Patents

Literature

53results about How to "Realize precise machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

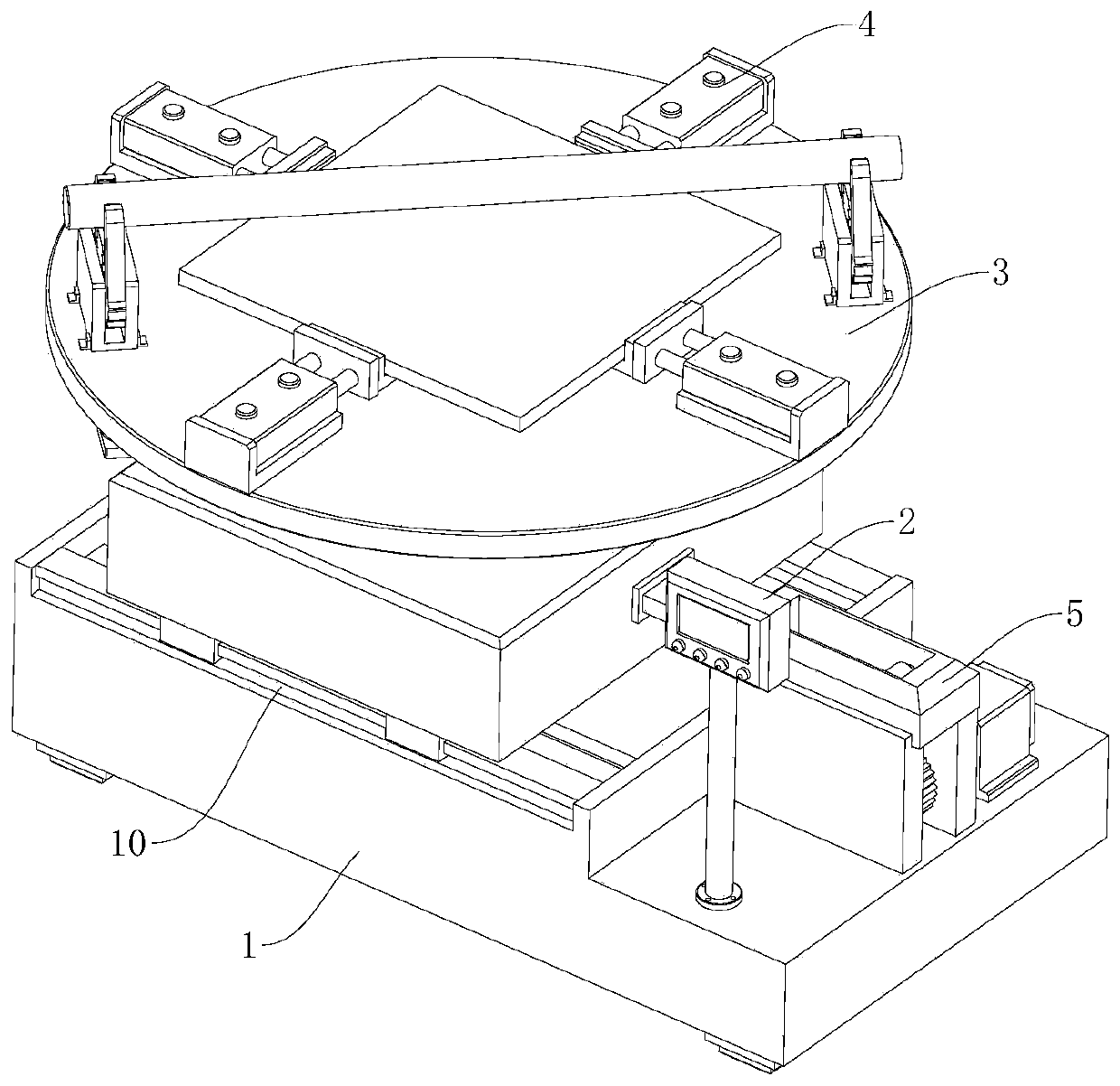

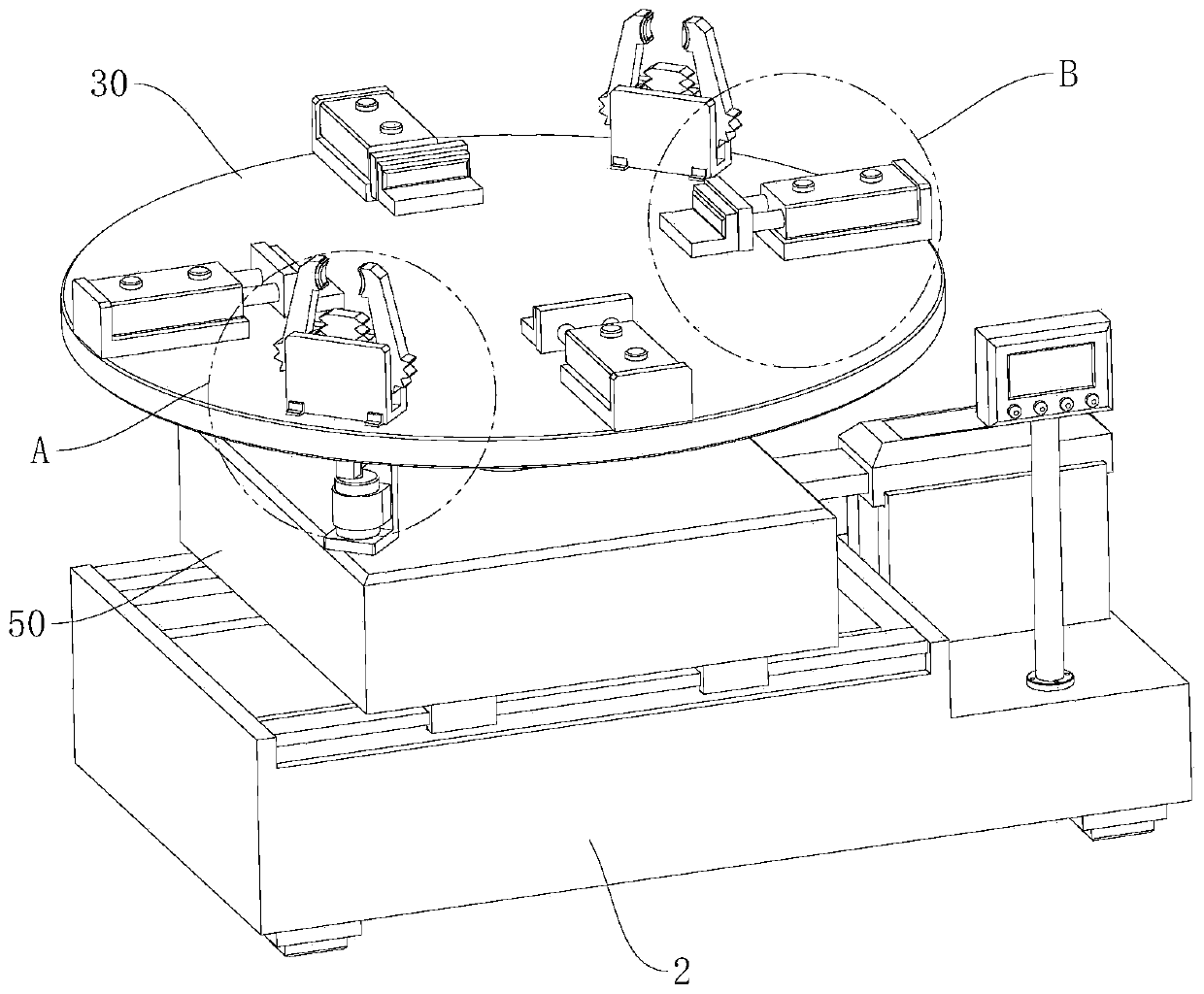

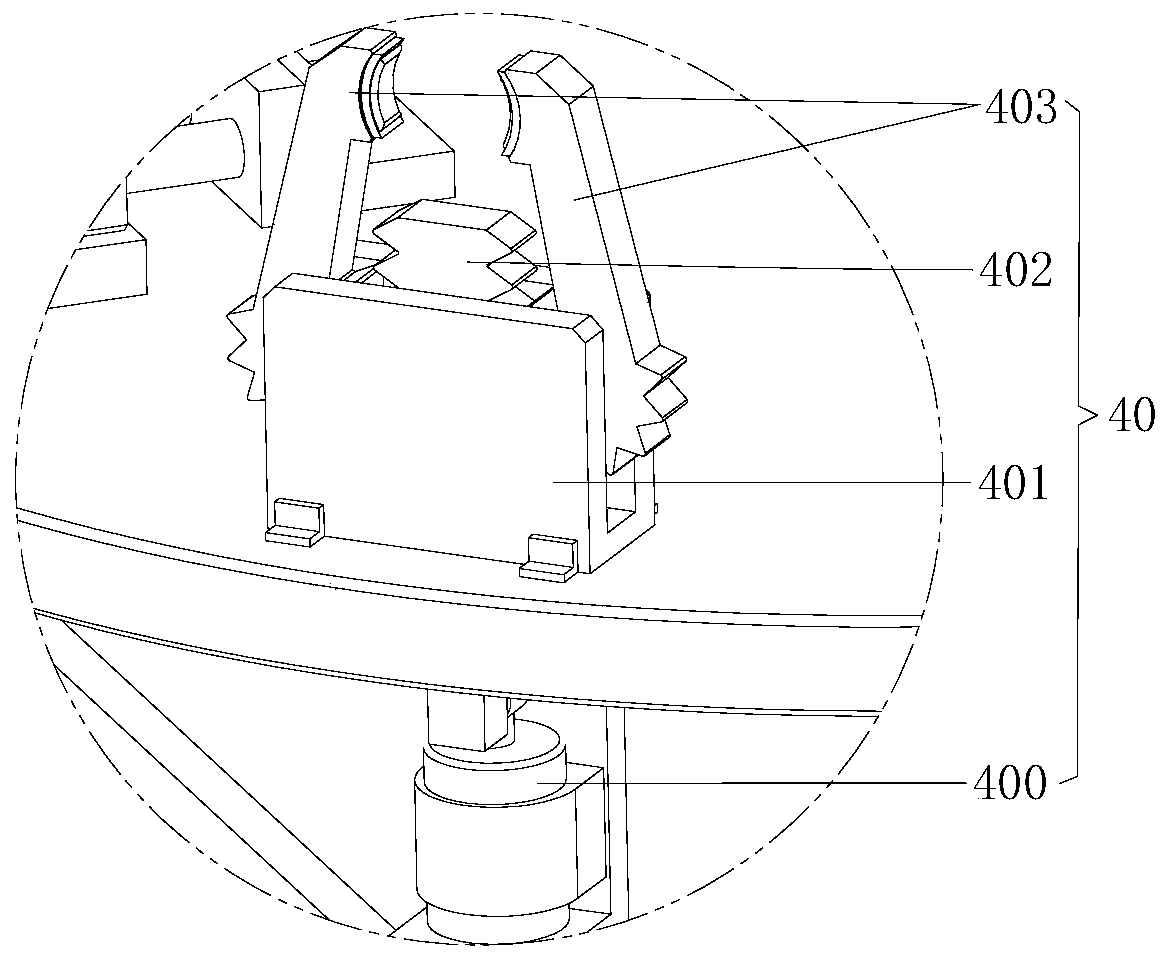

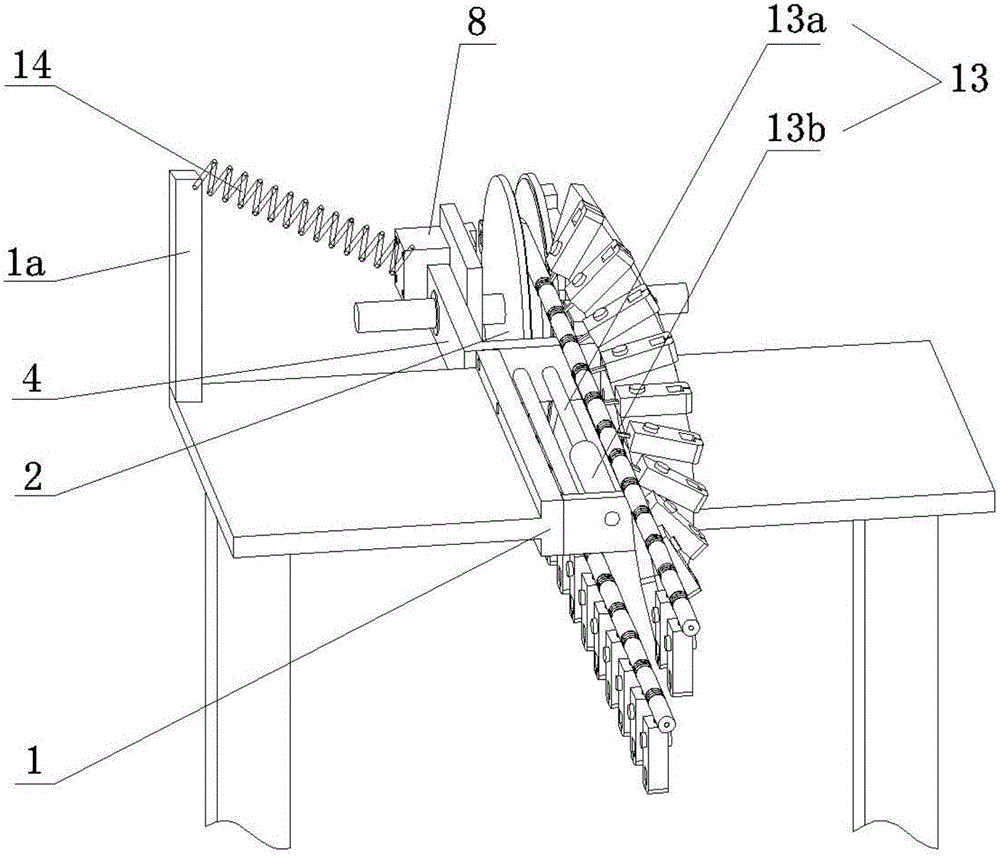

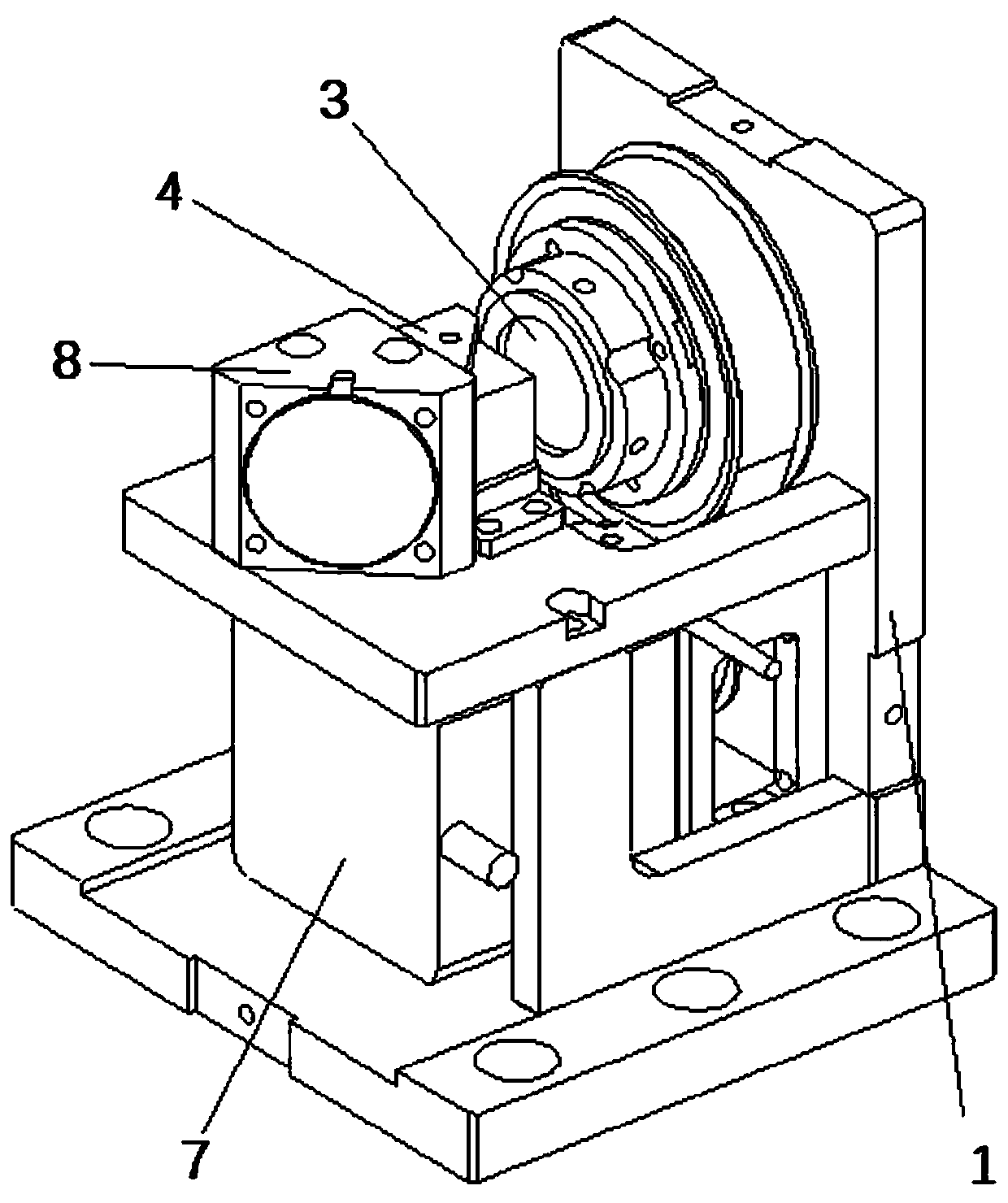

Adjustable positioning table used for aluminum alloy machining and use method

InactiveCN111230521ARealize precise machiningImprove practicalityMeasurement/indication equipmentsLarge fixed membersMetal machiningStructural engineering

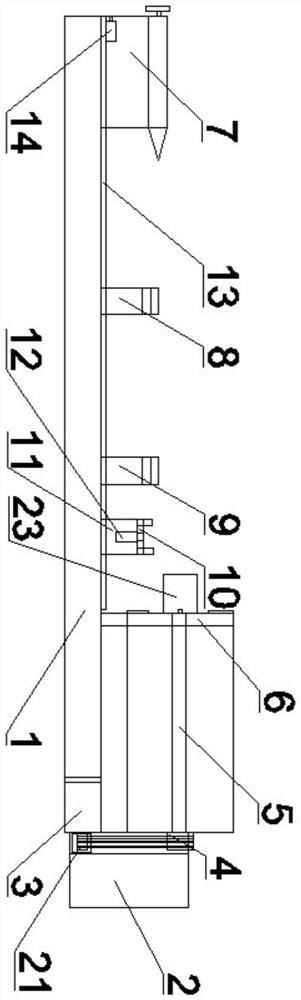

The invention relates to the technical field of metal machining, in particular to an adjustable positioning table used for aluminum alloy machining. The adjustable positioning table comprises a base and further comprises a controller, a rotating mechanism, a fixing mechanism and a sliding mechanism. The sliding mechanism is arranged on the top of the base so as to drive an aluminum alloy workpieceto slide. The sliding mechanism comprises a sliding table and a transmission assembly. The rotating mechanism is arranged on the top of the sliding table so as to drive the aluminum alloy workpiece to rotate. The rotating mechanism comprises a machining table and a driving assembly. The fixing mechanism is fixed to the top of the machining table so as to fix the aluminum alloy workpiece. The fixing mechanism comprises two first clamping assemblies and four second clamping assemblies, and the transmission assembly, the driving assembly, the two first clamping assemblies and the four second clamping assemblies are electrically connected with the controller. By means of the adjustable positioning table used for aluminum alloy machining, different shapes can be positioned, precise machining is achieved, meanwhile, the position of the workpiece does not need to be manually adjusted frequently by works, potential safety hazards are small, and in addition, the occupied space is small.

Owner:刘丽

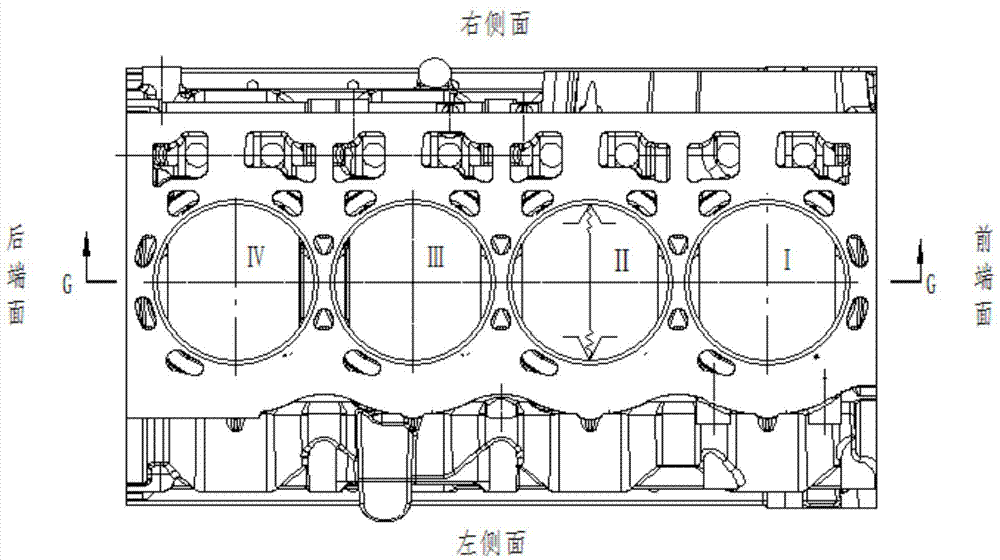

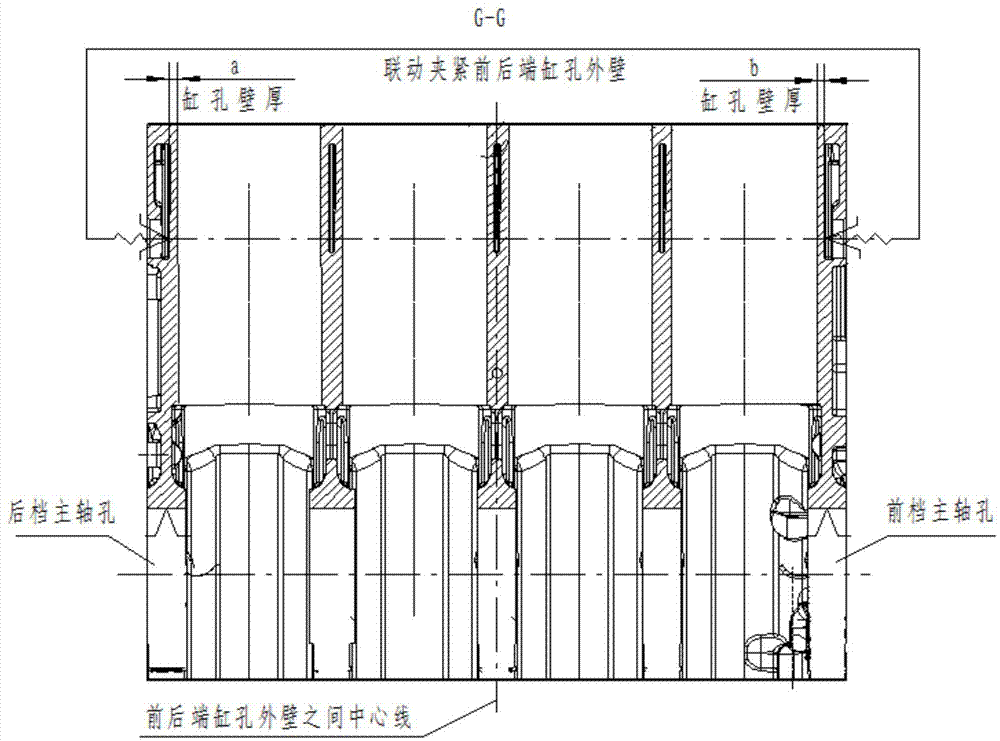

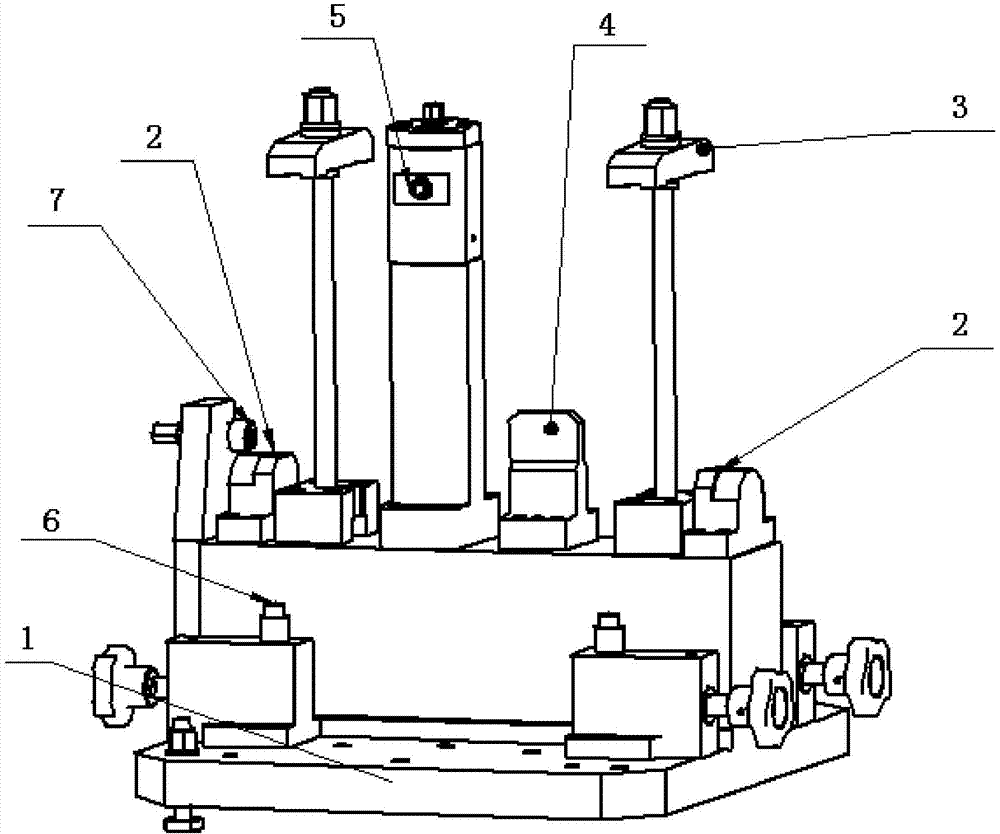

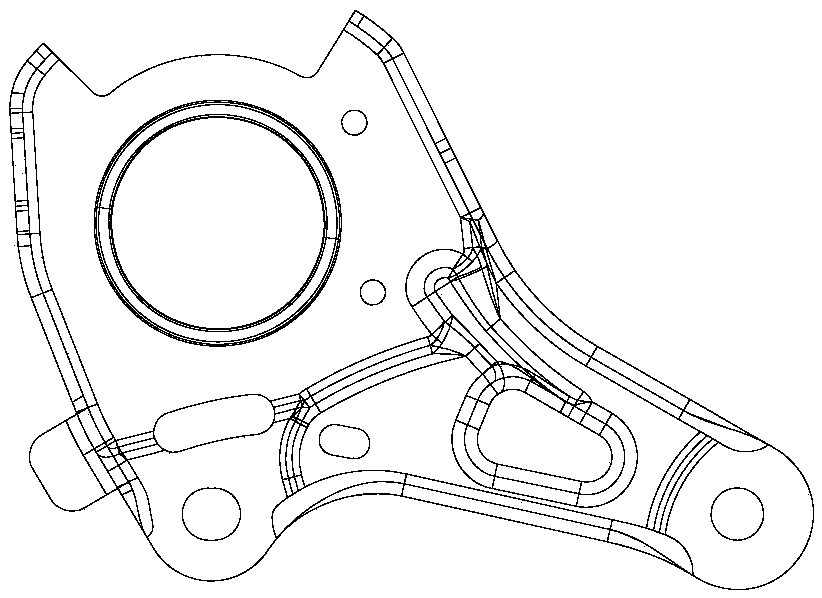

Air cylinder clamp

ActiveCN103753271ASimple structureRealize precise machiningPositioning apparatusMetal-working holdersPulp and paper industryMachining

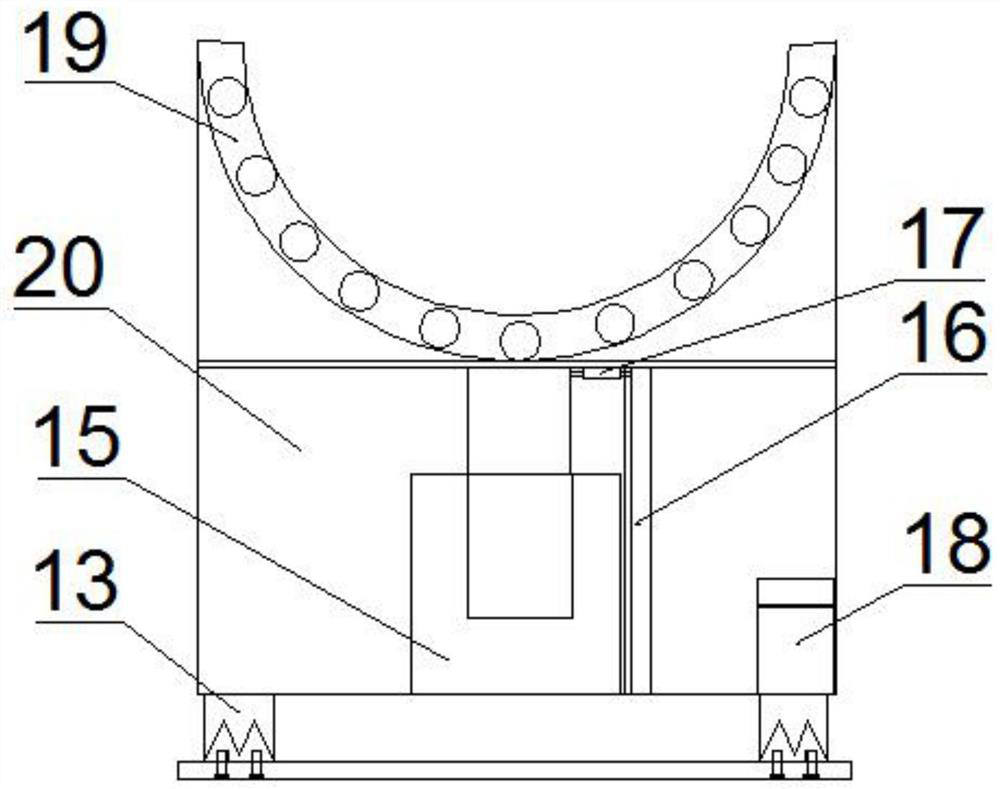

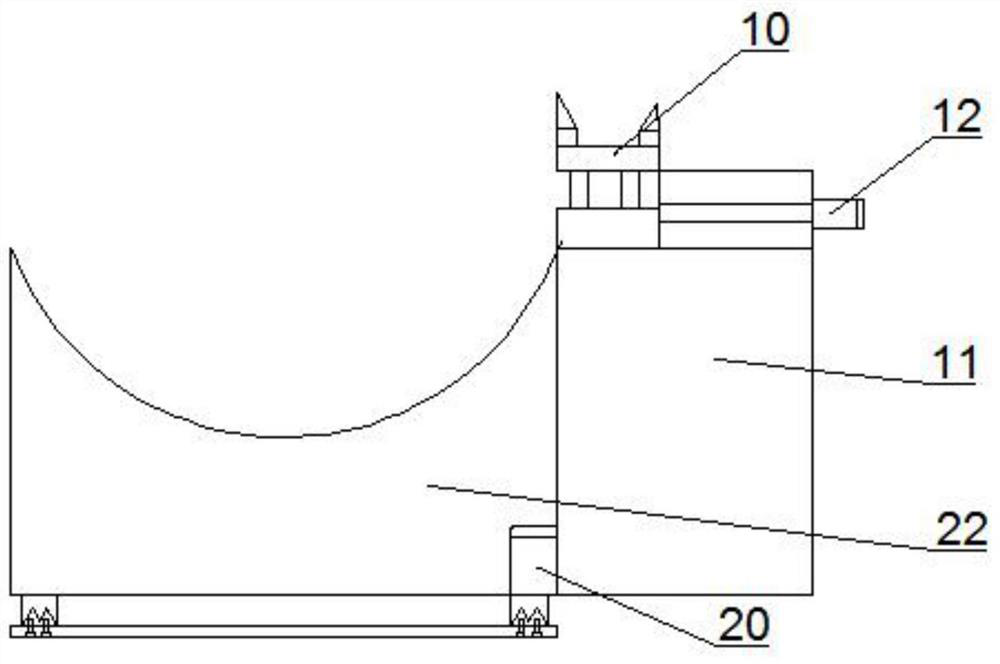

The invention discloses an air cylinder clamp. The air cylinder clamp comprises a base, spindle hole semicircular location blocks, clamping units and a cylinder hole slider linkage opening unit. Location end surface matched with to-be-located air cylinder front and rear stop spindle semicircular holes are arranged on the spindle hole semicircular location blocks. The clamping units are arranged on base location bosses on the inner sides of the spindle hole semicircular location blocks and comprise clamping supports, T-shaped screw pairs and clamping pressing blocks. A middle block bearing stop location block is provided with air cylinder bearing block location sides. The cylinder hole slider linkage opening unit comprises a base column and a cylinder hole slider component arranged at the top end of the base column. The air cylinder clamps clamp the air cylinder from the end and the sides, the measurement probe spot measurement function of a machining center spindle is used for finding reference coordinate values of machining of air cylinder process location pin holes, and accordingly, accurate machining of air cylinder process location pin holes is achieved, and the air cylinder hole wall thickness uniformity is guaranteed finally.

Owner:GUANGXI YUCHAI MASCH CO LTD

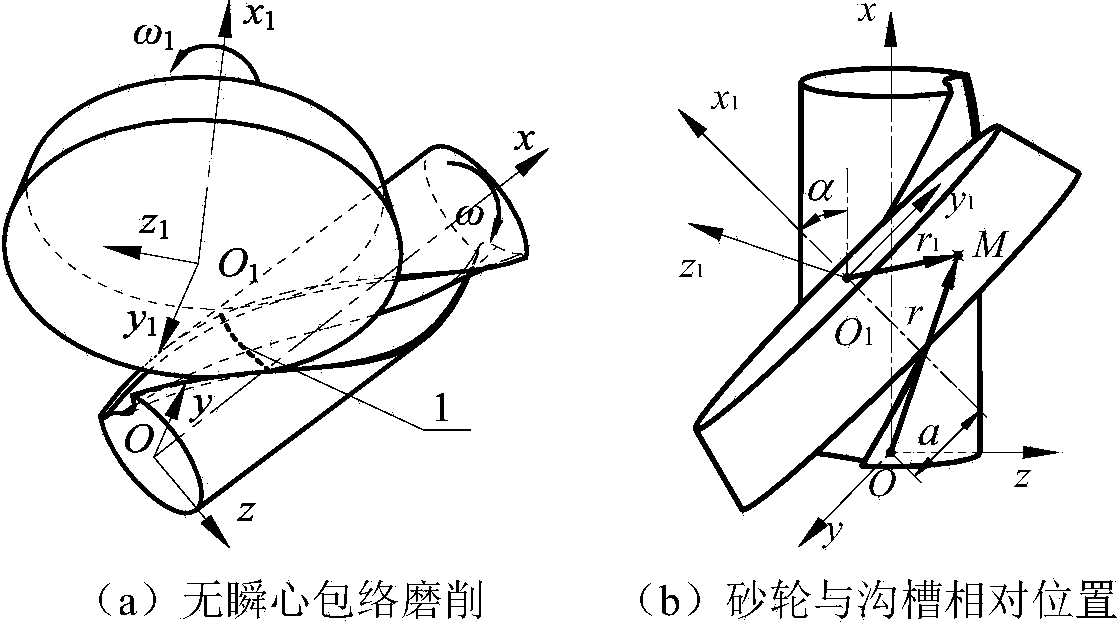

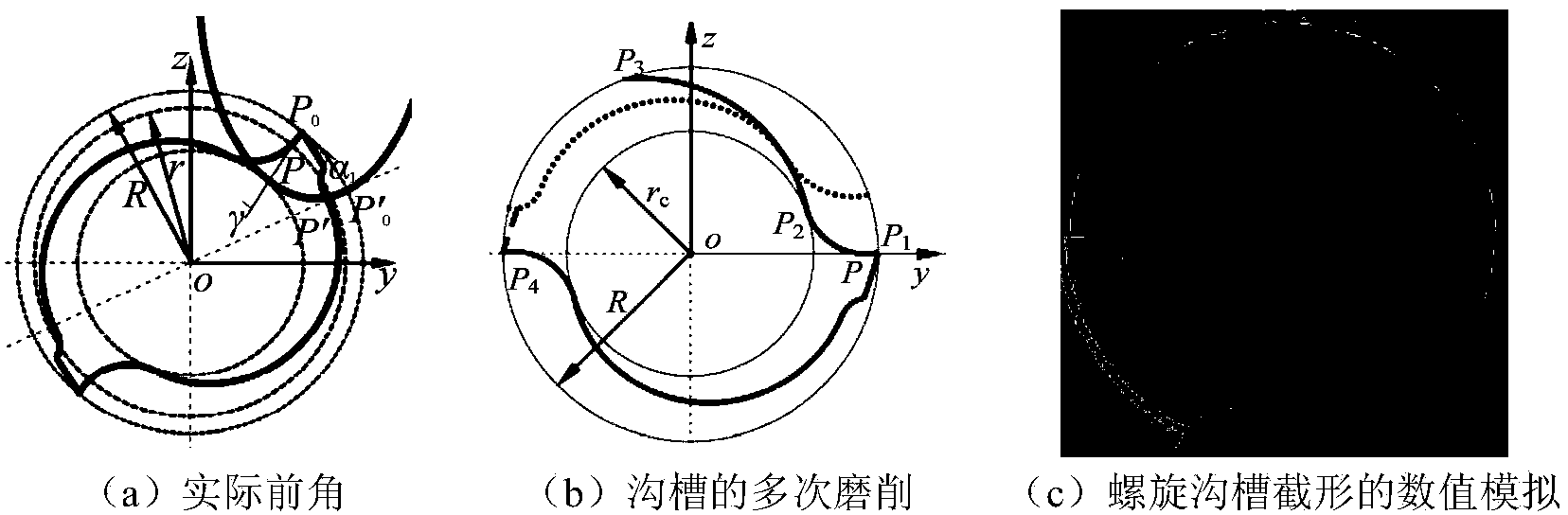

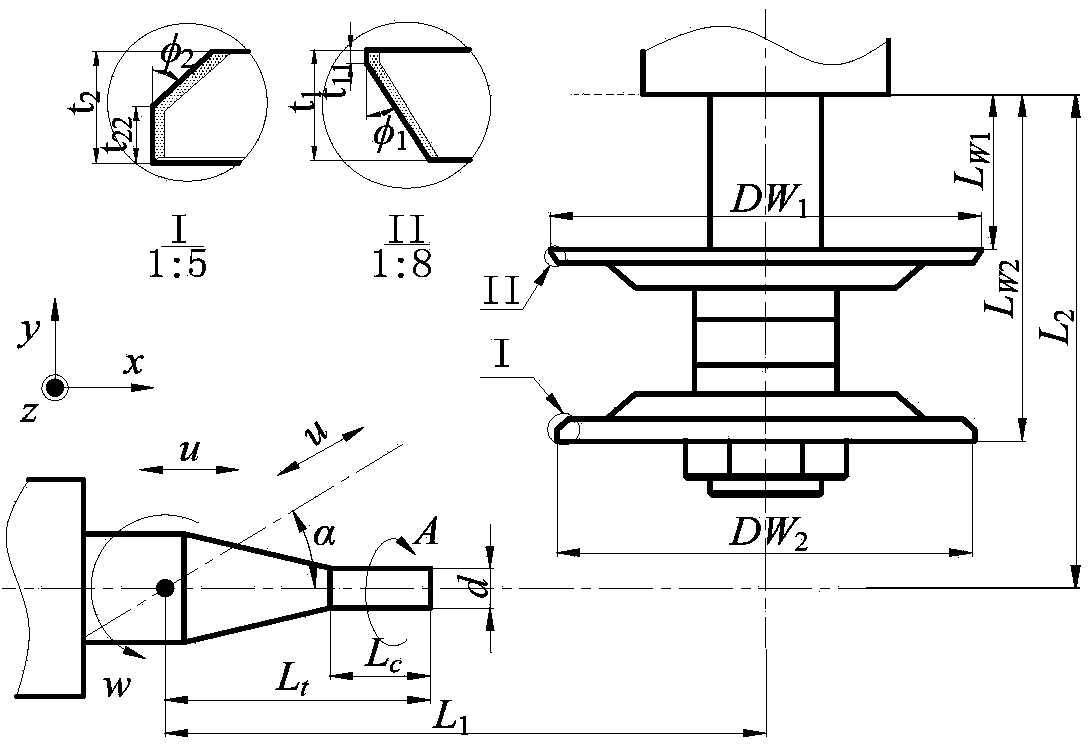

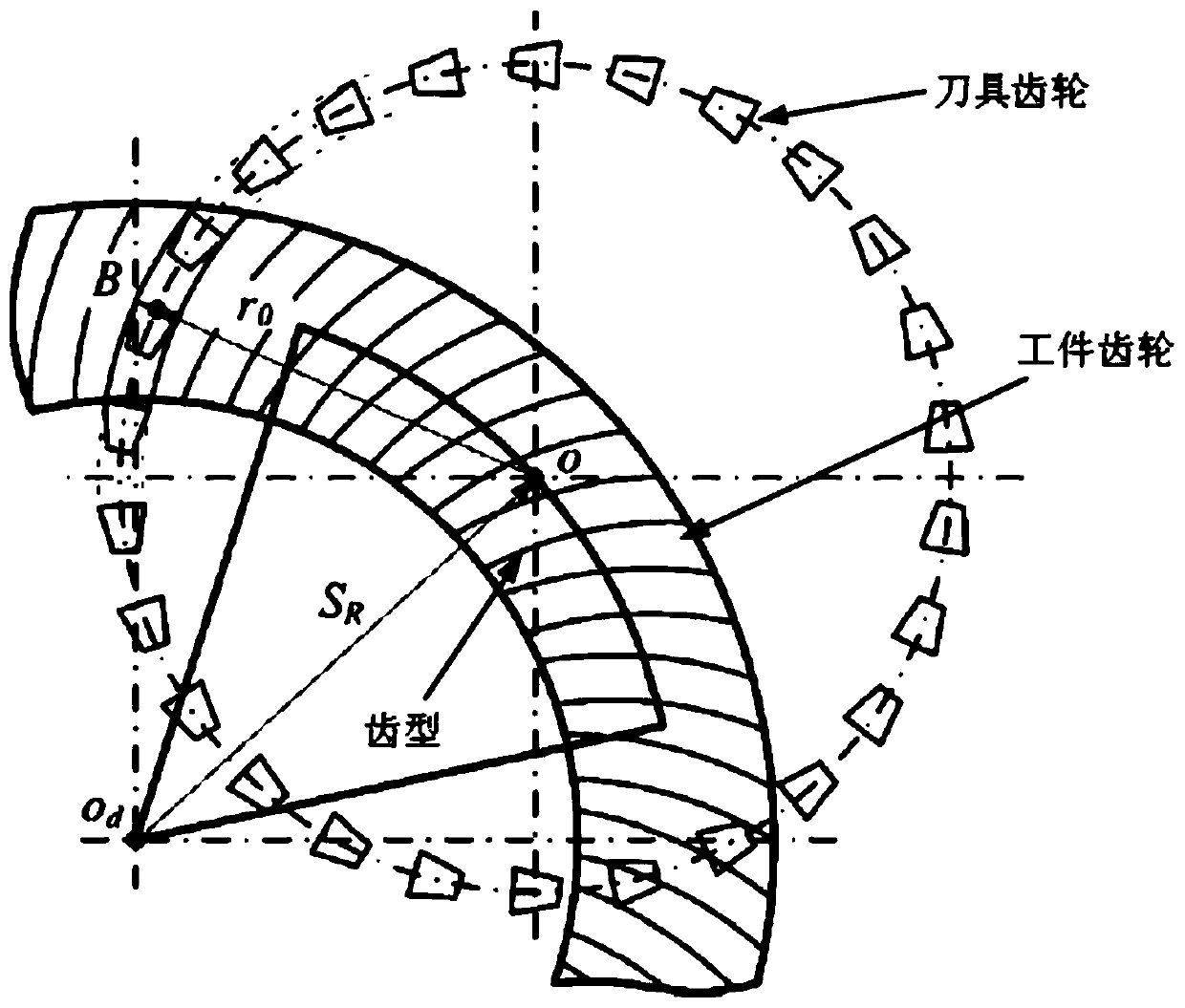

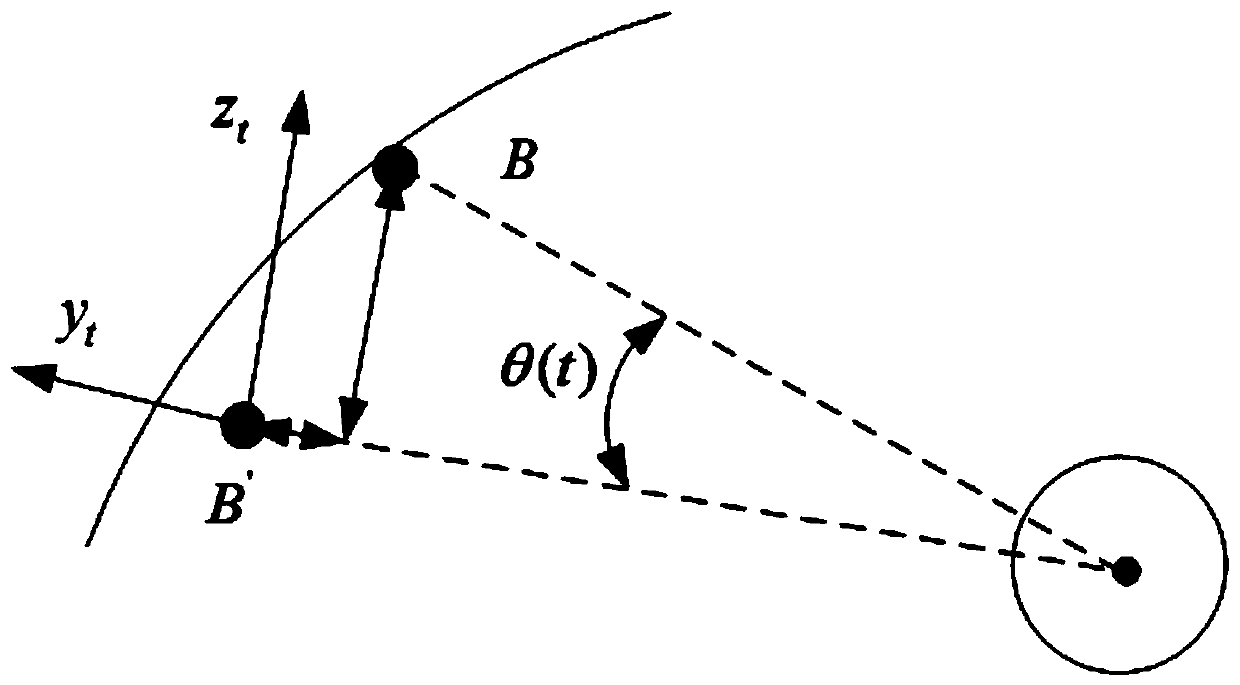

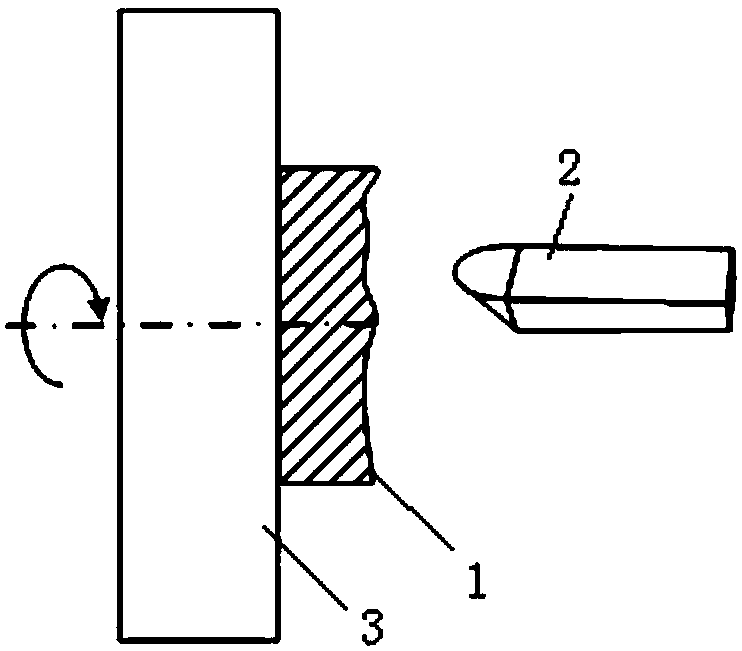

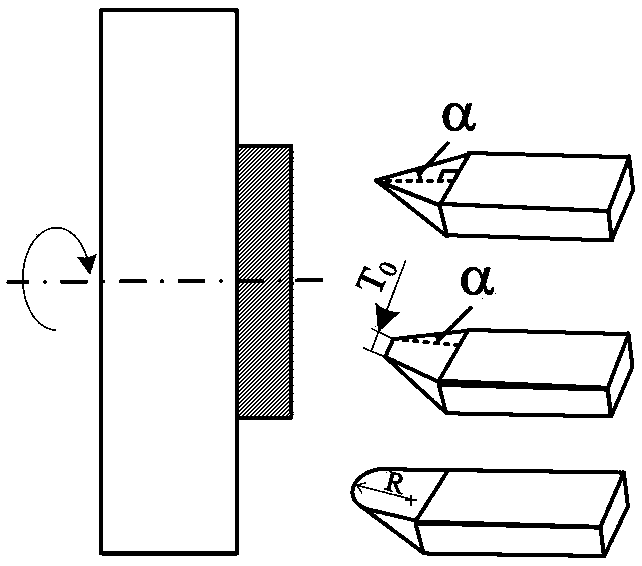

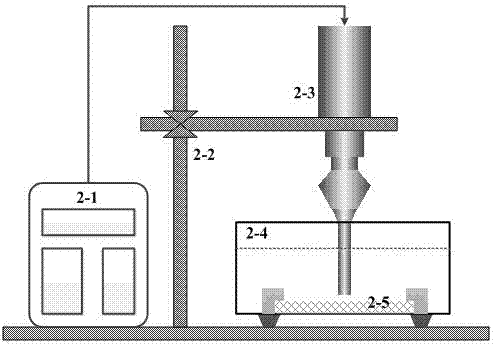

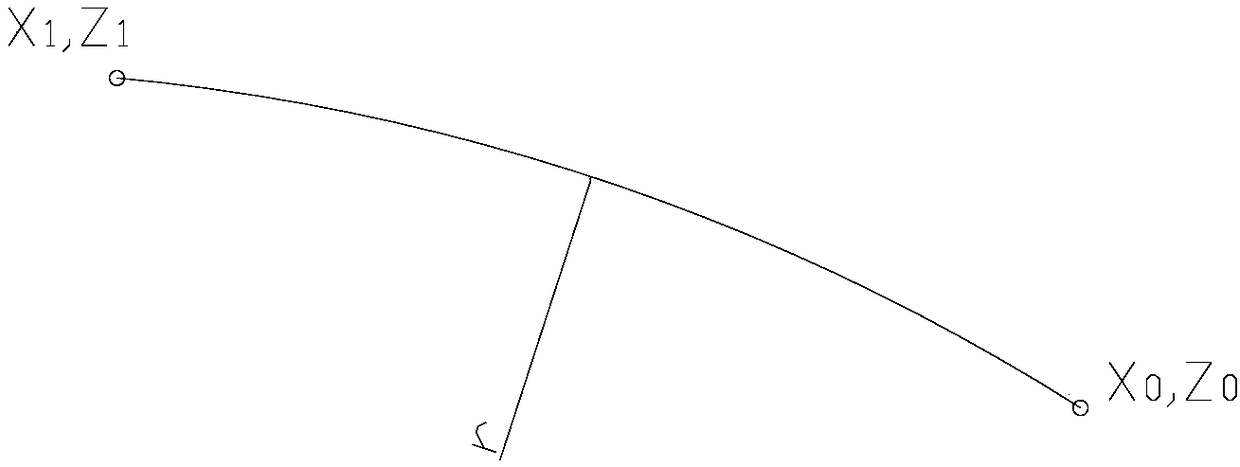

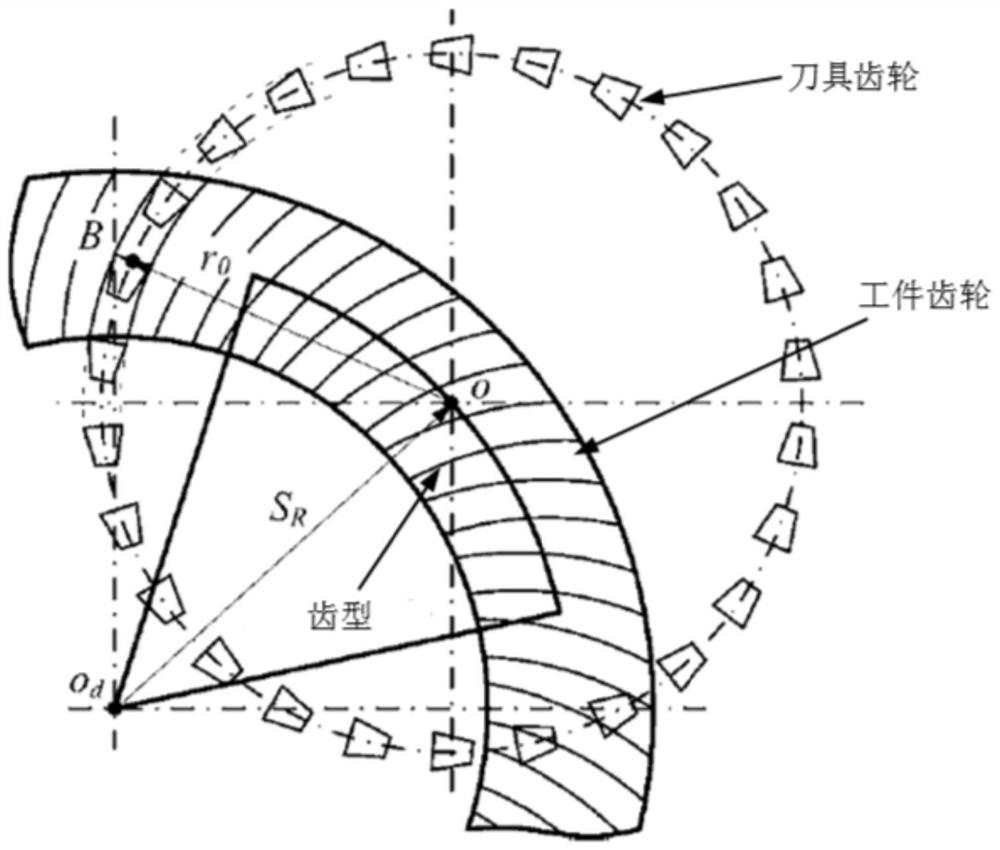

Non-instantaneous-pole envelope grinding method of spiral curved surface of superfine milling cutter

InactiveCN103862346ARealize precise machiningReduce contact areaMilling cuttersGrinding feed controlDiameter ratioEngineering

The side edge spiral curved surface of a superfine spiral end milling cutter is of a complex structure and is difficult to machine. A traditional grinding method cannot ensure machining accuracy of a part of a long and thin structure. The invention relates to a non-instantaneous-pole envelope grinding method of the spiral curved surface of the superfine milling cutter. When a cutter is ground, the shape and installation angle of a grinding wheel directly affect the shapes of the front corner, the rear corner and a chip groove of the side edge of the superfine milling cutter. The non-instantaneous-pole envelope principle and the homogeneous coordinate transform method are applied, a mathematical model is obtained by sectioning the spiral curved surface end generated by the standard conical grinding wheel in an envelope mode, and the method can be used for analyzing the influence on the geometric angle and the groove shape of the side edge of the superfine milling cutter from the installation angle and shape of the grinding wheel; in the model, the tilt angle of the grinding wheel is larger than the coangle of the spiral angle, the contact area decreases, and grinding force is reduced; the front cutter face, the rear cutter face and the chip groove are ground multiple times in an envelope generating mode, and the accuracy of geometrical parameters of the superfine milling cutter can be ensured. The non-instantaneous-pole envelope grinding method is suitable for accurate machining of superfine spiral structures with the high length-diameter ratio.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

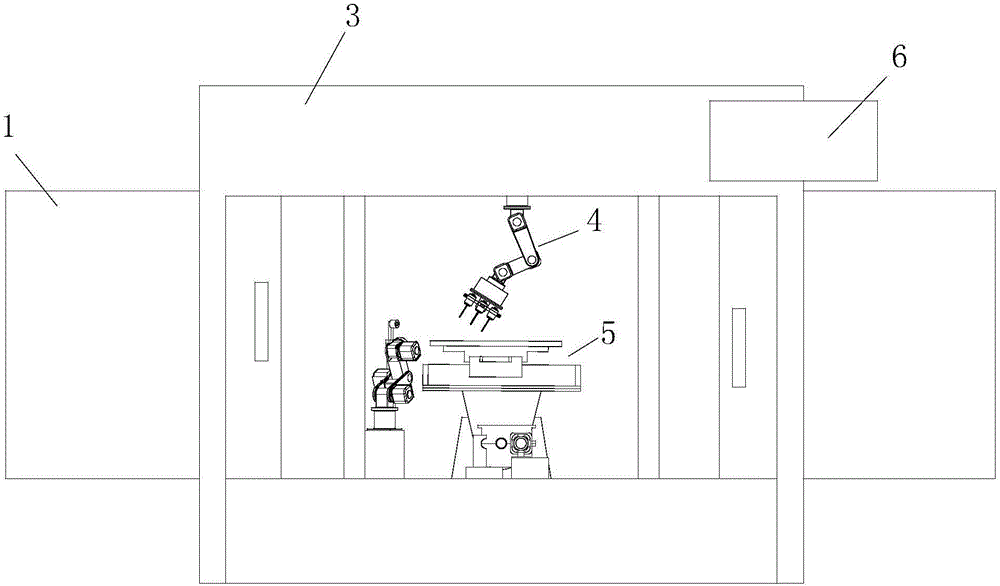

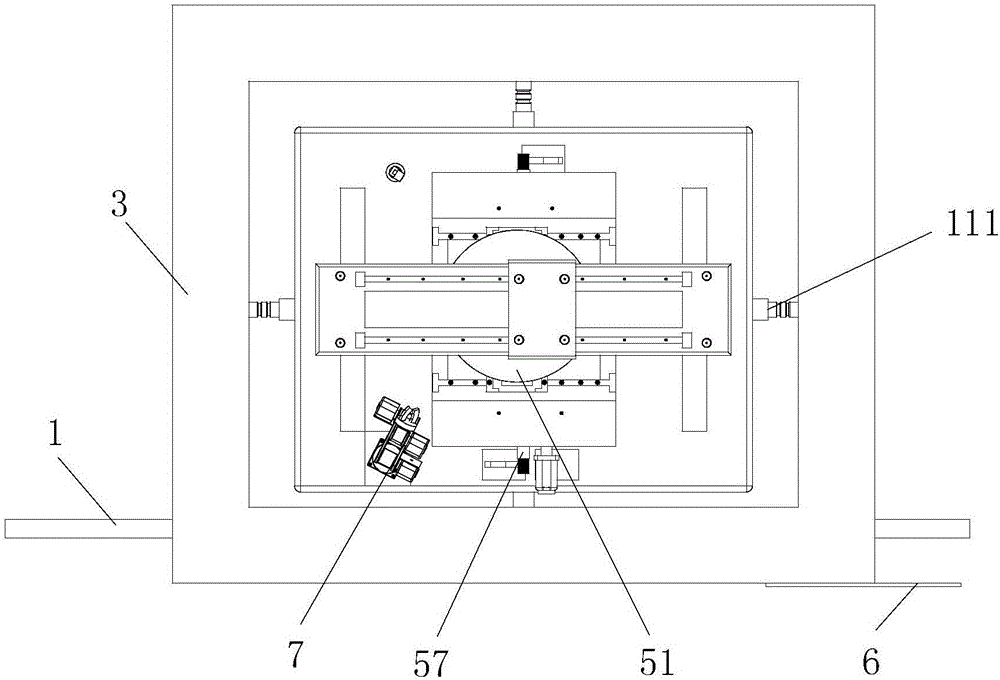

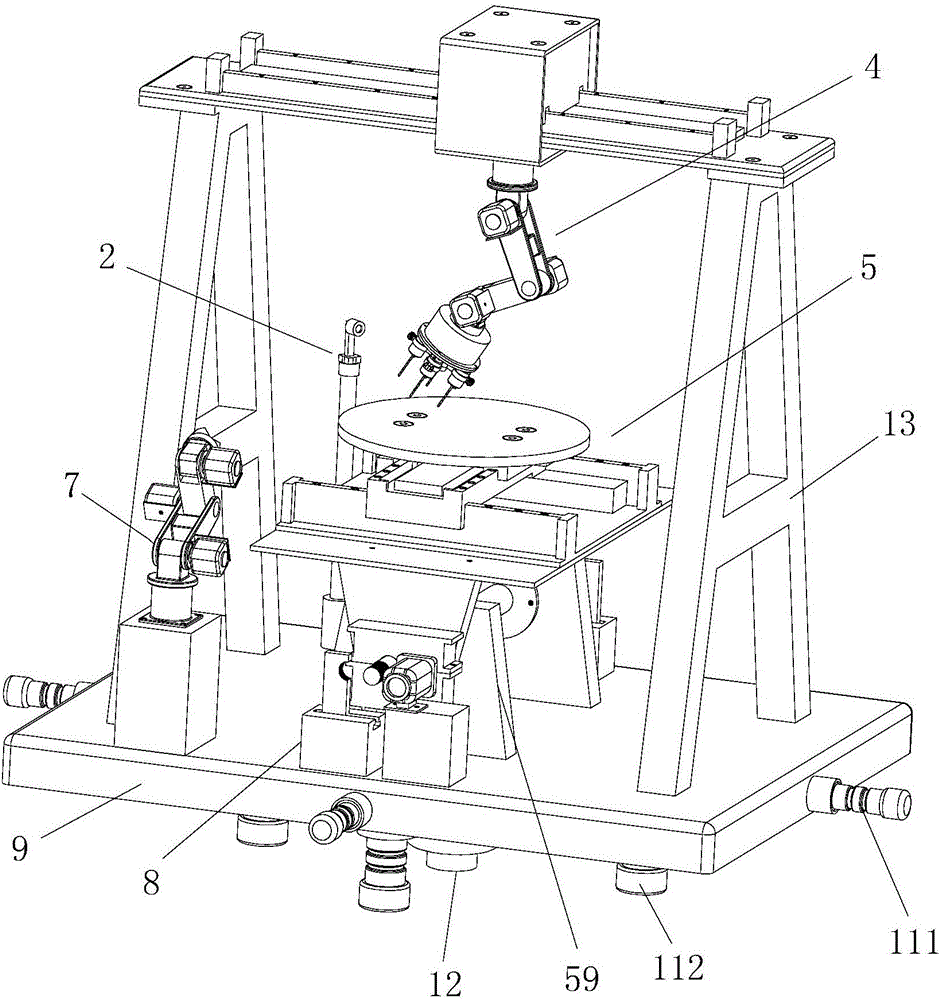

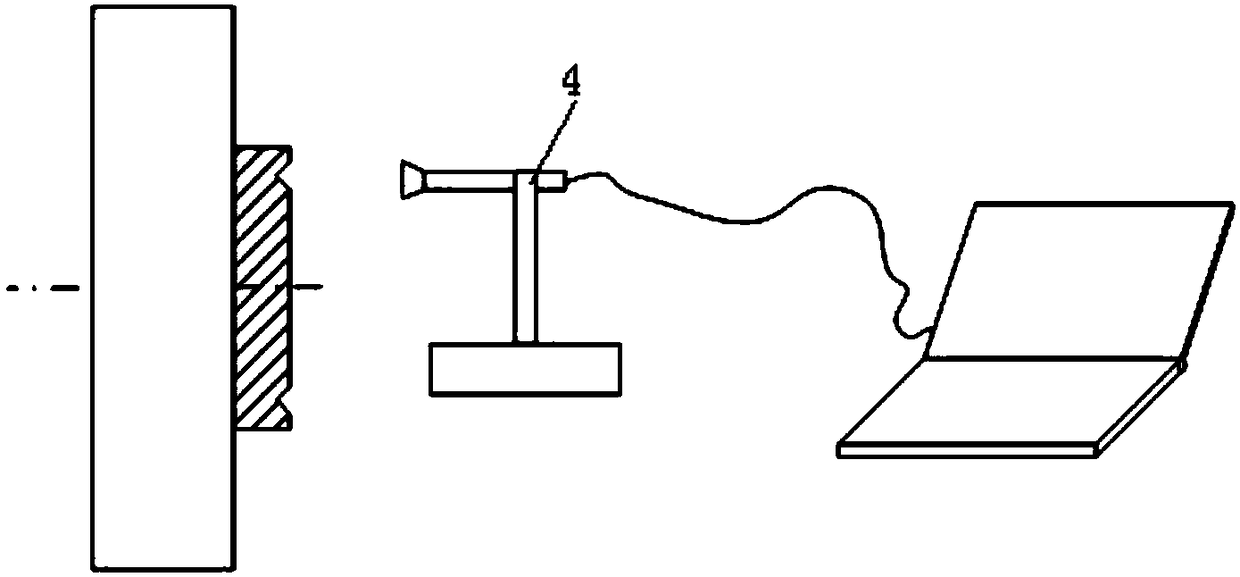

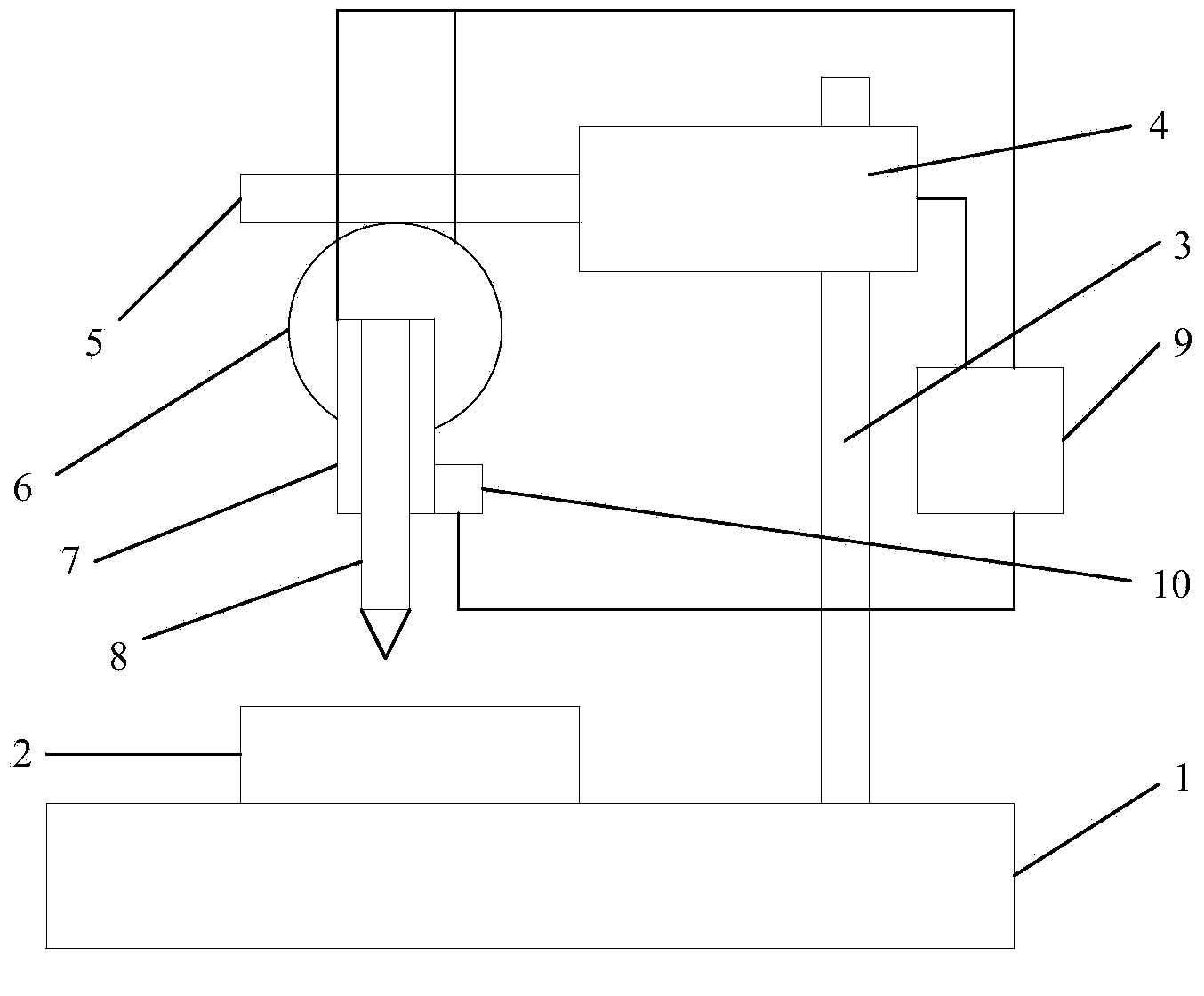

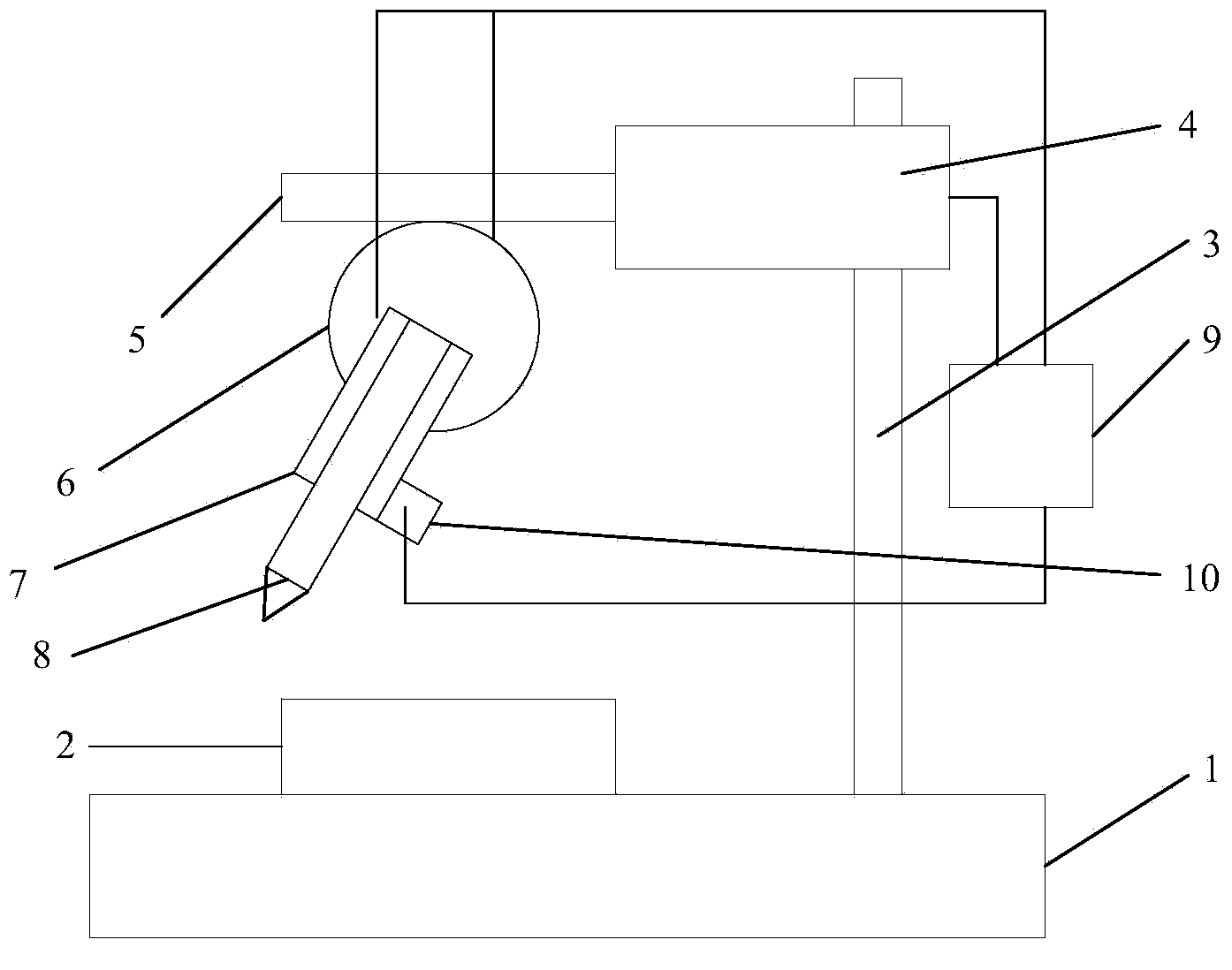

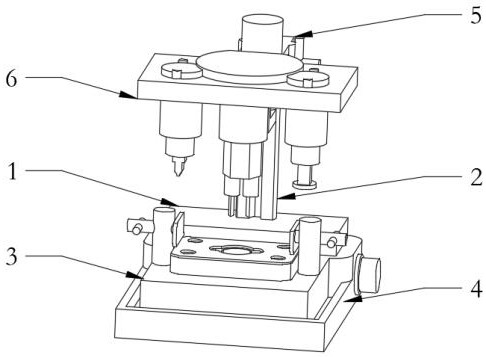

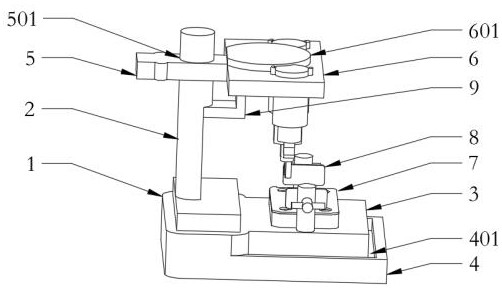

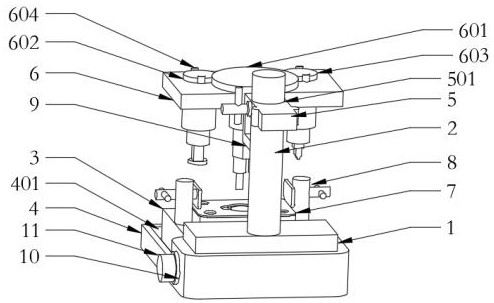

Micronano-sized micro hole machining tool

ActiveCN106807975ARealize precise machiningImprove finished product qualityDrilling/boring measurement devicesMeasurement/indication equipmentsCollection analysisControl system

The invention discloses a micronano-sized micro hole machining tool. The micronano-sized micro hole machining tool comprises a machining tool base, a cutting device, a multi-degree-of-freedom workbench system, a micronano microscope video system and a control system. The multi-degree-of-freedom workbench system is arranged on the machining tool base and comprises a workbench and a workbench driving device. The cutting device is arranged above the workbench. The micronano microscope video system is arranged on the machining tool base and located at one side of the multi-degree-of-freedom workbench system. The micronano microscope video system is used for performing image collection analysis on the machining process of workpieces on the workbench and transmitting collection analysis data to the control system. According to the micronano-sized micro hole machining tool, the micronano microscope video system is used for performing image collection analysis on the machining process of the workpieces on the workbench and transmitting the collection analysis data to the control system in time, the control system gives out control instructions to the cutting device and the multi-degree-of-freedom workbench system according to the collected workpiece machining information, and hence machining precision and finished product quality are improved.

Owner:SHANDONG UNIV OF SCI & TECH

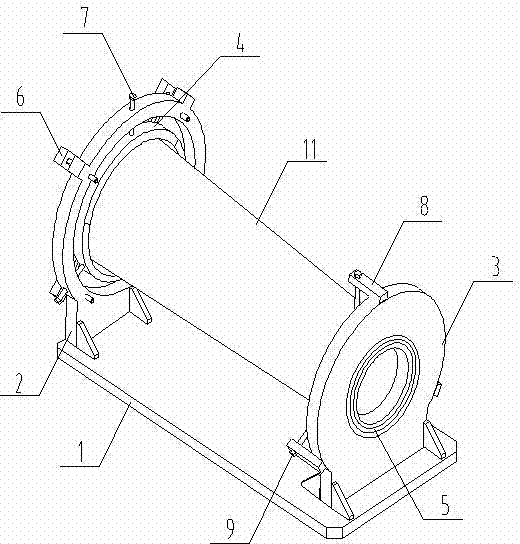

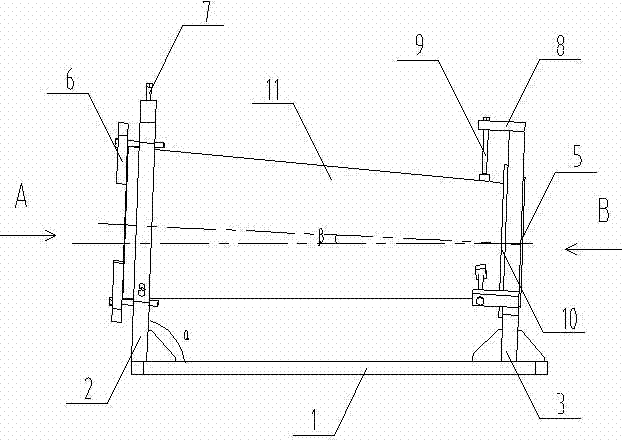

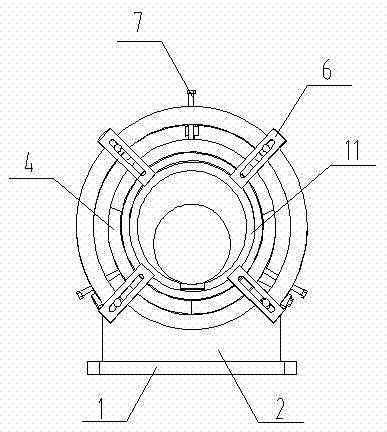

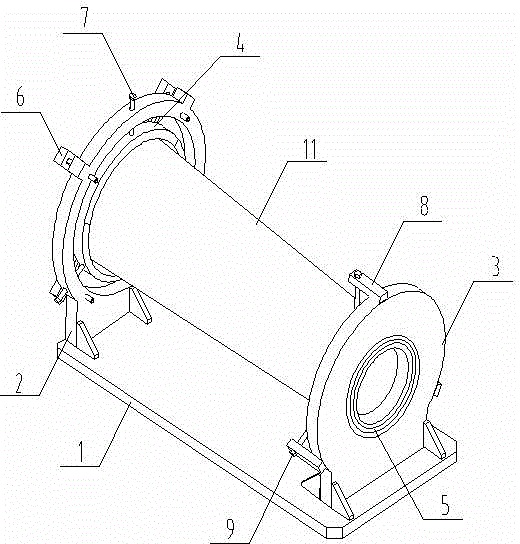

Taper sleeve positioning device used for machining internal key groove of taper sleeve by utilizing planer

ActiveCN103495884AImprove straightnessGuaranteed symmetryPlaning/slotting machinesPositioning apparatusCompression deviceUltimate tensile strength

The invention discloses a taper sleeve positioning device used for machining an internal key groove of a taper sleeve by utilizing a planer. The taper sleeve positioning device used for machining the internal key groove of the taper sleeve by utilizing the planer comprises a horizontally arranged rectangular base plate, wherein a first supporting table and a second supporting table in parallel are fixedly arranged on the base plate in the length direction of the base plate, the two supporting tables are both of a tabular structure, the upper portions of the two supporting tables are both of an annular structure, a first cushion block and a second cushion block are arranged inside the annular structure of the first supporting table and the annular structure of the second supporting table respectively, at least three compression devices are respectively arranged at the side, deviating from the second supporting table, of the first supporting table, three first adjusting bolts are arranged on the periphery of the annular structure of the first supporting table, three connecting plates are arranged on the periphery of the annular structure of the second supporting table, and a check plate is arranged at the periphery of the second cushion block and can prevent the second cushion block from penetrating through the annular structure of the second supporting table. By means of the taper sleeve positioning device used for machining the internal key groove of the taper sleeve by utilizing the planer, the key groove of the taper sleeve can be accurately machined through the planer, particularly the taper sleeve with the small-size taper hole can be directly machined, and therefore production efficiency is improved, and labor intensity is relieved.

Owner:CHONGQING HUAYU HEAVY IND ELECTROMECHANICAL CO LTD

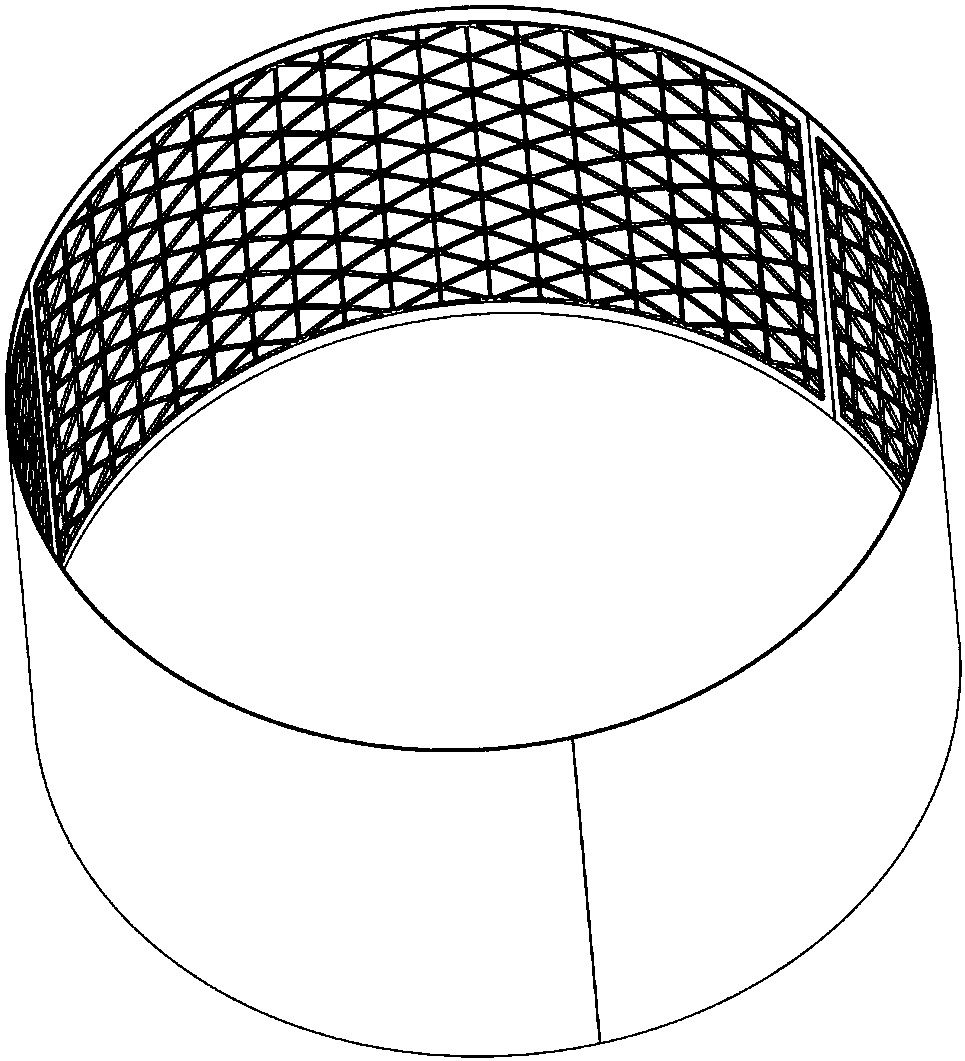

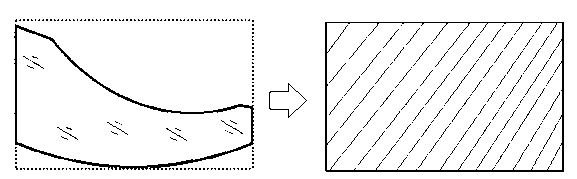

Low-deformation machining method of large aluminum alloy thin-wall mesh barrel section

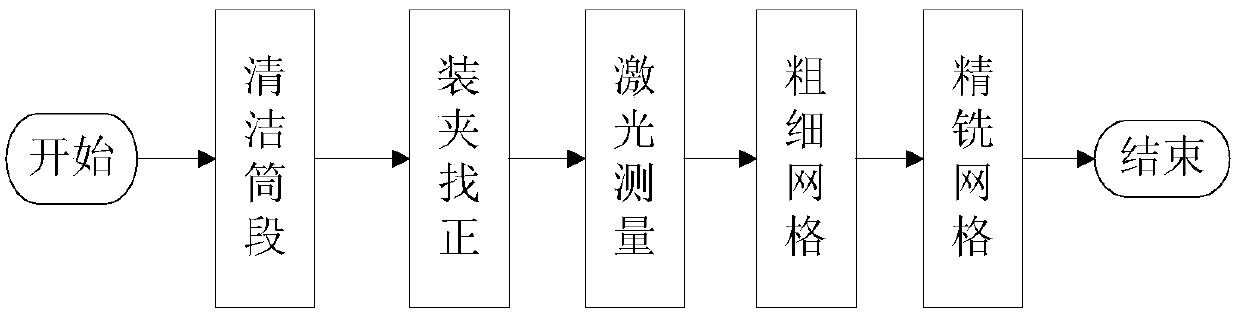

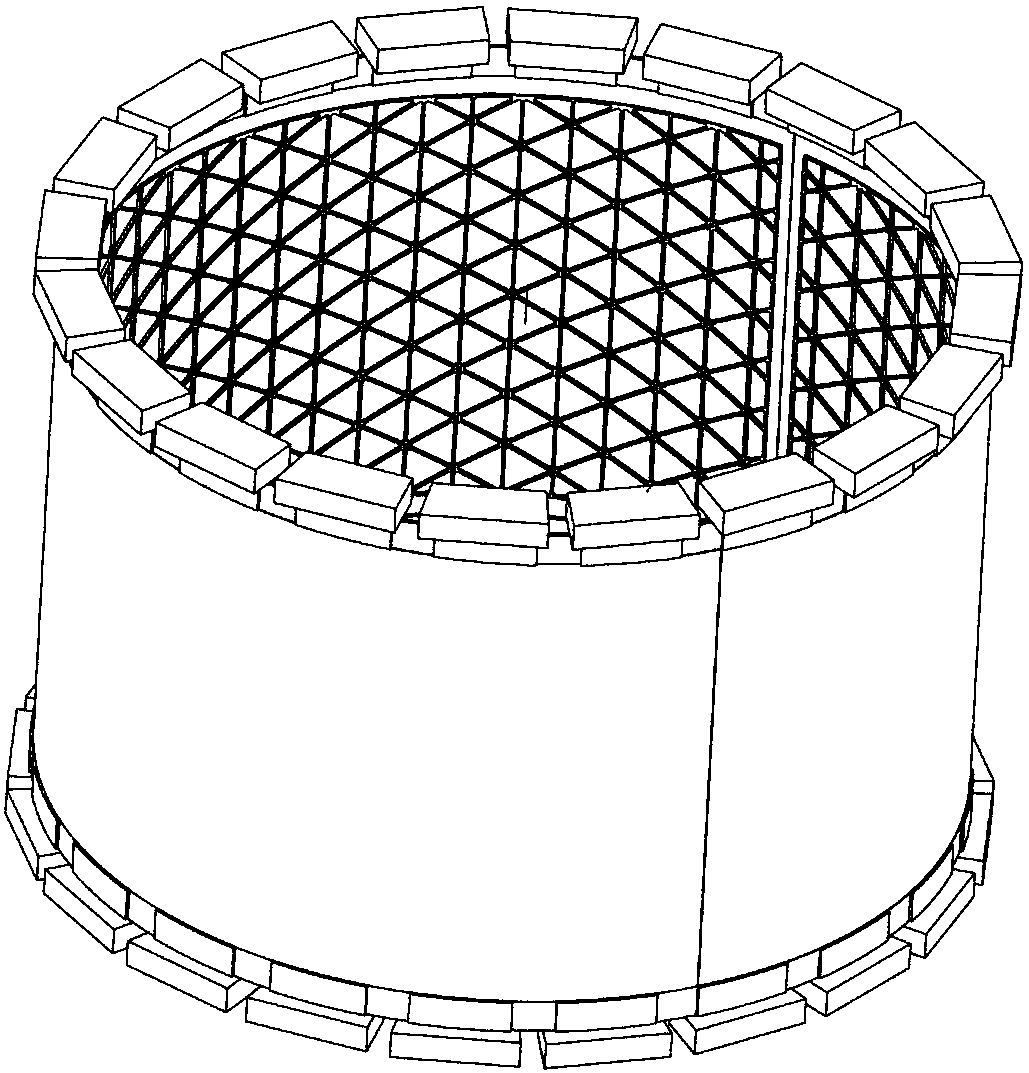

ActiveCN107617771AReduce distortionImprove product qualityMilling equipment detailsMachining deformationMachining process

The invention belongs to the machine manufacturing and machining technology, and particularly discloses a low-deformation machining method of a large aluminum alloy thin-wall mesh barrel section. Themethod comprises the steps of barrel section cleaning, clamping alignment, deformation laser measurement, rough-milling mesh sinking and finish-milling mesh sinking. The low-deformation machining method of the large aluminum alloy thin-wall mesh barrel section is achieved, deformation in the machining process is reduced, and the product quality is improved. A machining path of achieving machiningfrom the middle of the barrel section to the upper end and the lower end is adopted, on one hand, part machining stress can be reduced, on the other hand, part internal stress can be redistributed more averagely, and machining deformation can be effectively reduced. Compensation methods are adopted for achieving precise machining of the large aluminum alloy thin-wall mesh barrel section, part theoretical appearance deviation is eliminated through the laser compensation method, and part mesh thickness precise machining is achieved through the ultrasonic thickness compensation method.

Owner:CAPITAL AEROSPACE MACHINERY +1

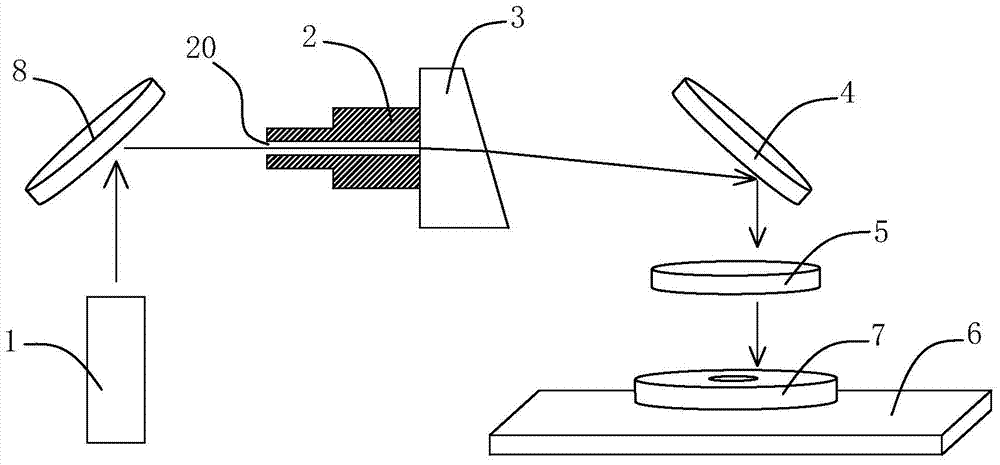

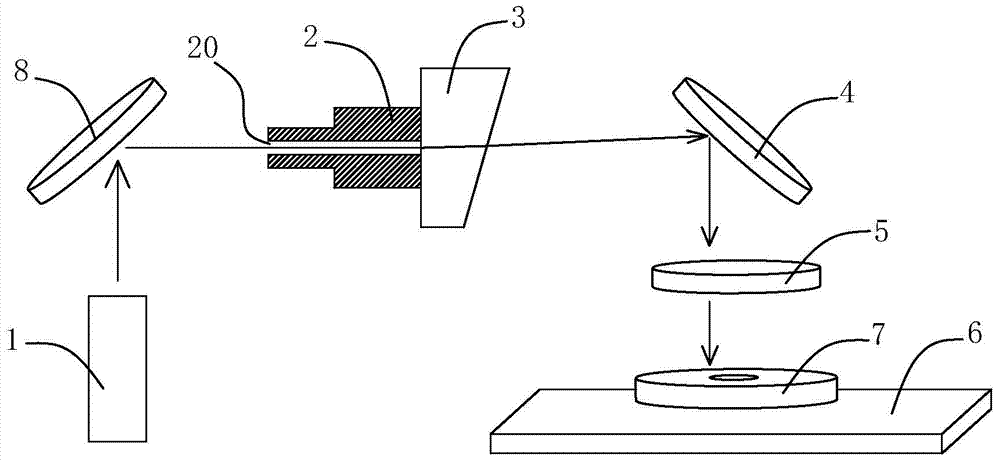

Laser drilling device used for machining hard and brittle substrate

InactiveCN103785955ASmall single pulse energyPhoton energy is highLaser beam welding apparatusLight guideQ-switching laser device

The invention discloses a laser drilling device used for machining a hard and brittle substrate. According to the device, a laser head is a Q-switch laser device, a wedge prism is fixedly connected with a driving device, the light-emitting surface of the wedge prism is an oblique surface, a light guiding hole is formed in the driving device, the driving device rotates around the axis of the light guide hole, and laser pulses emitted by the laser head are transmitted to the wedge prism through the light guiding hole, pass through a first reflector and a focus lens in sequence after being refracted through the wedge prism, and then are transmitted to the hard and brittle substrate. According to the laser drilling device, the Q-switch laser device serves as a laser source, and breakage of the hard and brittle substrate caused by overhigh thermal stress is avoided; meanwhile, due to the fact that the hard and brittle substrate does not need to be coated with PVA, machining processes are simplified, and machining efficiency is improved; furthermore, the driving device provided with the light guiding hole drives the wedge prism to rotate to enable the rotation of the wedge prism to be more stable, deviation of a laser drilling track is avoided, and accurate machining is achieved.

Owner:INNO LASER TECH CORP LTD +1

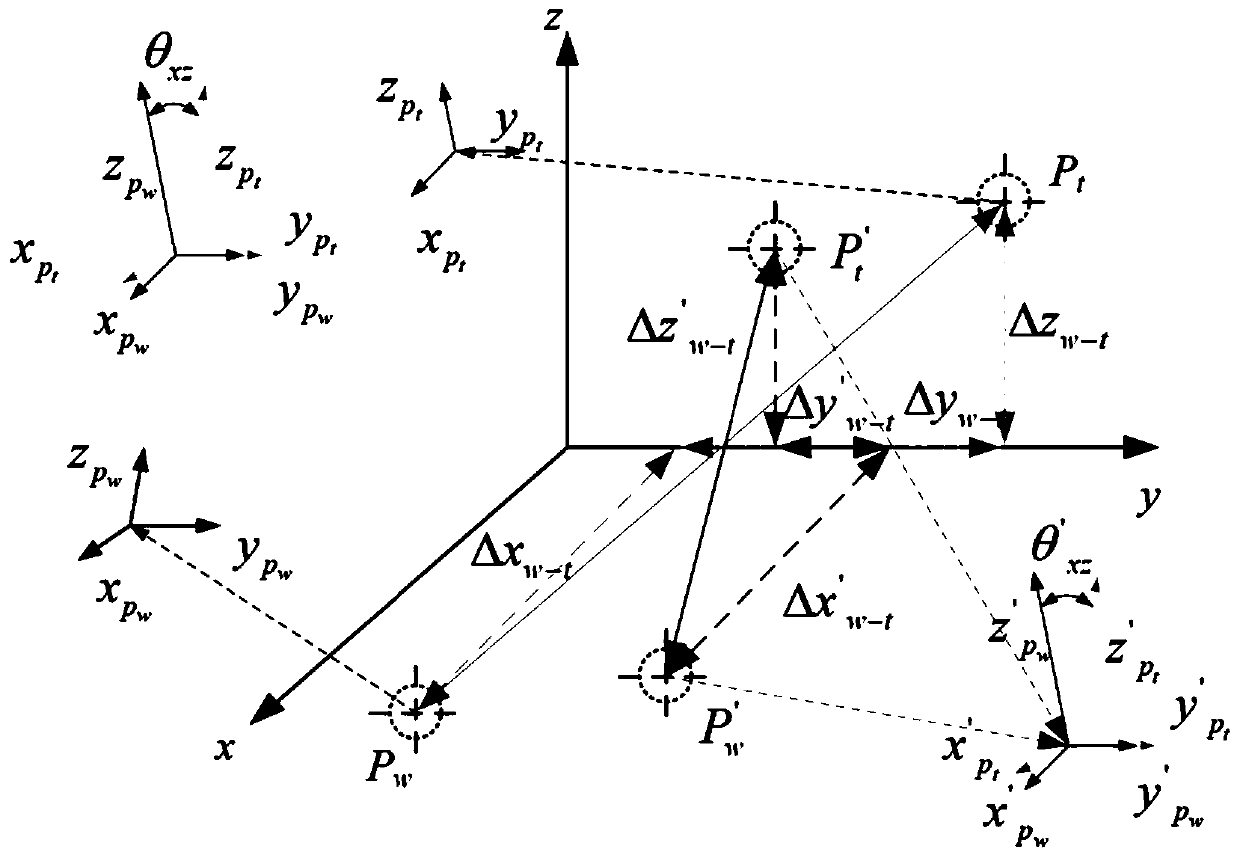

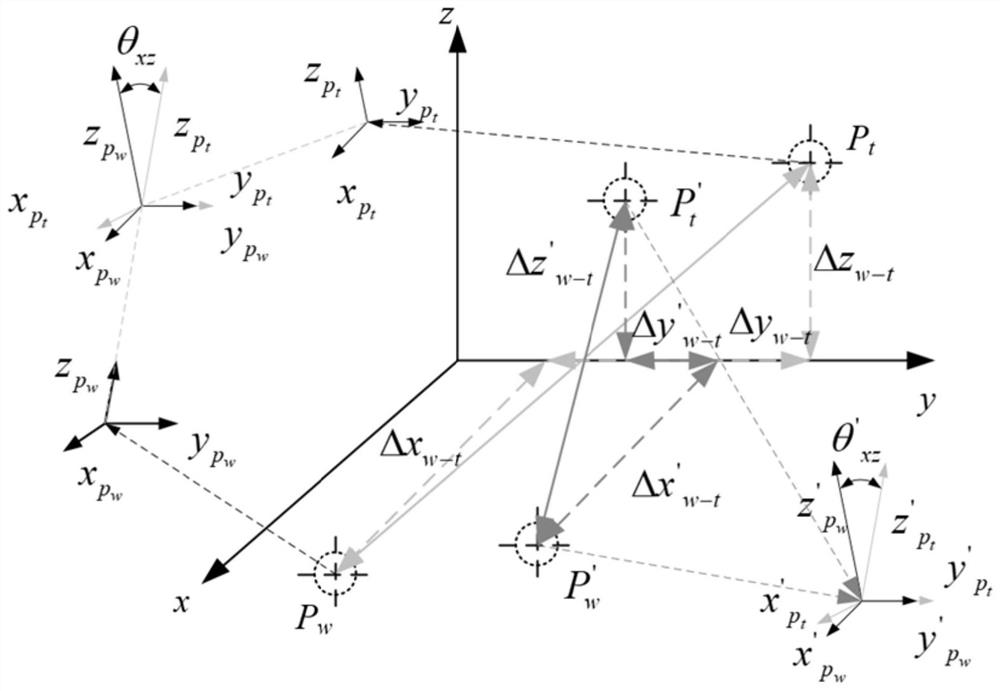

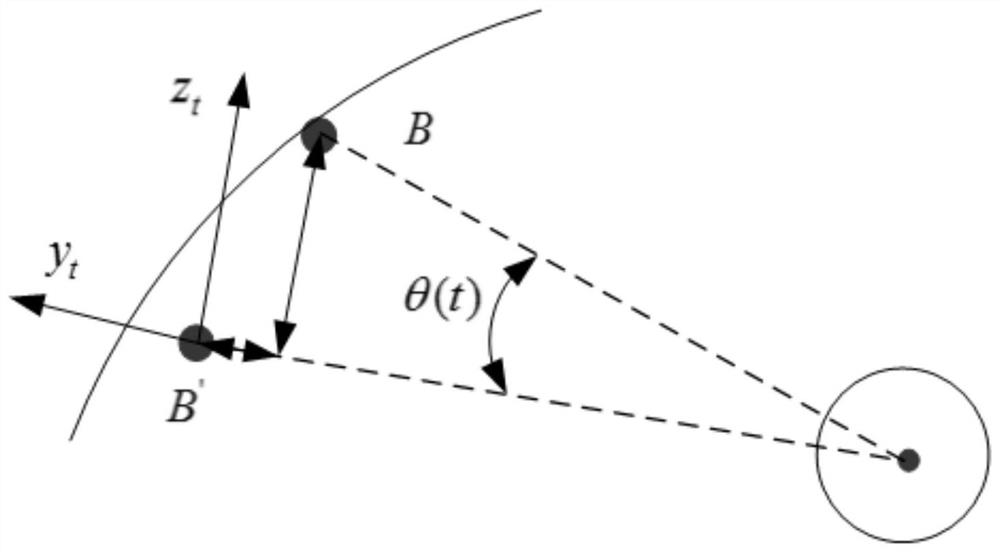

Milling tooth machining parameter and path compensation method

ActiveCN110125489ARealize precise machiningHigh precisionGear-cutting machinesGear teethCutting forceInstallation Error

The invention discloses a milling tooth machining parameter and path compensation method. The method comprises the following steps that S1, the installation error of the relative position of a tool and a workpiece is obtained, and the relative position between the tool and the workpiece after being installed is obtained by measuring the position of the tool and the workpiece, the installation error of the machine tool is obtained through subtracting the set relative position between the tool and the workpiece from the measured relative position; S2, the error of tool is obtained under action of cutting force and torque under action of cutting force by calculating; and S3, compensation is carried out on the machining parameters and the machining path, the set machining parameters are compensated through the error obtained in the step S1, and the compensated machining parameters are obtained; and the set machining path is compensated through the errors obtained in the step S1 and the step S2 so as to obtain the compensated machining path. According to the method, the machining errors are compensated, so that accurate machining of the gear is realized, and the precision of the workpiece is improved.

Owner:CENT SOUTH UNIV

Tool-changing machining method based on CCD camera in-situ measurement

ActiveCN108526492AAvoid errorsAvoid wear and tearAutomatic control devicesMeasurement/indication equipmentsCcd cameraComputer science

The invention discloses a tool-changing machining method based on CCD camera in-situ measurement. The method comprises the steps that the width of a circular ring is obtained through CCD camera measurement; and the reference position of a machined plane of a workpiece is modified according to the width of the circular ring; subsequent machining is conducted with the reference position as the reference; and after a tool is worn to a certain degree, a sequential process including primary feeding, calculation and secondary feeding is implemented for a newly-mounted tool. By means of the method, precise machining of a microstructural array with the machining depth being D is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

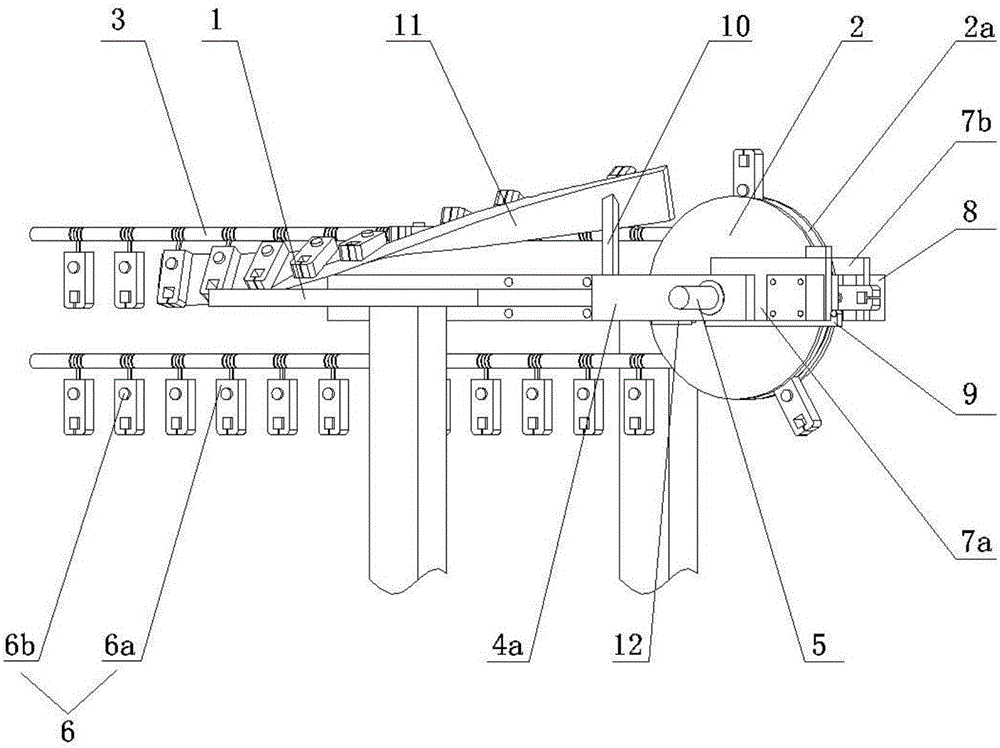

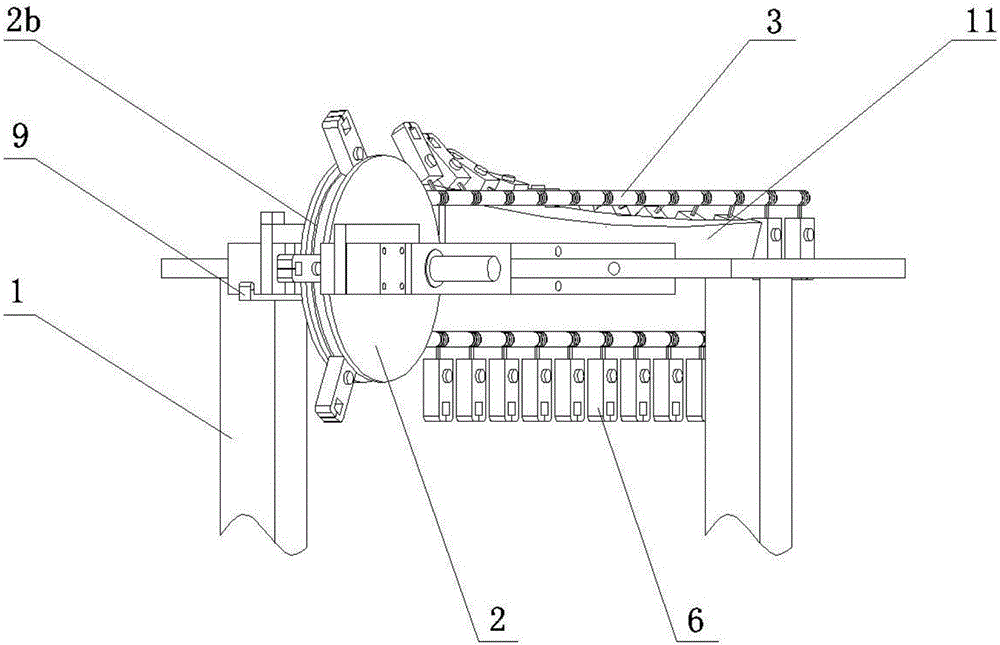

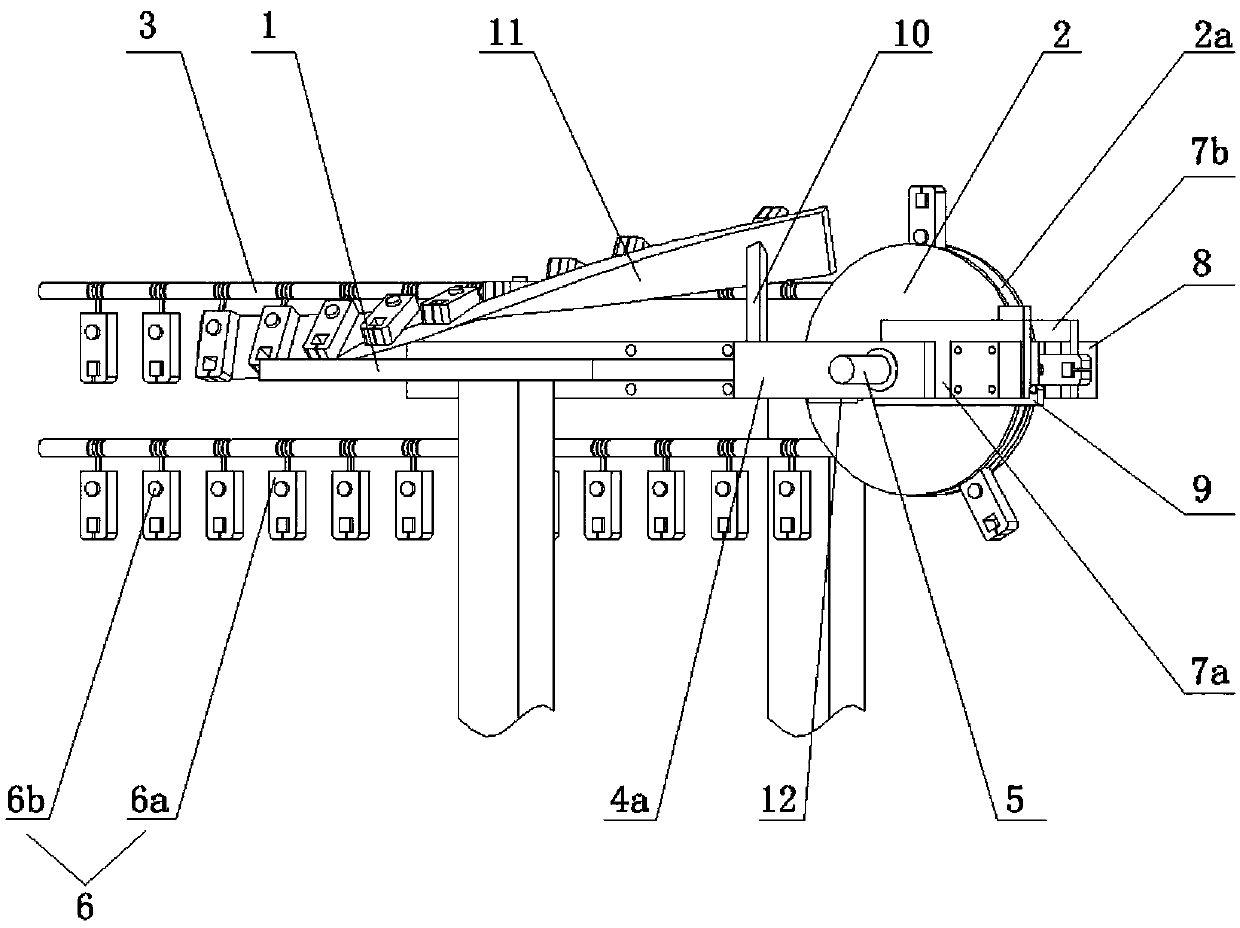

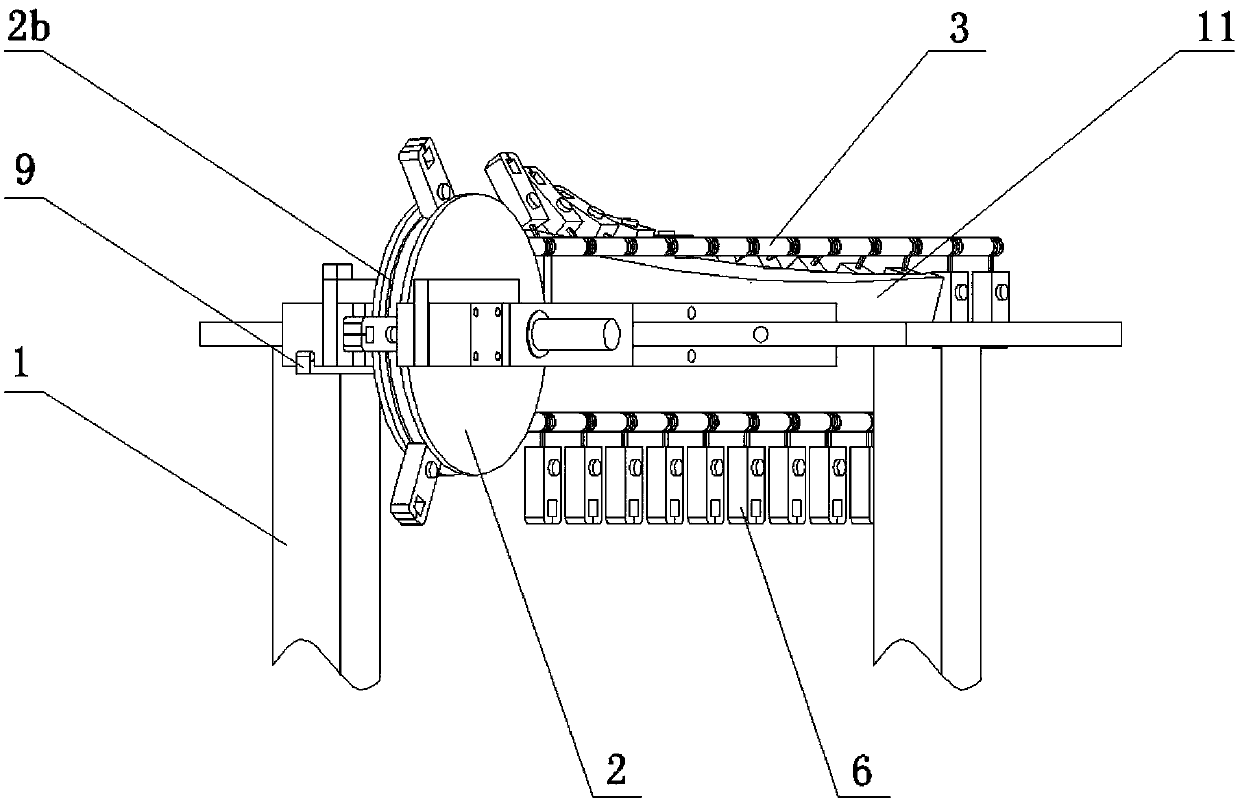

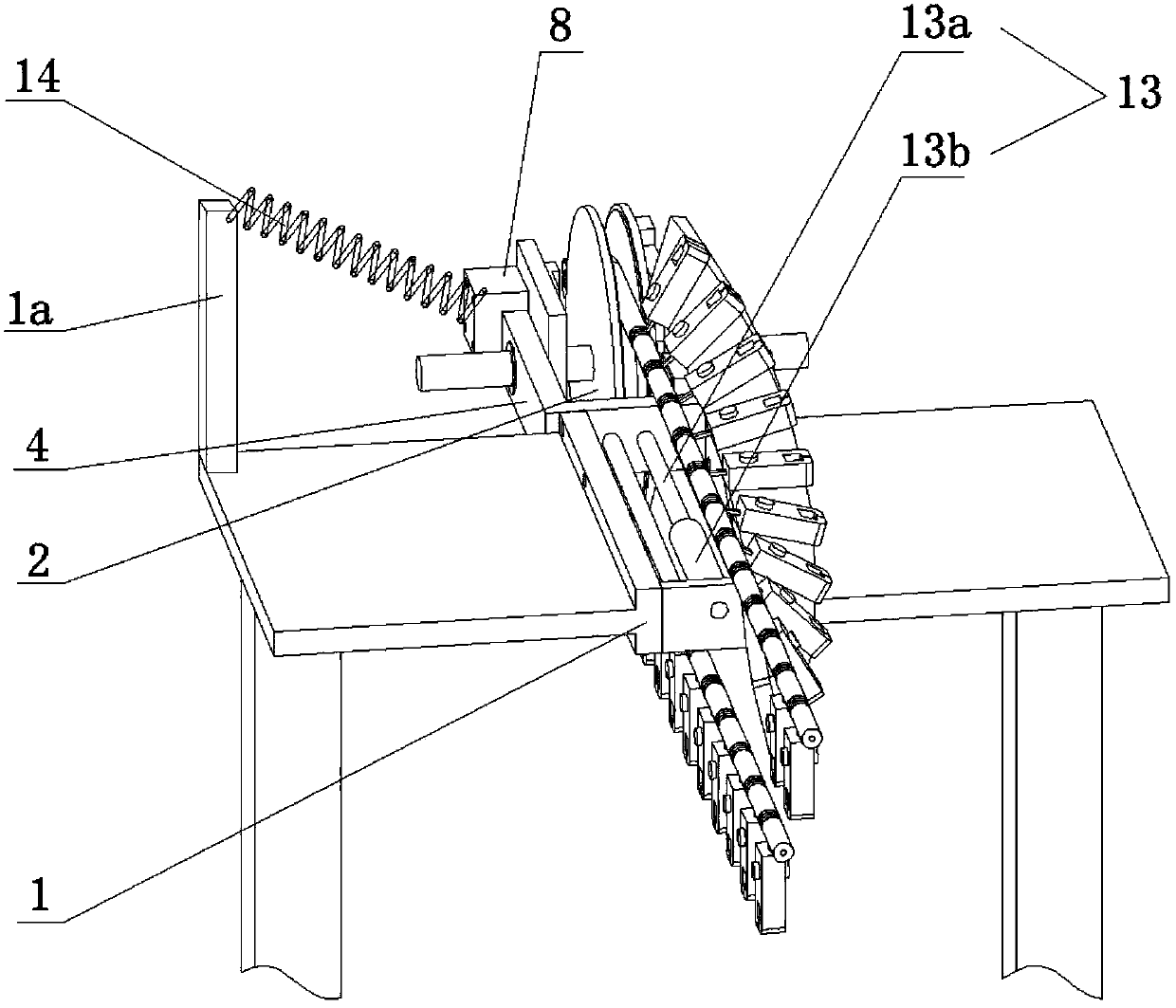

Clamping mechanism applicable to oil edge materials and method for clamping oil edge materials

ActiveCN105880116AMobile stabilityPositioning and opening precisionLiquid surface applicatorsLeather/skins/hides/pelt chemical treatment apparatusRotating disc

The invention belongs to the technical field of automatic edge oiling machines, and particular relates to a clamping mechanism applicable to oil edge materials. The clamping mechanism comprises a rack, a rotating disc and a string clamp rope, clamps are arranged on the string clamp rope at intervals, the rack comprises a rotating disc support frame, a clamp guide plate, a clamp detection device and a clamp opening device, a rotating disc shaft is arranged on the rotating disc support frame, the rotating disc is connected to the rotating disc support frame through the rotating disc shaft, an annular groove is formed in the periphery of the rotating disc, the string clamp rope is arranged in the annular groove in a sleeved mode, and a power source which drives the string clamp rope to rotate around the rotating disc is connected to the string clamp rope; each clamp comprises a clamp body and a button, the width of the bottom end of each clamp body is smaller than that of the annular groove, and the width of the annular groove is smaller than that of each button. The clamping mechanism applicable to the oil edge materials is simple in structure, convenient and safe to operate and high in work efficiency and can position the clamps accurately and achieve precise processing of small materials.

Owner:潘声君

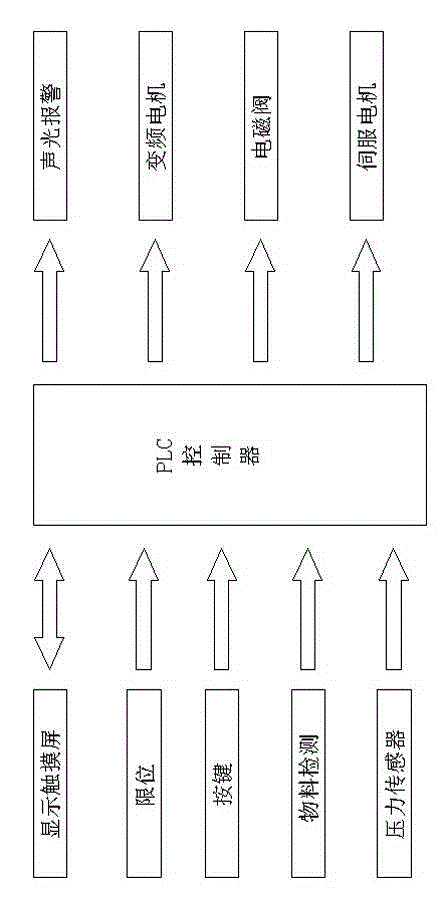

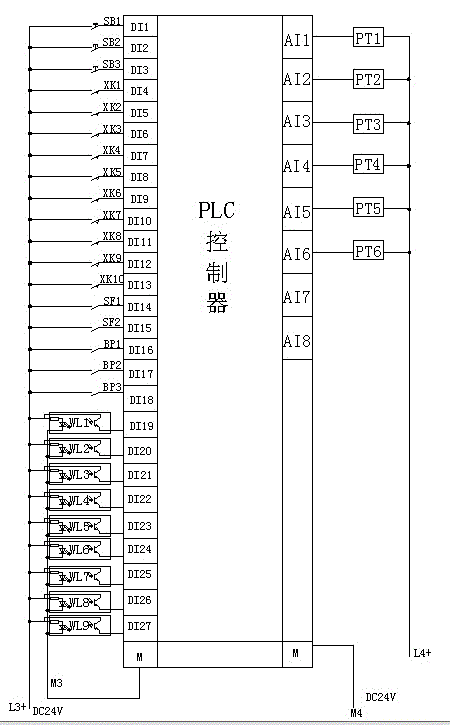

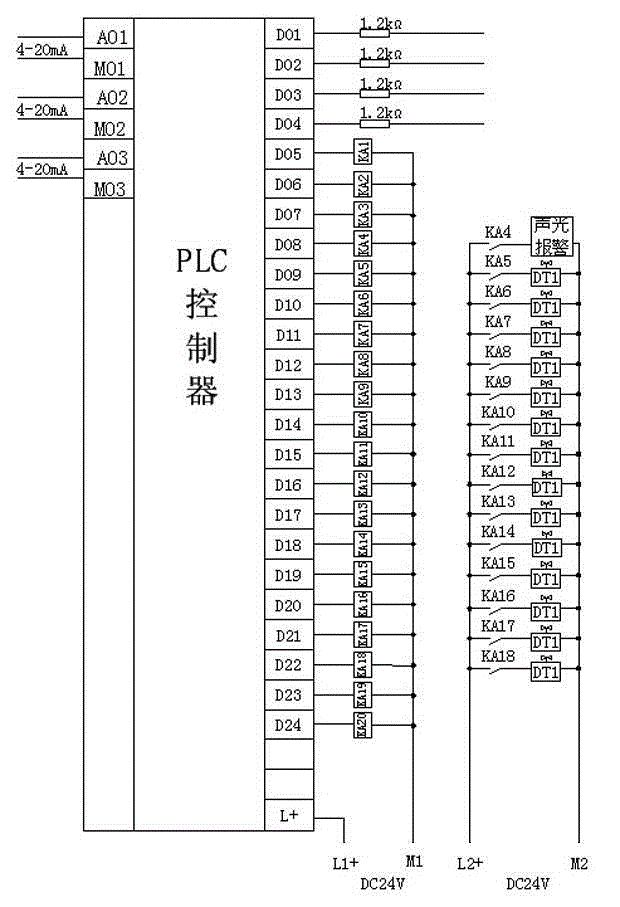

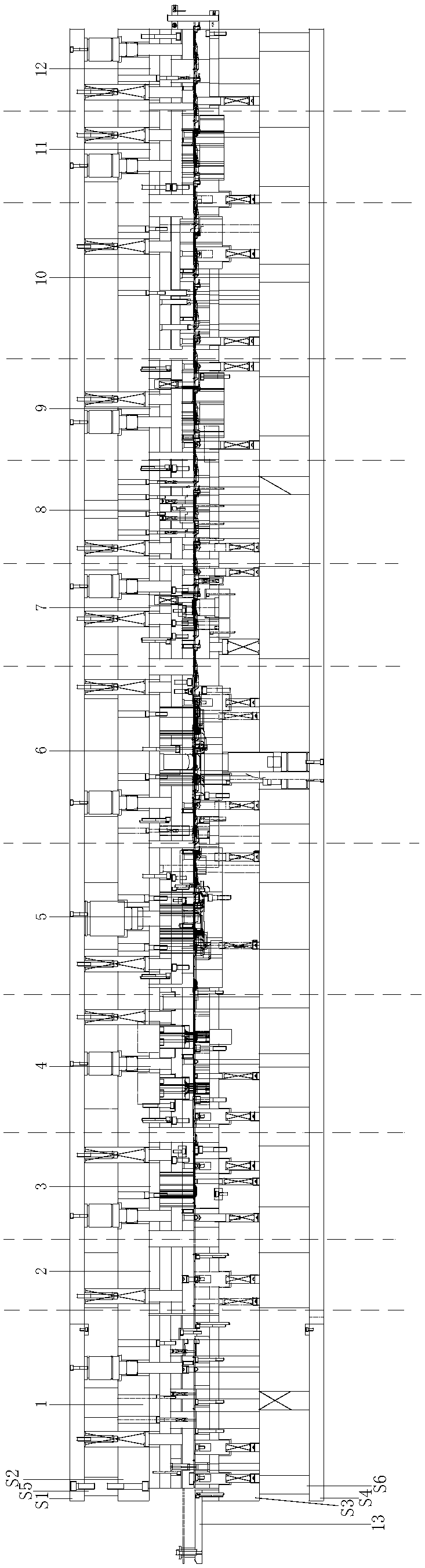

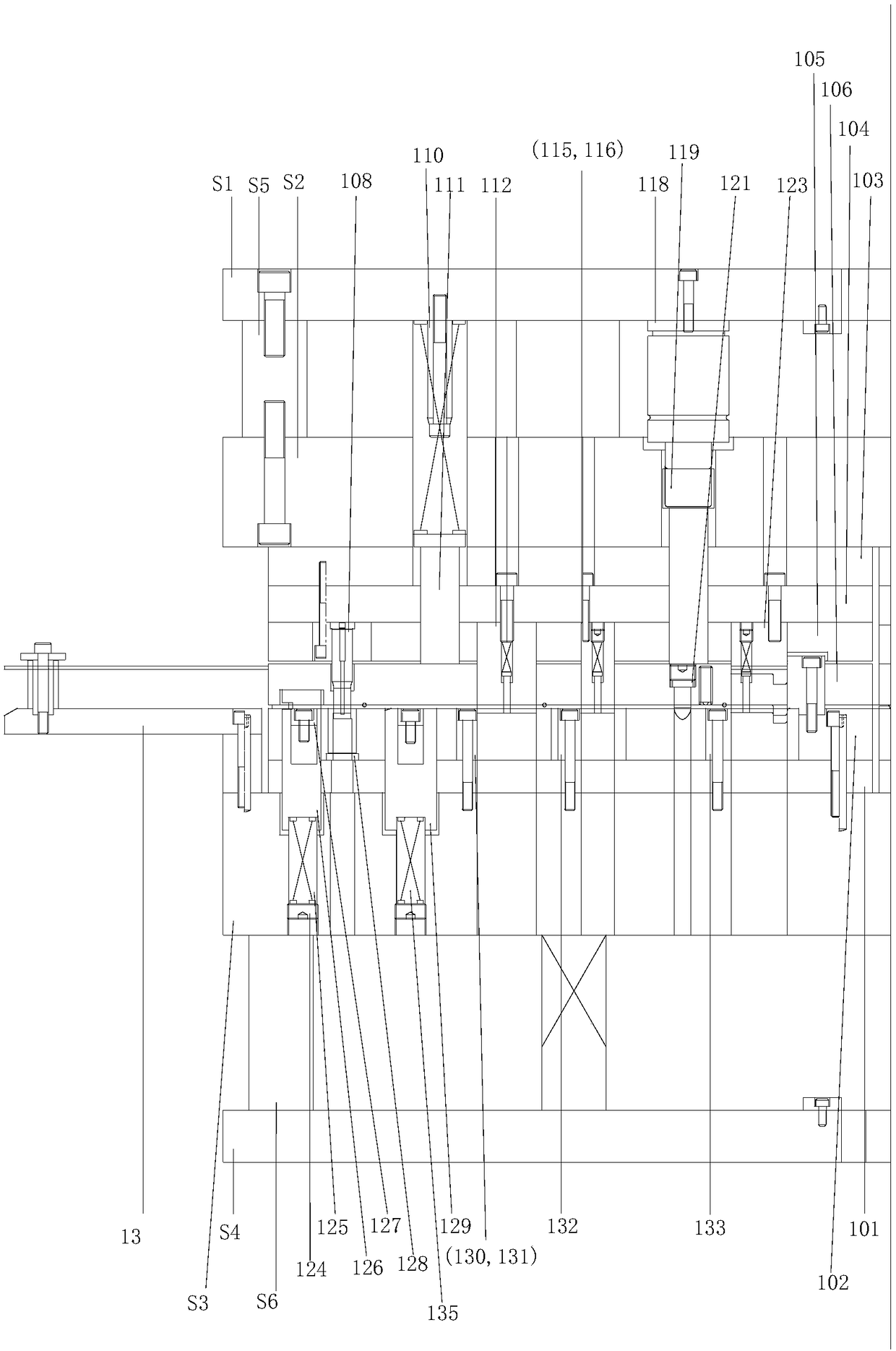

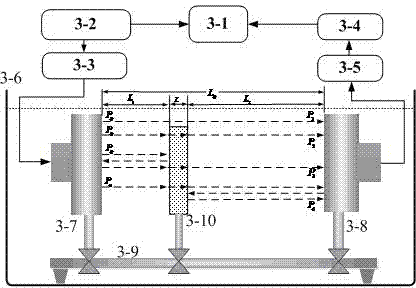

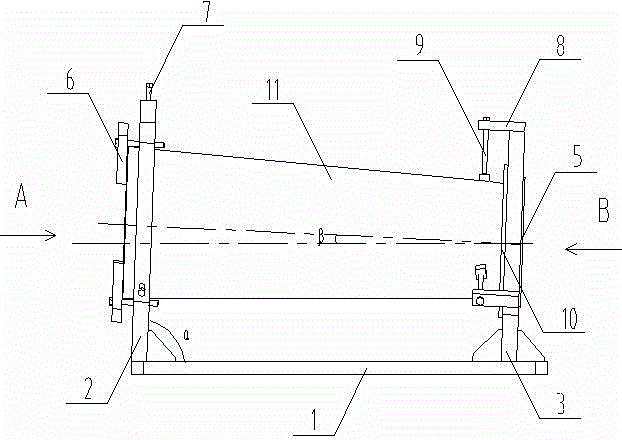

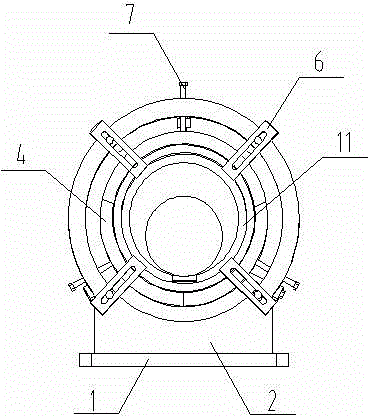

Automatic control system applicable to pipeline prefabricating production line

InactiveCN102880108ARealize precise machiningSave man hoursProgramme control in sequence/logic controllersAutomatic controlMessage Passing Interface

The invention provides an automatic control system applicable to a pipeline prefabricating production line. The automatic control system mainly comprises a PLC (Programmable Logic Controller) controller and a display touch screen which are connected in an MPI (Message Passing Interface) communication mode; the digital input of the PLC controllers includes a key-pressing signal input interface, a limiting signal input interface and a material detecting signal input interface; the analog input of the PLC controllers includes a sensor signal input interface; the digital output of the PLC controllers includes servo motor control, variable frequency motor starting / stopping control, solenoid valve control and acousto-optic alarm; and the analog output of the PLC controllers includes given transducer speed. With the adoption of the automatic control system provided by the invention, a pipeline can be precisely processed, the time for work in the pipeline blanking stage can be reduced, the labor and the material are saved, the labor intensity of workers is reduced, the working efficiency is improved, the automatic production level is improved, rich content is provided for man-machine communication, once the production line has a fult, a matured and reliable pre-processing scheme is provided so that the influence caused by the fault can be reduced to the minimum.

Owner:CHINA 22MCC GROUP CORP

Drilling equipment capable of automatically adjusting drilling angle

InactiveCN103506653ARealize precise machiningAutomatic control devicesFeeding apparatusNumerical controlPetroleum engineering

The invention discloses drilling equipment capable of automatically adjusting the drilling angle. A drill bit is installed on an angle adjusting motor which can be rotated in a multi-angle mode. The required drilling angle is determined by a numerical control unit according to the angle of the surface of a material to be machined, the numerical control unit controls the angle adjusting motor to adjust the drill bit to the corresponding angle and controls the drill bit to drill, and then objects with the irregular surfaces can be accurately machined.

Owner:ANHUI QIFENG MACHINERY & EQUIP

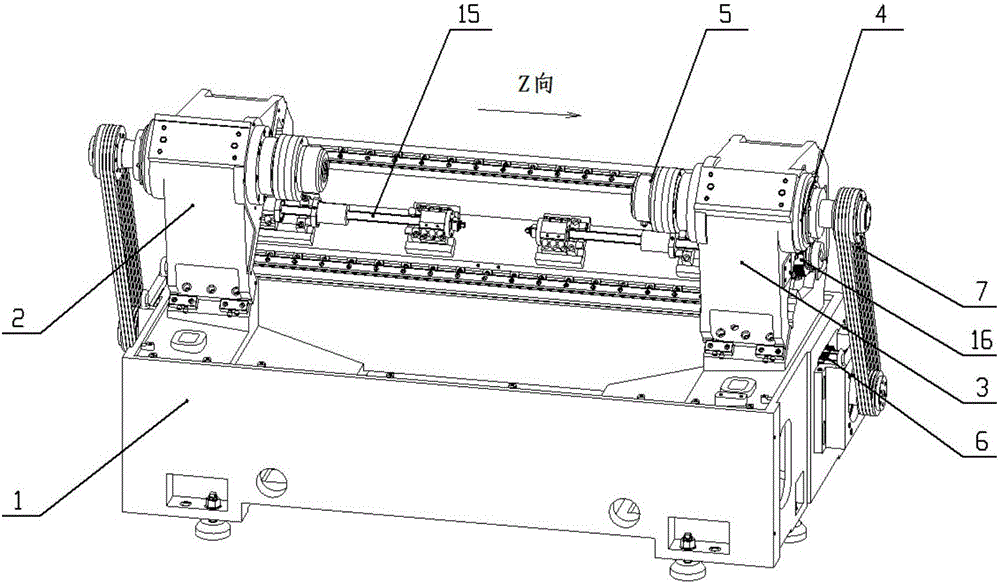

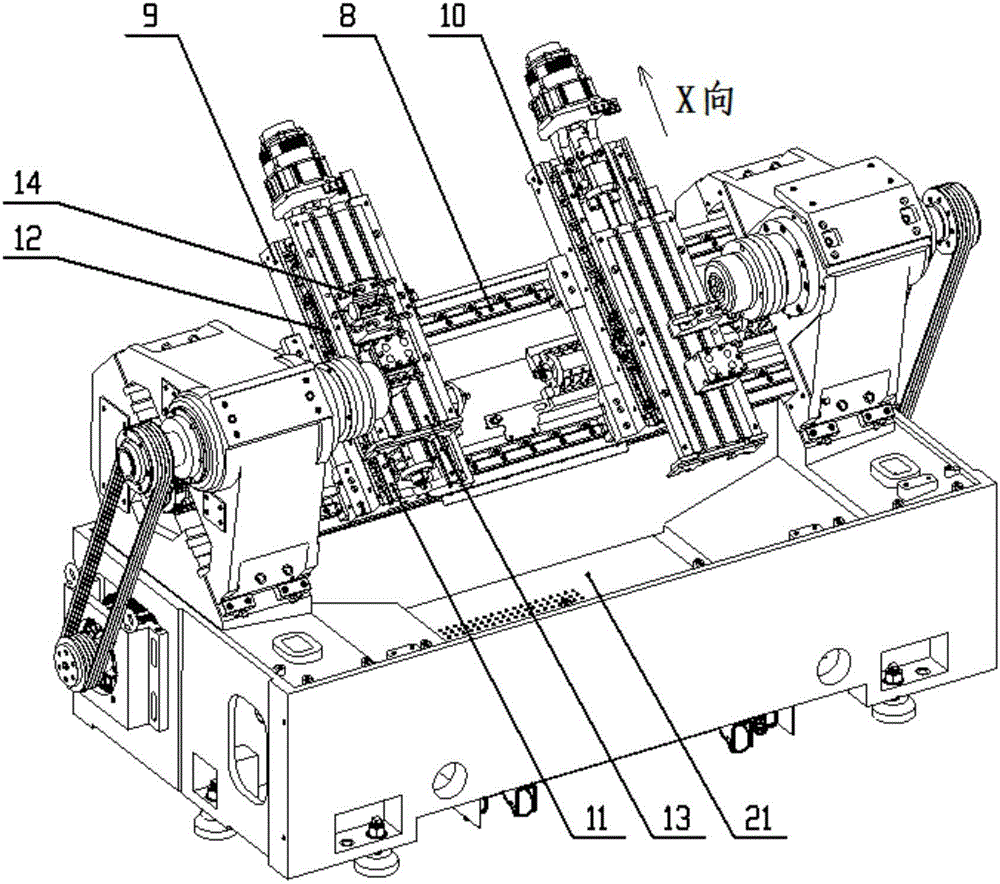

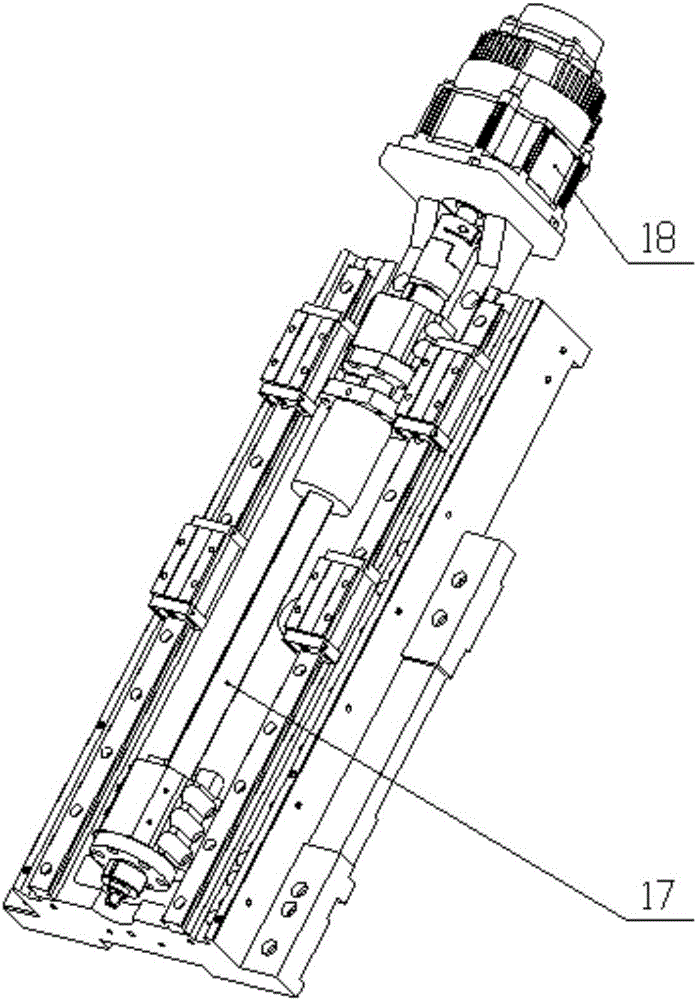

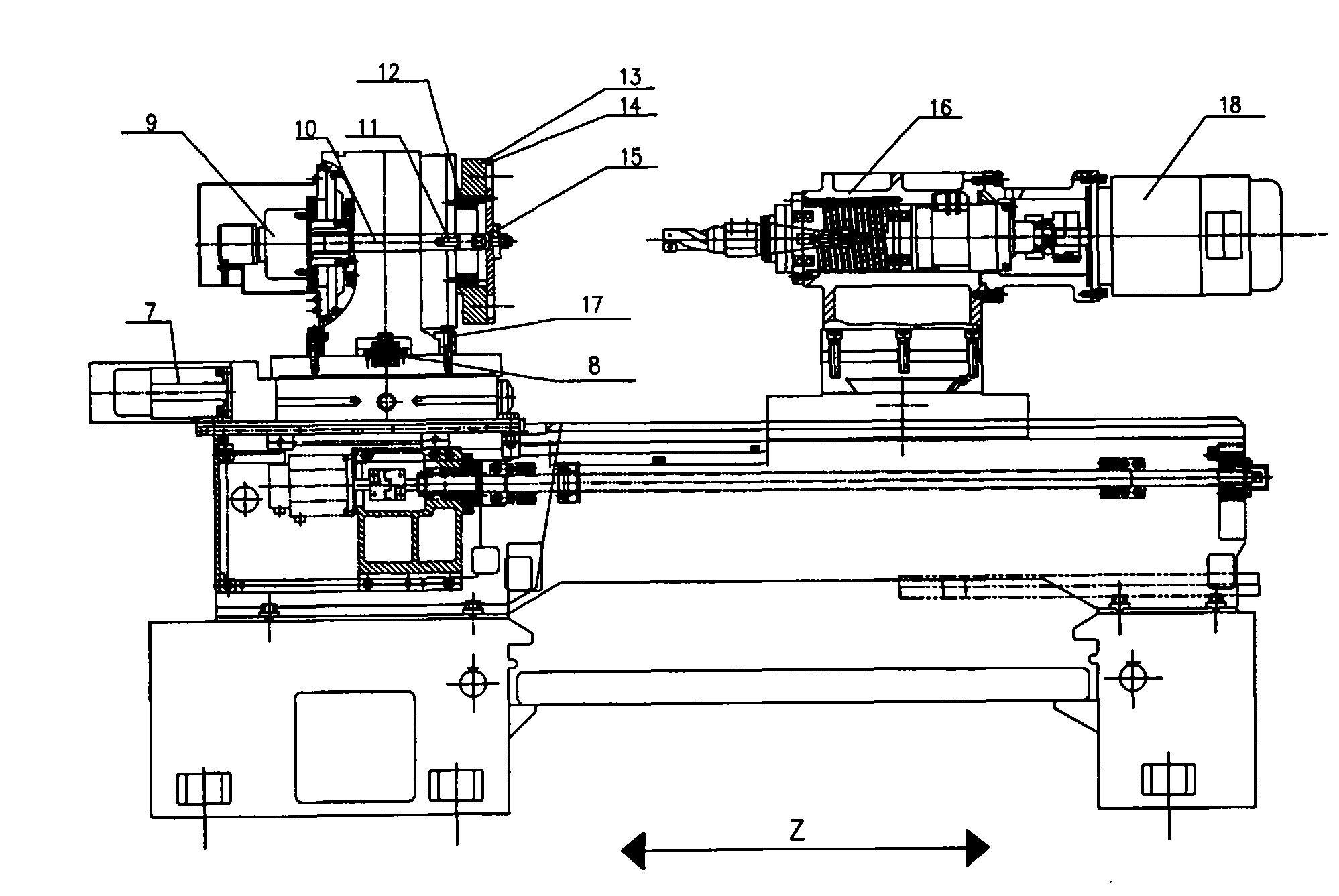

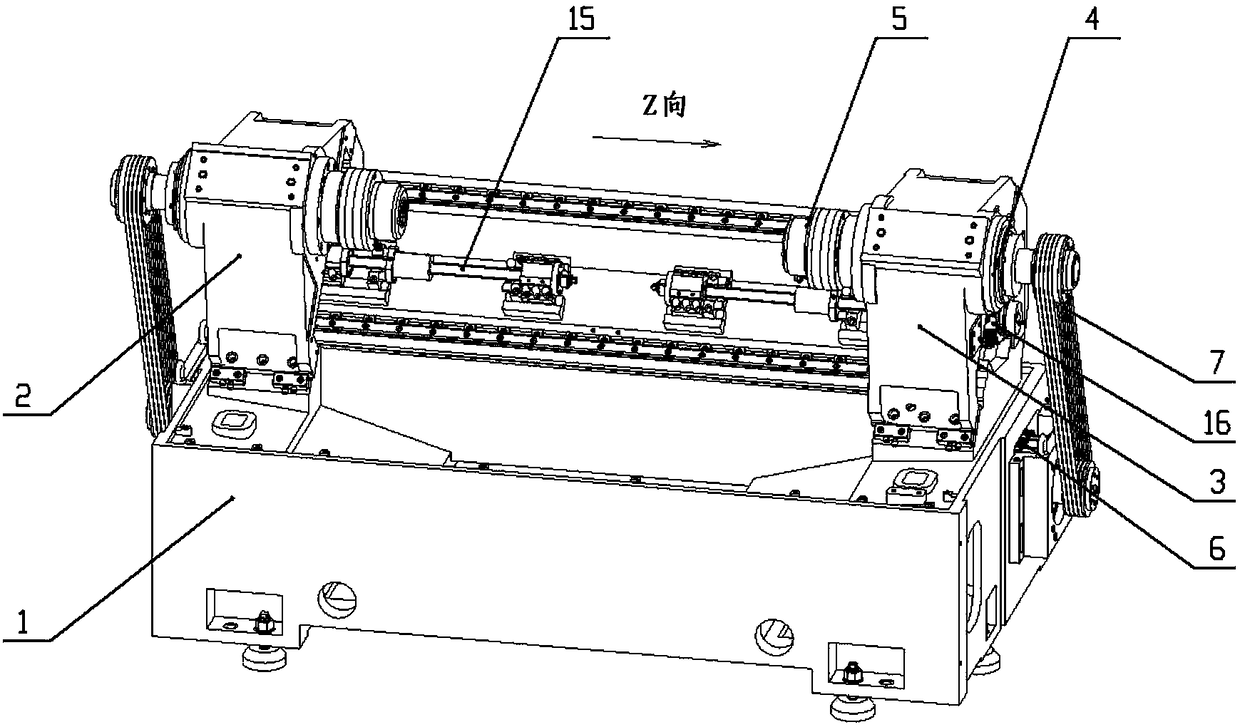

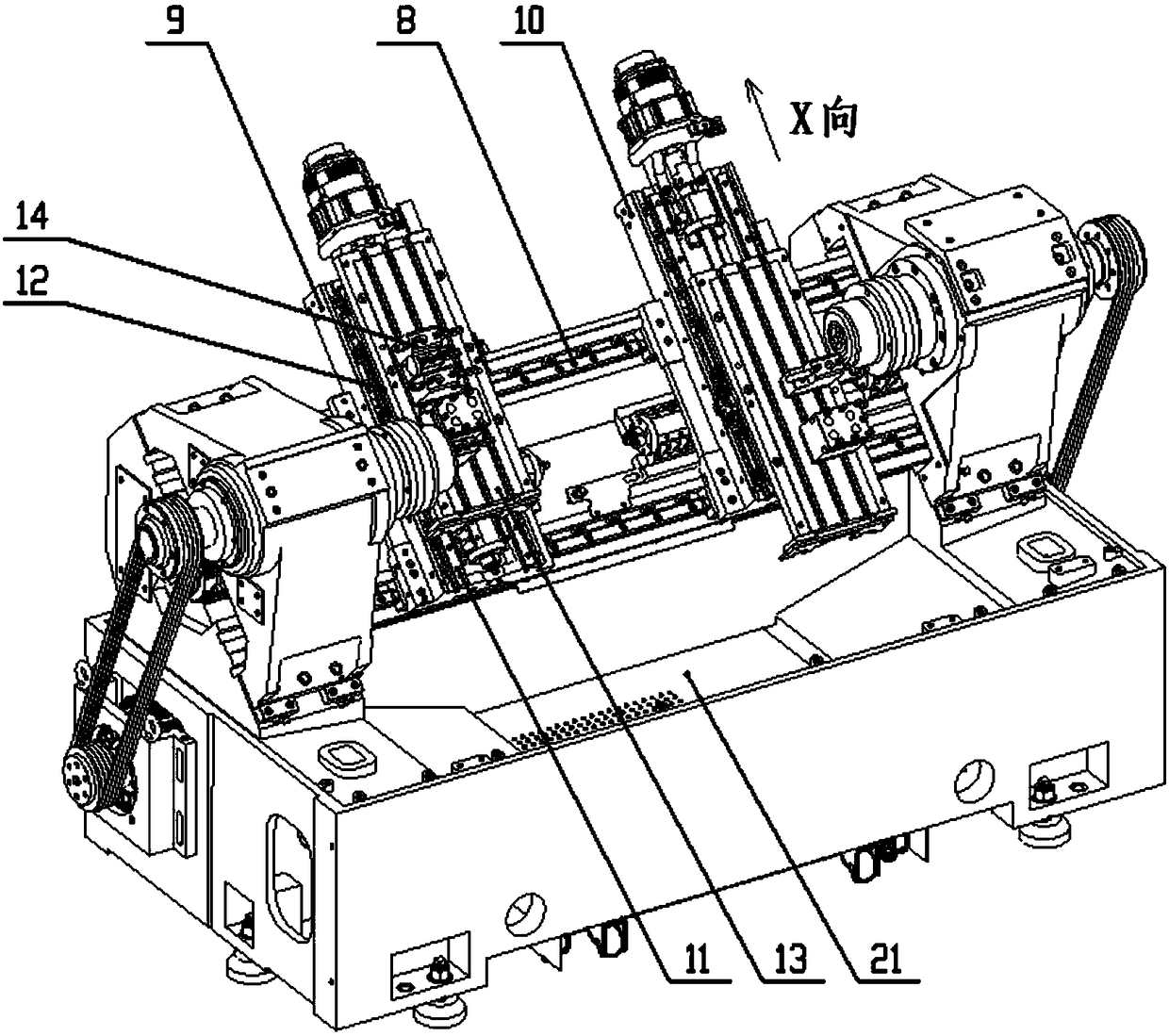

Oblique lathe bed double-spindle and double-row-tool numerical control lathe capable of achieving automatic feeding and discharging inside

ActiveCN106180760ARealize precise machiningReduce auxiliary timeAutomatic/semiautomatic turning machinesMetal working apparatusDouble rowSlide plate

The invention discloses an oblique lathe bed double-spindle and double-row-tool numerical control lathe capable of achieving automatic feeding and discharging inside. A lathe bed is provided with a left spindle box and a right spindle box which are oppositely arranged. Spindle units are arranged in the spindle boxes. Material clamping devices are arranged at the front ends of the spindle units. The spindles are connected with spindle power main servo motors through belts. A left saddle and a right saddle are arranged on the lathe bed in the Z direction in parallel and can move left and right in the Z direction. Sliding plates are arranged on the left saddle and the right saddle and move in the X direction in the corresponding saddles. The left spindle box and the right spindle box are symmetrically arranged with the center of the lathe bed as the symmetric face, the saddles are symmetrically arranged with the center of the lathe bed as the symmetric face, the sliding plates are symmetrically arranged with the center of the lathe bed as the symmetric face, and row tool plates are symmetrically arranged with the center of the lathe bed as the symmetric face. An automatic lathe interior feeding and discharging mechanism is arranged on the lathe bed and the spindle boxes, a scrap discharging box is arranged at the bottom of the lathe bed, outer protection parts are arranged on the lathe bed, and spindle control system double CRT boxes are fixed to the outer protection part. Accurate machining in all procedures including bearing ring inner circles, outer circles, end faces, chamfers, grooves, dustproof grooves and the like is finished on one machine tool, original machining procedures of several machine tools are combined to be conducted on one machine tool, the occupied area is reduced, and the production efficiency is improved.

Owner:SHENYANG MASCH TOOL CO LTD

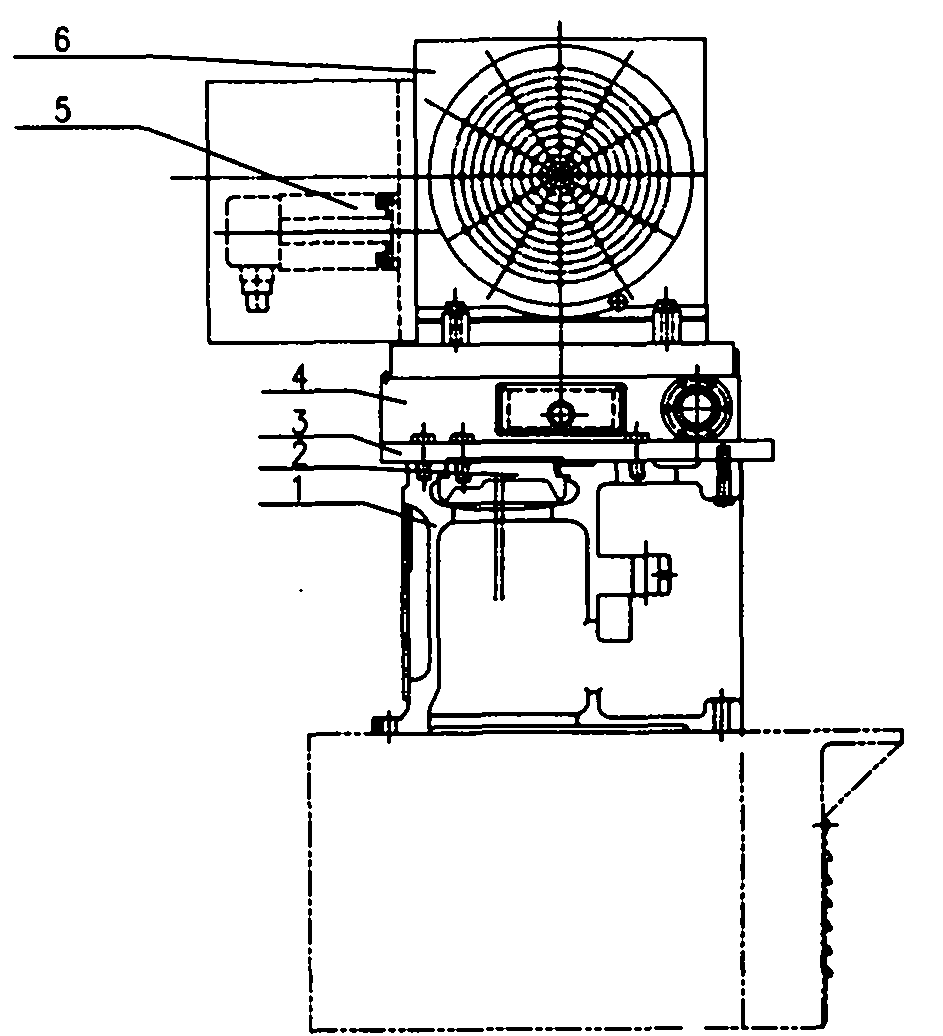

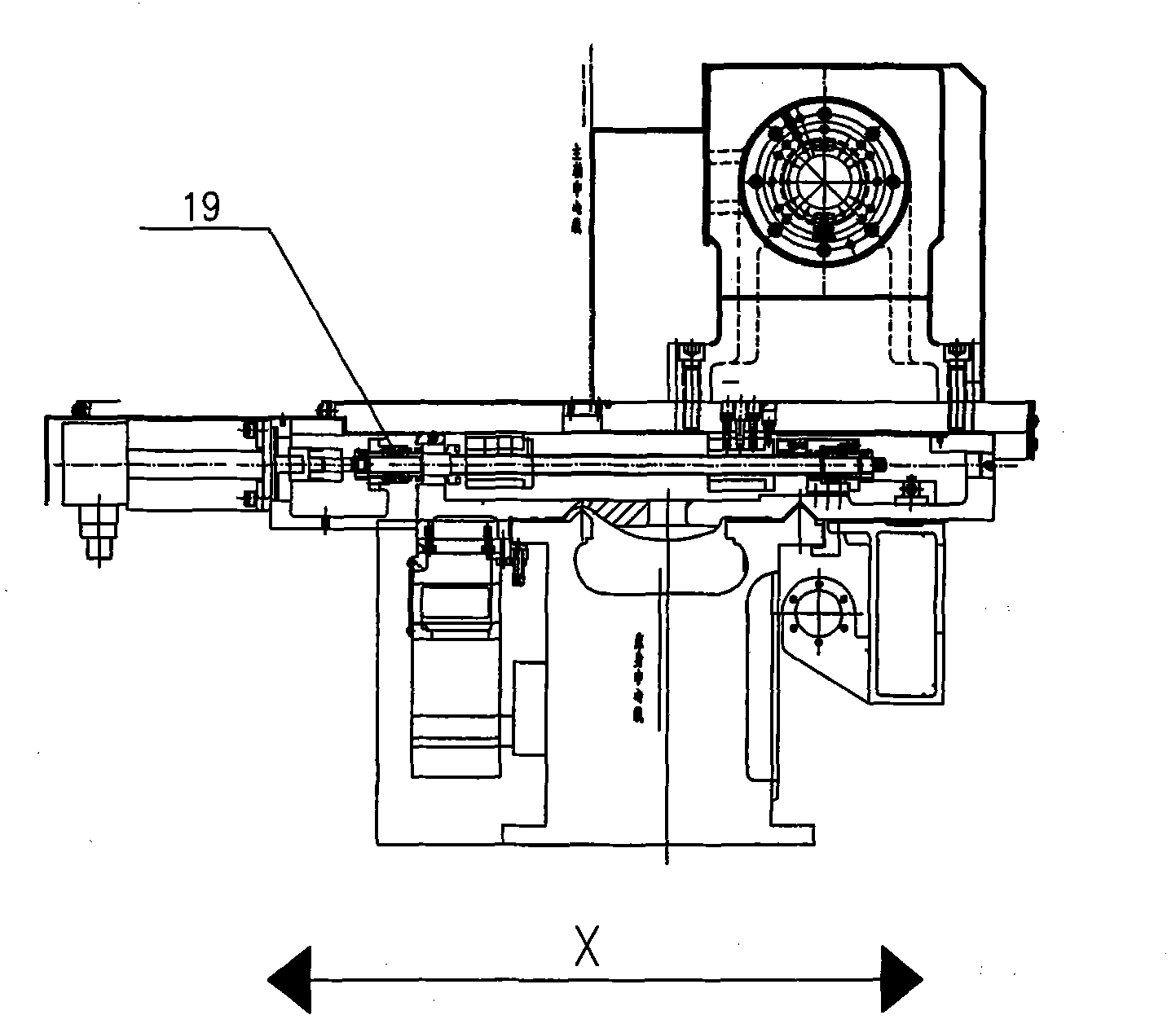

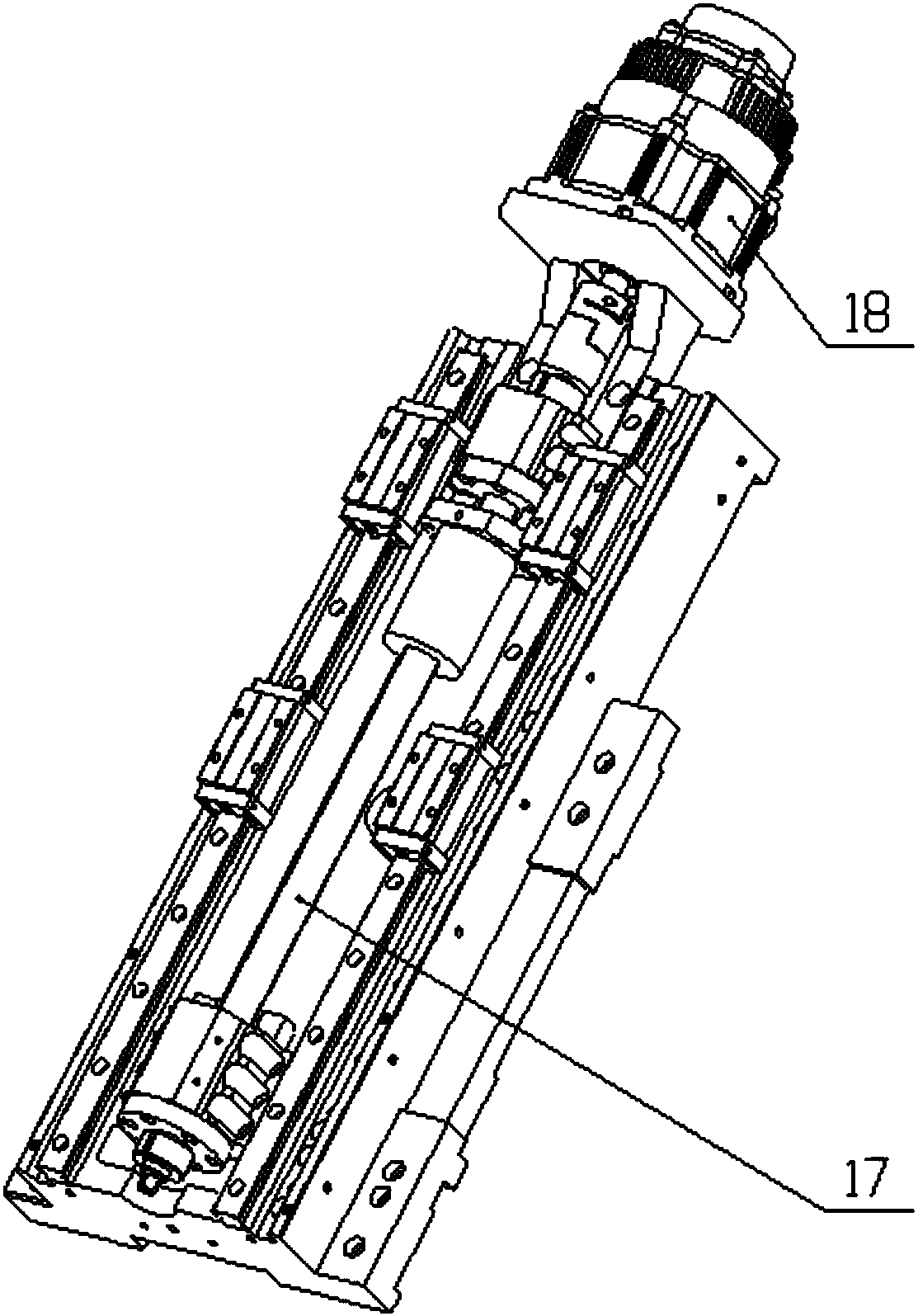

Numerical control machine tool for machining bearing retainer

ActiveCN101912983ARealize precise machiningFeeding apparatusLarge fixed membersNumerical controlControl system

A numerical control machine tool for machining a bearing retainer comprises a body, a control system, a hydraulic circuit and a cooling system. Each axis is equipped with a motor and a B-axis horizontal rotating table on the left of the body is fixed with the body. The machine tool is characterized in that a locating hole is arranged in the circle center on the upper part of the B-axis horizontal rotating table; an axis hole corresponding to a locating axis is arranged at the bottom of a C-axis vertical rotating table; the locating axis is arranged in locating axis holes of the B-axis horizontal rotating table and the C-axis vertical rotating table and is fixed on a B-axis work table together with a C-axis work table by a bolt and a locating pin respectively; a fixture is installed on a C-axis vertical turntable of the numerical control machine tool; a saddle is arranged on the right of the Z-direction body; a sliding plate is arranged on the saddle and moves along an X axial screw in the saddle; and a cutter spindle housing is fixed on the sliding plate in the Z direction and can move on the sliding plate and the saddle in the X and Z directions. The numerical control machine tool can realize one-time assembling and fixing, thus satisfying precise machining of the part end face holes and the circumference holes of the bearing retainer.

Owner:SHENYANG MASCH TOOL CO LTD

Automobile angle plate sheet continuous stamping die

ActiveCN108393397ARealize precise machiningEasy to processShaping toolsVehicle componentsPunchingEngineering

The invention relates to the technical field of automobile part machining, in particular to an automobile angle plate sheet continuous stamping die. The automobile angle plate sheet continuous stamping die comprises an upper locating plate, an upper die plate, a lower die plate and a lower locating plate which are arranged from top to bottom; a plurality of upper foot pads are arranged between theupper locating plate and the upper die plate; a plurality of lower foot pads are arranged between the lower die plate and the lower locating plate; and a feed plate, a first-time trimming process stamping die, a chamfering process stamping die, a forming process stamping die, a raising process stamping die, a first-time flanging process stamping die, a second-time flanging process stamping die, afirst-time shaping process stamping die, a second-time trimming process stamping die, a second-time shaping process stamping die, a punching and trimming process stamping die, a third-time shaping process stamping die and a cutting process stamping die are sequentially arranged between the upper die plate and the lower die plate from left to right. Finish machining on automobile angle plate sheets can be realized, manufacturing processes are simplified, and the machining precision and processing efficiency are improved, so that the production efficiency is improved and a product yield is raised.

Owner:无锡诺飞高新技术有限公司

A CNC lathe with inclined bed, double spindles, double rows of cutters and automatic loading and unloading inside the machine

ActiveCN106180760BRealize precise machiningReduce auxiliary timeAutomatic/semiautomatic turning machinesMetal working apparatusBlade plateNumerical control

Owner:SHENYANG MASCH TOOL CO LTD

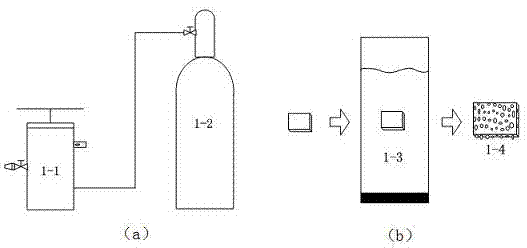

Ultrasonic process technology of tissue engineering scaffold material with controllable permeability

InactiveCN102441994APermeability precision machiningRealize precise machiningUltrasonic cavitationManufacturing technology

The invention discloses an ultrasonic process technology of a tissue engineering scaffold material with controllable permeability. On the basis of requirements of the tissue engineering scaffold material, and aiming at the problem of toxicity of residual solvent in a chemical foaming manufacturing technology, the ultrasonic process technology comprises the following steps of: performing physical foaming on a biodegradable material by using a CO2 solid-state foaming technology so as to obtain closed-cell scaffold materials with different pore-size distributions and mechanical strengths; aiming at the problems such as poor permeability and the like of the closed-cell scaffold materials, breaking foam hole walls of the tissue engineering scaffold material through ultrasonic cavitation and micro-jet energy of pulse power ultrasounds so as to enhance connectivity of foam holes; meanwhile, adjusting the permeability of the scaffold material by adjusting the duty ratio of impulse ultrasounds during processing so as to control the degradation rate; and measuring attenuation coefficients of the scaffold material by using ultrasonic insertion in stead of a measuring technology, estimating the permeability of the material by measuring the attenuation coefficients, and guiding the selection and the control of the pulse duty factor and the ultrasonic power in the process technology.

Owner:NANJING NORMAL UNIVERSITY

A clamping mechanism suitable for oil-edged materials and a method for clamping oil-edged materials

ActiveCN105880116BLocation pinpointingRealize precise machiningLiquid surface applicatorsLeather/skins/hides/pelt chemical treatment apparatusEngineeringRotating disc

The invention belongs to the technical field of automatic edge oiling machines, and particular relates to a clamping mechanism applicable to oil edge materials. The clamping mechanism comprises a rack, a rotating disc and a string clamp rope, clamps are arranged on the string clamp rope at intervals, the rack comprises a rotating disc support frame, a clamp guide plate, a clamp detection device and a clamp opening device, a rotating disc shaft is arranged on the rotating disc support frame, the rotating disc is connected to the rotating disc support frame through the rotating disc shaft, an annular groove is formed in the periphery of the rotating disc, the string clamp rope is arranged in the annular groove in a sleeved mode, and a power source which drives the string clamp rope to rotate around the rotating disc is connected to the string clamp rope; each clamp comprises a clamp body and a button, the width of the bottom end of each clamp body is smaller than that of the annular groove, and the width of the annular groove is smaller than that of each button. The clamping mechanism applicable to the oil edge materials is simple in structure, convenient and safe to operate and high in work efficiency and can position the clamps accurately and achieve precise processing of small materials.

Owner:潘声君

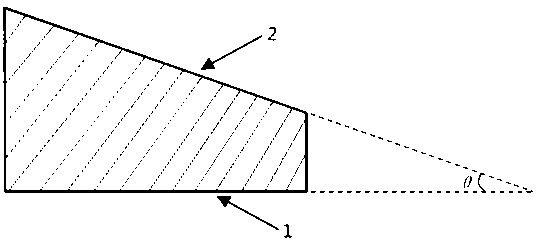

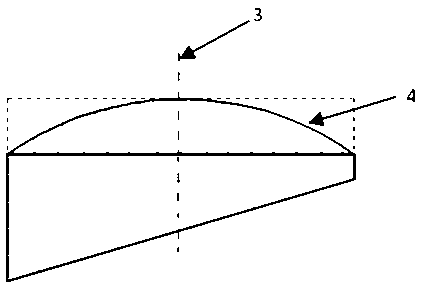

Method for processing Fery prism

The invention discloses a method for processing a Fery prism. The method comprises the steps of: (1) processing an initial structure cylinder of a curved prism Fery prism, wherein the diameter is equal to the diameter of a first curved surface of the Fery prism, the two end faces are planes vertical to the axis line of the cylinder, and the length of the cylinder is equal to the maximum length size of a workpiece in the axial direction of an optical axis of the first curved surface of the Fery prism plus a cutting removal amount; (2) processing an oval plane on the cylinder by cutting to obtain a wedge cylinder structure of the Fery prism, wherein the wedge cylinder structure spatially contains the Fery prism to be processed; (3) processing the first curved surface on the circular end face of the cylinder; and (4) processing a second curved surface on the oval plane. The method provided by the invention has the advantages of simple process, low cost and easiness in control of optical axis included angle precision, and is suitable for single part processing or small batch processing.

Owner:苏州七色光智能科技有限公司

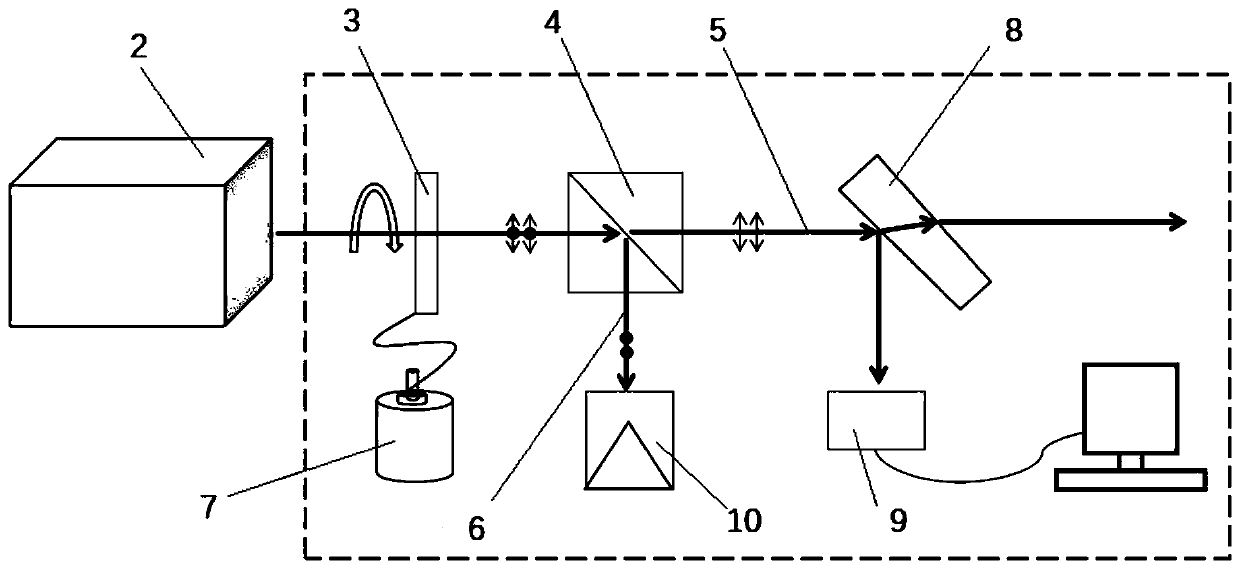

Laser power regulation device, laser cutting device and laser cutting machine

InactiveCN111069792AExcellent output characteristicsThermal deformation stabilityLaser beam welding apparatusBeam splittingEngineering

The invention provides a laser power regulation device, a laser cutting device and a laser cutting machine. The laser power regulation device comprises a support, a laser device, a half-wave plate anda polarization beam splitting prism. The laser device is used for emitting cutting laser. The half-wave plate is rotatably arranged on the support. The light incident position of the half-wave platecorresponds to a laser head of the laser device. The light incident position of the polarization beam splitting prism is opposite to the light emergent position of the half-wave plate. The cutting laser emitted by the laser device passes through the half-wave plate and then passes through the polarization beam splitting prism. The polarization beam splitting prism is used for perpendicularly splitting P-direction polarized laser and S-direction polarized laser in the cutting laser. Through the laser power regulation device, the technical problem of how to stably and accurately regulate the output power of laser without affecting the output characteristics of the laser is solved.

Owner:东莞市盛雄激光先进装备股份有限公司

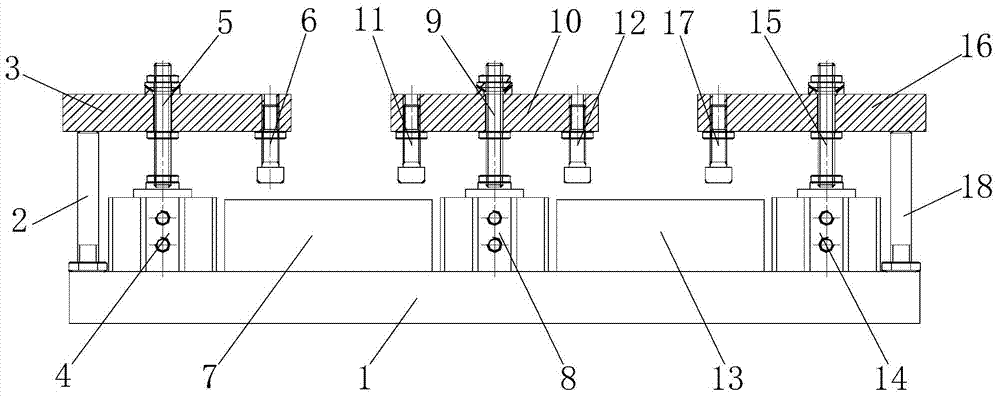

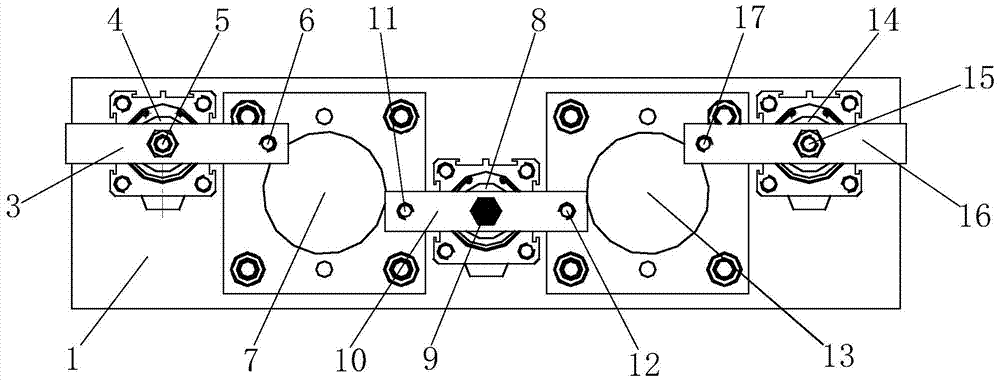

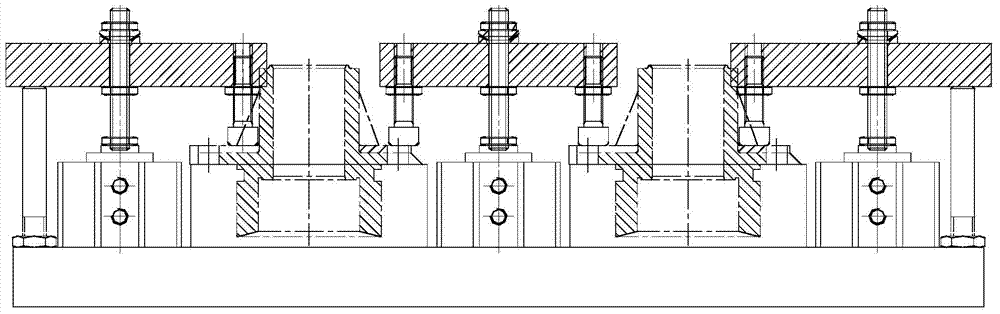

Clamp for turning pump body bearing holes

InactiveCN104259881AEasy clampingReasonable structural designWork clamping meansPositioning apparatusEngineeringMechanical engineering

The invention relates to a clamp for turning pump body bearing holes. The clamp comprises a clamp body, a first clamping device, a second clamping device, a third clamping device, a first installation seat and a second installation seat. The first clamping device, the second clamping device and the third clamping device are located on the upper end face of the clamp body in the left, middle and right. The first installation seat is arranged between the first clamping device and the second clamping device, and the second installation seat is arranged between the second clamping device and the third clamping device. The clamp facilitates clamping, is reasonable in structure design, high in stability and capable of achieving accurate machining of bearing holes of two pump bodies in an assisting mode and capable of improving clamping and machining efficiency.

Owner:HENAN FEILONG WUHU AUTOMOBILE PARTS

Processing method for oral cavity all-ceramic restoration

InactiveCN109938859ARealize precise machiningAvoid damageArtificial teethAll ceramicUltrashort pulse laser

The embodiment of the invention discloses a processing method for an oral cavity all-ceramic restoration. The method comprises the following steps that a, scanning data of a preparation body is acquired and then reconstructed into three-dimensional data; b, three-dimensional data of the all-ceramic restoration is designed in the three-dimensional data of the preparation body; c, the three-dimensional data of the all-ceramic restoration is imported into three-dimensional control software of an ultrashort pulse laser, according to the three-dimensional data of the all-ceramic restoration, a cutting trajectory is planned, working parameters of the ultrashort pulse laser are adjusted, and the ultrashort pulse laser is driven to conduct cutting according to the cutting trajectory so as to obtain the all-ceramic restoration. According to the processing method, by acquiring the three-dimensional data of the all-ceramic restoration and controlling the ultrashort pulse laser, manufacturing is conducted, the all-ceramic restoration can be precisely processed, the sintering process is not needed, the manufacturing time can be effectively shortened, the damage to the all-ceramic restoration inthe sintering process is avoided, the product quality of the all-ceramic restoration can be improved, and the service life is prolonged.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

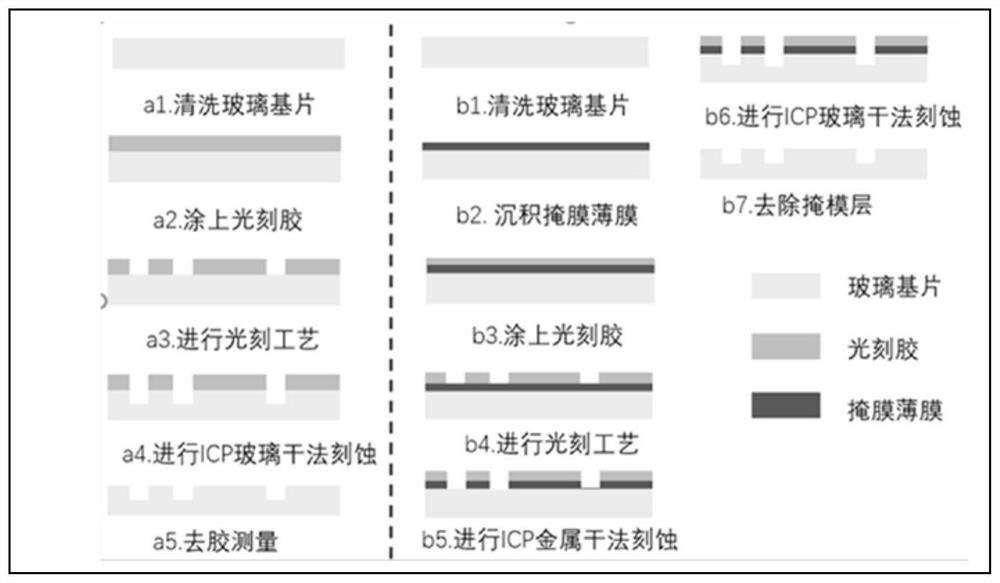

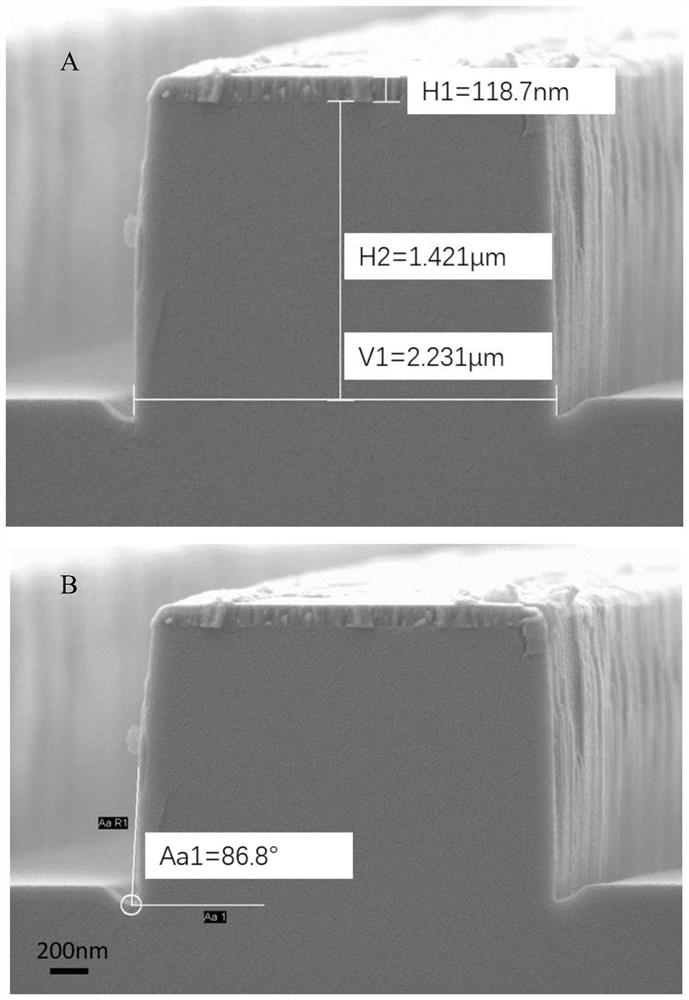

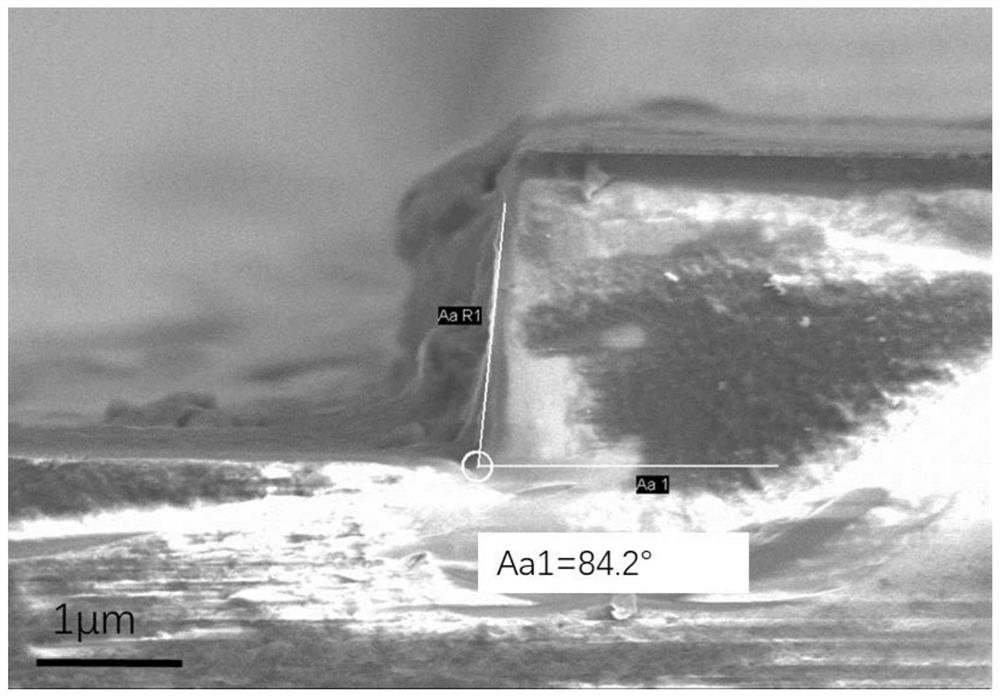

Processing method of fine micro-nano glass structure

PendingCN113788452APrecise size controlAccurate structure sizeMaterial nanotechnologyDecorative surface effectsMicro nanoThin membrane

The invention discloses a processing method of a fine micro-nano glass structure, which comprises the following steps: preparing a glass substrate, and cleaning and blow-drying the glass substrate; when the mask material is a non-photoresist material, depositing the mask film on the glass substrate, and then coating the photoresist; when the mask material is a photoresist material, coating photoresist on the glass substrate; transferring a structure to be processed onto the photoresist on the surface of the substrate in a photoetching manner; when the mask material is a non-photoresist material, the mask material being etched firstly, and then the glass substrate being etched; when the mask material is a photoresist material, only the glass substrate being etched; and removing the photoresist and the mask material by using a dry etching or wet etching method to form a final glass device structure. By adopting the preparation process disclosed by the invention, the glass etching rate can reach 710nm / min, the roughness is reduced to be below 40nm, and the side wall perpendicularity is close to 90 degrees.

Owner:SHANGHAI JIAO TONG UNIV

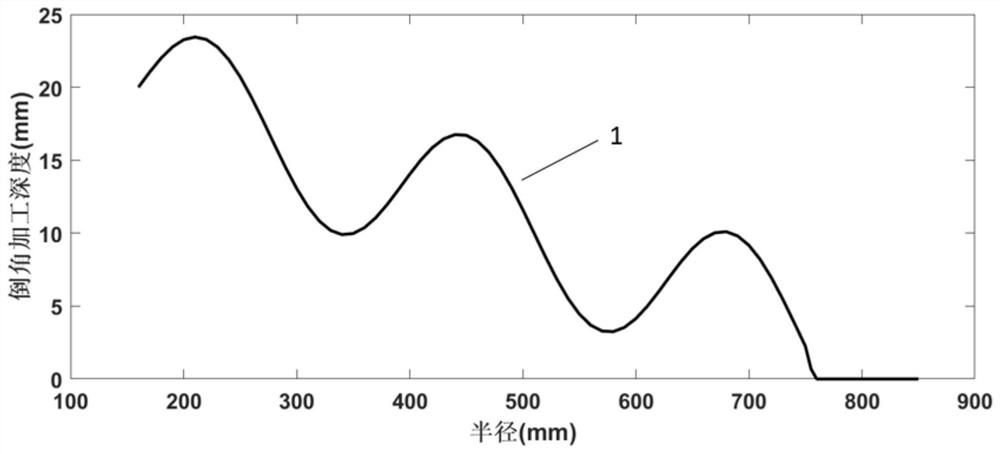

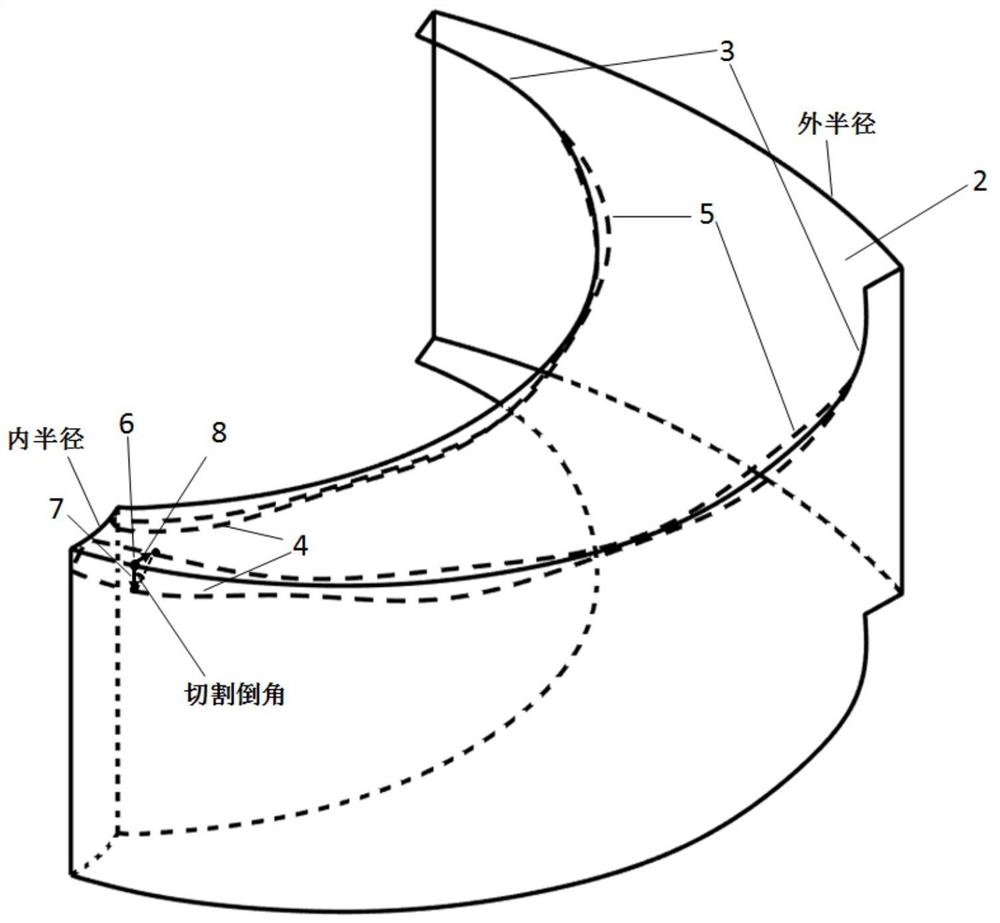

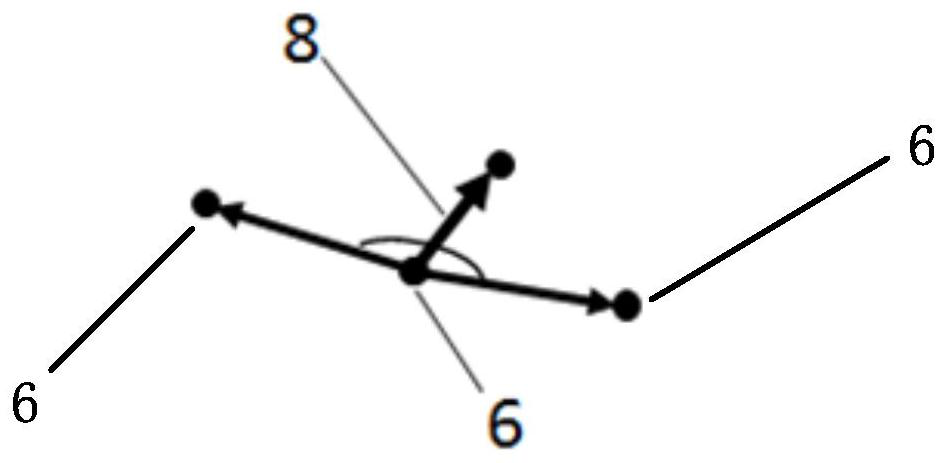

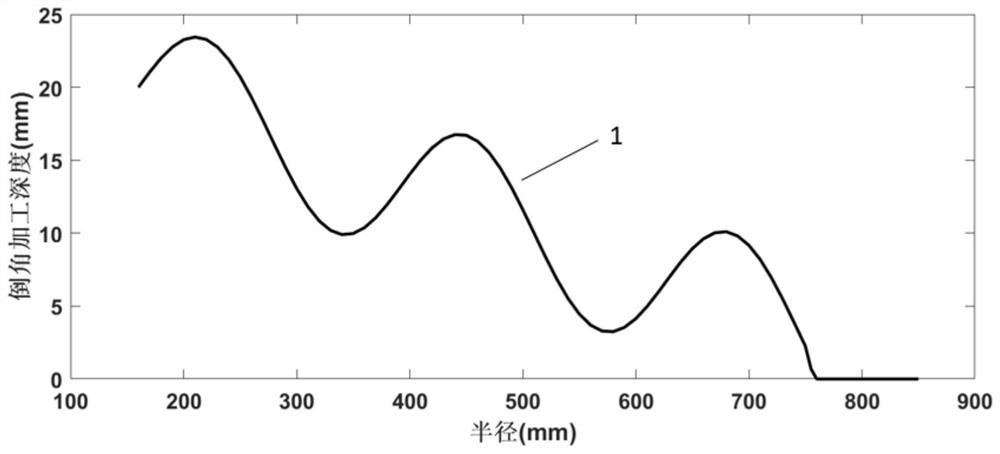

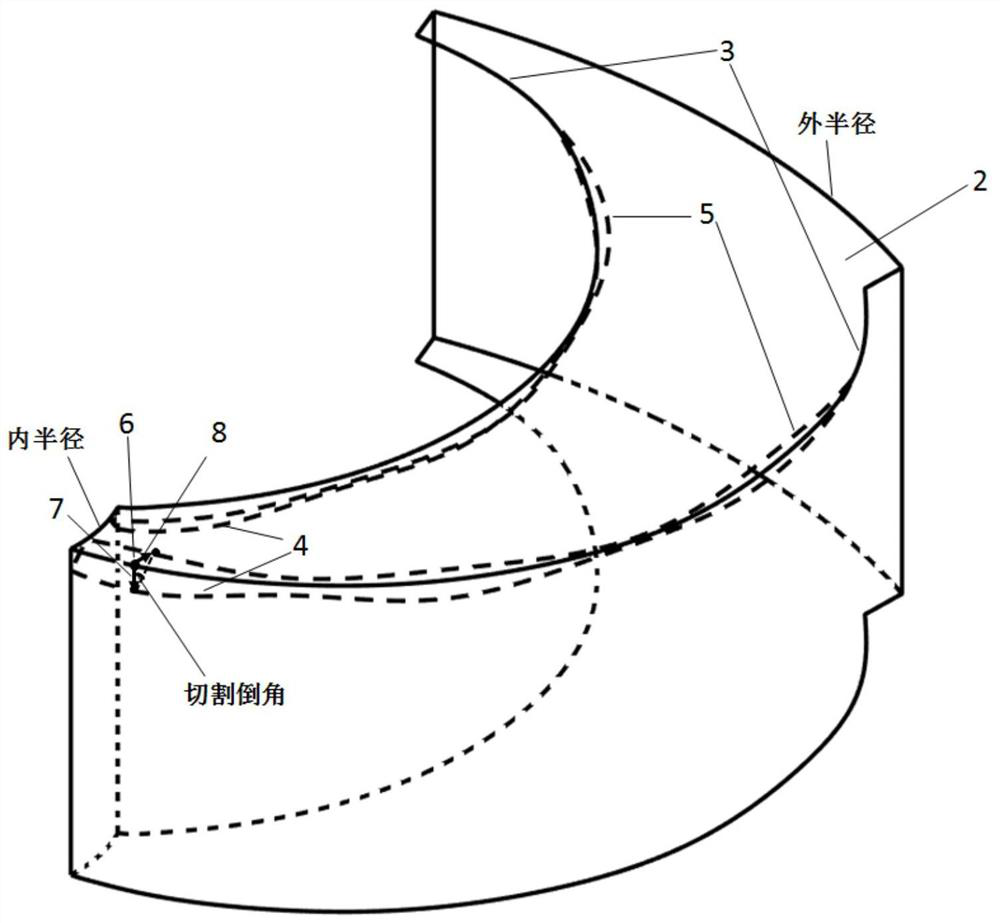

Variable-depth chamfering machining method for side edge of magnetic pole of spiral fan

ActiveCN111687685ARealize precise machiningHigh precisionAutomatic control devicesFeeding apparatusPhysicsLow magnetic field

The invention discloses a variable-depth chamfering machining method for the side edge of a magnetic pole of a spiral fan. The variable-depth chamfering machining method comprises the following stepsthat firstly, a shape body of a variable-depth chamfer of the side edge of the magnetic pole of the spiral fan is worked out to serve as a cutting body; difference set operation of Boolean operation is performed on the cutting body and the shape body, to be subjected to variable-depth chamfering, of the magnetic pole of the spiral fan, so that cutting of the cutting body on the side edge of the magnetic pole of the spiral fan is completed, and a spiral fan magnetic pole three-dimensional model after chamfering processing is generated after cutting; and spiral fan magnetic pole three-dimensional model after chamfering processing is imported into machine tool machining software so as to complete a machining program. According to the variable-depth chamfering machining method, by establishingthe variable-depth chamfering cutting body and establishing a bilinear angular bisector model, the variable-depth chamfering machining problem of the side edge of the magnetic pole of the spiral fanin a cyclotron is solved, a high-precision variable-depth chamfering cutting model is achieved through the Boolean operation function of the mechanical software, the consistency of chamfering machining of multiple magnets is improved, the asymmetry of a magnetic field is reduced, and the overall performance of an accelerator is improved.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

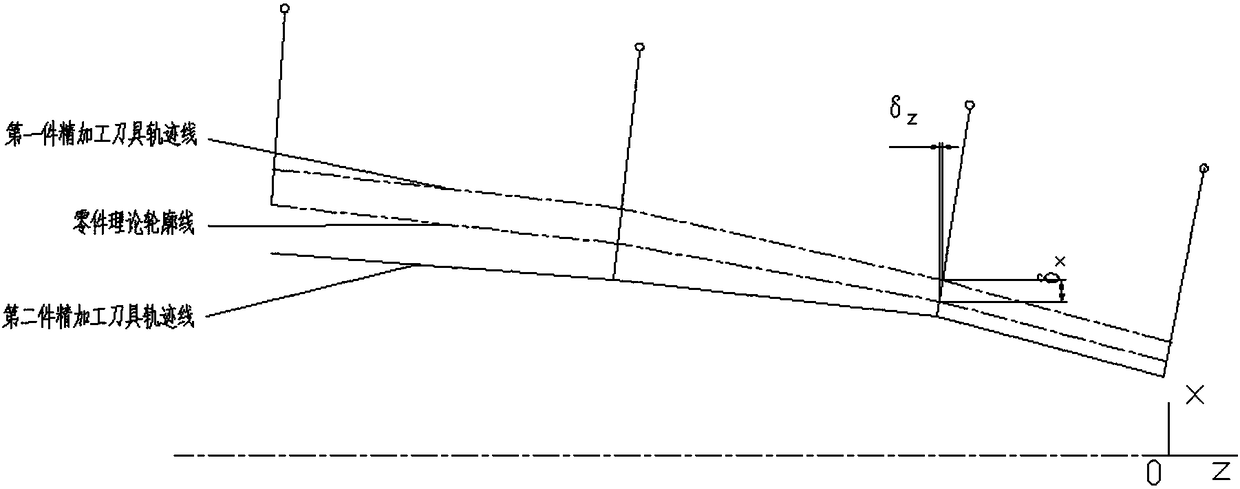

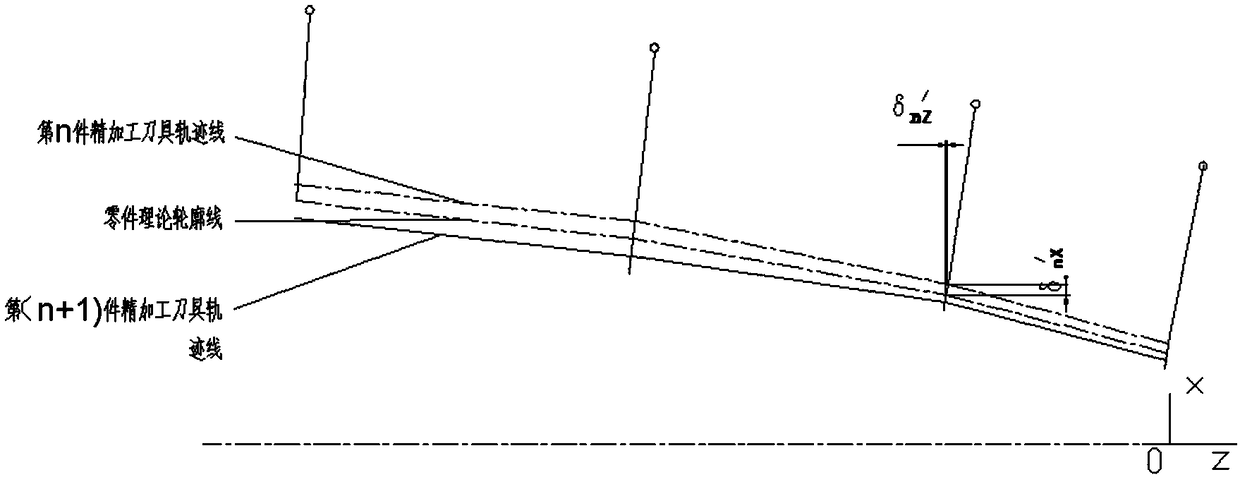

A Turning Method Compensating for Shape Errors Applicable to Mass Production Parts

ActiveCN106563817BRealize precise machiningImprove machining accuracyIndustrial engineeringTool wear

Owner:HUBEI SANJIANG SPACE XIANFENG ELECTRONICS&INFORMATION CO LTD

A milling gear processing parameter and path compensation method

ActiveCN110125489BRealize precise machiningHigh precisionGear-cutting machinesGear teethGear wheelCutting force

The invention discloses a milling tooth machining parameter and path compensation method. The method comprises the following steps that S1, the installation error of the relative position of a tool and a workpiece is obtained, and the relative position between the tool and the workpiece after being installed is obtained by measuring the position of the tool and the workpiece, the installation error of the machine tool is obtained through subtracting the set relative position between the tool and the workpiece from the measured relative position; S2, the error of tool is obtained under action of cutting force and torque under action of cutting force by calculating; and S3, compensation is carried out on the machining parameters and the machining path, the set machining parameters are compensated through the error obtained in the step S1, and the compensated machining parameters are obtained; and the set machining path is compensated through the errors obtained in the step S1 and the step S2 so as to obtain the compensated machining path. According to the method, the machining errors are compensated, so that accurate machining of the gear is realized, and the precision of the workpiece is improved.

Owner:CENT SOUTH UNIV

An electric cutting tool for aerospace titanium alloy structural parts

ActiveCN113635102BAvoid shakingRealize precise machiningOther manufacturing equipments/toolsPositioning apparatusWorking environmentTitanium alloy

The invention discloses an electric cutting tool for aerospace titanium alloy structural parts, which relates to the field of aerospace and aerospace, and includes a main platform body. A turning rod for slidingly adjusting the height of the top plate is installed on the main platform body via an adjustment column. The adjustment top plate There is an adjusting plate for bolt positioning in the middle of the rear end; the cutting tool can guide the residue into the slag guide groove, and then effectively collect the residue into the air bag through the traction of the exhaust fan to realize the automatic collection and treatment of the residue , to avoid residues from polluting the working environment, realize the overall clamping of the titanium alloy structure, realize the precise processing of the titanium alloy, reduce the loss rate of the titanium alloy processing, and adjust the distance between the top plate and the main table body according to the overall model size of the titanium alloy structure The vertical position between them is convenient for precise machining of titanium alloy structures. It can realize different processing methods for titanium alloy structures, improve the flexibility of tooling, reduce the number of adjustments of titanium alloy structures, and meet the multi-angle cutting processing of titanium alloys.

Owner:启东锋刃工具有限公司

A Taper Sleeve Positioning Device for Machining Taper Sleeve Inner Keyway by Planer

ActiveCN103495884BImprove straightnessGuaranteed symmetryPlaning/slotting machinesPositioning apparatusCompression deviceEngineering

The invention discloses a taper sleeve positioning device used for machining an internal key groove of a taper sleeve by utilizing a planer. The taper sleeve positioning device used for machining the internal key groove of the taper sleeve by utilizing the planer comprises a horizontally arranged rectangular base plate, wherein a first supporting table and a second supporting table in parallel are fixedly arranged on the base plate in the length direction of the base plate, the two supporting tables are both of a tabular structure, the upper portions of the two supporting tables are both of an annular structure, a first cushion block and a second cushion block are arranged inside the annular structure of the first supporting table and the annular structure of the second supporting table respectively, at least three compression devices are respectively arranged at the side, deviating from the second supporting table, of the first supporting table, three first adjusting bolts are arranged on the periphery of the annular structure of the first supporting table, three connecting plates are arranged on the periphery of the annular structure of the second supporting table, and a check plate is arranged at the periphery of the second cushion block and can prevent the second cushion block from penetrating through the annular structure of the second supporting table. By means of the taper sleeve positioning device used for machining the internal key groove of the taper sleeve by utilizing the planer, the key groove of the taper sleeve can be accurately machined through the planer, particularly the taper sleeve with the small-size taper hole can be directly machined, and therefore production efficiency is improved, and labor intensity is relieved.

Owner:CHONGQING HUAYU HEAVY IND ELECTROMECHANICAL CO LTD

A variable depth chamfering processing method for the side of a spiral fan magnetic pole

ActiveCN111687685BSolve the problem of variable depth chamferingImprove performanceAutomatic control devicesFeeding apparatusMagnetic polesStructural engineering

The invention discloses a processing method for variable-depth chamfering of the side of a spiral fan magnetic pole, comprising the following steps: firstly calculating a shape body of variable-depth chamfering of the side of a spiral fan magnetic pole as a cutting body; Perform Boolean subtraction operation on the spiral fan magnetic pole shape with chamfering at variable depth, so as to complete the cutting of the spiral fan magnetic pole side by the cutting body, and generate the chamfered spiral fan magnetic pole three-dimensional model after cutting; it will be completed The three-dimensional model of the spiral fan magnetic pole after processing chamfering is imported into the machine tool processing software to complete the processing program. The invention solves the problem of variable-depth chamfering processing on the side of the magnetic pole of the spiral fan in the cyclotron by establishing a variable-depth chamfering cutting body and a two-fold line angle bisector model, and realizes high-precision variable-depth chamfering through the Boolean operation function of the mechanical software. The corner cutting model helps to improve the consistency of chamfering of multiple magnets, reduce the asymmetry of the magnetic field, and improve the overall performance of the accelerator.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Machine tool capable of machining large-sized workpieces and use method of machine tool

PendingCN111644638ARealize precise machiningReduce difficultyAuxillary equipmentFeeding apparatusDrive shaftMachine

The invention discloses a machine tool capable of machining large-sized workpieces and a use method of the machine tool. The machine tool comprises a base and a control box. A motor is mounted on oneside of the base, and a first belt wheel is mounted on a rotor of the motor. The first belt wheel is in transmission connection with a second belt wheel at one end of a transmission shaft through a triangular belt, and a tightening disc is mounted at the other end of the transmission shaft. A stepping motor is mounted at the other end of the base, and a workpiece supporting device is mounted between the stepping motor and the tightening disc. A cutting and feeding device is mounted on the front side of the base. According to the machine tool capable of machining the large-sized workpieces andthe use method of the machine tool, the machine tool can complete some workpieces with special requirements, especially some workpieces incapable of being completely on common machine tools, the difficulty that the huge workpieces cannot be machined can be overcome by the machine tool, and the difficulty in special equipment requirements is solved.

Owner:SHANDONG YISHUI MACHINE TOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com