A Taper Sleeve Positioning Device for Machining Taper Sleeve Inner Keyway by Planer

A positioning device and internal keyway technology, applied in the field of mechanical processing, can solve the problems of difficulty in ensuring the qualified rate of parts, high labor intensity, and high difficulty in repairing, and achieve good processing and forming effects, reduce labor intensity, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

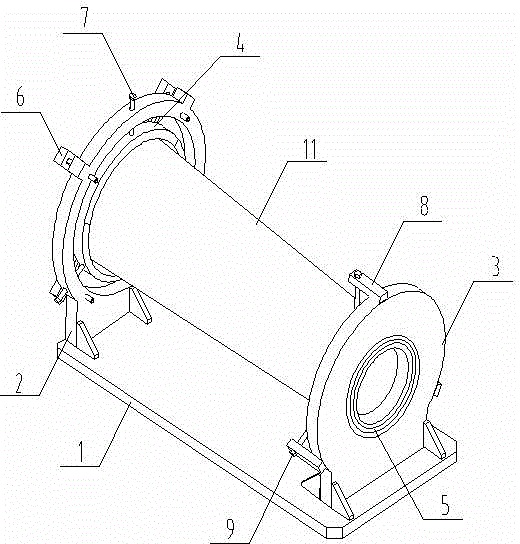

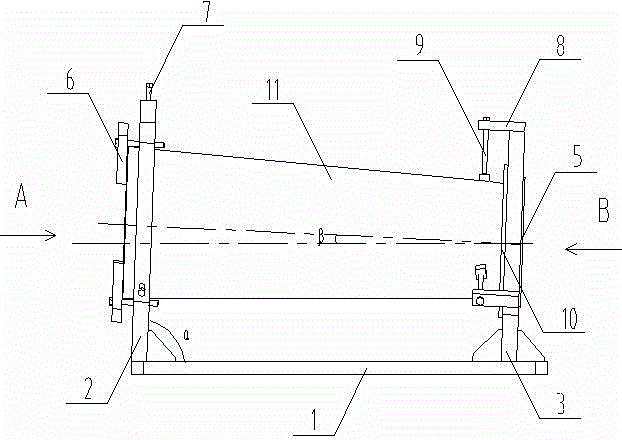

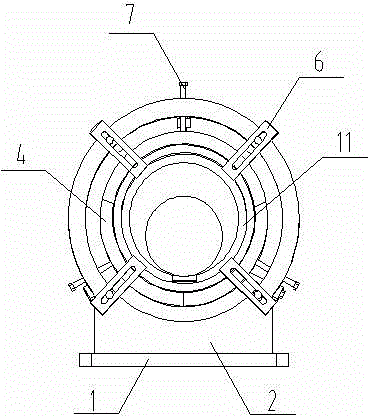

[0023] Example: see figure 1 , figure 2 , image 3 as well as Figure 4 , a taper sleeve positioning device for processing the inner keyway of the taper sleeve by a planer, comprising a horizontally arranged rectangular bottom plate 1, on which a first support platform 2 and a second support platform parallel to each other are fixed along the length direction of the bottom plate 1 3. The distance between the two support platforms is less than or equal to the length of the taper sleeve 11; during production, the bottom plate 1 and the two support bodies are made of metal plates and welded together; one side or both sides of the support platform and the bottom plate 1 Ribs are arranged between them, which can make the connection between the bottom plate 1 and the two support platforms more stable and have a stronger bearing capacity.

[0024] Both support platforms are of plate-like structure, and the upper part is in the form of a ring structure. There is an angle of α betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com