve. The process specifically comprises the following steps of firstly preparing a sand shell by using precoated sand as a raw material, baking the sand shell, pouring molten steel into the sand shell, taking down a to-be-cast valve after the to-be-cast valve is naturally cooled, solidified and formed, and obtaining a valve casting; and finally carrying out shot blasting, riser cutting, heat treatment, secondary shot blasting and finishing on the valve casting to obtain a valve blank, specifically, the method for manufacturing the sand shell by using the precoated sand as the raw material comprises the following specific steps of preparing a half shell or a half core by using the precoated sand as the raw material;and repairing and spraying the half shell and the half core of a valve body / valve cover while hot, and assembling to obtain the sand shell, specifically, the time consumption of the repairing processof the half core of the valve body / valve cover and the repairing process of the half shell needs to controlled to be less than or equal to 120 seconds; and in the spraying process, the temperature ofthe half shell and the temperature of the half core of the valve body / valve cover are kept 60 DEG C or above. The cast steel valve produced by the process is high in pressure test qualified rate.

Owner:YUANDA VALVE GRP CO LTD

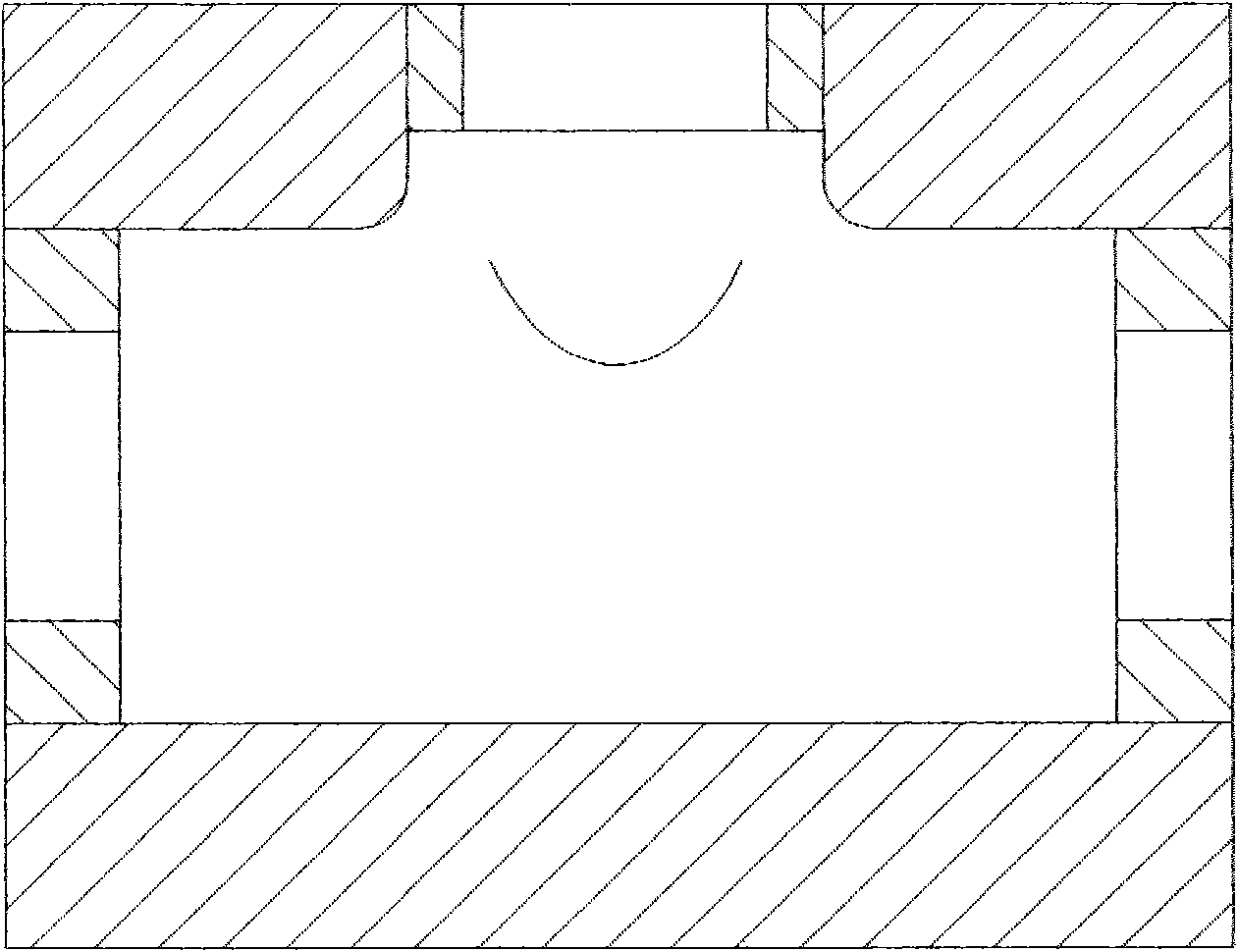

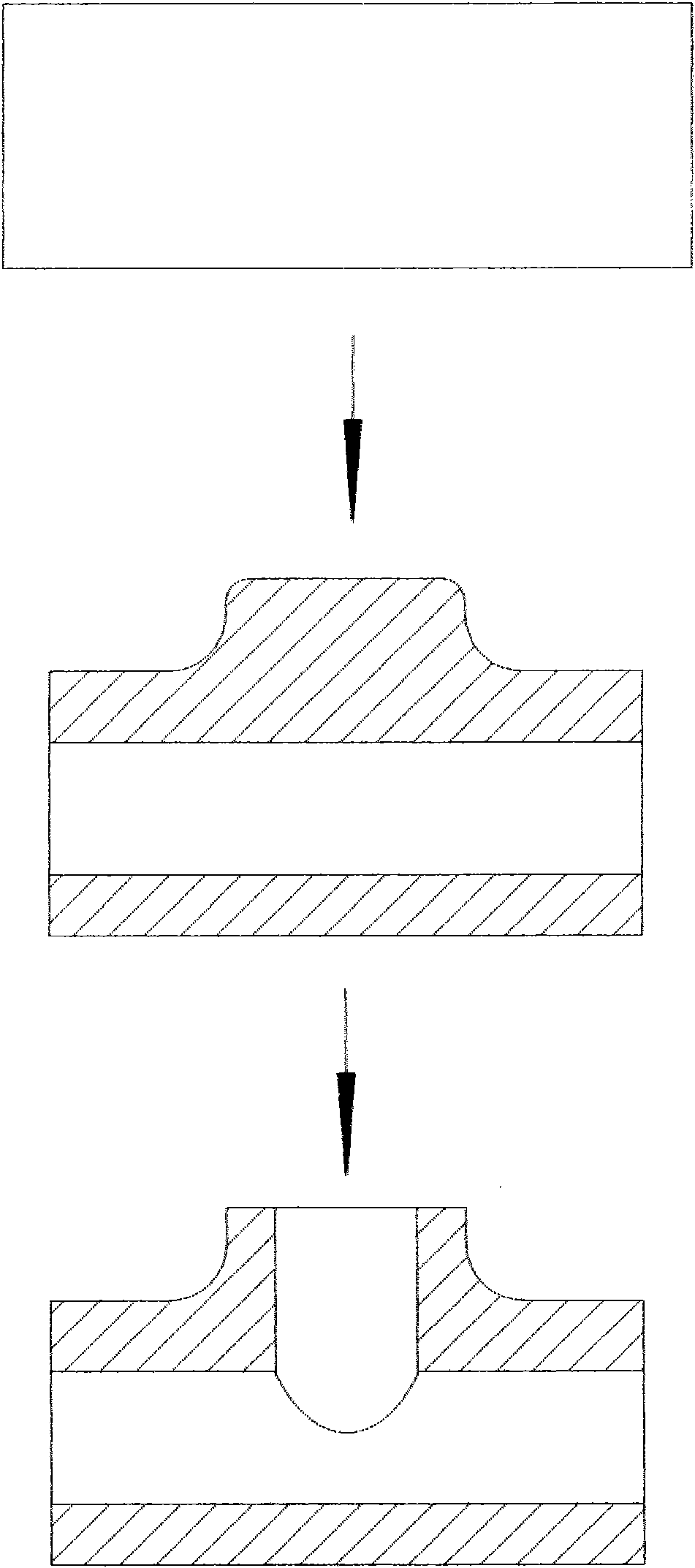

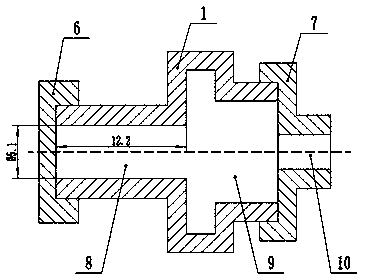

Forging backward extrusion technology of three-way pipe

InactiveCN101596559AIncrease heightIncrease the lengthExtrusion diesEngine componentsMaterial PerforationForge

The invention relates to the technical field of the preparation of a three-way pipe, in particular to a forging backward extrusion technology of the three-way pipe, comprising the steps of (1) extrusion of a forge bar: heating the forge bar to a forging temperature according to the material of the forge bar, horizontally placing the forge bar at the position corresponding to a main pipe in a three-way pipe forging mould, synchronously extruding and perforating the two ends of the forge bar by using two top cylinders, and performing backward extrusion on the main pipe in the forging mould to form a bump while forming the main pipe; and (2) performing backward extrusion and perforation by an upper top cylinder: using the upper top cylinder to perform backward extrusion and perforation downwards from the upward side of the bump, so as to form the three-way pipe. Compared with the prior art, the invention uses an integrated forging mould, ensures one-step molding, reduces technical energy consumption, greatly improves production efficiency, also cleans surface scale, and ensures smooth surface quality, proper product shape molding and excellent size. The height of the prepared branched pipe is increased by 30-60% compared with original technologies, so that welding and shooting are convenient; the pipe does not expand and explore easily; and the safety performance of running equipment is improved.

Owner:SHANGHAI CHANGQIANG POWER

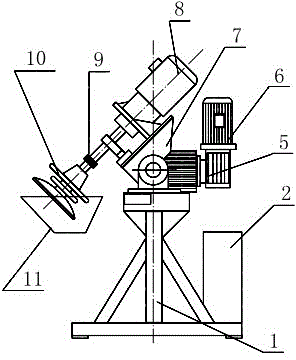

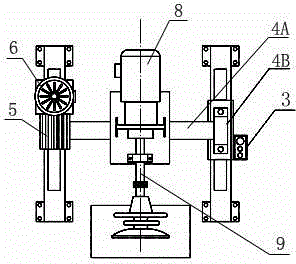

RTV anti-contamination flashover paint coating equipment for porcelain or glass umbrella or bell jar shaped insulator

The invention discloses RTV anti-contamination flashover paint coating equipment for a porcelain or glass umbrella or bell jar shaped insulator. The equipment comprises a main frame, a machine head rotary frame, a reducing frequency conversion motor and a fast insulator connector. The machine head rotary frame is rotationally connected to the main frame through a rotary shaft and bearing seats of two ends; the reducing frequency conversion motor is fixedly arranged on the machine head rotary frame; the output shaft of the reducing frequency conversion motor is connected to the fast insulator connector. The equipment has the advantages that the dip-coated porcelain or glass insulators of different specifications are stable in quality, the surfaces are smooth and are free of bubbles, the coating layers are free of accumulation and drop hanging, and the thickness is even; in the dip-coating process, the VOC emission amount is small, and the production is environment-friendly and safe; the dip-coating automation level is high, operation is easy, factories of the porcelain or glass insulators of different specifications can implement porcelain and glass insulator industrial automatic RTV anti-contamination flashover paint coating production through the equipment, and large amount of cost can be saved.

Owner:眉山拓利科技有限公司

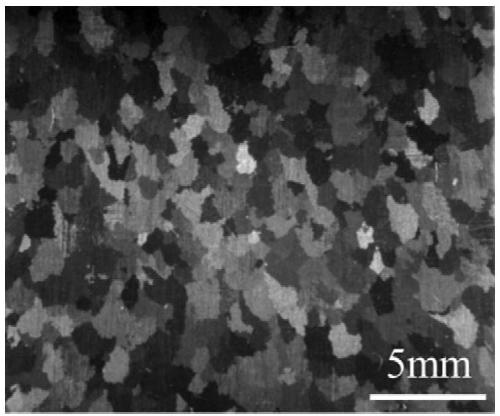

Method for preparing wide range pure nickel cold rolling coiled material

The invention discloses a method for preparing a wide range pure nickel cold rolling coiled material. The method includes the following steps of (1) subjecting pure nickel hot rolled plates to atmosphere annealing treatment; (2) subjecting the pure nickel hot rolled plates to cold rolling scale breaking, and removing oxide-scales by acid pickling to obtain plates; (3) cutting and trimming heads and tails of multiple plates on a finishing machine, then performing plasma tailor welding, and rolling to obtain a rolled billet; (4) rolling the rolled billet for one rolling process to obtain a coiled material; (5) performing oil removal processing; (6) performing vacuum annealing treatment; and (7) uncoiling, and cutting and removing head and tail leading tape portions to obtain the wide range pure nickel cold rolling coiled material, or repeating the steps (4), (5) and (6) once, uncoiling, and cutting and removing the head and tail leading tape portions to obtain the wide range pure nickel cold rolling coiled material. The method has the advantages that the method is simple, the industrialized production is easy to achieve, the pure nickel coiled material with the thickness of 0.5mm to 2.0mm and the breadth of 1200mm to 1400mm can be prepared through one to two times of cold rolling, and the blank of domestic wide range pure nickel coiled material is filled.

Owner:WESTERN TITANIUM TECH

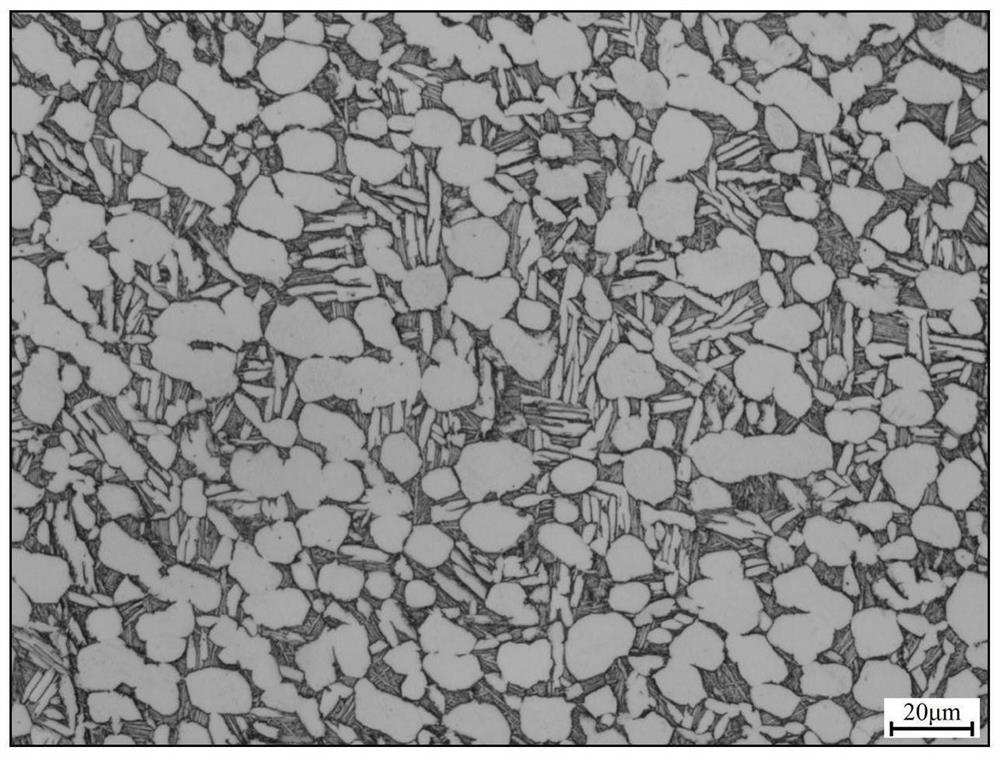

Wrought magnesium alloy with nanostructure characteristics and preparation method thereof

The invention provides a wrought magnesium alloy with nanostructure characteristics and a preparation method thereof. The alloy is prepared from, by mass, 0.8-1.5% of aluminum, 1.5-2.5% of zinc, 0.15-0.4% of calcium, 0.2-0.4% of manganese, 0.15-0.3% of gadolinium, and balance magnesium, wherein the content of impurity iron is controlled at 0.003% or less. The preparation method comprises the stepsthat 1, raw materials of an Mg ingot, an Al ingot, a Zn ingot, Mg-Ca and Mg-Gd intermediate alloy are smelted; 2, MnCl2 is added at lower temperature to remove iron; 3, secondary refining time afterMg-Ca is added is shortened, and the actual yield of Ca reaches 50-60%; 4, electromagnetic semi-continuous casting is carried out; 5, uniform treatment is carried out; 6, extrusion treatment is carried out to obtain a wrought magnesium alloy extruded bar. The wrought magnesium alloy with the nanostructure characteristics and the preparation method thereof have the advantages that a wrought magnesium alloy ingot blank is prepared by adopting a low-frequency electromagnetic semi-continuous casting technology, low-temperature extrusion can be achieved, the extruded material is in a nanometer complete recrystallized structure, and the mechanical properties at room temperature are excellent.

Owner:NORTHEASTERN UNIV

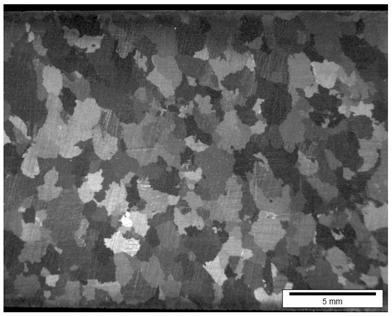

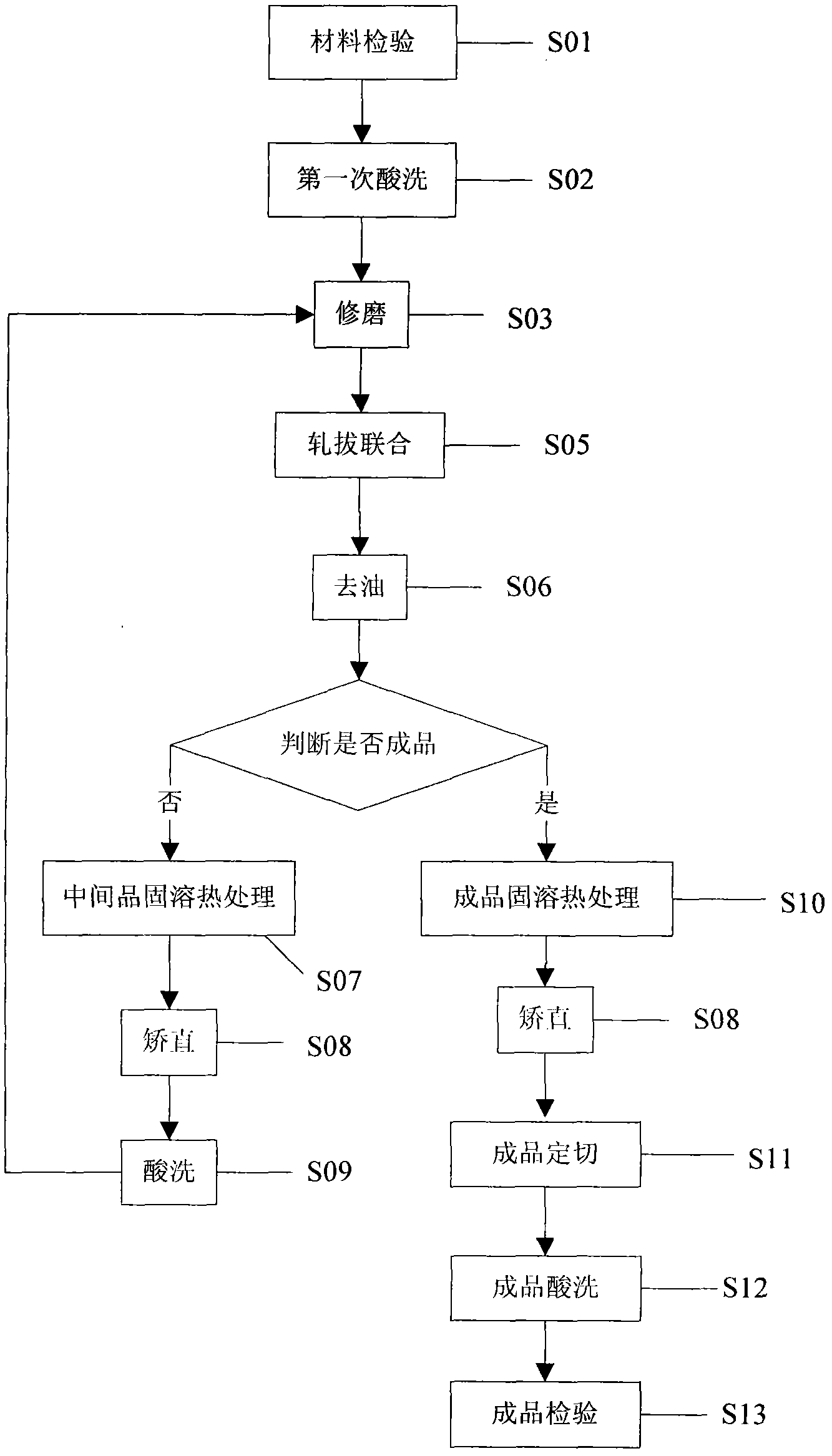

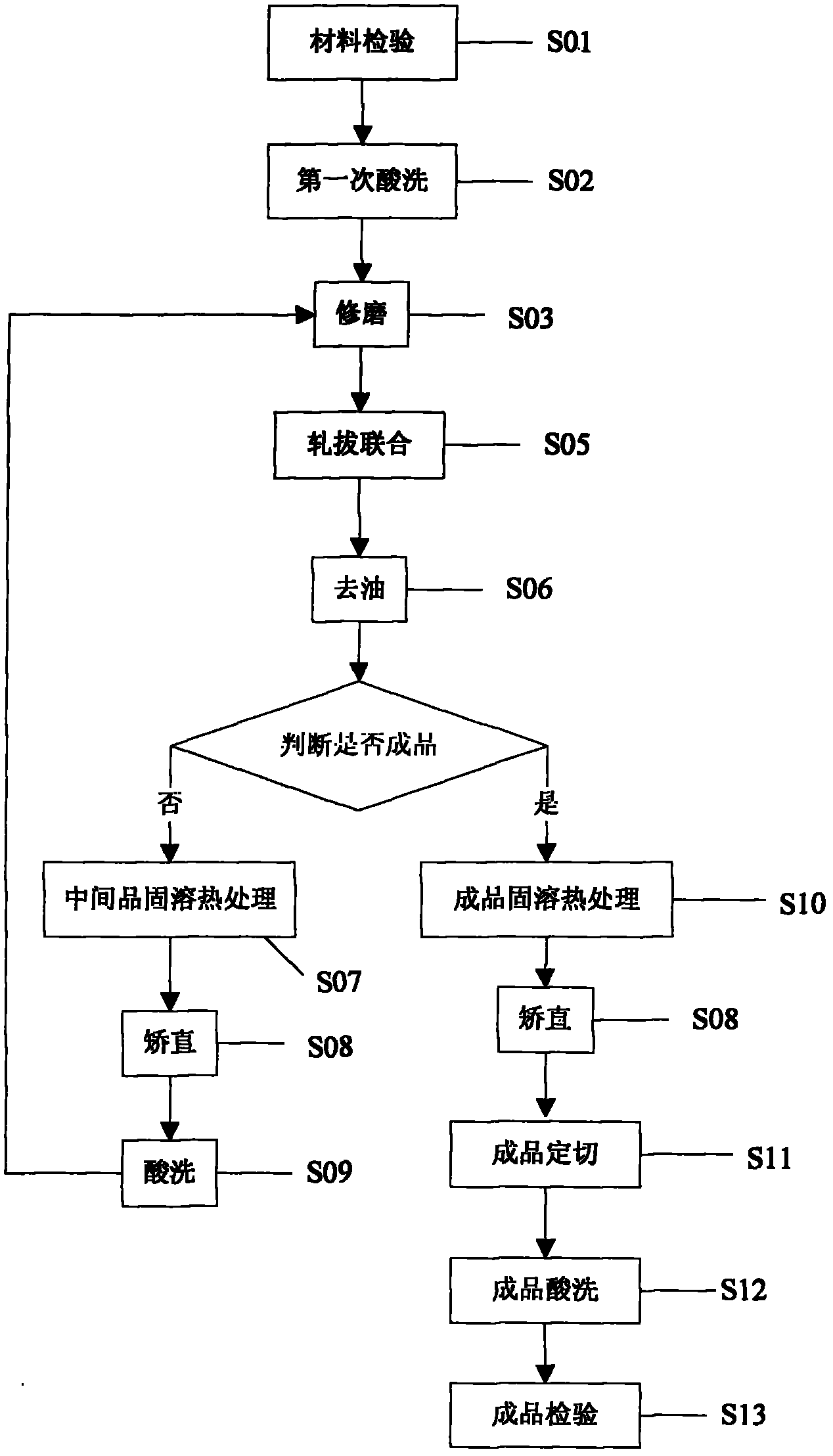

Manufacture method for seamless steel tube

The invention discloses a manufacture method for a seamless steel tube. The method is used for manufacture of austenite type free-cutting wear resistant stainless steel. The method comprises the following steps: 1) carrying a primary pickling for a blank material; 2) carrying out grinding, rolling-drawing combination, oil removing for the pickled blank material; 3) determining whether the resulting material meets the requirements of the finished product, wherein the resulting material is subjected to an intermediate product solid solution heat treatment, straightening and pickling, and the step 2) is repeatedly performed if the resulting material does not meet the requirements of the finished product; 4) carrying out a finished product solid solution heat treatment, straightening and fixed finished product cutting if the resulting material meets the requirements of the finished product; 5) carrying out pickling for the finished product. The temperature of the intermediate product solution heat treatment and the temperature of the finished product solid solution heat treatment are 1010-1150 DEG C, and a rapid cooling treatment is performed after the intermediate product solution heat treatment or the finished product solid solution heat treatment is performed, wherein the temperature of the intermediate product solution heat treatment is 1040-1150 DEG C, and the temperature of the finished product solid solution heat treatment is 1020-1100 DEG C. According to the present invention, the seamless steel tube manufacture method with characteristics of energy saving and simple process is provided; the technical problems in the prior art are solved; the yield and the whole product quality are improved, and especially the surface quality is improved, wherein the tensile strength Rm is more than or equal to 540 Mpa, the stipulated non-proportional extension strength Rp0.2 is more than or equal to 240 Mpa, the elongation at break A is more than or equal to 40%, and the rockwell hardness HRB is less than or equal to 90; the smooth surface can be achieve after pickling so as to provide the organization preparation for the next process, wherein the surface roughness Ra is less than or equal to 1.00 mum.

Owner:SUZHOU BEST METAL PROD

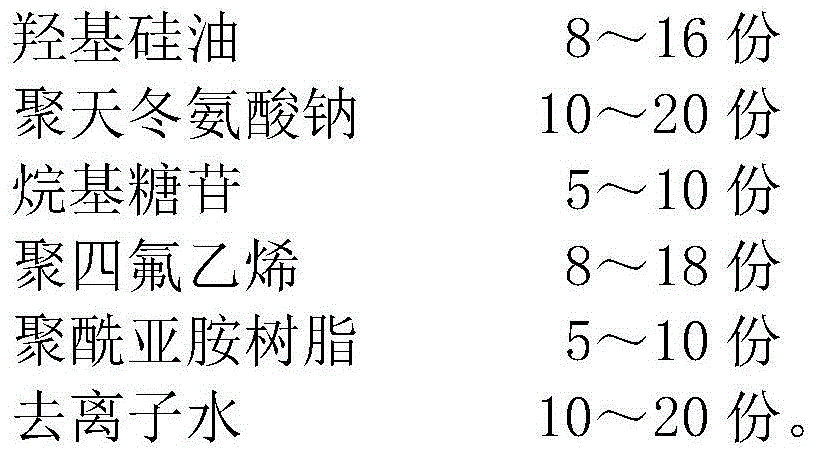

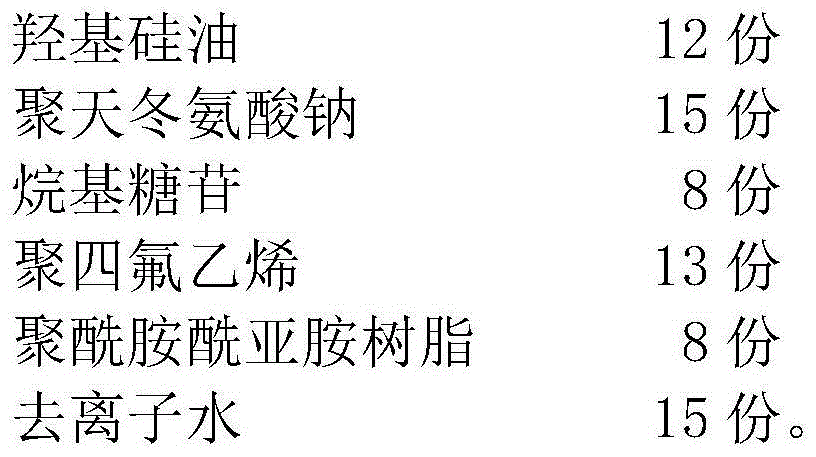

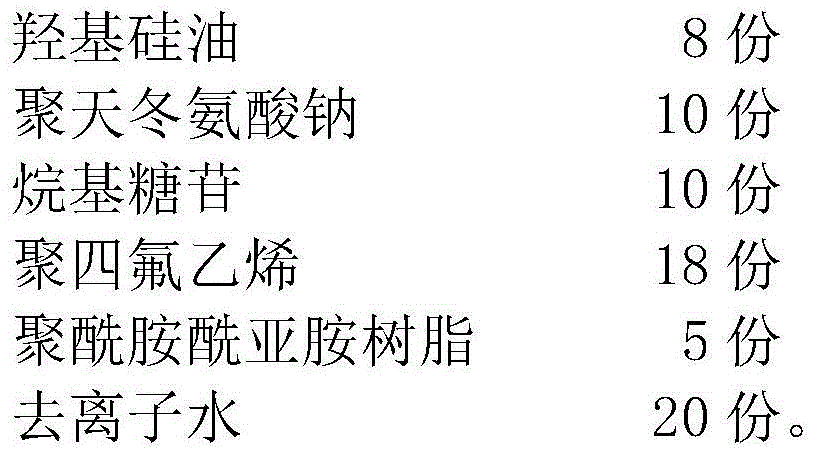

Metal surface treatment anti-sticking agent

The invention relates to the anti-sticking agent technical field, and particularly relates to a metal surface treatment anti-sticking agent prepared from the following raw materials in parts by weight: 8-16 parts of hydroxyl silicone oil, 10-20 parts of polyaspartic acid, 5-10 parts of alkyl glycoside, 8-18 parts of polytetrafluoroethylene, 5-10 parts of polyamideimide resin, and 10-20 parts of deionized water. The metal surface treatment anti-sticking agent is reasonable in composition, obvious in effect and stable in chemical properties, can effectively prevent adhesion between layers of a metal strip, and also has the function of corrosion resistance; the metal product surface quality is bright and clean; and the anti-sticking agent has good levelling property and thixotropy, meets processing at various temperatures, and can be used for a long time.

Owner:黄琳

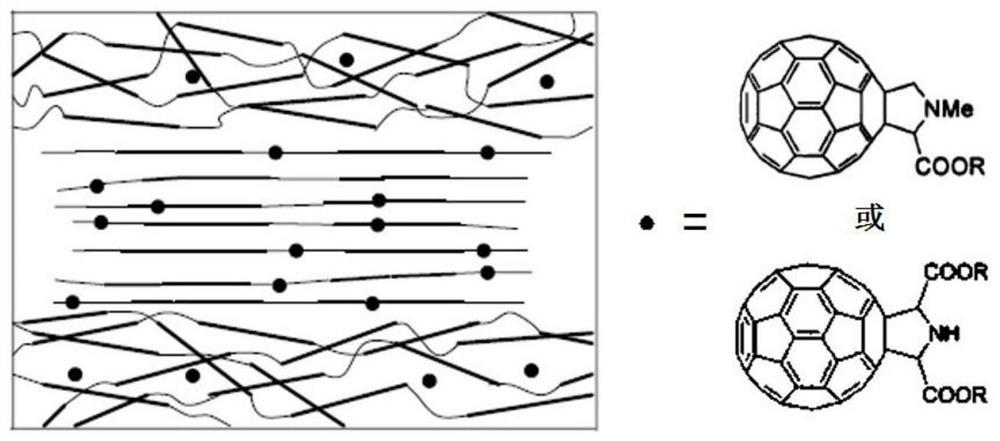

Preparation method of polymer film containing nano fullerene

ActiveCN112876846ALow viscosityImproved storage conditionsPhotovoltaic energy generationImidePolymer science

The invention relates to a method for doping modified polyimide containing nano fullerene, wherein the method comprises the following steps: firstly, reacting diamine with dianhydride in an organic solvent to obtain polyamide acid; adding amino-acid ester or substituted amino-acid ester modified nano fullerene, and uniformly mixing to obtain a polyamide acid / fullerene precursor solution; and coating the precursor solution to prepare a film, and performing high-temperature thermal imidization to obtain the polyimide / fullerene hybrid film. According to the method, the storage stability of the polyamide acid solution can be effectively improved, and particularly, the problem of viscosity reduction caused by molecular chain degradation at a relatively high storage temperature can be inhibited; and meanwhile, due to the introduction of the nano fullerene, and on the basis of not influencing the surface smoothness of the polyimide film, the scratch resistance and the heat-conducting property of the film material are improved.

Owner:北京市科学技术研究院分析测试研究所(北京市理化分析测试中心)

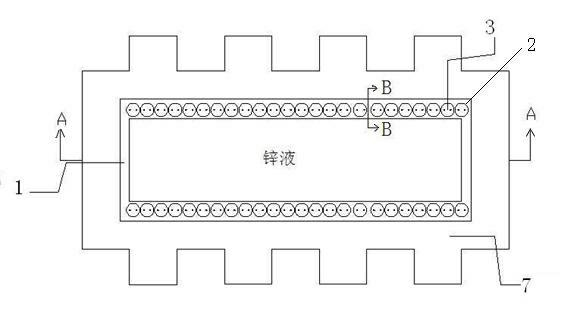

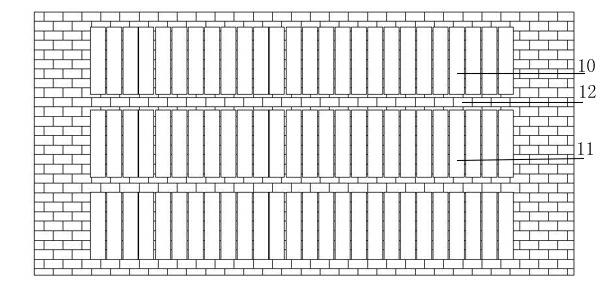

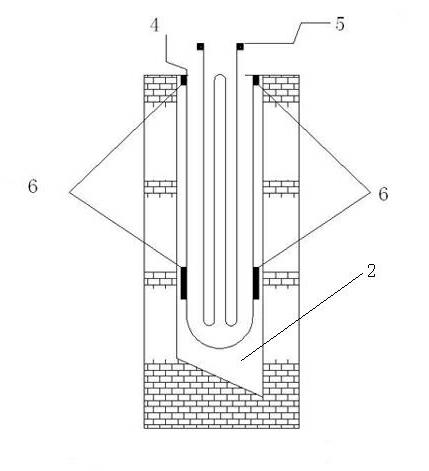

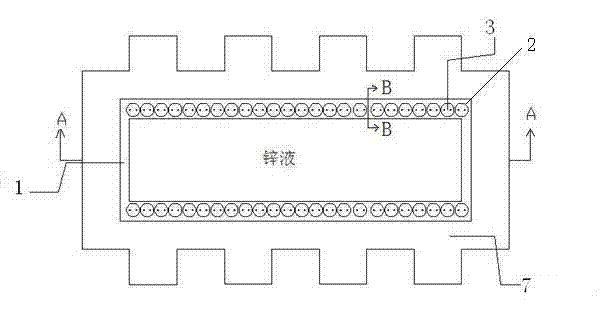

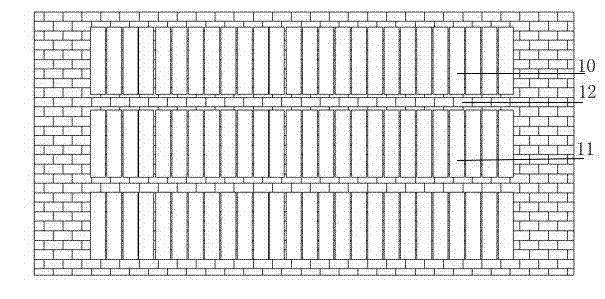

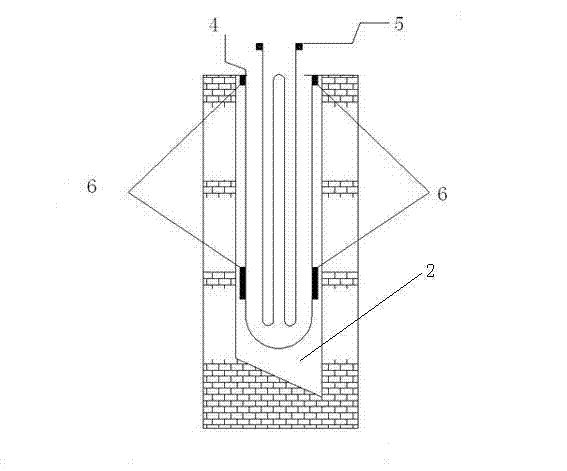

Novel ceramic zinc pot and electrical heating arrangement method

InactiveCN102154603AMeet the needs of modern galvanizingMeet the requirements for plating other workpiecesHot-dipping/immersion processesHeater elementsElectricityBrick

The invention discloses a novel ceramic zinc pot which comprises a zinc pot body consisting of refractory ceramic bricks, wherein a plurality of placing positions which are perpendicular to the bottom surface of the zinc pot body are arranged on the side wall of the zinc pot body and extend sequentially along the length of the side wall, and heating units are arranged on the placing positions; the heating units comprise quartz glass tubes fixed inside the placing positions; and electrical heating wires are arranged in the quartz glass tubes, and sheaths are arranged outside the quartz glass tubes. Due to the adoption of a new electrical heating arrangement mode, the size of the zinc pot can meet the requirement of modern galvanization, the problem of plating large-scale workpieces is solved, and the invention has the advantages that the novel ceramic zinc pot is easy to operate, safe in use, and saves energy and zinc. Simultaneously, the invention also discloses an electrical heating arrangement method for the novel ceramic zinc pot.

Owner:CHONGQING GUANGREN TOWER MFG

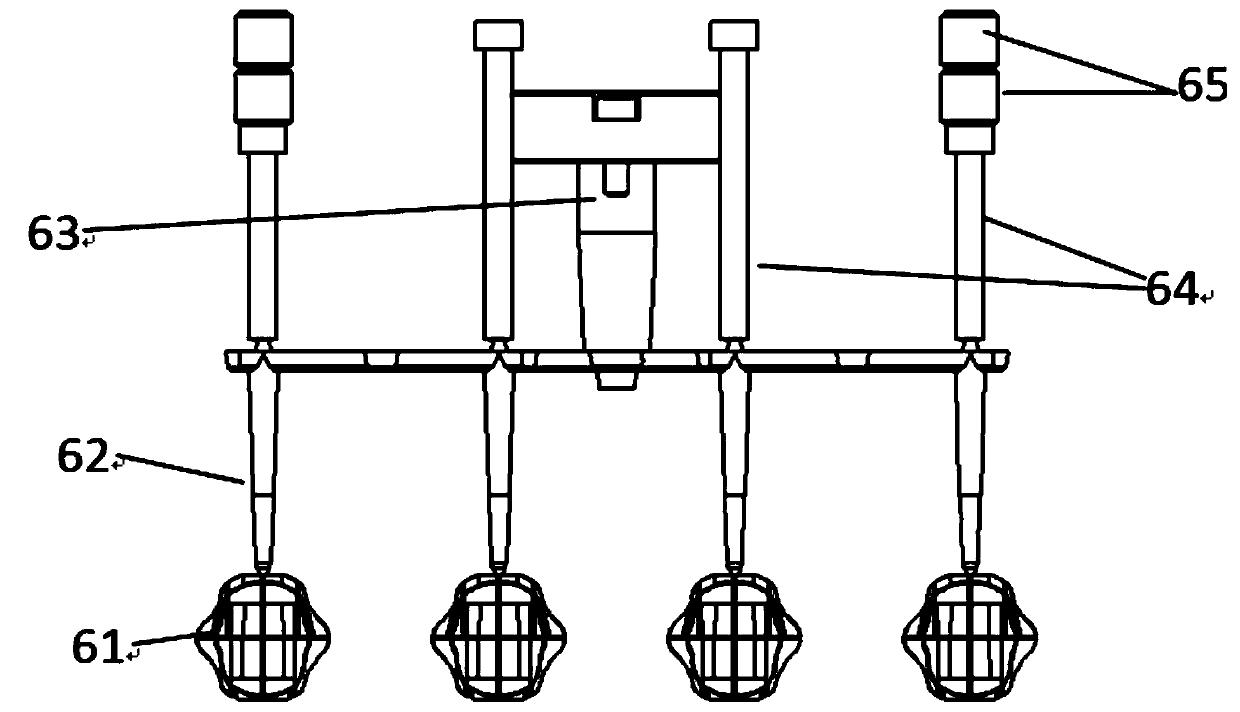

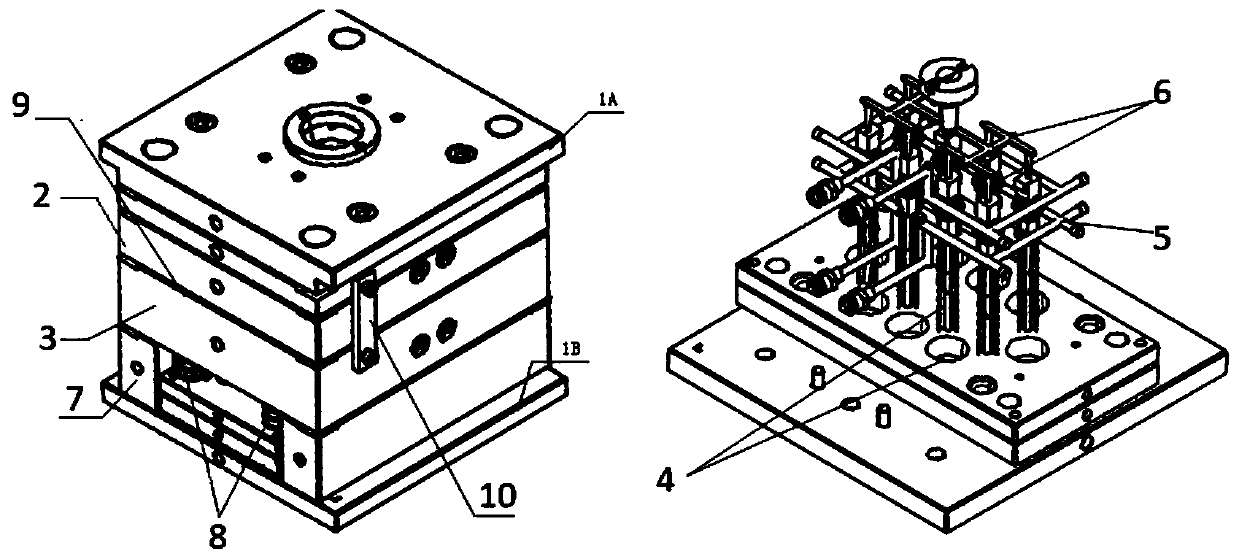

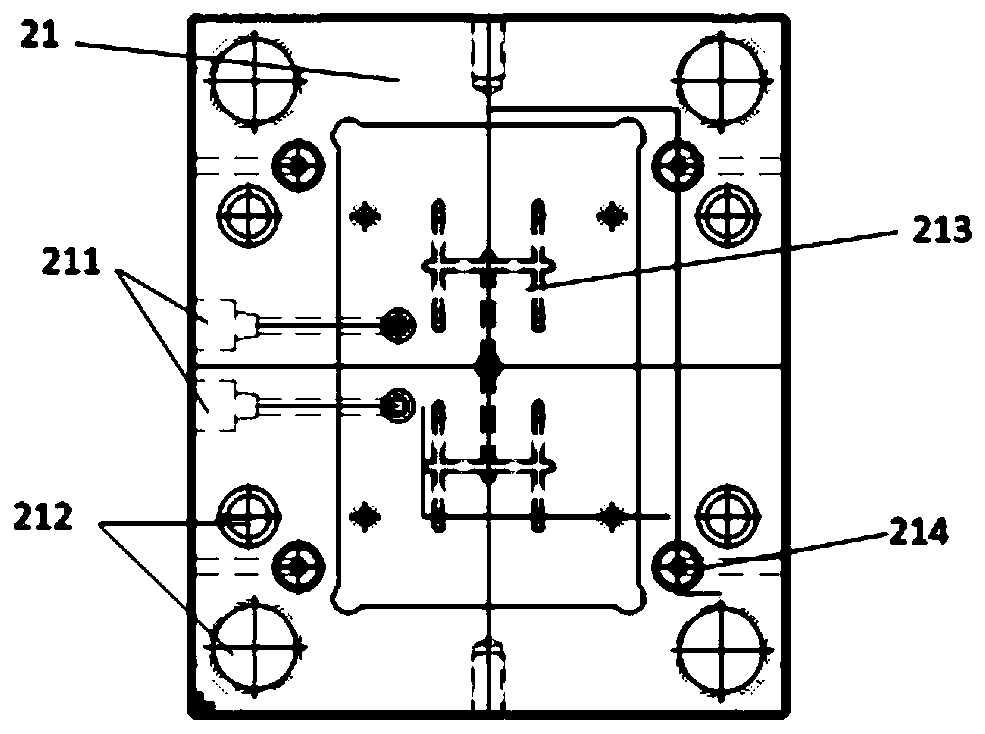

Mold for manufacturing obstructing and explosion suppression ball

PendingCN111098459ASimple materialEconomical and easy to transportDomestic articlesMagnetorheological fluidEngineering

The invention discloses a mold for manufacturing an obstructing and explosion suppression ball. The mold comprises a first seat plate, a second seat plate, a fixed mold mechanism, a movable mold mechanism, an ejecting mechanism, a cooling mechanism, a filling mechanism, a limiting mechanism, a resetting mechanism, an exhaust mechanism and a fixing mechanism; the fixed mold mechanism and the movable mold mechanism are arranged between the first seat plate and the second seat plate, an explosion suppression ball space for injection molding arranged in the inner part is of a thin-walled frameworkstructure, the ejecting mechanism ejects the explosion suppression ball, a sleeve barrel with magnetorheological fluid is additionally arranged on the resetting mechanism to actively control the displacement of a movable mold, the impact of vibration on an injection molding workpiece is reduced, the problems of complex structure, difficult manufacturing, low efficiency and high replacement rate of an explosion suppression filler are solved, and the advantages that the surface quality of the produced explosion suppression ball is smooth, shrinkage defects are eliminated, the wall surface can be thinner, the mass is less, the volume is small, and output is stable are achieved.

Owner:TIANJIN UNIV RENAI COLLEGE

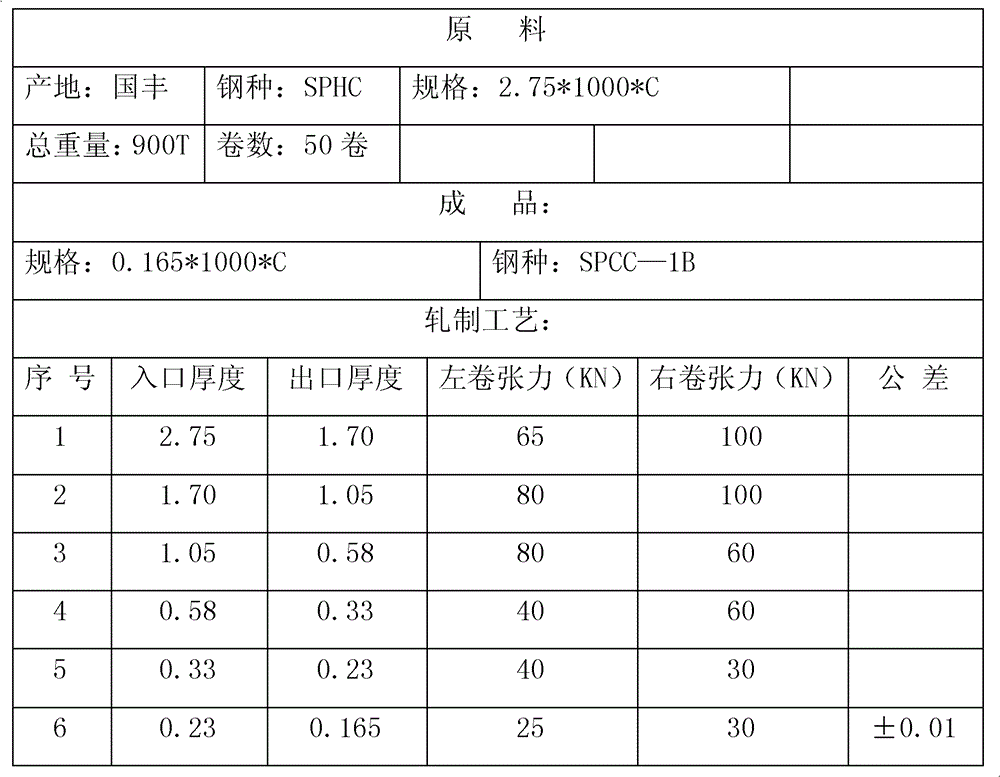

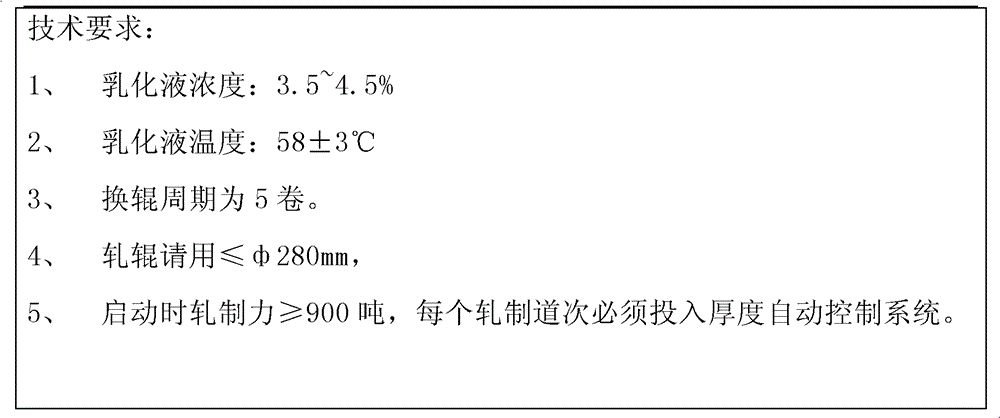

Production method of cold rolling thin slab with size of 2.75->0.165*1000mm

The invention provides a production method of a cold rolling thin slab with a size of 2.75->0.165*1000mm. The method comprises the following steps: planning standard production according to working conditions; regulating the technical parameters of rolling oil in the rolling process; regulating the roughness and roll shape of a roller; using the roller in a sequence from small to large on a rolling pass so as to finally obtain the finished cold rolling thin slab, wherein the cold rolling thin slab has the specified size of 2.75->0.165*1000mm and the deformation of 94%. The production method has the effects that the cold rolling thin slab with the size of 2.75->0.165*1000mm has a bright and clean surface and has high cleanness; after rolling, the steel coil has no corrosion within one month; simultaneously, the production efficiency is increased by above 30%, production cost is reduced by 260 yuan per ton, the yield of the thin slab is improved, the loss of steel coil transportation isreduced, and manpower resources are saved.

Owner:TIANJIN HENGXING STEEL IND

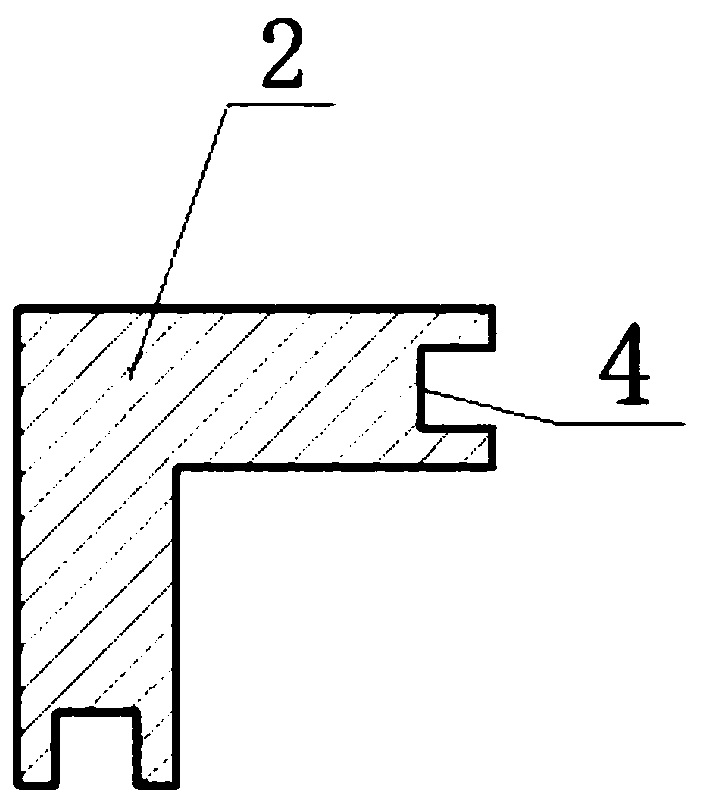

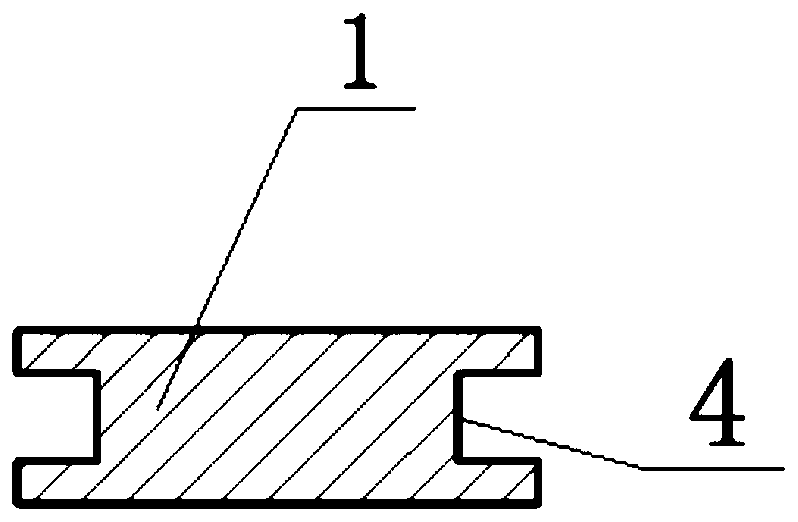

Combined type aluminum alloy formwork system and application method thereof

InactiveCN110185254AEasy to disassembleHigh surface flatnessForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksMaterials scienceAluminium alloy

The invention provides a combined type aluminum alloy formwork system and an application method thereof. The formwork system includes vertical formwork columns, corner formwork columns and wall formworks, wherein the vertical formwork columns, the corner formwork columns and the wall formworks are made of aluminum alloy materials; the vertical formwork columns and the corner formwork column are erected on the ground, and mortise grooves are formed in the vertical formwork columns and the corner formwork columns; and the wall formworks are provided with tenons, and through cooperation of the mortise grooves and the tenons, the wall formworks are arranged between two adjacent vertical formwork columns in a stacked mode, or between two adjacent corner formwork columns, or between adjacent vertical formwork columns and the corner formwork columns. The application method includes the steps that according to construction drawings, a wall skeleton is built, the corner formwork columns are installed, the vertical formwork columns are installed, and the wall formworks are installed, then concrete is poured, and the combined type aluminum alloy formwork system is dismantled after the concrete solidification. By adopting the technical scheme, through the cooperation of the mortise grooves and the tenons, the wall formworks can be disassembled and assembled more conveniently, the assemblyconsistency of the multiple wall formworks can be ensured, the assembly accuracy of the formwork system can be improved, and the foundation for improving the construction quality can be laid.

Owner:NO 1 CONSTR ENG CO LTD OF GUIZHOU CONSTR & ENG GRP

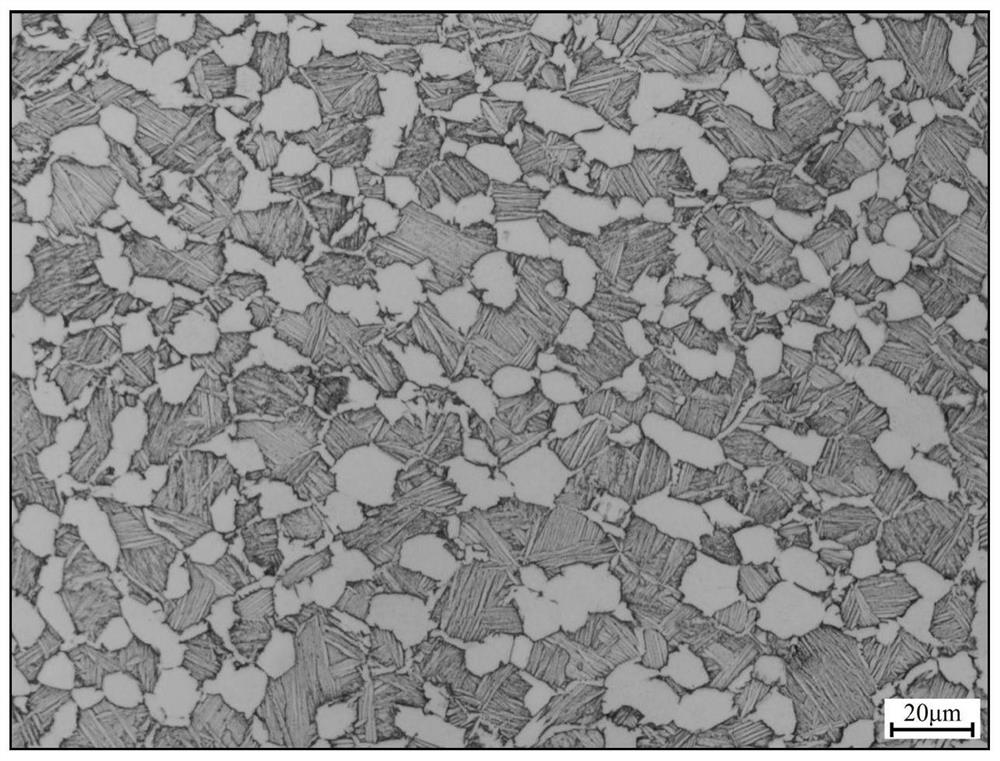

Short-process preparation method for medium-strength and high-toughness titanium alloy medium-thickness plate

ActiveCN113564397AUniform grain sizeShorten the processing cycleMetal-working apparatusIngotWater cooling

The invention discloses a short-process preparation method for a medium-strength and high-toughness titanium alloy medium-thickness plate. The short-process preparation method comprises the following steps that 1, raw materials are made into electrodes to be smelted; 2, a titanium alloy cast ingot is subjected to air cooling after heat preservation and forging; 3, a first forging stock titanium alloy is subjected to air cooling after heat preservation and forging; 4, a second forging stock titanium alloy is subjected to air cooling after heat preservation and forging; 5, a third forging stock titanium alloy is subjected to heat preservation and then water cooling; 6, the water-cooled titanium alloy forging stock is subjected to heat preservation and shaping after forging; and 7, a plate blank is subjected to solution aging treatment and machining, and the medium-strength and high-toughness titanium alloy medium-thickness plate is obtained. According to the short-process preparation method for the medium-strength and high-toughness titanium alloy medium-thickness plate, the titanium alloy cast ingot is subjected to cogging forging above the phase transformation point, a large-deformation uniform forging technology and deformation below the phase transformation point, then homogenization treatment at the lower temperature above the phase transformation point and large-deformation forging below the temperature of the phase transformation point are combined, the medium-strength and high-toughness titanium alloy medium-thickness plate can be obtained only through the four-heating-number forging technology, and the machining processing period can be greatly shortened and the machining cost can be reduced on the premise of ensuring the material performance.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

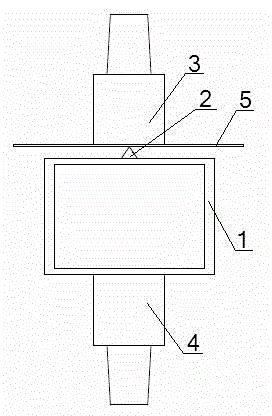

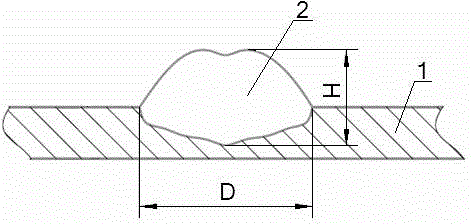

Novel metal welding method

ActiveCN105269138AEasy and flexible operationLow costResistance welding apparatusElectrical resistance and conductanceMetallic materials

Provided is a novel metal welding method. The method comprises: firstly, welding a bulge on a to-be-welded position of a first metal material, and then using a resistance welding machine or an electrode holder whose upper electrode and lower electrode are flat electrodes to weld the first metal material with the bulge with a second metal material. The design enlarges application range, improves strength of a welded joint and surface quality, and reduces production cost and prolongs service life of the electrodes.

Owner:DONGFENG COMML VEHICLE CO LTD

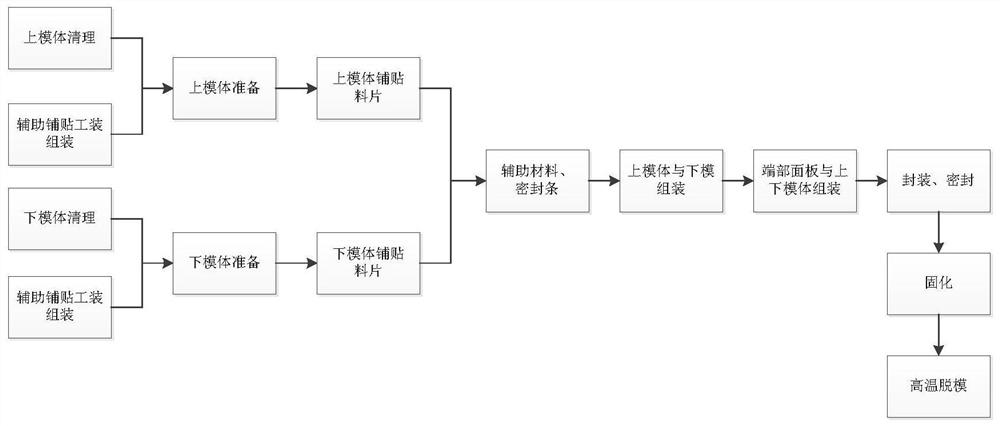

Forming method of high-rigidity conical-structure carbon fiber composite tube

PendingCN112477192ATake full advantage of stretchabilityNot easy to wrinkleTubular articlesFiberCarbon fiber composite

The invention provides a forming method of a high-rigidity conical-structure carbon fiber composite tube. The problem that a large-size conical-structure carbon fiber composite tube is large in manufacturing difficulty is mainly solved. According to the forming method disclosed by the invention, the conical carbon fiber composite tube is prepared through the operations of cleaning parts, mountinga paving auxiliary tool, paving unidirectional prepreg in cavities of an upper die body and a lower die body, pre-compacting and paving auxiliary materials, mounting sealing strips, fastening and pumping to negative pressure, detecting the vacuum degree, curing and the like. The forming method disclosed by the invention is particularly suitable for manufacturing the conical carbon fiber compositetube with the length larger than 6 m, and the internal quality and the surface quality of the products are high.

Owner:NANJING DONGJU CARBON FIBER COMPOSITE RES INST CO LTD +1

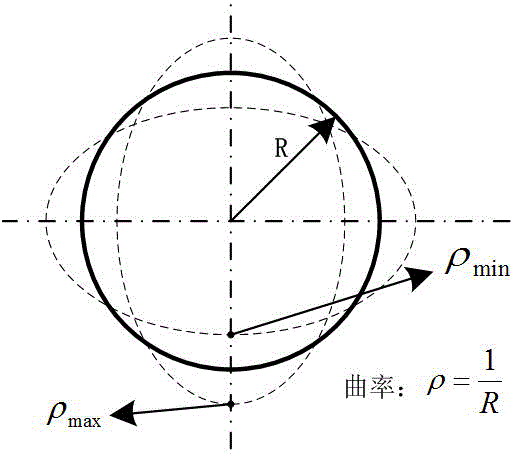

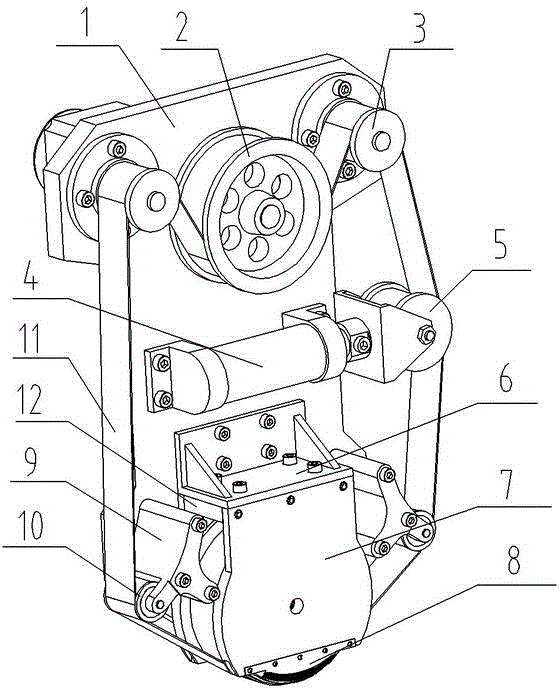

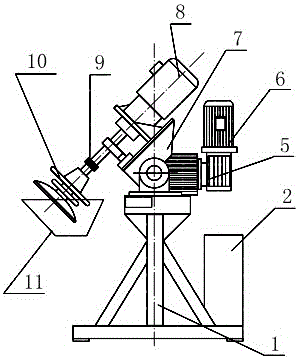

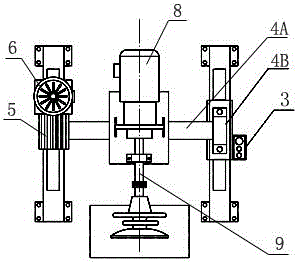

Stepless variable curvature abrasive belt grinding tool head

InactiveCN104816222AGuaranteed reliabilityWide range of changesBelt grinding machinesBelt grindingEngineering

The invention discloses a stepless variable curvature abrasive belt grinding tool head which comprises a support plate bearing device, a power device, a stepless variable curvature device, a sealing device, a tensioning gear and an abrasive belt. The abrasive belt is driven by an abrasive belt drive motor and is supported by driving wheels, idle wheels, the tensioning gear, a support roller and a stepless variable curvature device. During the grinding process, rotating angle of the variable curvature motor is adjusted for changing curvature size of grinding position of stepless variable curvature contact wheel. A feed screw nut structure in the stepless variable curvature device can keep the curvature size for realizing stepless variable curvature grinding function. The sealing device adapts change of the curvature and prevents pollution to the interior structure of the stepless variable curvature device from the dust. The curvature change of the contact wheel is mild and the curvature change range is great.

Owner:JILIN UNIV

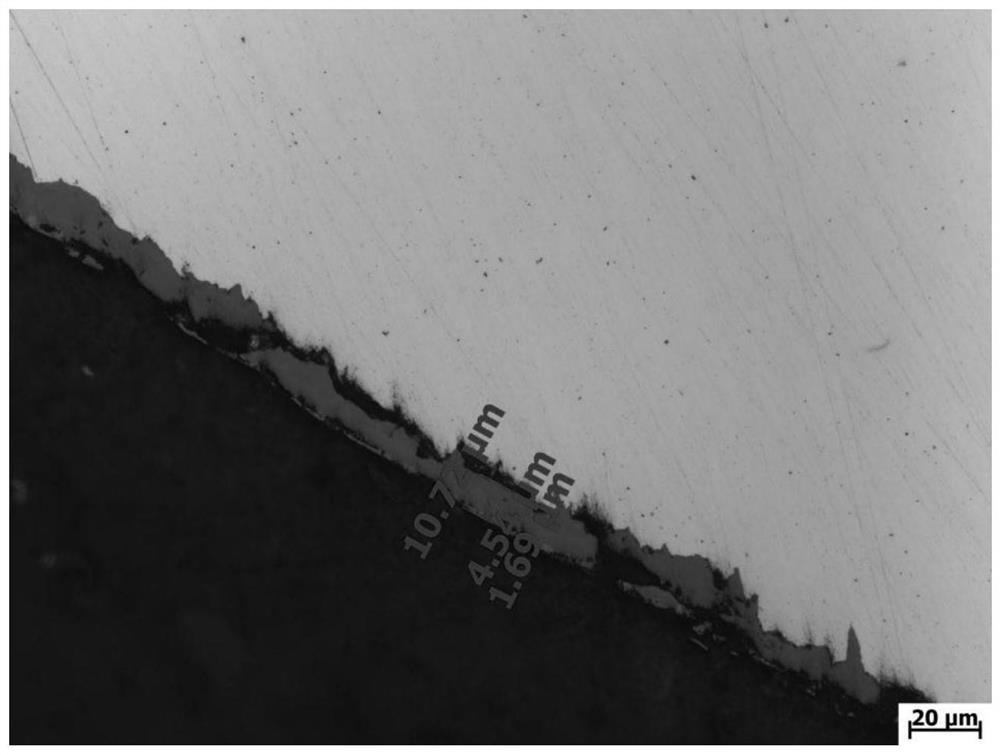

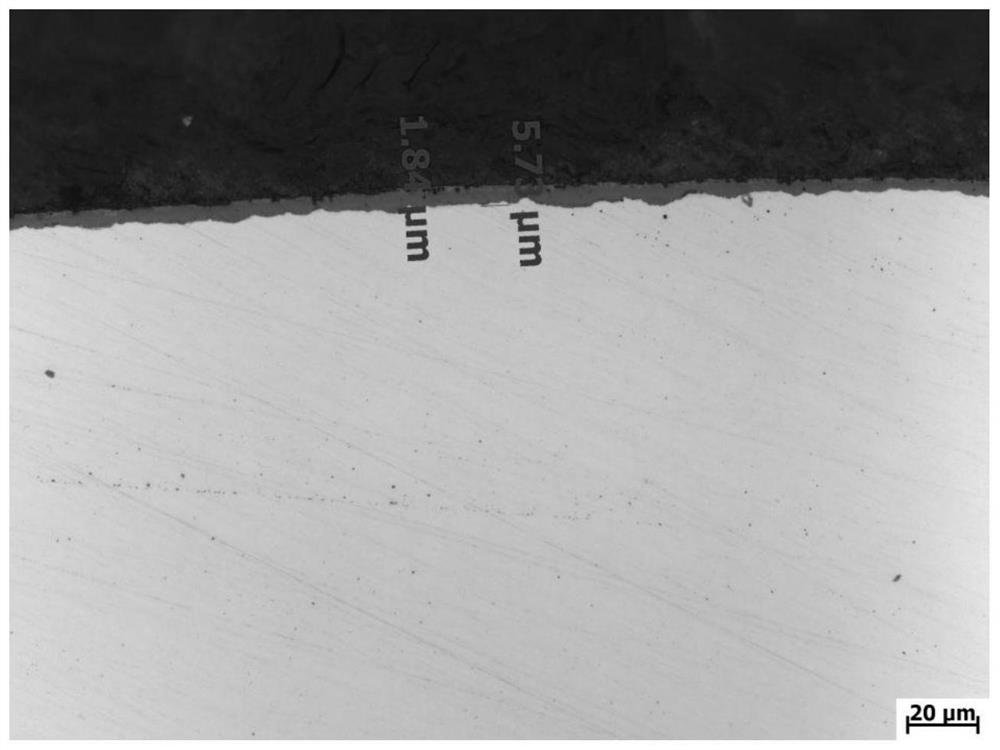

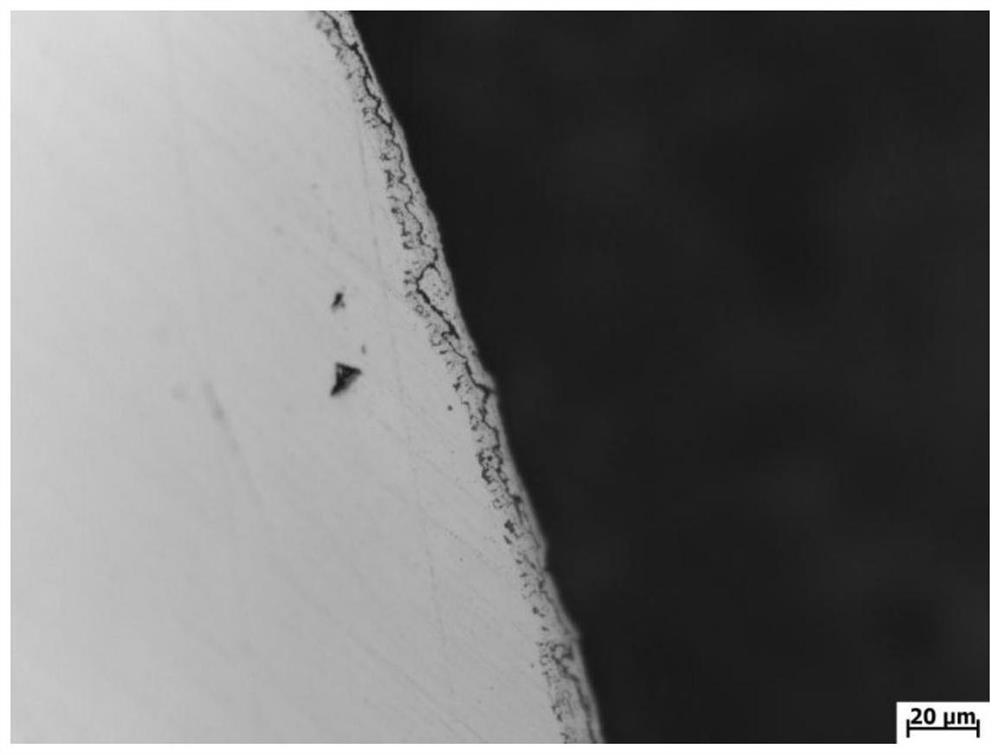

High-carbon chromium bearing steel wire rod production method free of pickling after spheroidizing annealing

PendingCN113843299ANo abnormalities such as unevenness were foundSmooth surface qualityProcess efficiency improvementMetal rolling arrangementsWire rodMetal

The invention belongs to the technical field of metal product production, and relates to a high-carbon chromium bearing steel wire rod production method free of pickling after spheroidizing annealing. The method comprises the steps that a continuous casting billet is obtained through converter smelting, LF refining, VD vacuum treatment and continuous casting; then, the continuous casting billet is subjected to heat insulation pit slow cooling, in-furnace heating, high-pressure water dephosphorization, controlled rolling, controlled cooling, collecting and packaging, finishing, and inspection; and finally spheroidizing annealing and drawing are performed. During annealing treatment, a hot-rolled wire rod is heated to 790-810 DEG C, cooled to 690-720 DEG C after heat preservation, cooled to 600-650 DEG C again after heat preservation at the cooling speed less than or equal to 20 DEG C / h, and finally discharged to be cooled. The wire rod is drawn without surface treatment to obtain a wire rod product. The thickness of the oxidized scale of the wire rod is increased to 14 microns or above, the proportion of Fe3O4 in the oxidized scale is increased to 30% or above from original 15-20%, the performance is good, and abnormal phenomena such as uneven carbides are not found.

Owner:JIANGSU YONGGANG GROUP CO LTD

High-impact low-shrink cast nylon composite material and preparation method thereof

The invention provides a carbon fiber ball-modified cast nylon composite material and a preparation method thereof. The composite material is prepared from 100 parts of lactam, 5-40 parts of carbon fiber ball, 0.5-3 parts of antioxidant, 0.5-3 parts of lubricating agent, 0.2-2 parts of catalyst and 0.2-1.5 parts of initiator. The carbon fiber balls are innovatively taken as filler for plastic modification, the aim of improving the toughness and dimensional stability of cast nylon is reached by utilizing anionic in-situ polymerization of lactam, and the surface quality of the product is also improved. The operational process is simple, and the prepared composite material is high in surface quality and excellent in performance and is suitable for large-scale industrial production.

Owner:HEFEI GENIUS NEW MATERIALS

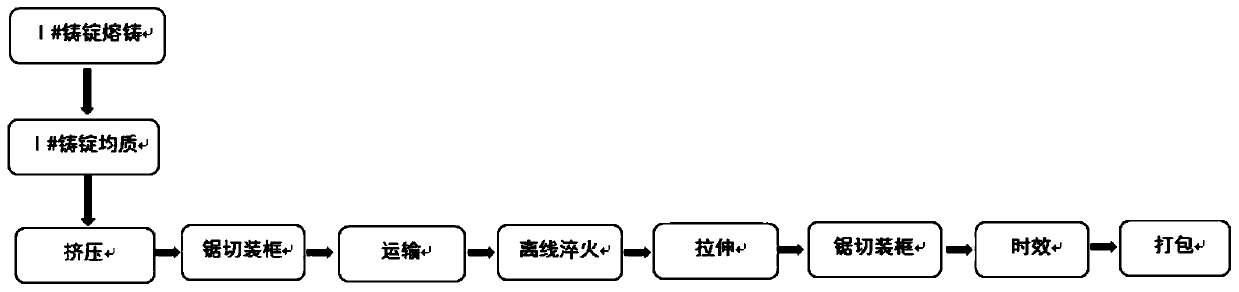

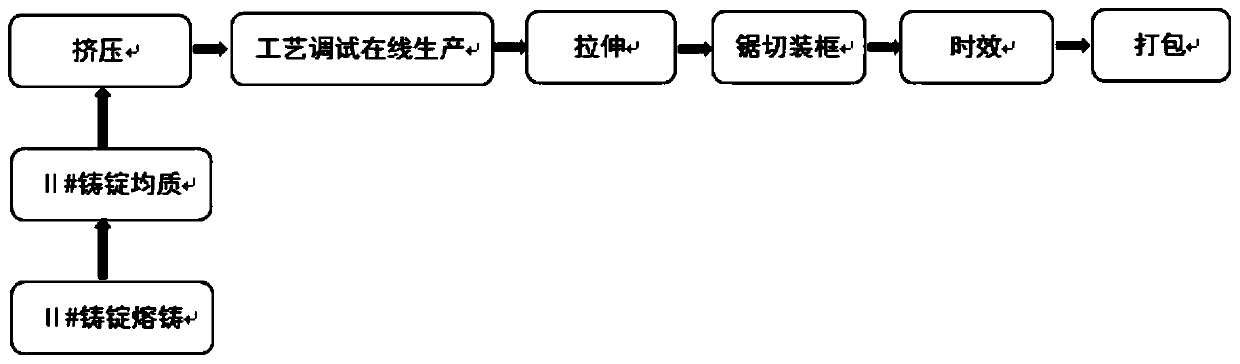

A kind of 2007 aluminum alloy bar production process

The invention belongs to the technical field of aluminum alloy manufacturing and relates to a 2007 aluminum alloy rod manufacturing process. The 2007 aluminum alloy rod manufacturing process comprisesthe following steps of casting, homogenizing, extruding, online quenching, stretching, sawing and framing, aging heat treatment and packaging, wherein the homogenizing process comprises the steps ofheating an aluminum alloy cast ingot obtained by casting to a temperature of 480 degrees centigrade, preserving the heat of the aluminum alloy cast ingot for 8 h, heating the aluminum alloy cast ingotto 510 degrees centigrade, preserving the heat of the aluminum alloy cast ingot for 3 h, and cooling the aluminum alloy cast ingot 360-420 degrees centigrade to obtain the homogenized aluminum alloycast ingot; and therefore, the breakthrough pressure of an extruder in the extruding process is reduced to 260 Bar, stable extrusion is made easier in the whole extruding process, a situation of pressure building of equipment is uneasy to cause, the equipment and a mold are uneasily damaged, and a problem that the online quenching of a 2007 aluminum alloy rod is difficult is solved.

Owner:CHINA ZHONGWANG

Equipment for coating rtv anti-pollution flashover paint for porcelain or glass umbrella type and bell jar type insulators

The invention discloses RTV anti-contamination flashover paint coating equipment for a porcelain or glass umbrella or bell jar shaped insulator. The equipment comprises a main frame, a machine head rotary frame, a reducing frequency conversion motor and a fast insulator connector. The machine head rotary frame is rotationally connected to the main frame through a rotary shaft and bearing seats of two ends; the reducing frequency conversion motor is fixedly arranged on the machine head rotary frame; the output shaft of the reducing frequency conversion motor is connected to the fast insulator connector. The equipment has the advantages that the dip-coated porcelain or glass insulators of different specifications are stable in quality, the surfaces are smooth and are free of bubbles, the coating layers are free of accumulation and drop hanging, and the thickness is even; in the dip-coating process, the VOC emission amount is small, and the production is environment-friendly and safe; the dip-coating automation level is high, operation is easy, factories of the porcelain or glass insulators of different specifications can implement porcelain and glass insulator industrial automatic RTV anti-contamination flashover paint coating production through the equipment, and large amount of cost can be saved.

Owner:眉山拓利科技有限公司

Novel ceramic zinc pot and electrical heating arrangement method

InactiveCN102154603BMeet the needs of modern galvanizingMeet the requirements for plating other workpiecesHot-dipping/immersion processesHeater elementsElectricityBrick

The invention discloses a novel ceramic zinc pot which comprises a zinc pot body consisting of refractory ceramic bricks, wherein a plurality of placing positions which are perpendicular to the bottom surface of the zinc pot body are arranged on the side wall of the zinc pot body and extend sequentially along the length of the side wall, and heating units are arranged on the placing positions; the heating units comprise quartz glass tubes fixed inside the placing positions; and electrical heating wires are arranged in the quartz glass tubes, and sheaths are arranged outside the quartz glass tubes. Due to the adoption of a new electrical heating arrangement mode, the size of the zinc pot can meet the requirement of modern galvanization, the problem of plating large-scale workpieces is solved, and the invention has the advantages that the novel ceramic zinc pot is easy to operate, safe in use, and saves energy and zinc. Simultaneously, the invention also discloses an electrical heating arrangement method for the novel ceramic zinc pot.

Owner:CHONGQING GUANGREN TOWER MFG

Narrow-groove long hole lost-foam casting method

InactiveCN111390111AHigh yieldImprove pass rateFoundry mouldsFoundry coresUltimate tensile strengthLost-foam casting

The invention discloses a narrow-groove long hole lost-foam casting method applied to the field of casting. The lost-foam casting method comprises the following steps that a dried flour core with a carbonized surface is inserted into a narrow slit or a long hole in a white mold block, and is bonded and sealed through using lost-foam glue, wherein the flour core is composed of flour and iron sand or steel shots, the flour accounts for 10%-25% of the weight of the iron sand or the steel shots, the flour core can also be composed of the flour and sand grains, and the flour accounts for 1 / 5-1 / 2 ofthe weight of the sand grains; a flour mixture is uniformly mixed and kneaded with water, and extrusion molding is performed with a core mold; the flour core is dried and carbonized in the core moldin an anoxic environment, wherein the drying temperature is 60 DEG C-90 DEG C, the drying time is 1 h-2 h, the carbonization temperature is 150 DEG C-200 DEG C, and the carbonization time is 15 min-30min; and in order to improve the strength of the flour core, a core bar is placed in the flour core, and the flour core is easy to scatter and convenient to clean. According to the method, a narrow-groove or long-hole casting with a smooth surface can be obtained, scribing machining is avoided, and the metal yield and the product percent of pass are increased.

Owner:HANDAN HUIQIAO COMPOSITE MATERIAL TECH CO LTD

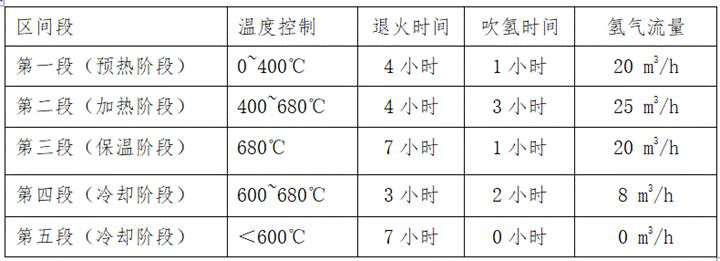

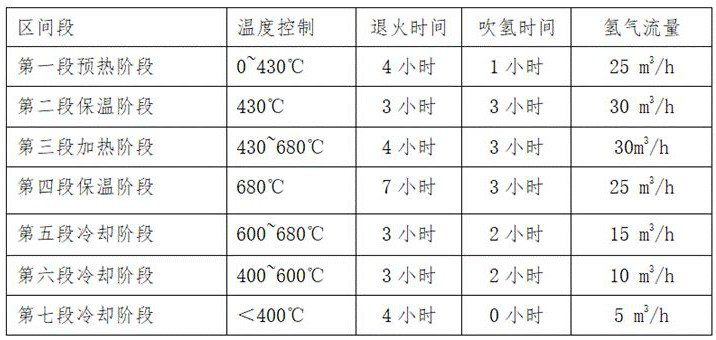

Hydrogen-rich circulating annealing process for cold-rolled oil drum plate

PendingCN114561520AImprove mechanical propertiesQuality improvementFurnace typesProcess efficiency improvementHydrogen purityMetallurgy

The invention discloses a hydrogen-rich circulating annealing process for a cold-rolled oil drum plate, which is characterized in that a steel coil comprises the following chemical components: 0.04-0.08% of C, 0.02-0.03% of Si, 0.26-0.33% of Mn, less than 0.01% of P, less than 0.005% of S and the balance of Fe and residual elements, the oil drum plate cold-rolled steel coil subjected to hot rolling and cold rolling is placed on a furnace platform of a cover type annealing furnace, an inner cover is buckled firstly, then a heating cover is buckled, a medium pipeline is connected, nitrogen is used for purging air, hydrogen is used for purging nitrogen, and the steel coil is subjected to hot rolling and cold rolling; two heat preservation processes of 430 DEG C and 680 DEG C are adopted, heat preservation is conducted for 3 hours at the temperature of 430 DEG C, annealing and heat preservation are conducted for 7 hours at the temperature of 680 DEG C, recrystallization temperature annealing is conducted, hydrogen tail gas discharged in the annealing process is collected through a main pipeline, hydrogen with the hydrogen purity being 99.999%, the dew point being-65 DEG C or below and the oxygen content being 5 ppm or below is obtained, and hydrogen recycling is achieved. And the annealed steel coil is subjected to flattening treatment with the elongation of 1.1%, the surface of the steel coil is cleaned with flattening liquid with the concentration of 3%-5%, and the high-surface oil drum plate product is obtained.

Owner:XINJIANG BAYI IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com