An electric cutting tool for aerospace titanium alloy structural parts

An aerospace and titanium alloy technology, which is applied in the aerospace field, can solve the problems that the position of the titanium alloy structure is not fixed firmly, the processing method of the titanium alloy structure is single, and the titanium alloy structure cannot be precisely processed, so as to avoid shaking, ensure precise processing, The effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

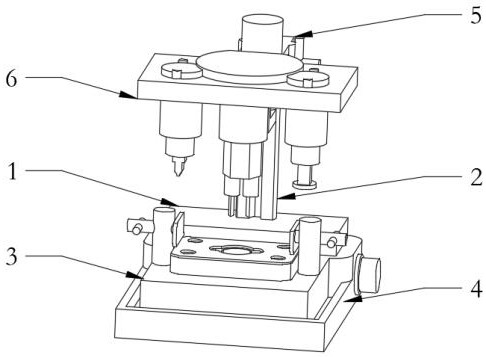

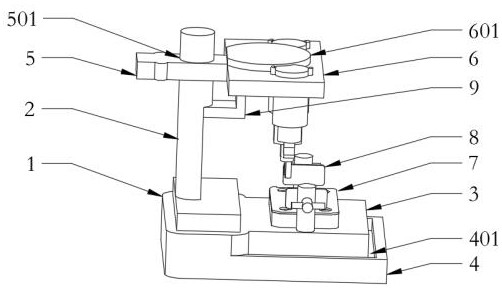

[0028] see Figure 1-8, the present invention provides a technical scheme of electric cutting tooling for aerospace titanium alloy structural parts: it includes a main platform body 1, a turning rod 9 for sliding the height of the top plate 6 is installed on the main platform body 1 via an adjustment column 2, and the rear of the top plate 6 An adjustment plate 5 for bolt positioning is arranged in the middle of the end, a processing plate mechanism 7 for cutting operation platform is arranged at the upper end of the front side operation platform 3 of the main platform body 1, and a clamp for clamping is arranged at the middle position of the upper surface of the operation platform 3 The holding mechanism 8; the overall shape of the turning rod 9 is an inverted L shape, the outer surface of the adjustment column 2 is provided with a chute 201 near the middle position of the front side, and the middle position of the upper surface of the adjustment plate 5 is provided with a rou...

Embodiment 2

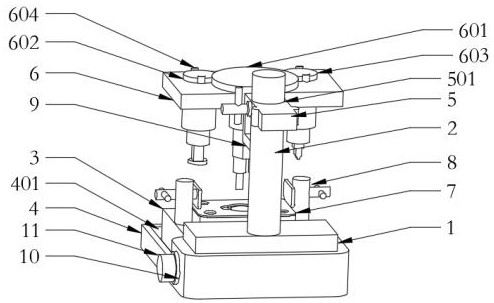

[0031] Such as Figure 1-8 As shown, the main platform body 1 is included, and the turning rod 9 for sliding the height of the top plate 6 is installed on the main platform body 1 via the adjustment column 2. An adjustment plate 5 for bolt positioning is arranged in the middle of the rear end of the top plate 6. The main platform body 1 The upper end of the front console 3 is provided with a processing plate mechanism 7 for the cutting operation platform, and the middle position of the upper surface of the console 3 is provided with a clamping mechanism 8 for clamping; the top plate 6 includes a control module 601 for controlling the operation of the equipment A No. 1 motor 602 is installed in the middle of one side of the top plate 6, and a No. 2 motor 603 is installed in the middle of the other side of the top plate 6 corresponding to the No. 1 motor 602. The top sides of the No. 1 motor 602 and the No. 2 motor 603 are symmetrically fixed Be provided with bayonet 604, wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com