A milling gear processing parameter and path compensation method

A technology of processing parameters and compensation methods, which is applied in the direction of metal processing equipment, gear teeth, gear cutting machines, etc., can solve the problems of difficult control of processing errors, difficulty in accurately compensating comprehensive processing errors, and inability to meet precision processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0046] A tooth milling processing parameter and path compensation method of the present invention includes steps S1, S2, and S3.

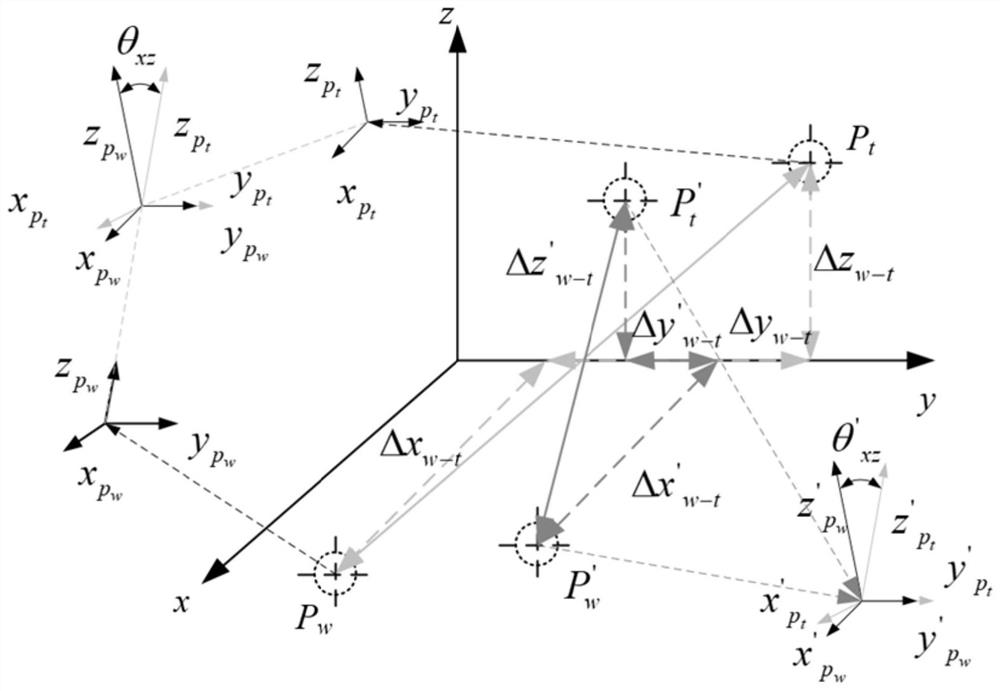

[0047] S1: Obtain the installation error of the relative position between the milling tool and the workpiece, obtain the relative position of the tool and the workpiece after installation by measuring the positions of the milling tool and the workpiece, and subtract the relative position set by the tool from the measured relative position to obtain the machine tool The installation error; specifically, after installing the milling tool, the actual relative position of the tool and the workpiece P t -P w Relative to the ideal position P t '-P w 'Such as figure 1 shown. The ideal relative position of the tool and the workpiece can be obtained by decrypting the program code of the gear milling machine tool. The actual r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com