Ultrasonic process technology of tissue engineering scaffold material with controllable permeability

A tissue engineering scaffold and ultrasonic processing technology, which is applied in the field of biomedical engineering and tissue engineering scaffold material processing, can solve the problem that the permeability of the scaffold material cannot be changed, the balance between the mechanical properties of the material and the permeability is difficult to control, and the manufacturing process of the scaffold material is difficult. Difficult to precisely control and other issues, to achieve the effect of maintaining mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

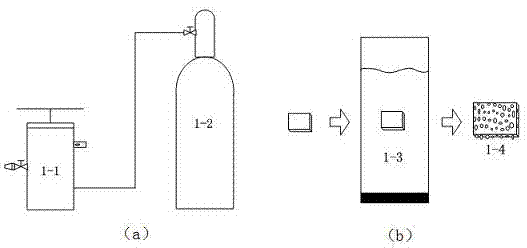

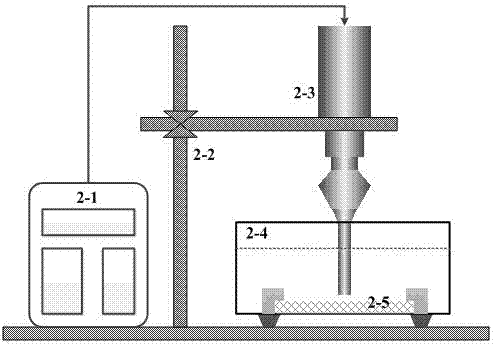

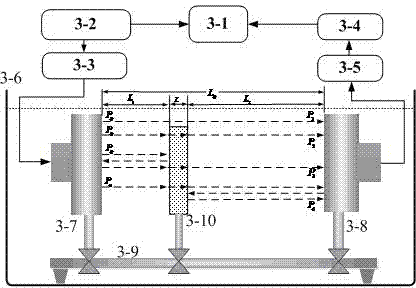

[0036] The idea of the present invention to solve the technical problems of ultrasonic processing is: (1) According to the basic requirements of tissue engineering scaffold materials, aiming at the toxicity of solvent residues in chemical foaming production, using CO 2 Solid-state foaming technology physically foams the raw materials of degradable scaffolds to obtain closed-cell foam materials with certain mechanical strength and cell size distribution; (2) For the poor permeability of closed-cell tissue engineering scaffold materials, slow cell growth and metabolism , long degradation time and uncontrollable problems, through ultrasonic cavitation and micro-jet flow of pulse power ultrasound to break the cell wall of the tissue engineering scaffold material, enhance the connectivity of the cells, and improve the tissue under the premise of e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com