Equipment for coating rtv anti-pollution flashover paint for porcelain or glass umbrella type and bell jar type insulators

An anti-pollution flashover coating and insulator technology, applied in insulators, electrical components, circuits, etc., can solve the problems of low product quality stability, easy occurrence of dead angles, poor appearance quality, etc., to ensure quality consistency and controllability , The effect of reducing labor intensity and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

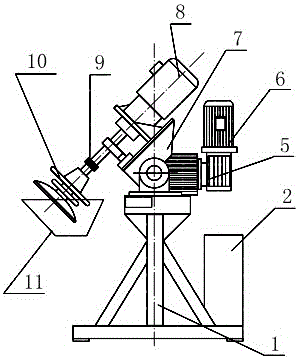

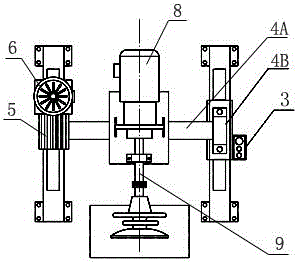

[0027] Equipment for coating RTV anti-pollution flashover coatings on porcelain or glass umbrella-type and bell-type insulators, including main frame 1, machine head rotating frame 7, deceleration frequency modulation motor 8 and insulator quick-connect connector 9, the machine head rotates The frame 7 is rotatably connected to the main frame 1 through a corner shaft and the bearing blocks 4 at both ends thereof, and a deceleration frequency modulation motor 8 is fixedly arranged on the head rotation frame 7, and the output shaft of the deceleration frequency modulation motor 8 Connect with the insulator quick connector 9. The PLC control box 2 is also externally connected with a control button 3 as a switch. The PLC control box 2 is installed on the bottom of the main frame 1 , and the control button 3 is installed on one side of the upper part of the main frame 1 .

Embodiment 2

[0029] Equipment for coating RTV anti-pollution flashover coatings on porcelain or glass umbrella-type and bell-type insulators, including main frame 1, machine head rotating frame 7, deceleration frequency modulation motor 8 and insulator quick-connect connector 9, the machine head rotates The frame 7 is rotatably connected to the main frame 1 through a corner shaft and the bearing blocks 4 at both ends thereof, and a deceleration frequency modulation motor 8 is fixedly arranged on the head rotation frame 7, and the output shaft of the deceleration frequency modulation motor 8 Connect with the insulator quick connector 9. It also includes a corner reducer 5 and a corner motor 6 , the input end of the corner reducer 5 is connected to the output shaft of the corner motor 6 , and the output end is connected to the bearing seat 4 . The PLC control box 2 is also externally connected with a control button 3 as a switch. The PLC control box 2 is installed on the bottom of the main ...

Embodiment 3

[0031] Equipment for coating RTV anti-pollution flashover coatings on porcelain or glass umbrella-type and bell-type insulators, including main frame 1, machine head rotating frame 7, deceleration frequency modulation motor 8 and insulator quick-connect connector 9, the machine head rotates The frame 7 is rotatably connected to the main frame 1 through a corner shaft and the bearing blocks 4 at both ends thereof, and a deceleration frequency modulation motor 8 is fixedly arranged on the head rotation frame 7, and the output shaft of the deceleration frequency modulation motor 8 Connect with the insulator quick connector 9. It also includes a PLC control box 2, and the deceleration frequency modulation motor 8 is connected with the PLC control box 2 through a data line. The PLC control box 2 is also externally connected with a control button 3 as a switch. The PLC control box 2 is installed on the bottom of the main frame 1 , and the control button 3 is installed on one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com