Narrow-groove long hole lost-foam casting method

A lost foam casting and long hole technology, used in long hole casting and narrow slit fields, can solve the problems of difficult cleaning of sand cores, poor surface quality of long holes, poor heat dissipation conditions, etc., to improve metal yield and save manpower. Cost, avoid the effect of scribing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] For long-hole through-hole castings with a diameter of Ф10 and a length of 55mm, in order to ensure the quality of the through-hole, in most cases, it is cast into a solid body and then drilled by scribing. This process not only adds two processes, but also causes Metal waste, production efficiency is also very low, the best way is to use casting one-time molding.

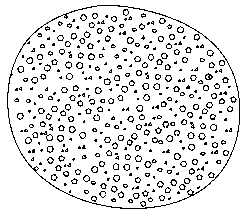

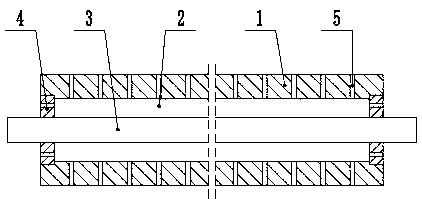

[0017] When making the lost foam white module, in order to facilitate the demoulding of the through hole, it is necessary to reserve at least 2-3% of the draft angle, considering the shrinkage deformation of the module, the dimensions of the two ends of the mold pin of the through hole are 11.5mm and 10.5mm, The dimensions of the two ends of the through hole of the module are generally 11.2-11.3mm and 10.2-10.3mm, and the dimensions of the two ends of the through hole of the casting are about 10mm and 11mm. Therefore, the through hole of the casting is conical, and the size needs to be controlled twice by th...

Embodiment 2

[0025] For a long hole with a diameter less than Ф6mm, whether it is a through hole or a blind hole, no matter how deep the hole is, the lost foam casting can no longer be directly cast, and it can only be obtained by scribing and drilling. Casting.

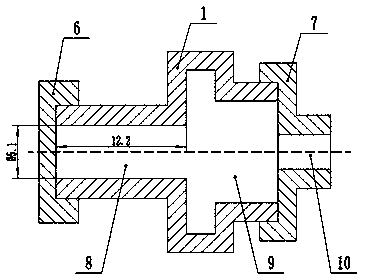

[0026] For castings with a blind hole of Ф5×12, the shape and size of the flour mandrel are as attached image 3 As shown, the flour mandrel is positioned and fastened by two semicircular molds 1, and the two ends are threaded to connect the threaded blind end 6 and the threaded end 7, so that the flour mandrel is fixed as a whole. An injection port 10 is designed at the threaded port end 7, and air holes are drilled on the two semicircular dies 1, the threaded blind end 6 and the threaded port end 7, and the flour kneading material is extruded into the core cavity from the injection port 10, and the Air can escape through the vent holes so that the flour rub fills the core cavity to form a flour core. The flour core is divided...

Embodiment 3

[0034] A narrow groove with a width of 12mm, a depth of 30mm, and a length of 100mm is designed at the thick and large position of the casting. The conventional lost foam process operation is to apply a coat of paint to the white module. After the coating of the narrow groove is dried, resin sand is inserted into the narrow groove, and then Carry out the second coating drying. After the molten metal is poured, due to the extremely poor heat dissipation conditions of the resin sand core in the narrow groove, the resin sand is easy to sinter into one under the combined action of vacuum and high-temperature molten metal, making it difficult to clean the narrow groove and resulting in a high scrap rate.

[0035] Using the method of drying and carbonizing the flour core can make the cleaning of the narrow groove simple. First, determine the structural size of the flour mandrel according to the shrinkage ratio of the metal, as shown in the attached Figure 4 shown. The flour mandr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com