Patents

Literature

375 results about "Machining toolpath" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for fitting and interpolating G01 code based on quadratic B spline curve

InactiveCN101539769AAccurate descriptionMeet the precision requirementsProgramme controlAutomatic control devicesNumerical controlApplicability domain

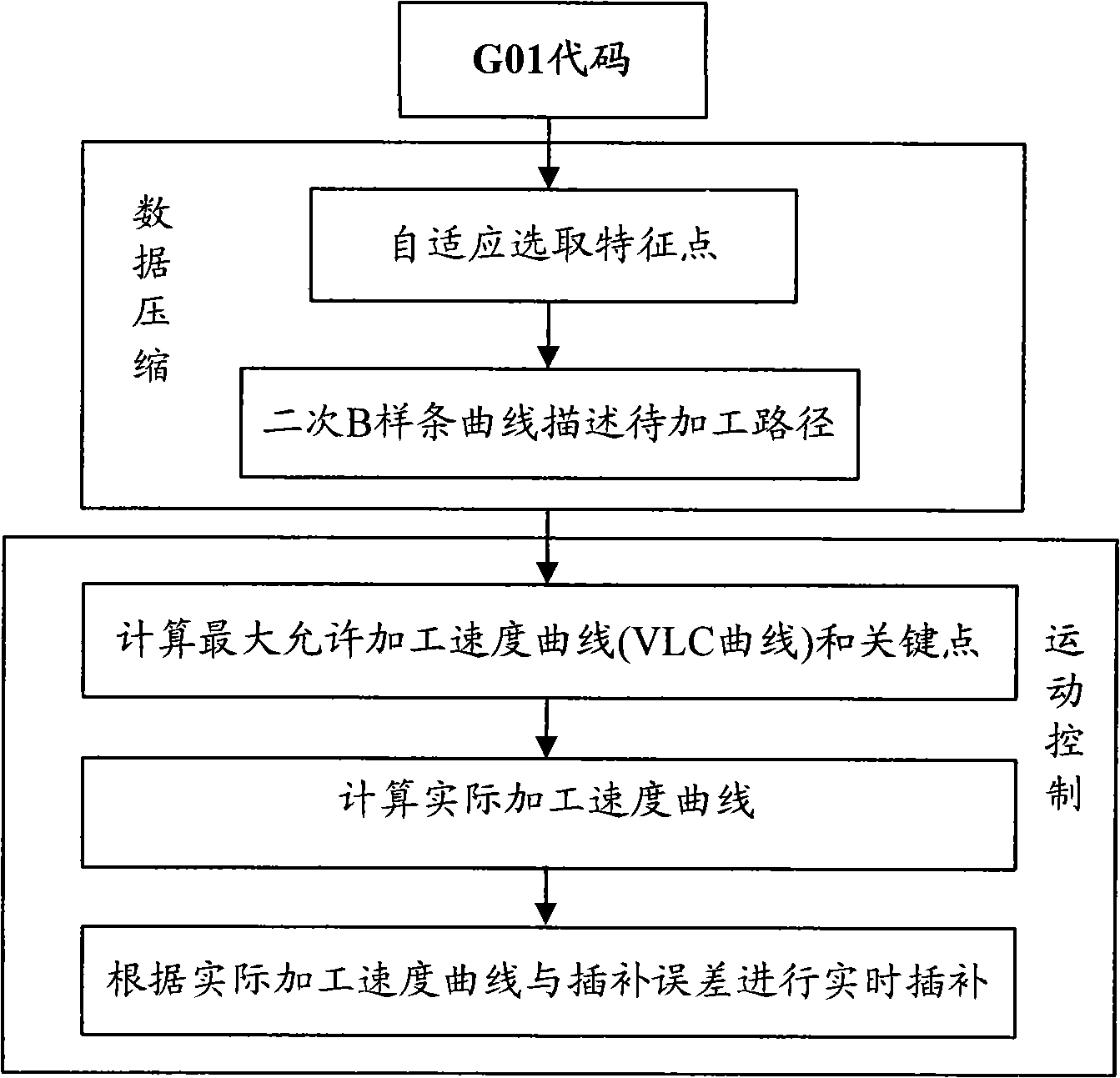

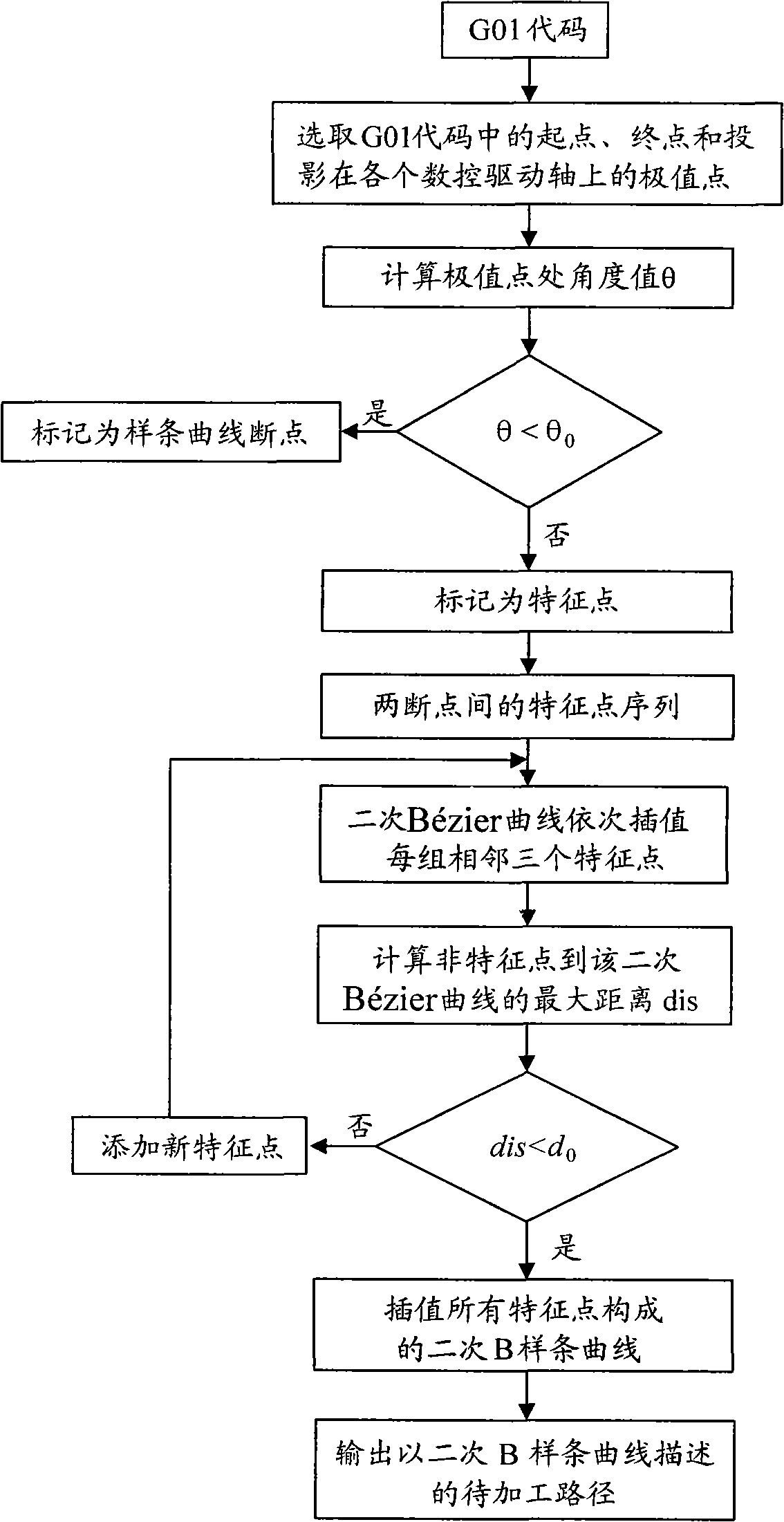

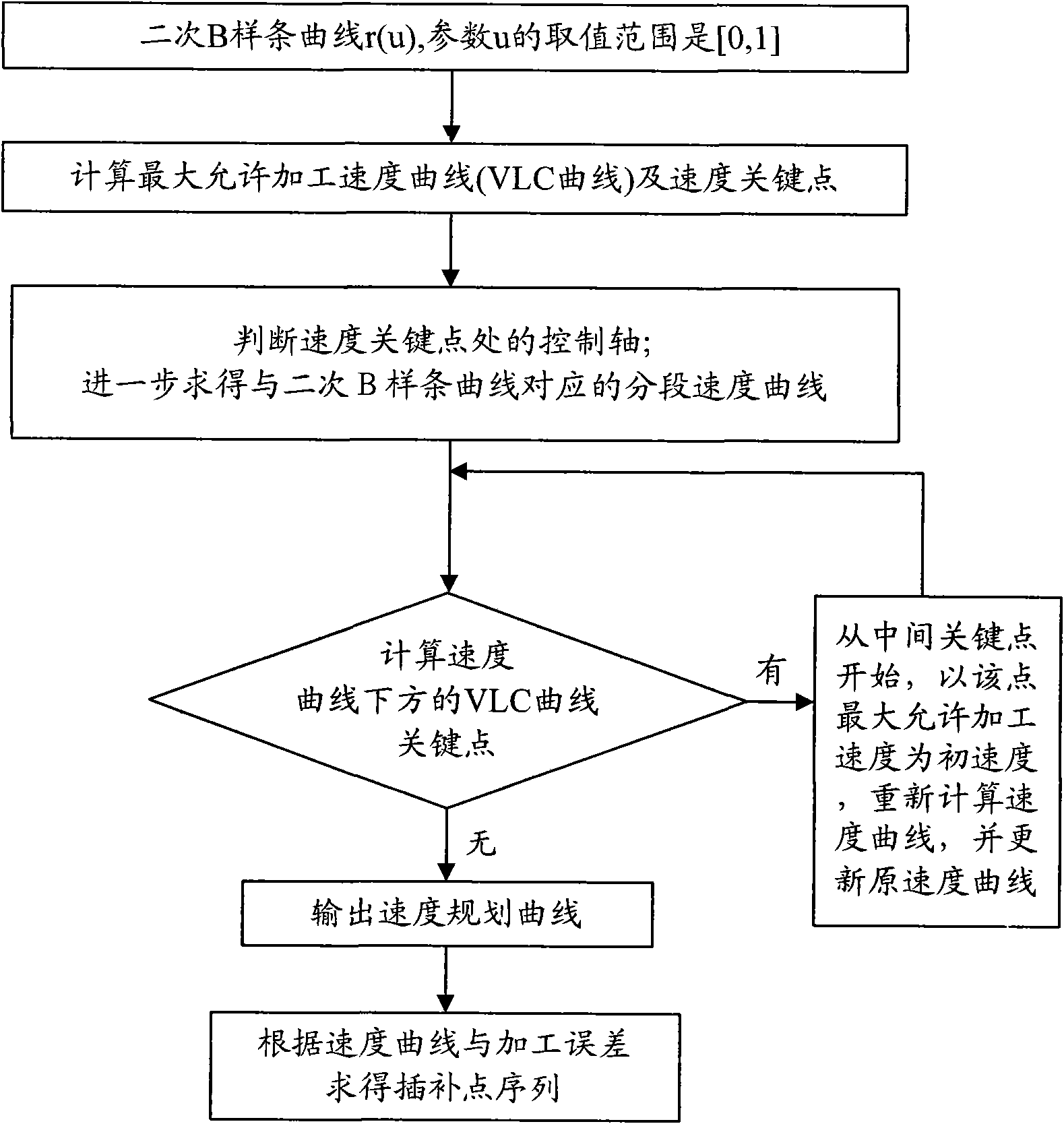

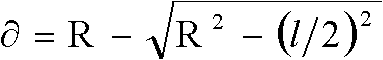

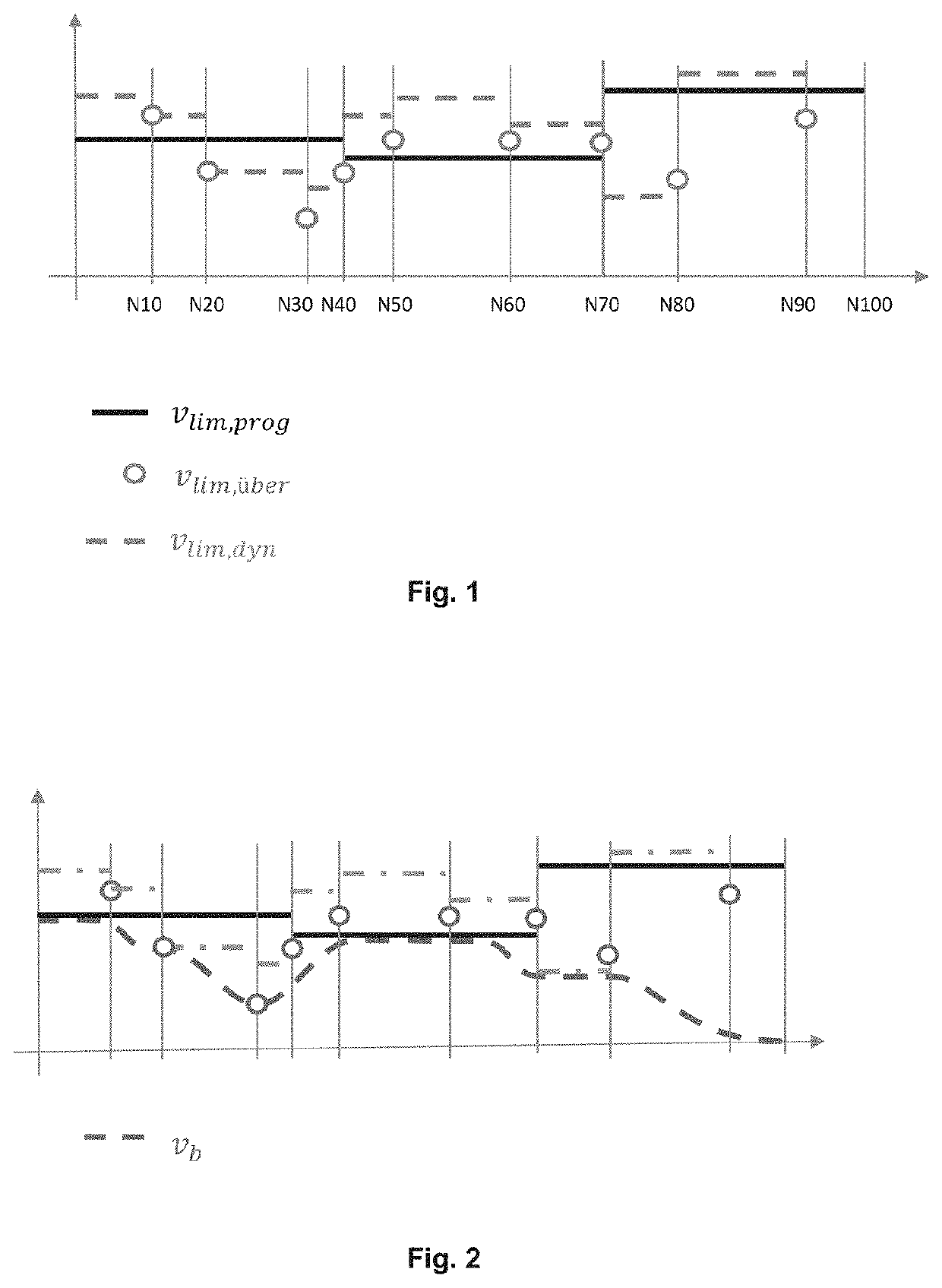

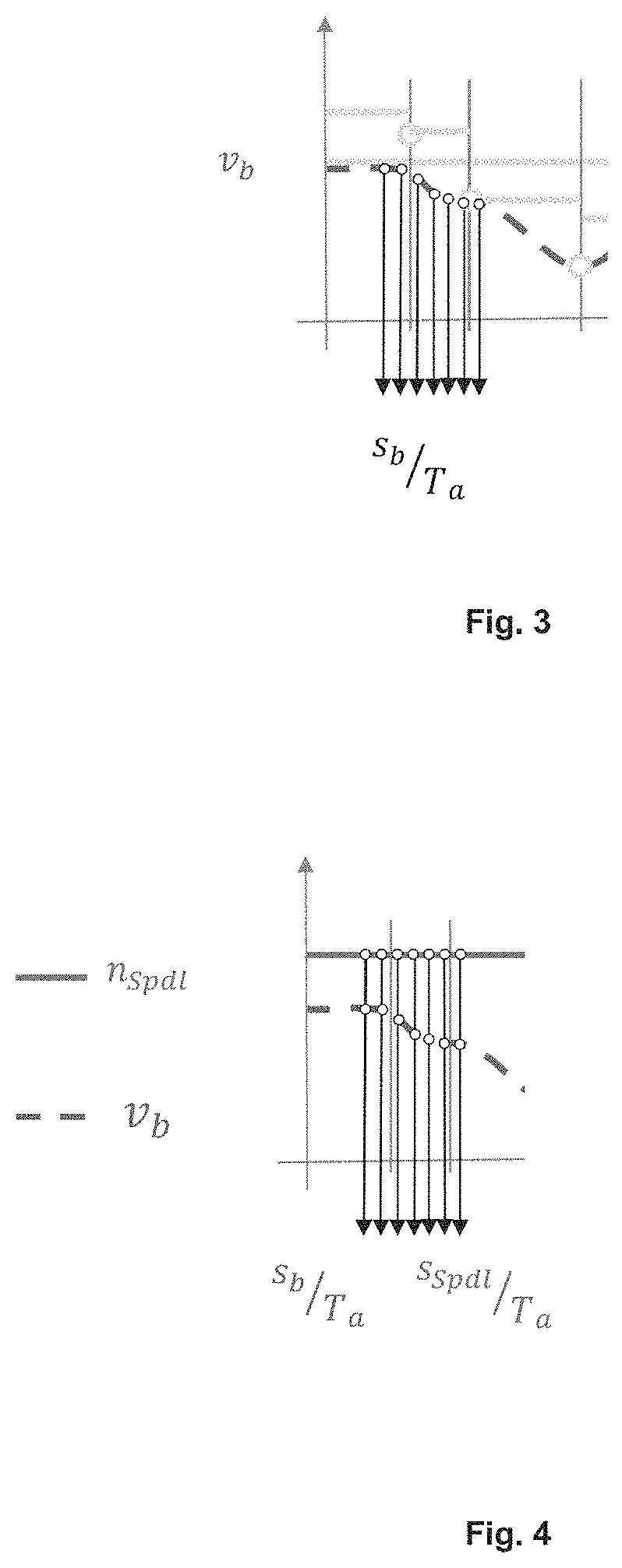

The invention discloses a method for fitting and interpolating a G01 code based on a quadratic B spline curve, comprising the following steps of: by an adaptive approach selecting each characteristic point of each group of small line segment which is described by the G01 code; fitting a route which is to be processed with the quadratic B spline curve of all the characteristic points; according to the characteristic of the quadratic B spline curve and the limit of the acceleration of each driving shaft of the numerical control machine, simultaneously obtaining the maximum permissible machining velocity curve (VLC curve) of the quadratic B spline curve and the each speed key point on the VLC curve; according to the each speed key point, the control axis of the each key point, the maximum permissible machining velocity and the VLC curve, computing real machining velocity; according the real machining velocity curve and a interpolating error computing interpolating point and completing real-time interpolation. The invention has fast computing velocity, high machining precision, stable working performance and wide application range, can complete the interpolating computation of the spline curve in real time and meet digital control processing requirement of fast velocity and high precision under a premise that the preset precision of the system is met.

Owner:ACAD OF MATHEMATICS & SYSTEMS SCIENCE - CHINESE ACAD OF SCI

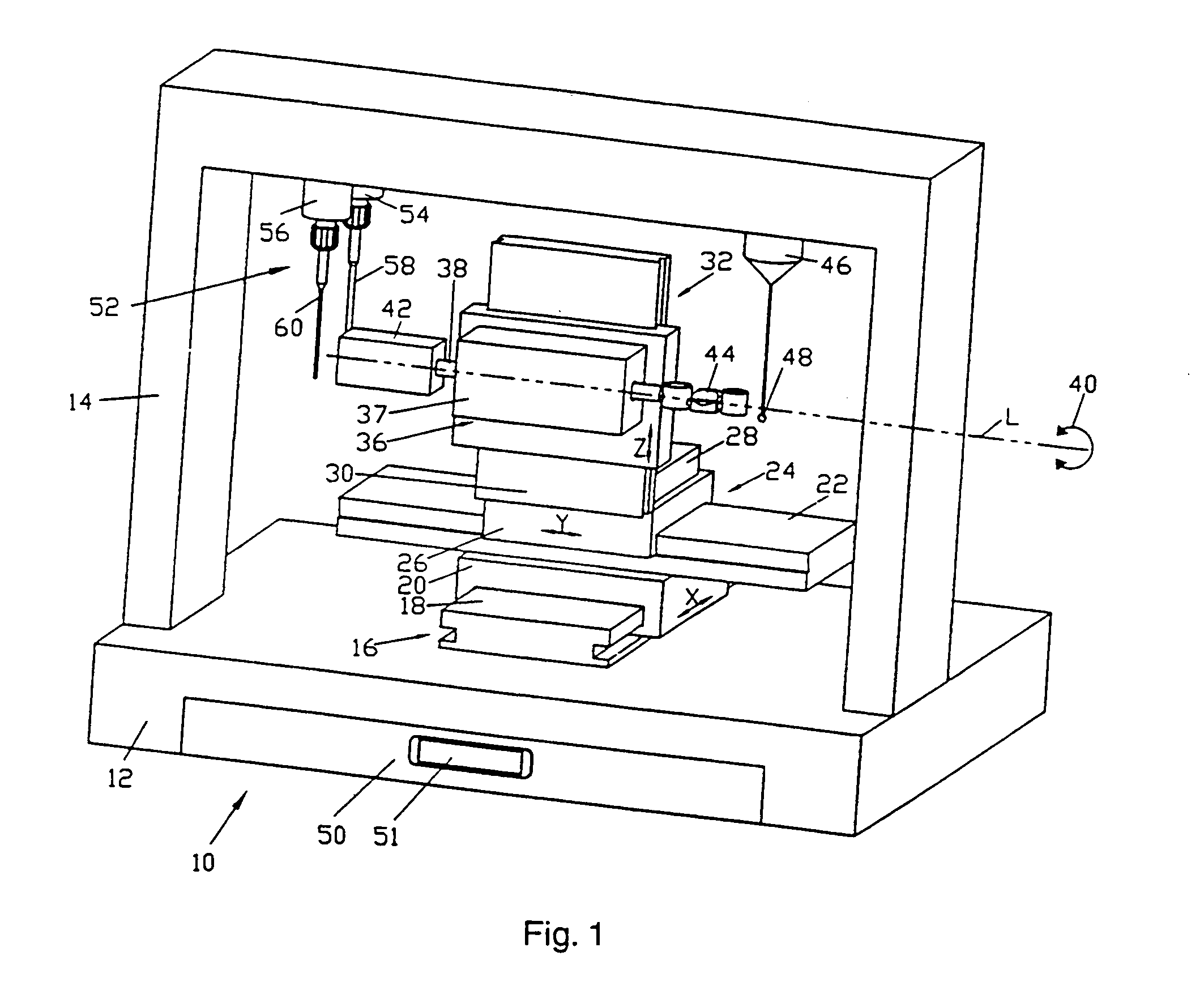

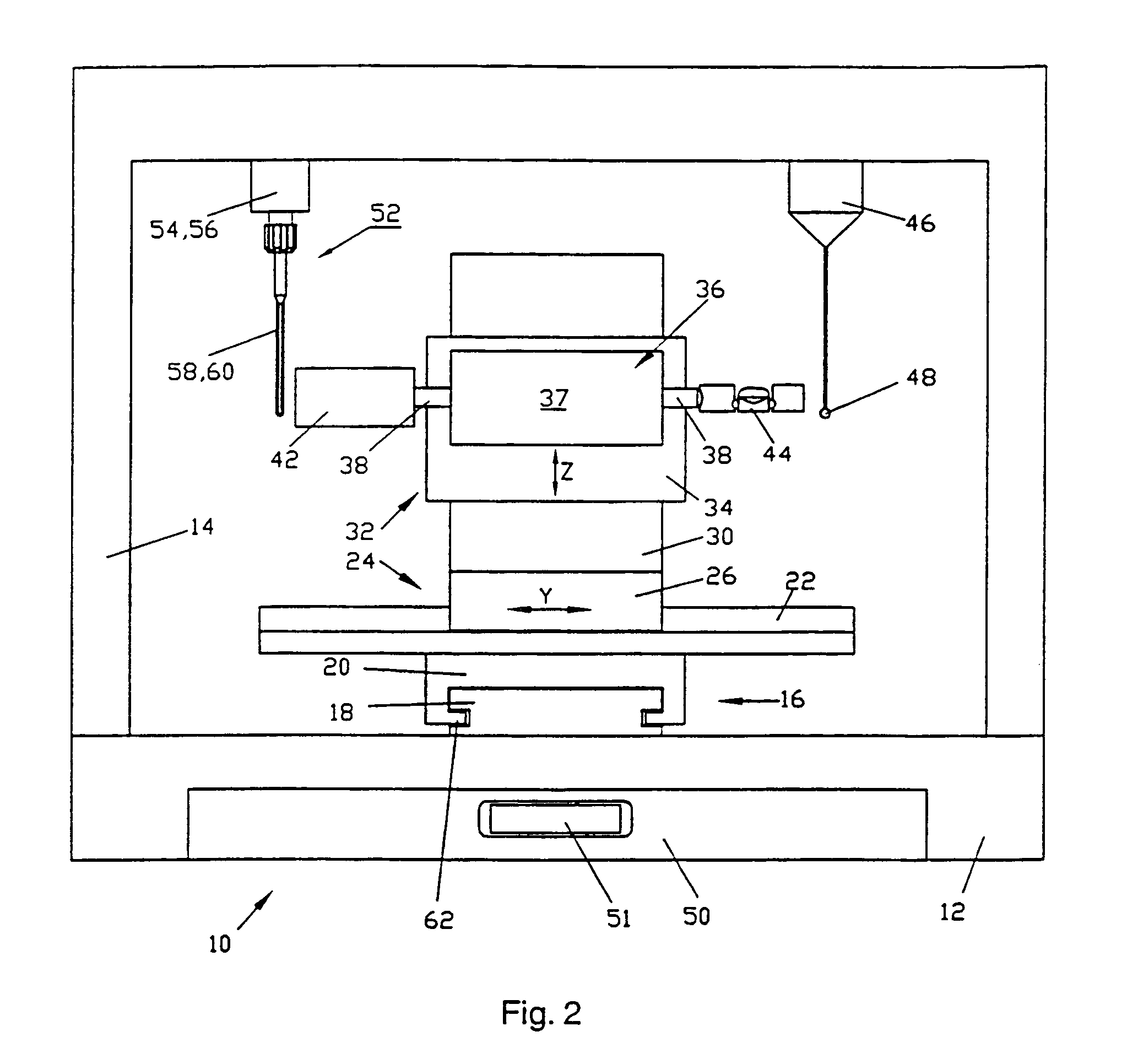

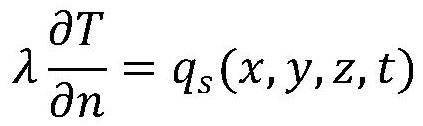

Machine tool for the production of base structures for false teeth

InactiveUS6905293B1Performance advantageAutomatic control devicesMilling machinesDenturesThree dimensional shape

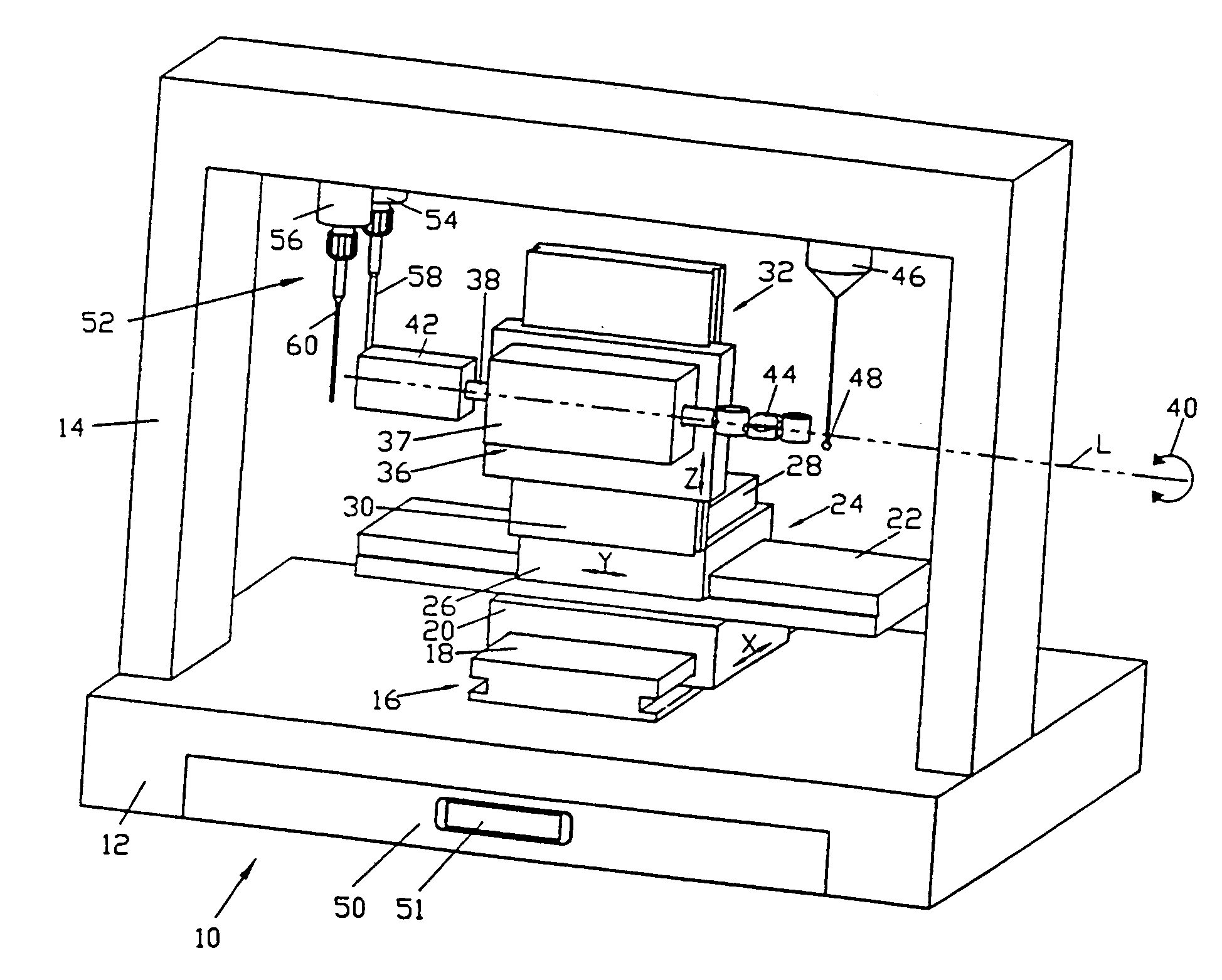

The invention relates to an automatic machine tool, for the production of base structures, for false teeth, in particular, for tooth crowns and / or tooth bridges of exact three-dimensional shape. Said base structures may be fixed to prepared natural and / or artificial tooth stumps. The machine tool comprises a machine frame, or a body, a work piece carrier, with a rotation shaft, at least one digitization unit, at least one machining unit and an electronic arithmetic and control unit for all drive lines. A carrier for the workpiece, a blank, and / or for the machining unit(s), serves as displacement unit, with three translational axes in the x-, y- and z-directions. The digitization of the preparation model and the machining of the blank are carried out on the same machine tool, at different times. The machining paths for the blank are calculated from the measured and stored digitized data and a predetermined material-specific scaling factor, before the machining of the blank.

Owner:ETH ZZURICH

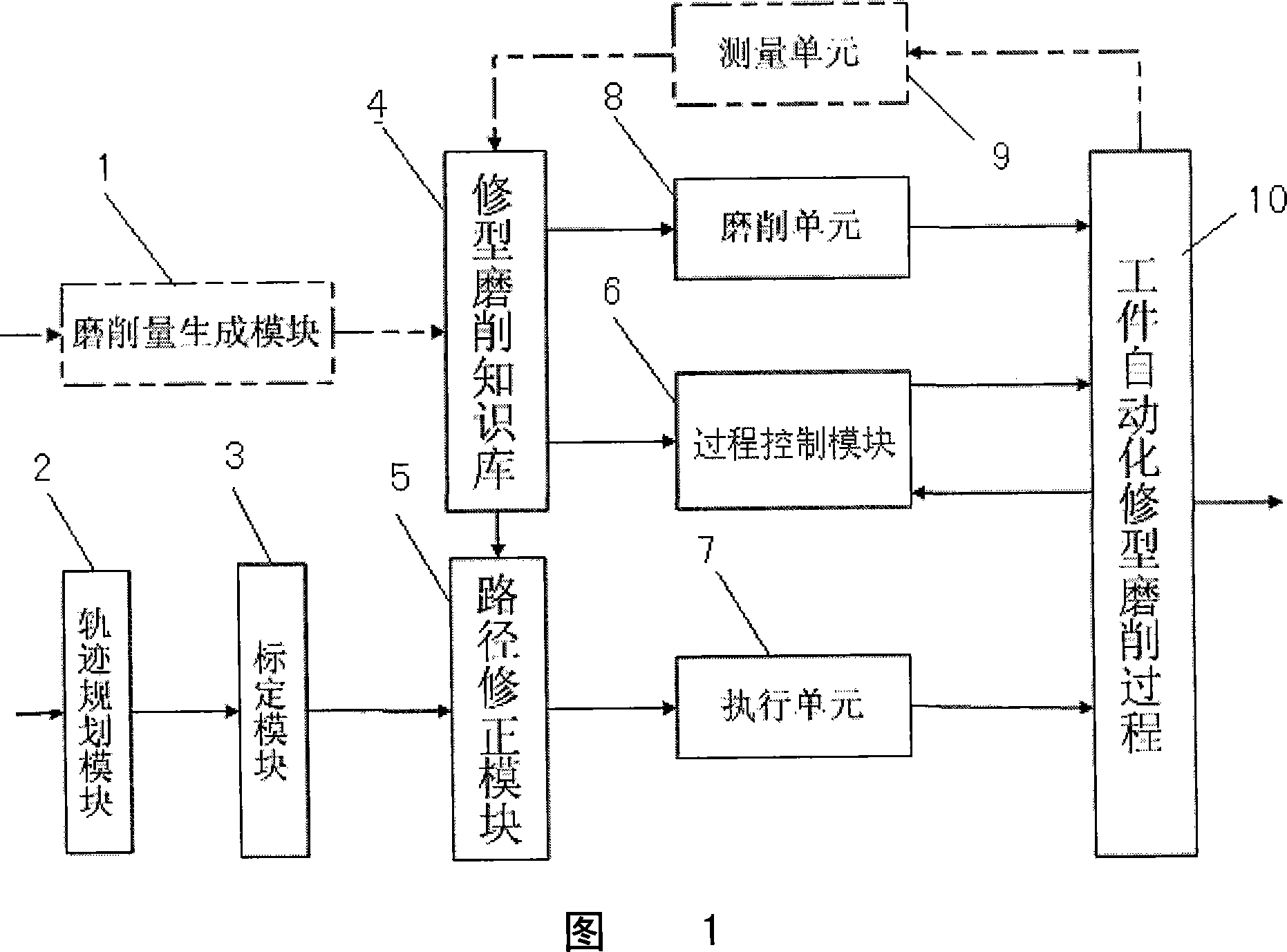

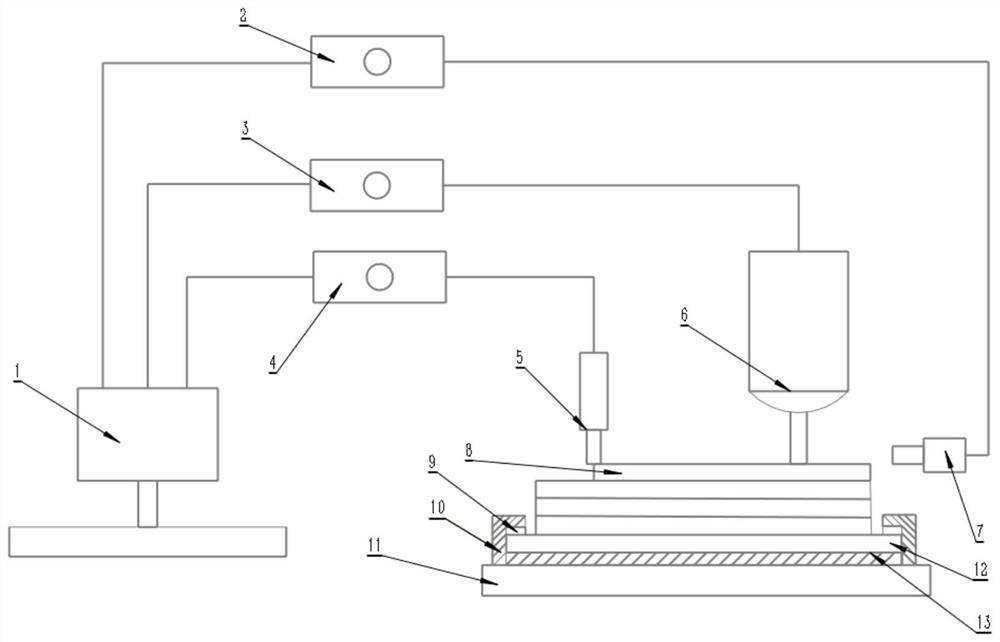

Abrasive belt grinding processing method and device capable of automatic repair and maintain for workpiece

InactiveCN101234479ARealize automatic profile grindingRealize profile grindingBelt grinding machinesAutomatic grinding controlExecution unitHigh dimensional

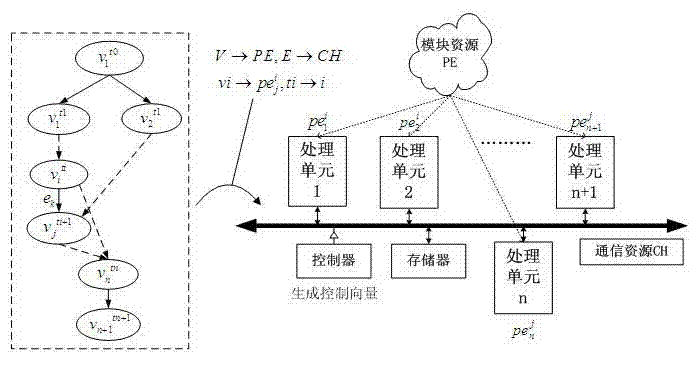

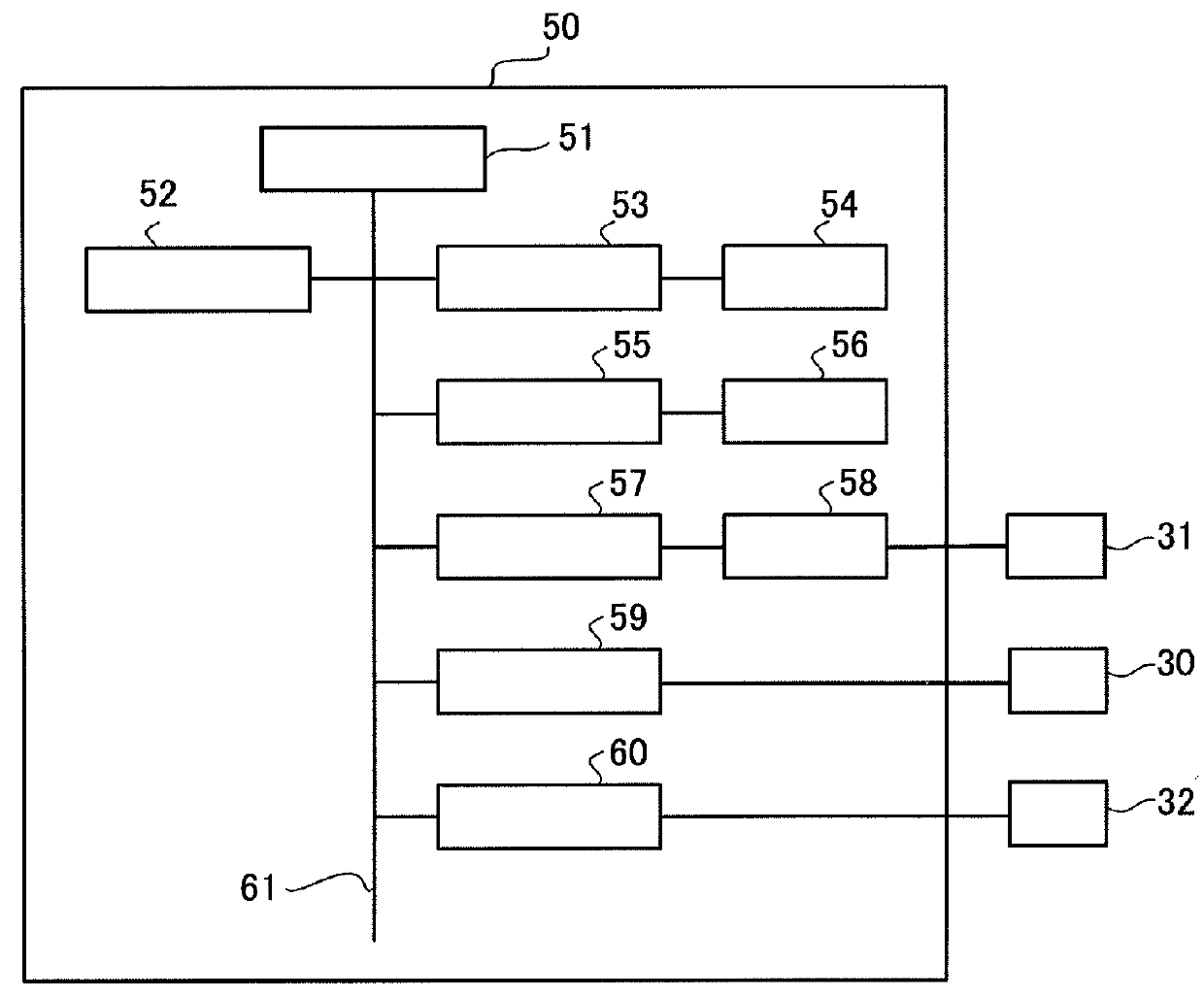

The invention relates to a belt grinding processing method which can dress workpiece automation and a device thereof. And the invention is a dressing and grinding system formed by a set of automation equipments, adopts intelligent process to control, and realizes the automation dressing and grinding processing of the complex profile workpiece in the manner of grinding belts. The device of the invention comprises a control unit, an execution unit, a grinding unit, etc., sections; wherein, the control unit comprises a plurality of software modules; the grinding and dressing knowledge base is the key software module, which can generate automatically all the grinding parameters according to the grinding amounts of all the input points; and other software modules, for example, path correction module, generate actual processing path finally according to the parameters; the execution unit is a robot or a digital machine tool, which can receive the actual processing path of the control unit, and can generate machining track; the grinding unit is a belt grinder which can receive commands from the execution unit, and can finish the dressing grinding of the workpieces. The belt grinding processing method can be widely applied in the dressing grinding processing of the workpieces with variety of high-dimensional accuracy and complex profile.

Owner:天津智通信息系统集成有限公司

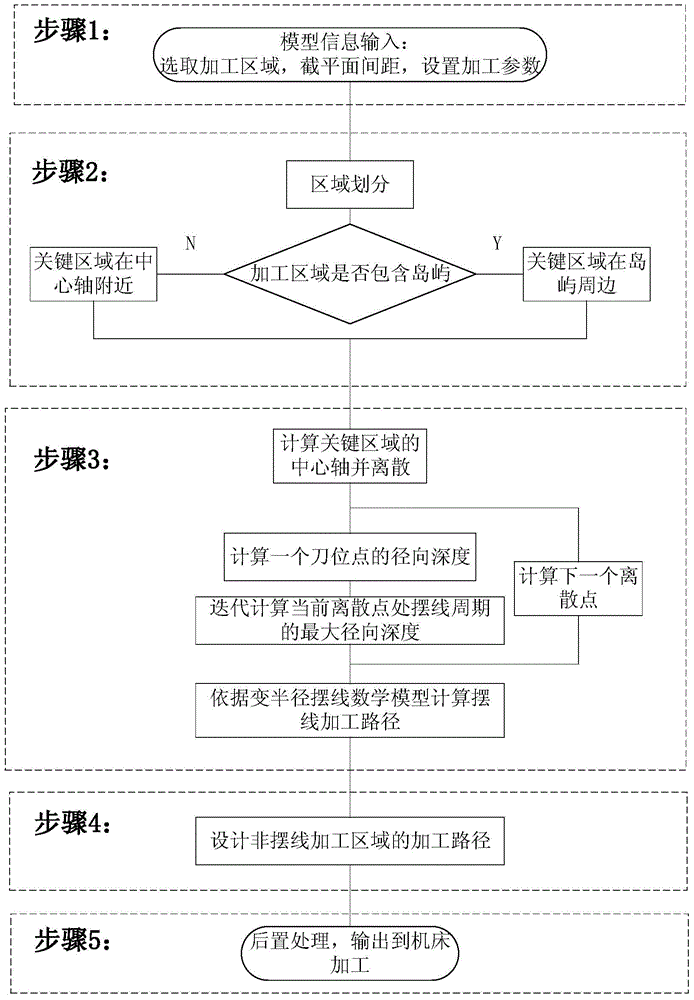

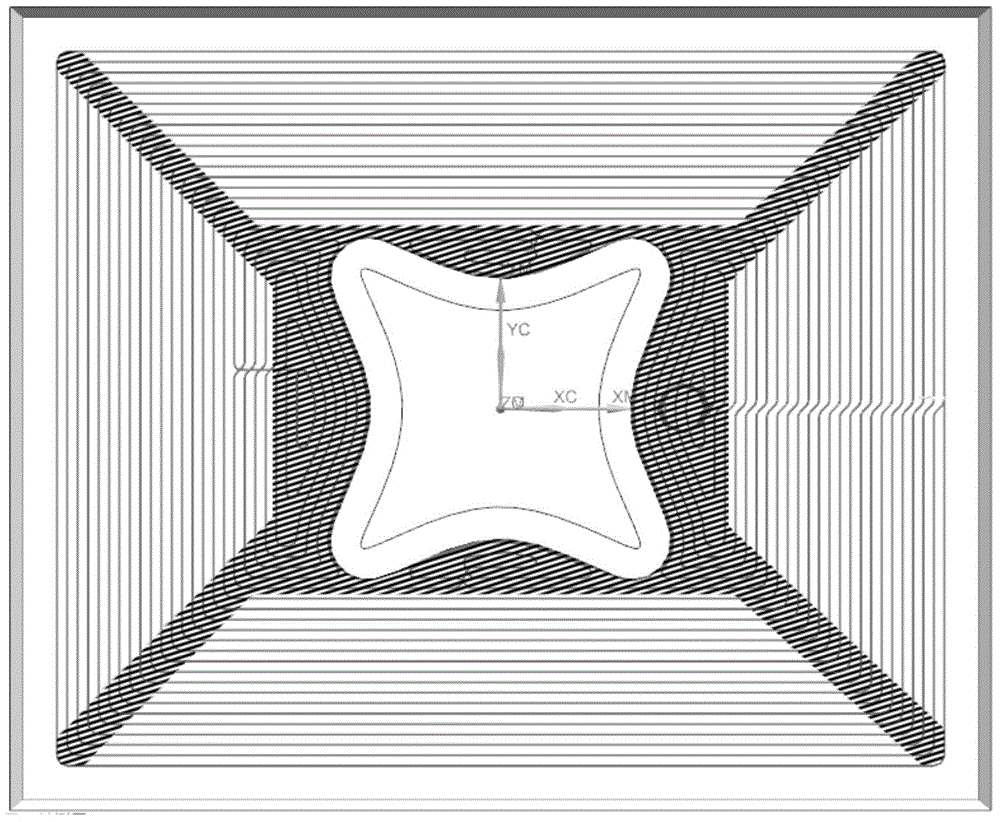

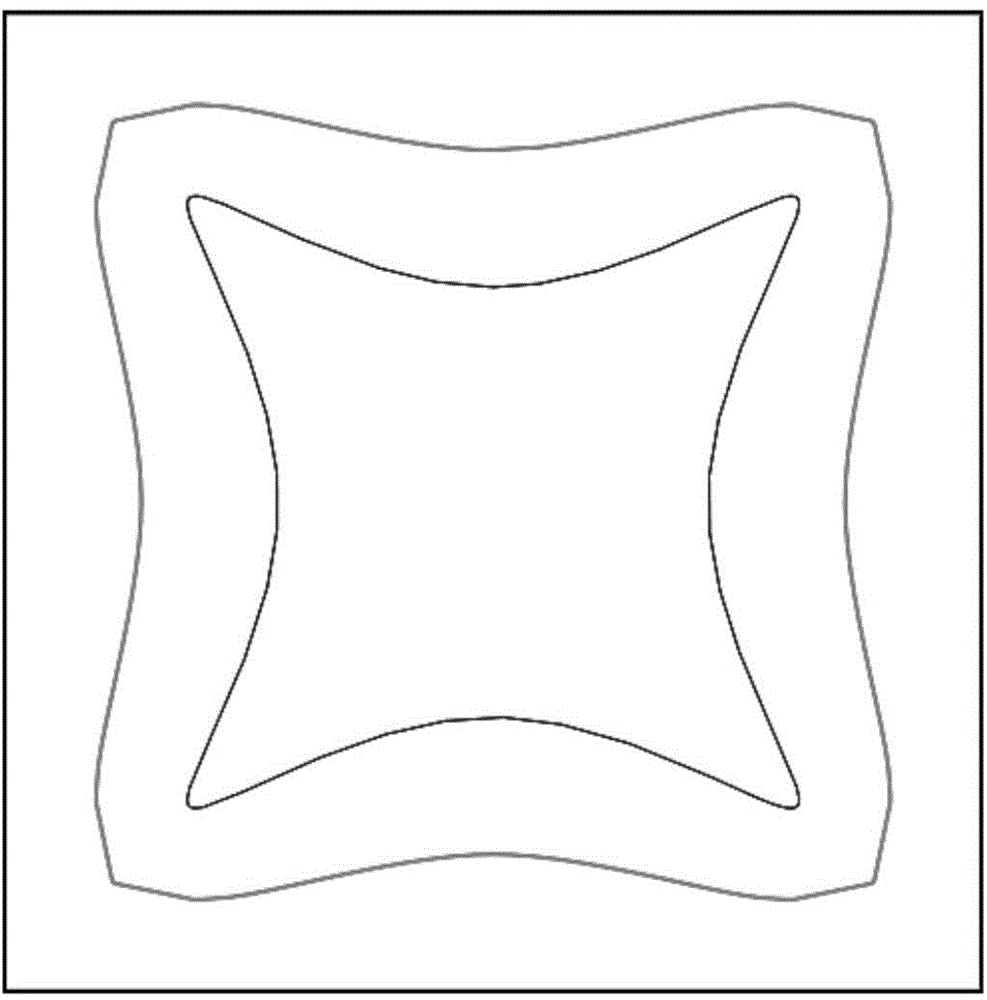

Method suitable for cycloid high-speed milling machining path

ActiveCN104090528AReduce redundancyShorten the lengthProgramme controlComputer controlMathematical modelCutter location

The invention discloses a method suitable for a cycloid high-speed milling machining path. The method includes the steps of firstly inputting part model information and part characteristic information, and automatically dividing a machined area to obtain a key cycloid machined area and a traditional cycloid machined area; according to boundary information of the key area, calculating a cycloid center path, carrying out dispersing, and iteratively calculating the cycloid single-cycle maximum radial depth of each discrete point with the simplex method; then, screening the discrete points of the variable-radius cycloid center axis according to the maximum radial cutting-in depth; after screening is completed, calculating the cycloid machining path of the key area according to a mathematic model of a variable-radius cycloid, and carrying out dispersing on cutter location points; finally, machining left areas with a traditional machining method. By means of the method, the cycloid path is short, the time for passing through an idle-cutting path is short, and the redundancy is low; the cutter contact angle and the radial cutting-in depth can be kept relatively stable, the problems that in the high-speed milling process, the cutter contact angle is prone to sudden change, and the idle-cutting path is long are solved, the machining path is stable, and the milling efficiency is improved.

Owner:ZWCAD SOFTWARE CO LTD

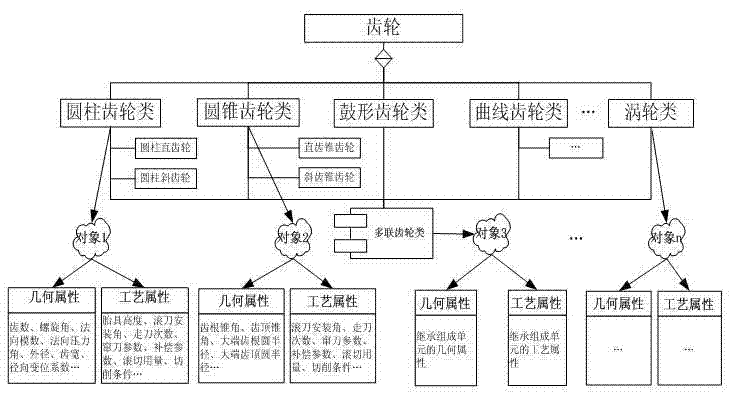

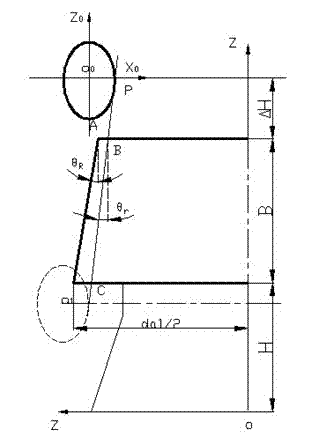

Method of CNC automatic programming for gear hobbing based on standard template and expression driving

InactiveCN103197605AImprove standardizationQuality assuranceProgramme controlComputer controlNumerical controlHobbing

The invention discloses a method for CNC automatic programming of gear hobbing based on a standard template and expression driving. The method includes the following steps: 1, through a human-computer interaction interface, a numerical control programmer selects a workpiece and a tool and sets necessary machining parameters; 2, a mathematical model corresponding to a gear in a hobbing model base is automatically called by a system, point coordinate values of tooling paths are calculated, and all technological parameter data needed by the machining are confirmed; 3, according to an NC standard template structure and a NC standard template module, the NC standard template of the gear is automatically generated, and a gear template base is built; and 4, the system calls the NC standard template from the gear template base and intensively extracts parameter values from the technological parameter data, instantiation of the NC standard template is completed through an expression driving algorithm, and a numerical control program is obtained. The method for the CNC automatic programming of the gear hobbing based on the standard template and the expression driving has the advantages of being capable of achieving the automatic programming of the gear hobbing.

Owner:CHONGQING UNIV

Machining method based on Bezier curve corner smooth transition algorithm

ActiveCN111061213ASolve the feed rateError controllableNumerical controlManufacturing computing systemsAlgorithmEngineering

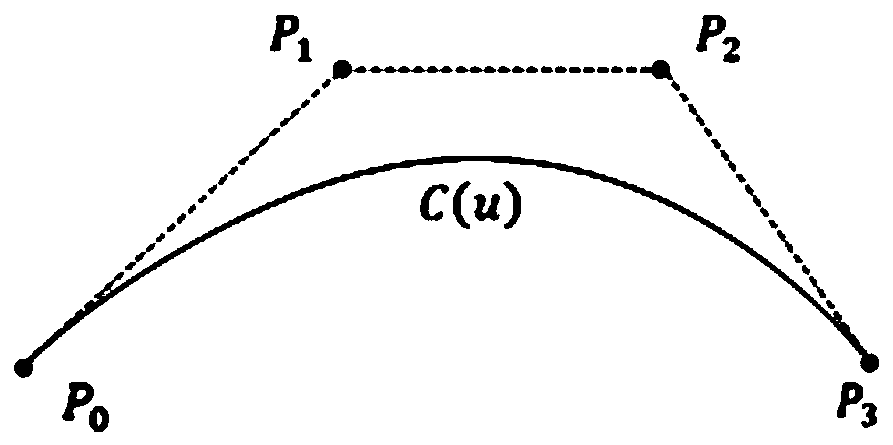

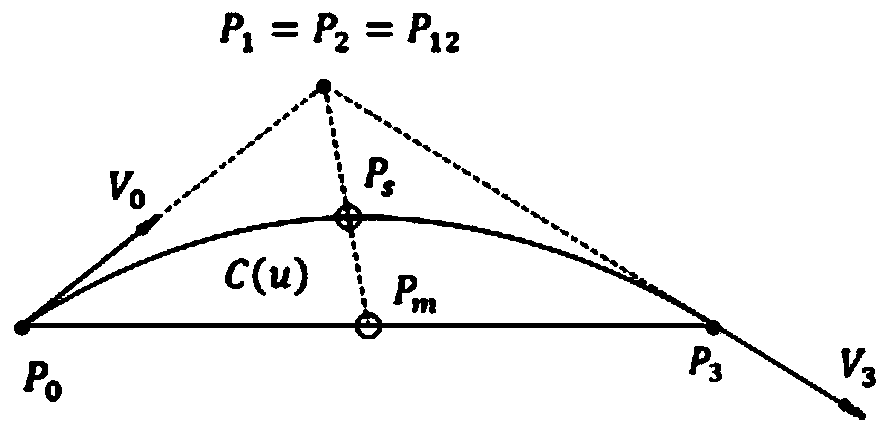

The invention discloses a machining method based on a Bezier curve corner smooth transition algorithm. The machining method comprises the following steps: firstly, acquiring discrete data points of the tracks of small line segments by using CAD / CAM software; secondly, reading in three data points, marking a middle point as an inflection point, and calculating the length, the rotation angle and theunit direction vector of micro line segments on the two sides of the inflection point; thirdly, constructing different corner arc transition vector models with G2 continuous characteristics accordingto the value range of the central angle; fourthly, calculating a transition error and a curvature extreme value, determining the positions of transfer points on the two sides of the corner and the length of a transition section according to a preset approximate error constraint and a maximum curvature limit, and substituting the positions and the length into the model to solve a transition curve,thus completing smooth transition of one corner; and fifthly, repeatedly reading in data points, sequentially finishing smooth transition of all corners, and outputting a processing path for realizing smooth connection between small line segments by adopting the transition curves.

Owner:TIANJIN UNIV

Method for generating numerical control machining toolpath through triangular Bezier surface

InactiveCN102091966AEasy accessAccurate acquisitionAutomatic control devicesFeeding apparatusNumerical controlEngineering

The invention provides a method for generating a numerical control machining toolpath through a triangular Bezier surface, which is characterized by comprising the following steps of: planning tool location drive points according to model characteristics of a triangular Bezier surface model, acquiring an instantaneous machining area based on dynamic indexes of the triangular Bezier surface, calculating a tool location point corresponding to each triangular Bezier surface in the instantaneous machining area through iteration, taking a tool location point with the highest projection position in a tool shaft direction as a current tool location point, performing interference-free tool location point calculation on the tool location drive points one by one, detecting a limit machining error between adjacent tool location points, controlling the toolpath accuracy by adopting a binary interpolation method, and generating the numerical control machining toolpath which meets the accuracy requirement. Experiments prove that the method is quick in toolpath generation and high in accuracy, and is suitable for generating a numerical control machining ball toolpath through a complicated triangular Bezier surface.

Owner:SHANDONG UNIV OF TECH

Milling method

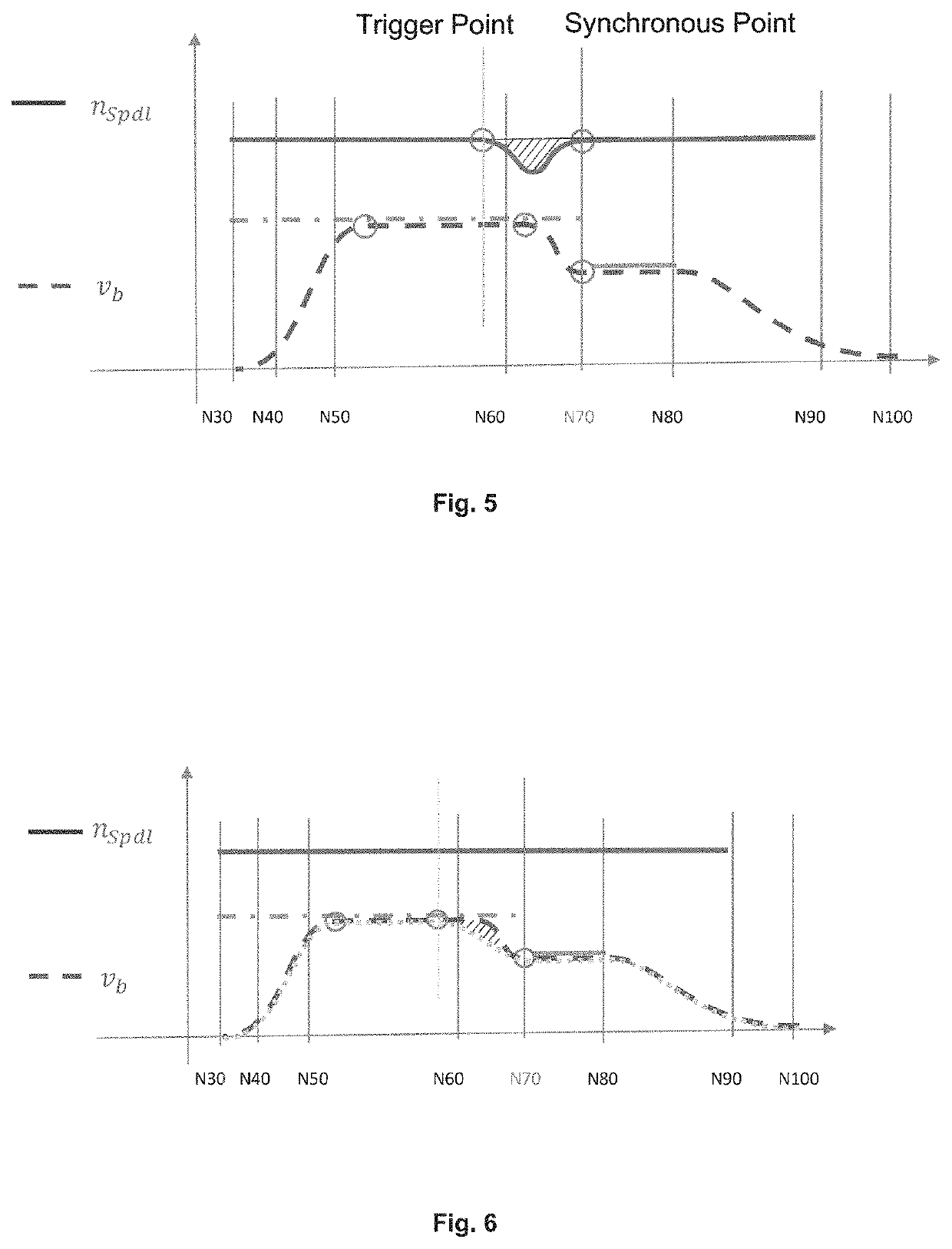

The invention relates to a method for machining a workpiece by means of a milling tool arranged on a rotatable spindle, the spindle being moved relative to the workpiece or the workpiece being moved relative to the spindle along a machining path and, at the same time, the spindle rotating about a spindle axis. In said method, an improvement in the surface quality is achieved by controlling the rotational speed and / or the phase position of the rotation of the spindle along the machining path, the machining path comprising linear parallel tracks and the phase position of the spindle along the machining path being substantially the same on adjacent tracks, the phase position being controlled by varying the rotational speed of the spindle and / or the advancing speed of the spindle relative to the workpiece along the machining path.

Owner:EXERON

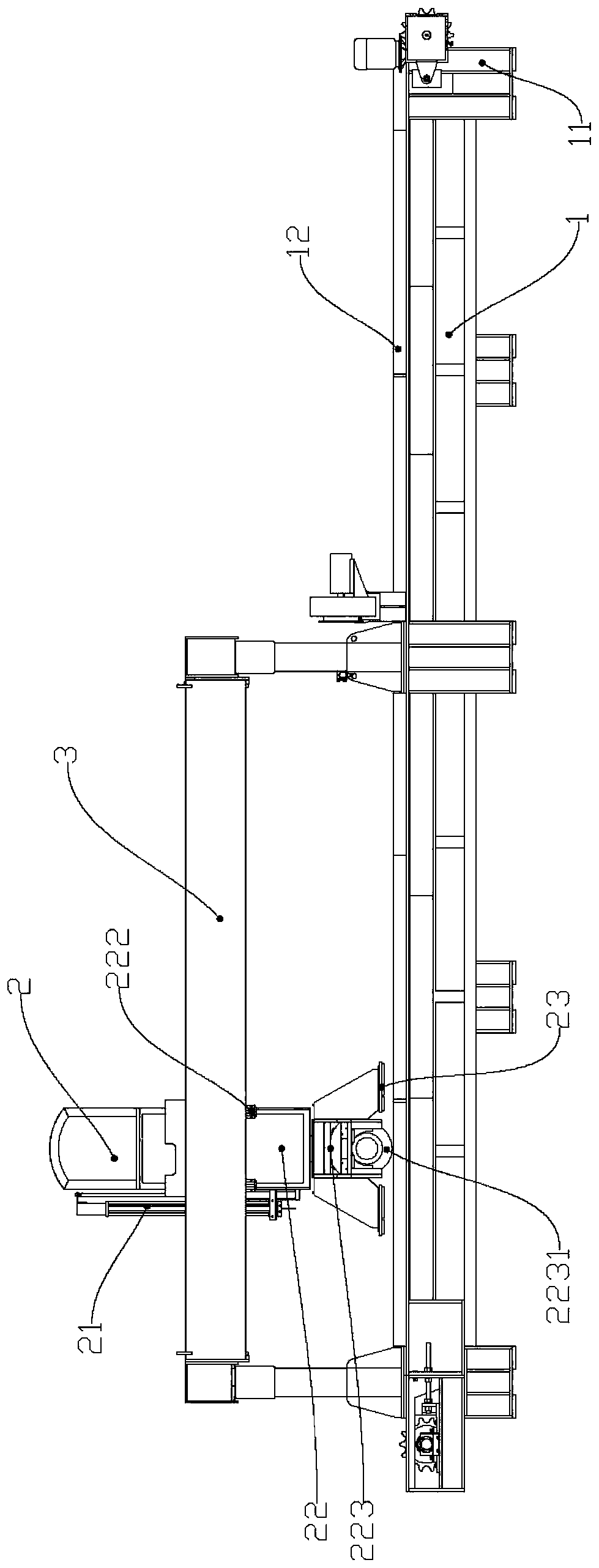

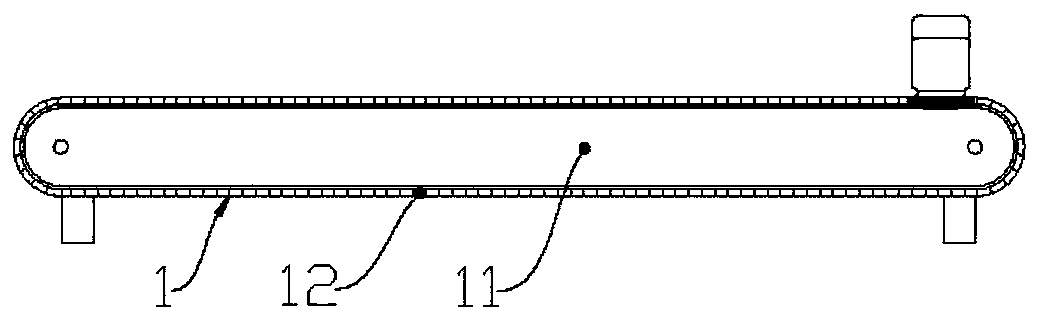

Bending-straightening machine for a long workpiece, device for feeding in and removing said workpiece and method for bend-traightening long workpieces

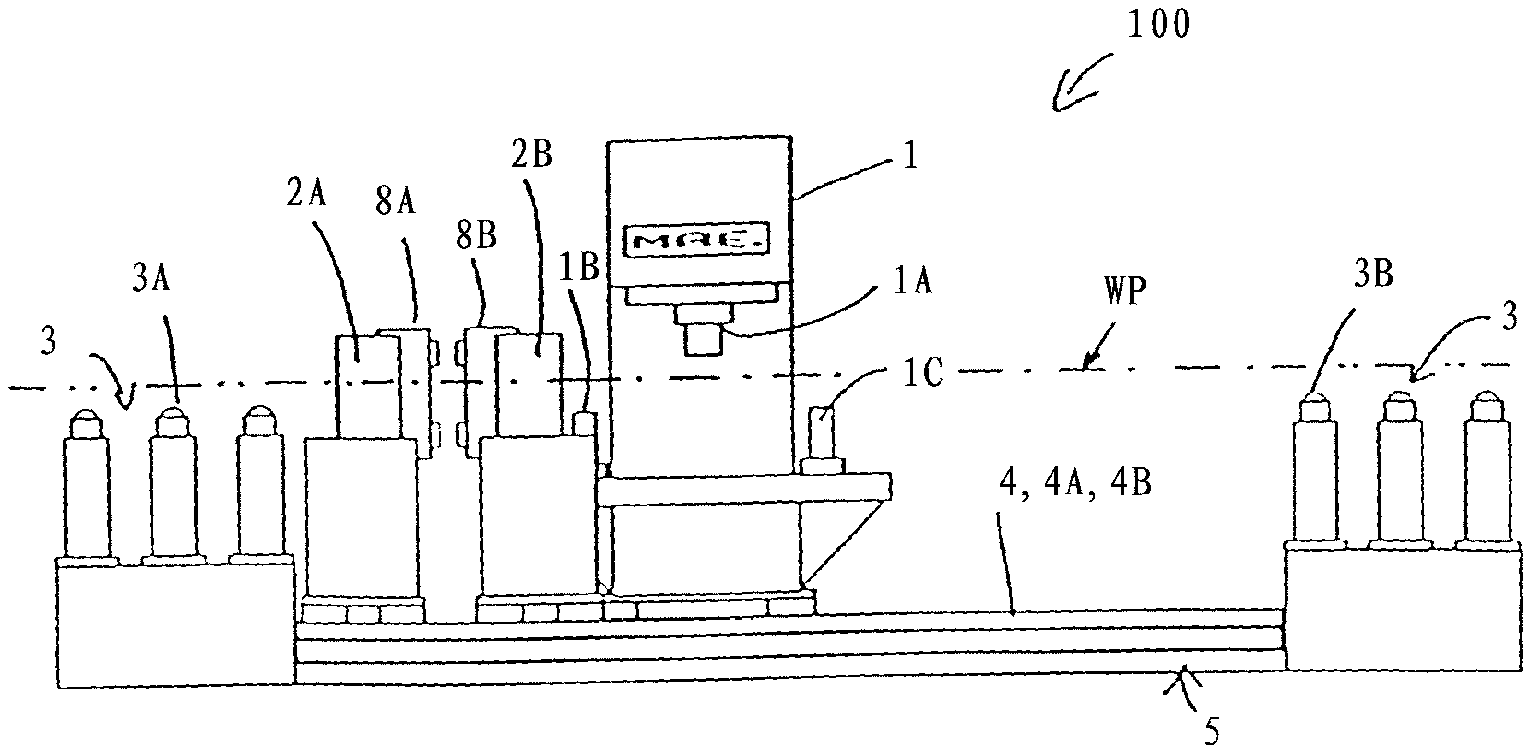

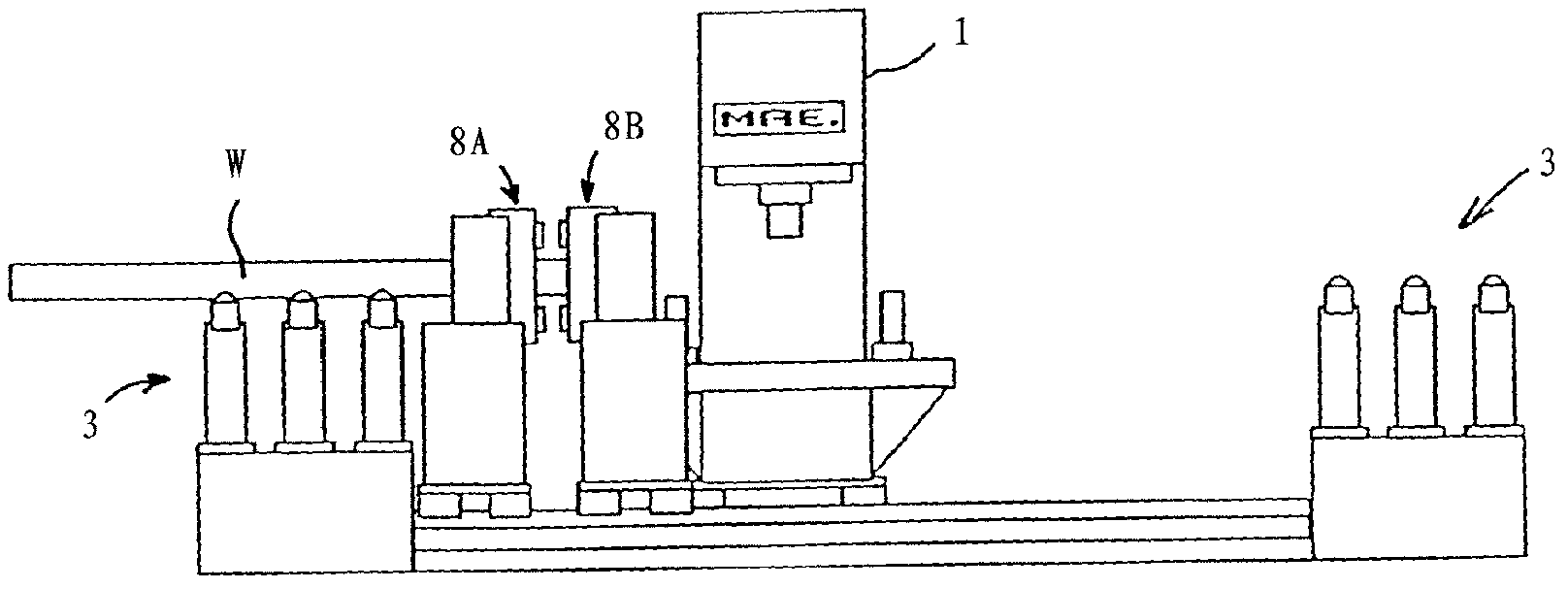

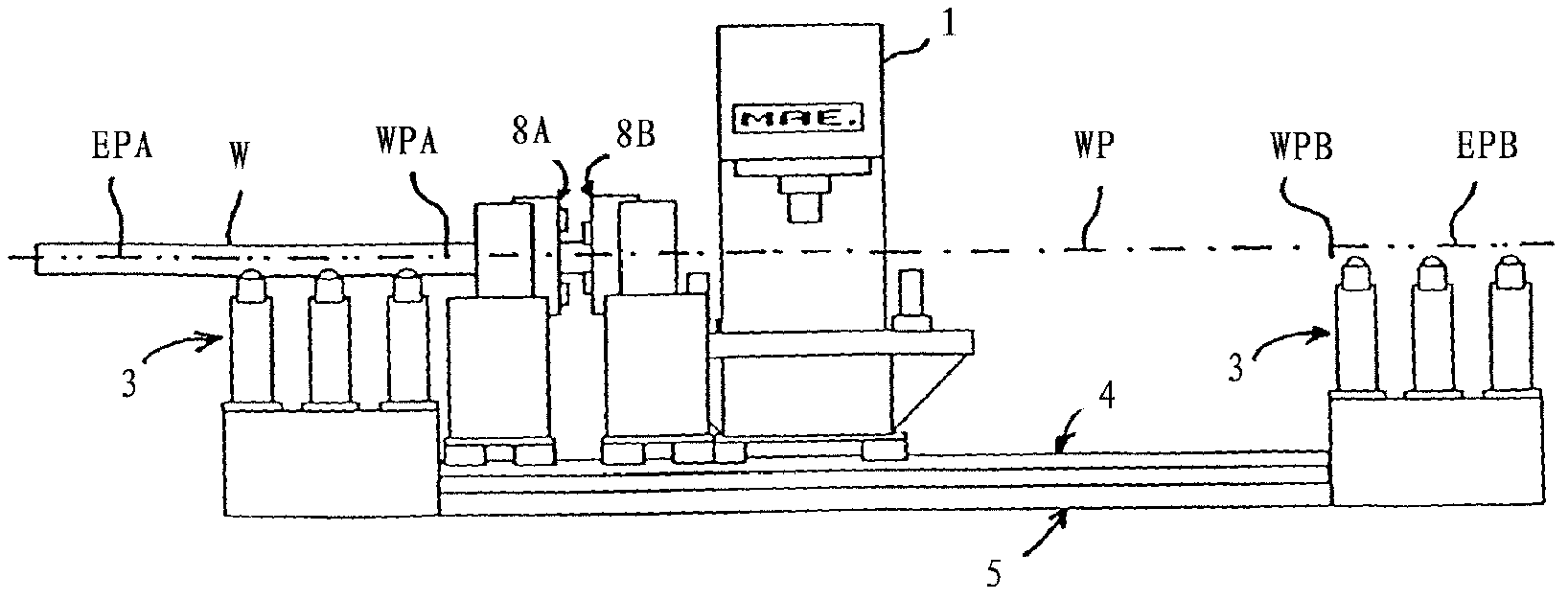

ActiveCN103228373AUnlimited useUnlimited choicesMetal-working feeding devicesPositioning devicesMachineIndustrial engineering

The invention relates to a device for feeding long workpieces (W) into and removing same from a processing machine, such as a bending-straightening machine, in which the long workpiece (W) located in the processing positions defines a processing section (WP) and the long workpiece (W) is supported at both end regions thereof by a respective gripping arrangement (2A, 2B). In straight extension (EPA, EPB) of the processing section (WP), a horizontal conveying means (3) for the long workpiece (W) adjoins at least one head end (WPA, WPB) of the processing section (WP). At least one of the gripping arrangements (2A, 2B) has a gripper head (8A, 8B) for frictionally gripping an end (WA, WB) of the workpiece (W) conveyed by the horizontal conveying means and drive means for drawing the workpiece (W) to be straightened into the processing section (WP) and for pushing out the straightened workpiece onto the at least one horizontal conveying means by means of the gripper head.

Owner:MAE MASCH U APP GOETZEN GMBH & CO KG

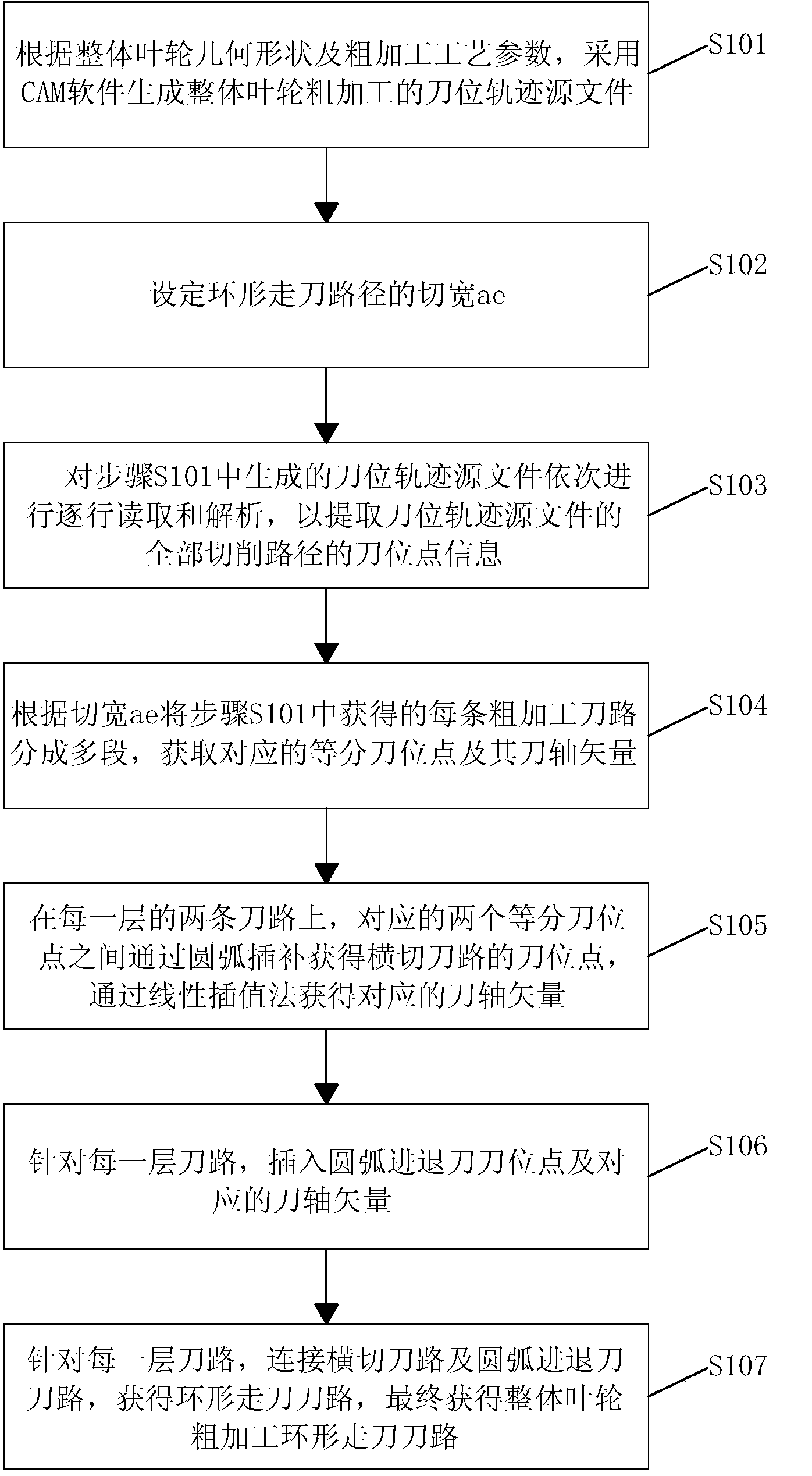

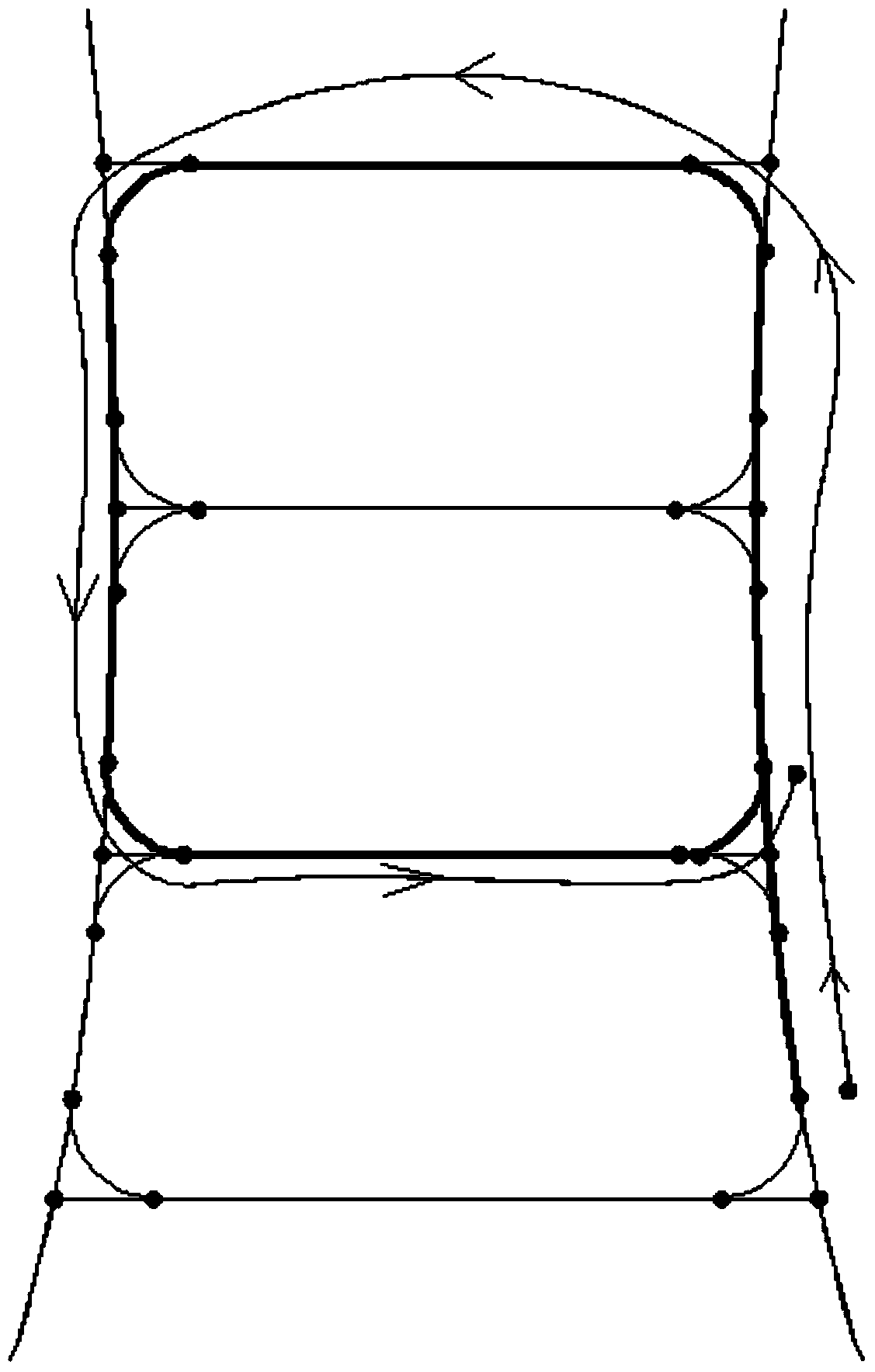

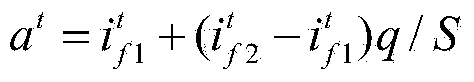

Annular feed path planning method of integral impeller rough machining

ActiveCN104181865AReasonable distributionReduce wearProgramme controlComputer controlImpellerControl theory

The invention discloses an annular feed path planning method of integral impeller rough machining. According to the method, an existing bilateral-offset feed mode is replaced by the feed mode perpendicular to the impeller axial direction, each transverse cutting path perpendicular to the impeller axial direction is connected through an arc feeding and retracting cutter to form an annular cutting path, and a layer of rough machining path is composed of a plurality of annular cutting paths. By means of the method, through reasonable machining feed path planning, the total length of the feed paths is shortened, and the problem of the low machining efficiency caused by redundant machining feed paths existing in a traditional integral impeller rough machining method is solved.

Owner:JIANGSU JITRI HUST INTELLIGENT EQUIP TECH CO LTD

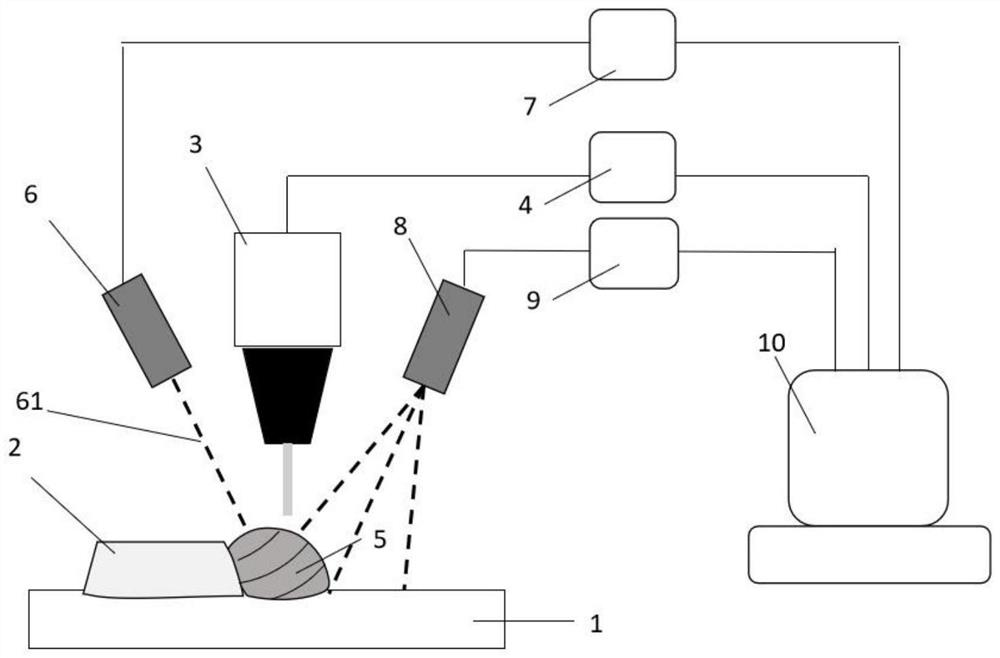

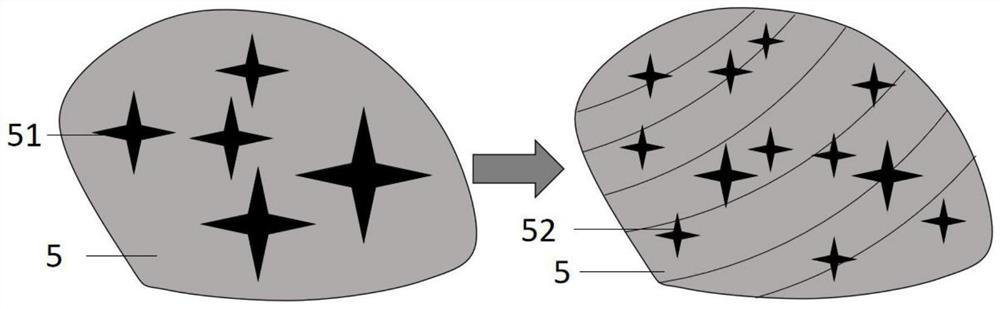

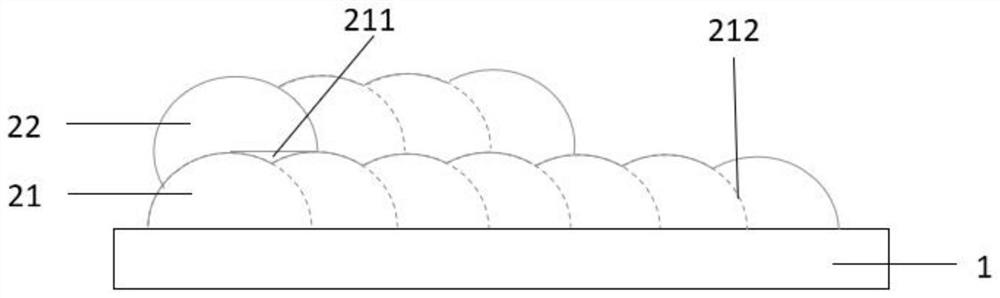

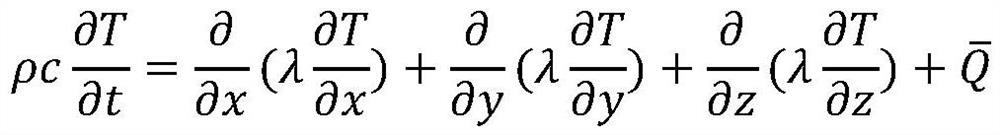

Laser shock assisted electric arc additive manufacturing method

The invention relates to a laser shock assisted electric arc additive manufacturing method, belongs to the field of additive manufacturing, and solves the problems that in the prior art, grains in anelectric arc additive component are thick and large, and holes, oxides and other defects exist. The laser shock assisted electric arc additive manufacturing method comprises the following steps that 1, an electric arc additive machining path is designed; 2, electric arc additive machining parameters are set; 3, the included angle between a laser cleaning head and a welding gun and machining parameters of a pulse laser cleaning machine are determined; 4, the included angle between a laser shock wave emitting head and the welding gun and machining parameters of a pulse laser shock emitter are determined; 5, the welding gun, the laser shock wave emitting head and the laser cleaning head work synchronously; and 6, an electric arc additive part is obtained according to the additive path. According to the laser shock assisted electric arc additive manufacturing method, through cooperative work of an electric arc additive device, a laser cleaning device and a laser impact device, the problemsthat the grains in the electric arc additive component are thick and large, and the holes, the oxides and the other defects exist are solved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Electric arc-laser composite additive manufacturing method

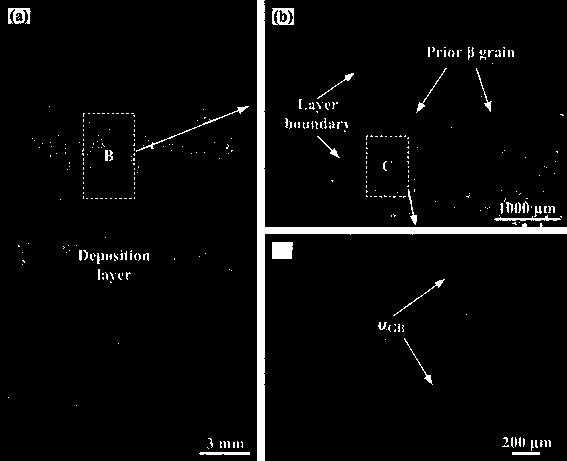

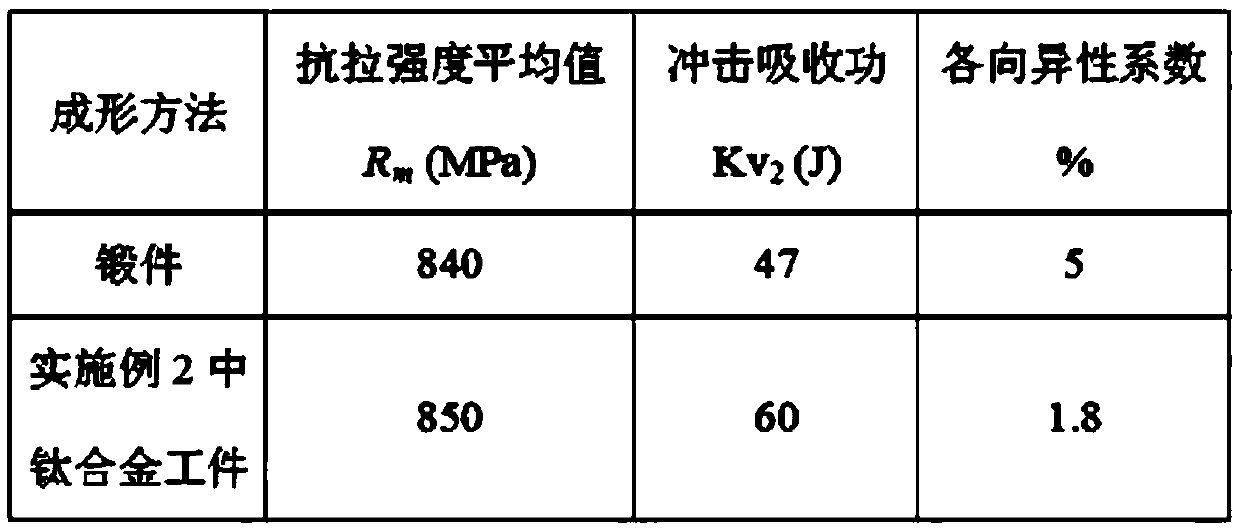

InactiveCN110860797AReduce internal stressControl forming precisionLaser beam welding apparatusLaser scanningMartensite

The invention discloses an electric arc-laser composite additive manufacturing method. The method comprises the following steps that the surface of a metal part to be machined is subjected to mechanical polishing, cleaning for oil stain removing and drying, the size of the metal part is measured, and then the metal part is placed on a workbench and fixed with a clamp for standby use; a three-dimensional model of the metal part to be machined is established to obtain a three-dimensional model file, the file is subjected to slicing treatment, a machining path of the electric arc additive material is obtained, process parameters of the electric arc additive material are set, and the part to be machined is subjected to layered sedimentation under an inert gas environment by adopting an electric arc fuse wire; and according to the texture of the machined metal part and the effective wall thickness of a to-be-printed layer, a corresponding laser scanning track, scanning power and scanning speed are selected through simulation of a temperature field, and the printed cladding layer is subjected to laser heat treatment. According to the method, the coarse columnar crystals in the forming part can be improved, the martensitic structure and dislocation are reduced, the anisotropy of additive manufacturing is remarkably reduced, and the forming precision is effectively controlled.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

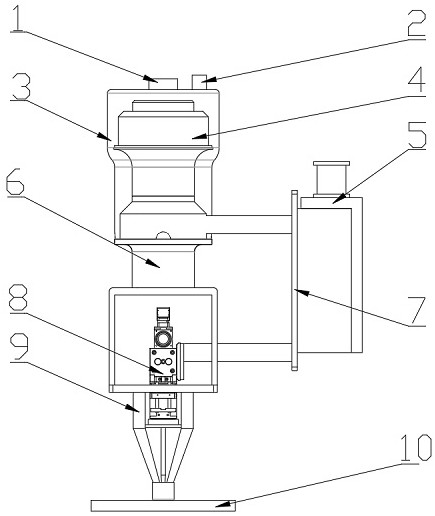

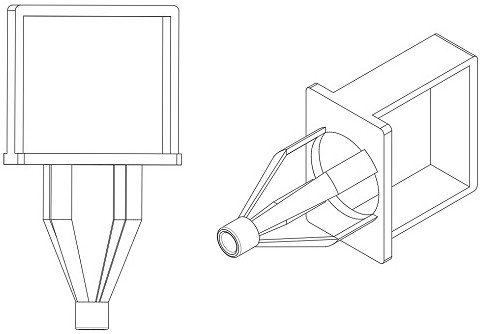

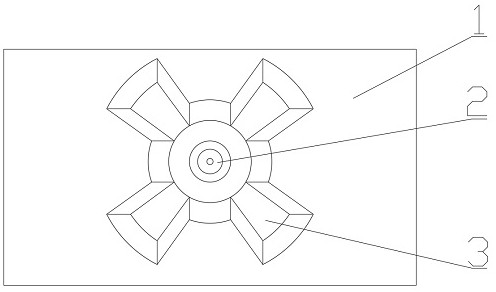

Ultrasonic impact and deposition forming integrated device and technology for improving structure and performance of additive manufacturing metal component

InactiveCN112342366AImprove cooling efficiencyGuaranteed concentrationAdditive manufacturing apparatusIncreasing energy efficiencyMaterial defectMetallic materials

The invention provides an ultrasonic impact and deposition forming integrated device and technology for improving the structure and performance of an additive manufacturing metal component, and belongs to the field of metal material additive manufacturing. A deposition forming device and an ultrasonic impact tool head are coaxially assembled, the impact path can be synchronously changed along withany machining path, an annular ultrasonic micro-forging tool head carries out synchronous impact forging along with a deposition layer in the metal deposition process, on the basis that plastic deformation happens to the deposition layer, the novel integrated impact device can promote dynamic recrystallization happening in a high-temperature area above the recrystallization temperature, and therefore grains are refined, material defects are reduced, and residual stress is eliminated. Compared with an existing device, according to the integrated device, the acting depth and the impact effect can be greatly improved, meanwhile, complex workpiece forming path planning and the ultrasonic impact path can be combined into one, the machining procedure of the complex metal component is greatly simplified, and design and manufacturing of a high-end machining center for forging increasing and reducing composite manufacturing are facilitated.

Owner:哈船制造科学研究院(烟台)有限公司 +2

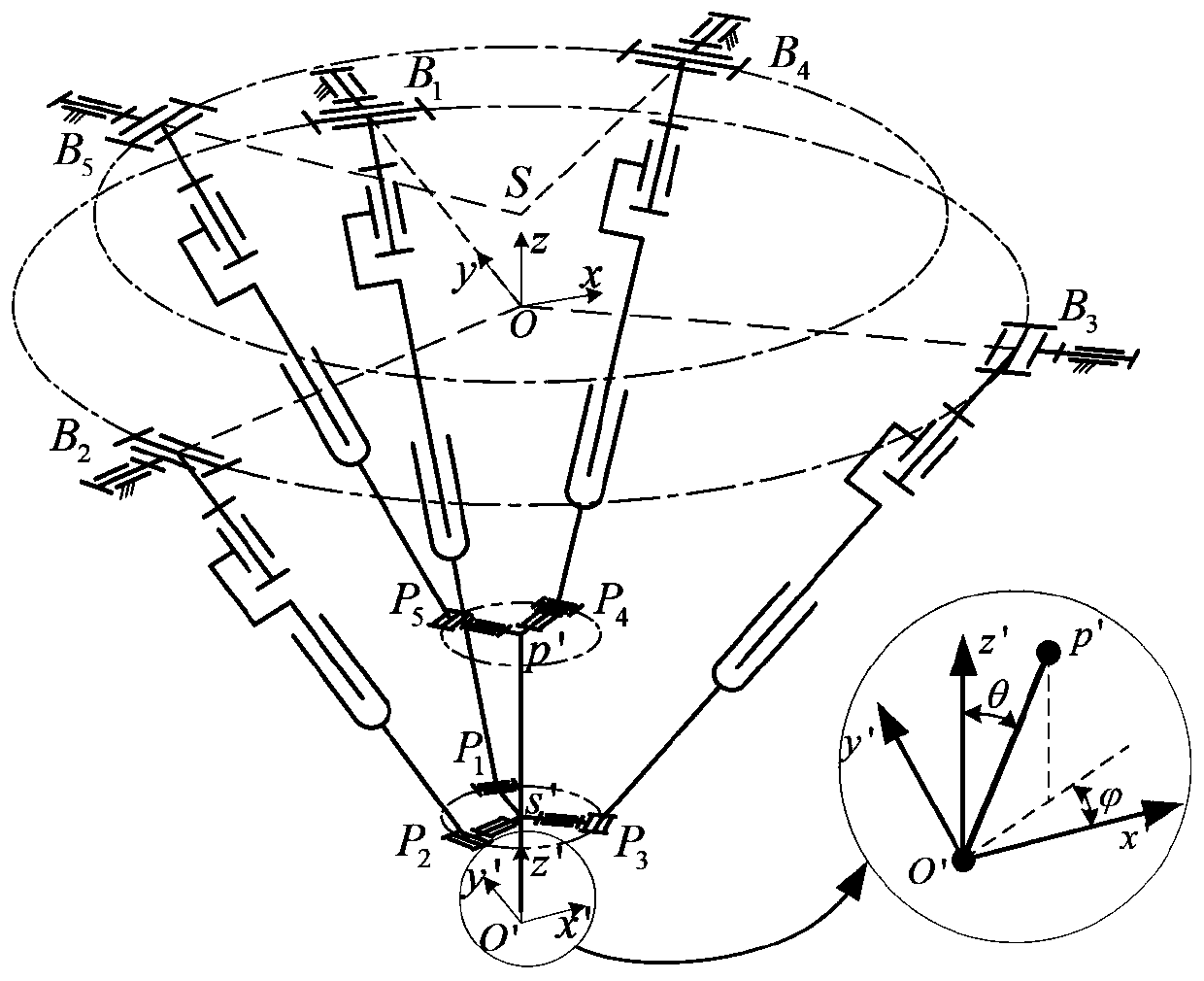

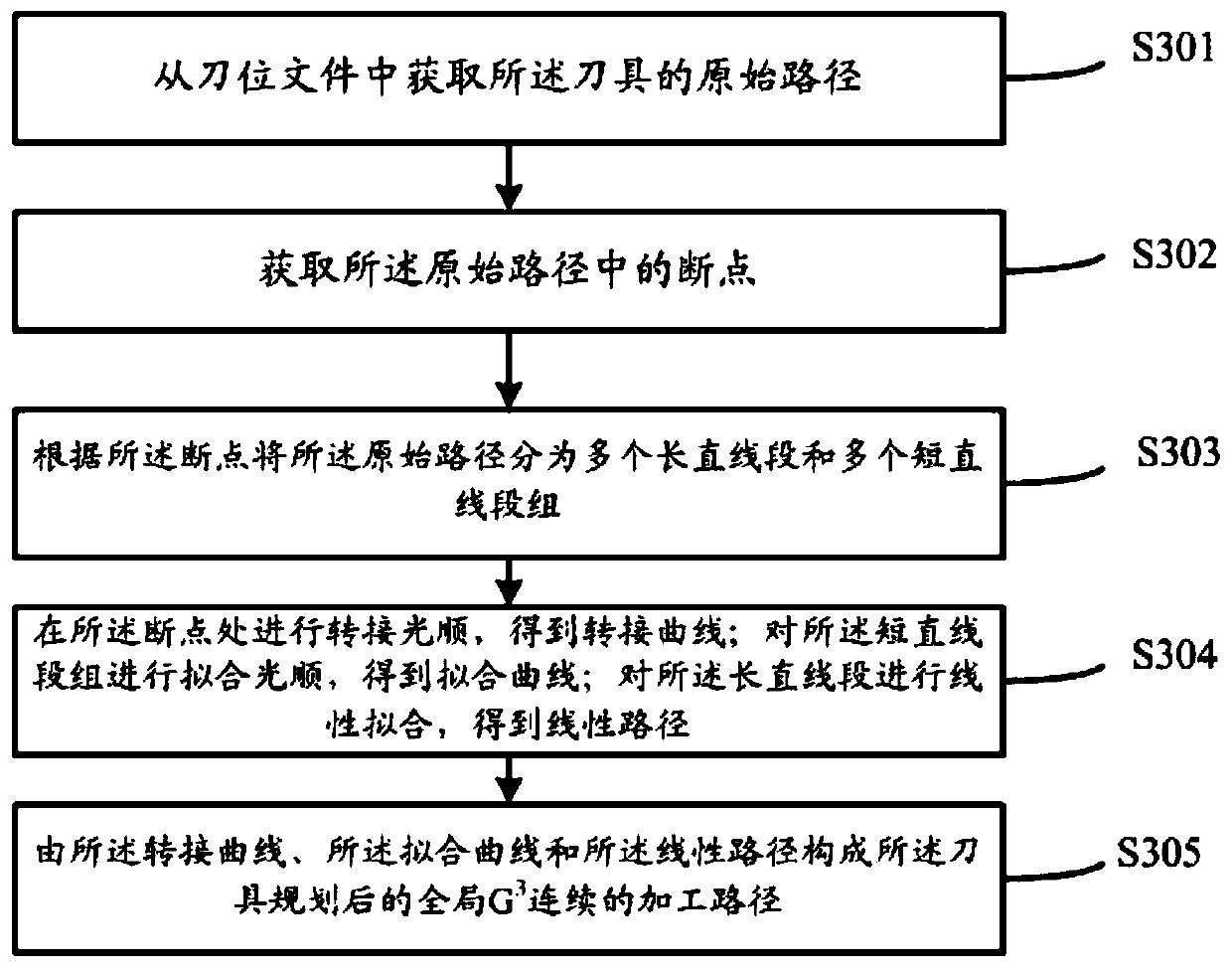

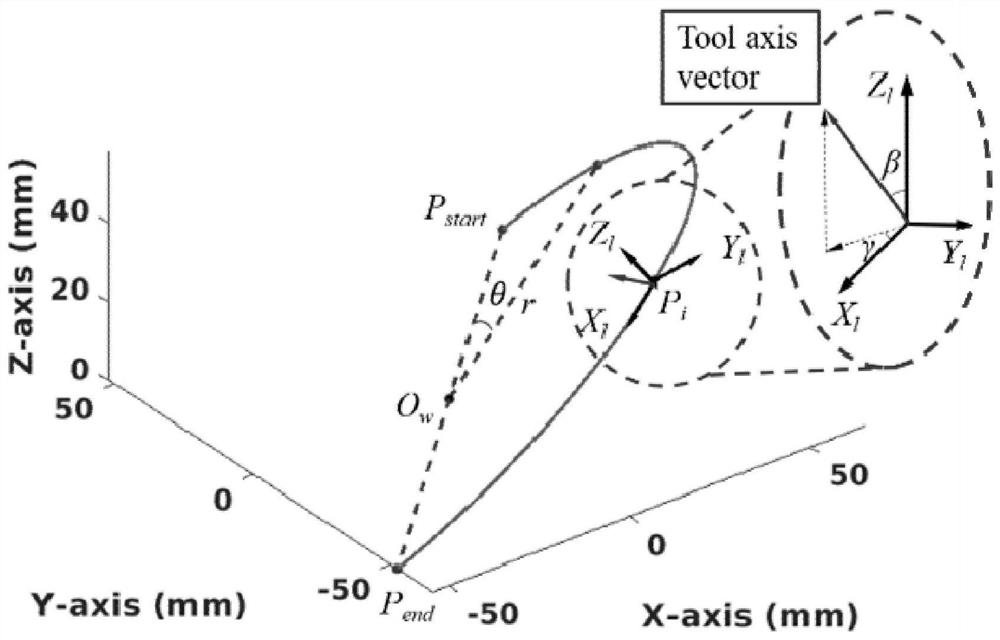

Tool path planning method of five-axis parallel machining robot

ActiveCN111230864AImprove machining accuracyImprove processing efficiencyProgramme-controlled manipulatorEngineeringStraight segment

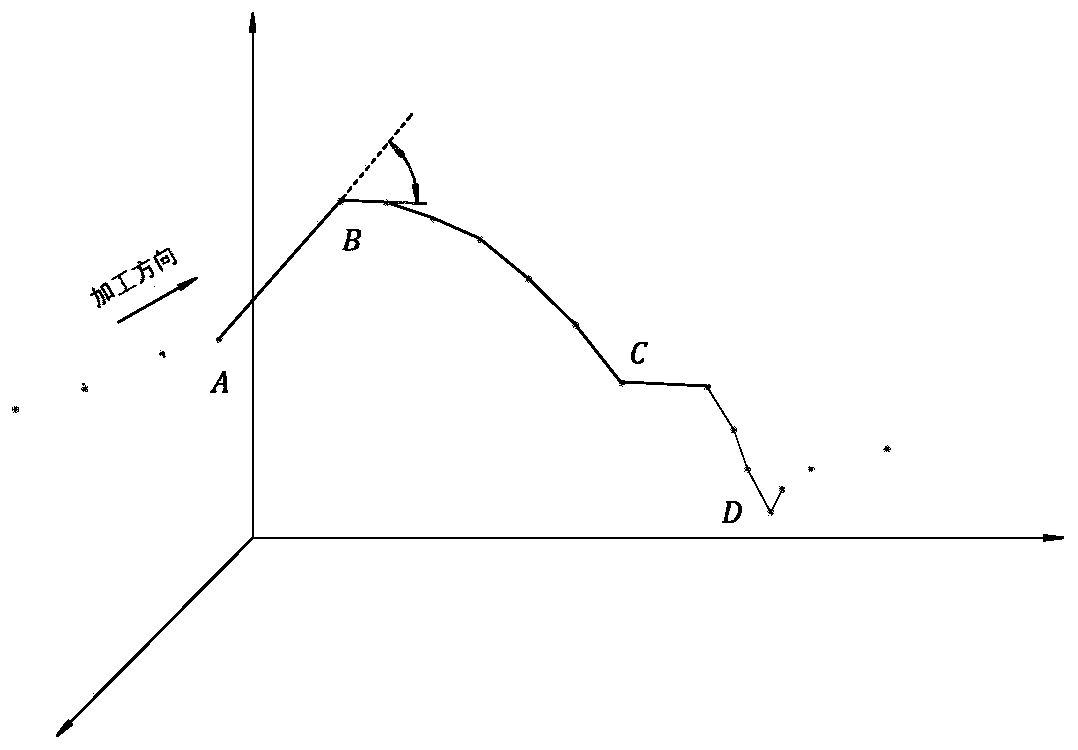

The invention relates to a tool path planning method of a five-axis parallel machining robot. The method comprises the steps that an original tool path is obtained from a tool location file; break points in the original path are obtained; according to the break points, the original path is divided into multiple long straight line segments and multiple short straight line segment groups; transfer fairing is carried out on the break points, fitting fairing is carried out on the short straight line segment groups, and linear fitting is carried out on the long straight line sections; and a plannedoverall G3 continuous machining path of a tool is formed by a transfer curve formed after transfer fairing, a curve formed by the short straight line segment groups subjected to fitting fairing and alinear path formed by the long straight line segments subjected to linear fitting. By means of the tool path planning method of the five-axis parallel machining robot, continuity of the machining path of the tool of the robot can be improved, and therefore machining precision and machining efficiency of the robot are improved.

Owner:TSINGHUA UNIV

Femtosecond laser precision removal method for thermal barrier coating of turbine blade

InactiveCN110773872AEfficient removalHigh precision removalLaser beam welding apparatusFemto second laserEngineering

The invention relates to the technical field of laser machining, and discloses a femtosecond laser precision removal method for a thermal barrier coating of a turbine blade. The method mainly includesthe following steps that firstly, before a workpiece is machined, the workpiece to be machined is installed on a workbench, and corresponding parameters of a laser device are set and mainly include laser wave lengths, pulse widths, repetition frequency and laser device operating power; secondly, computer aided design (CAD) software is utilized to set a machining path, and laser marking control software is used for setting specific machining conditions comprising the scanning speed, the scanning and scanning line intervals; and thirdly, at the beginning of machining, ultrashort pulse laser beams are emitted from a laser source. According to the femtosecond laser precision removal method for the thermal barrier coating of the turbine blade, by setting performance parameters of the laser device and adjusting a light beam adjustment transmission coordination and monitoring system through a control system, high-efficiency and high-precision removal of the thermal barrier coating on a complex curved surface is realized.

Owner:AIR FORCE UNIV PLA +1

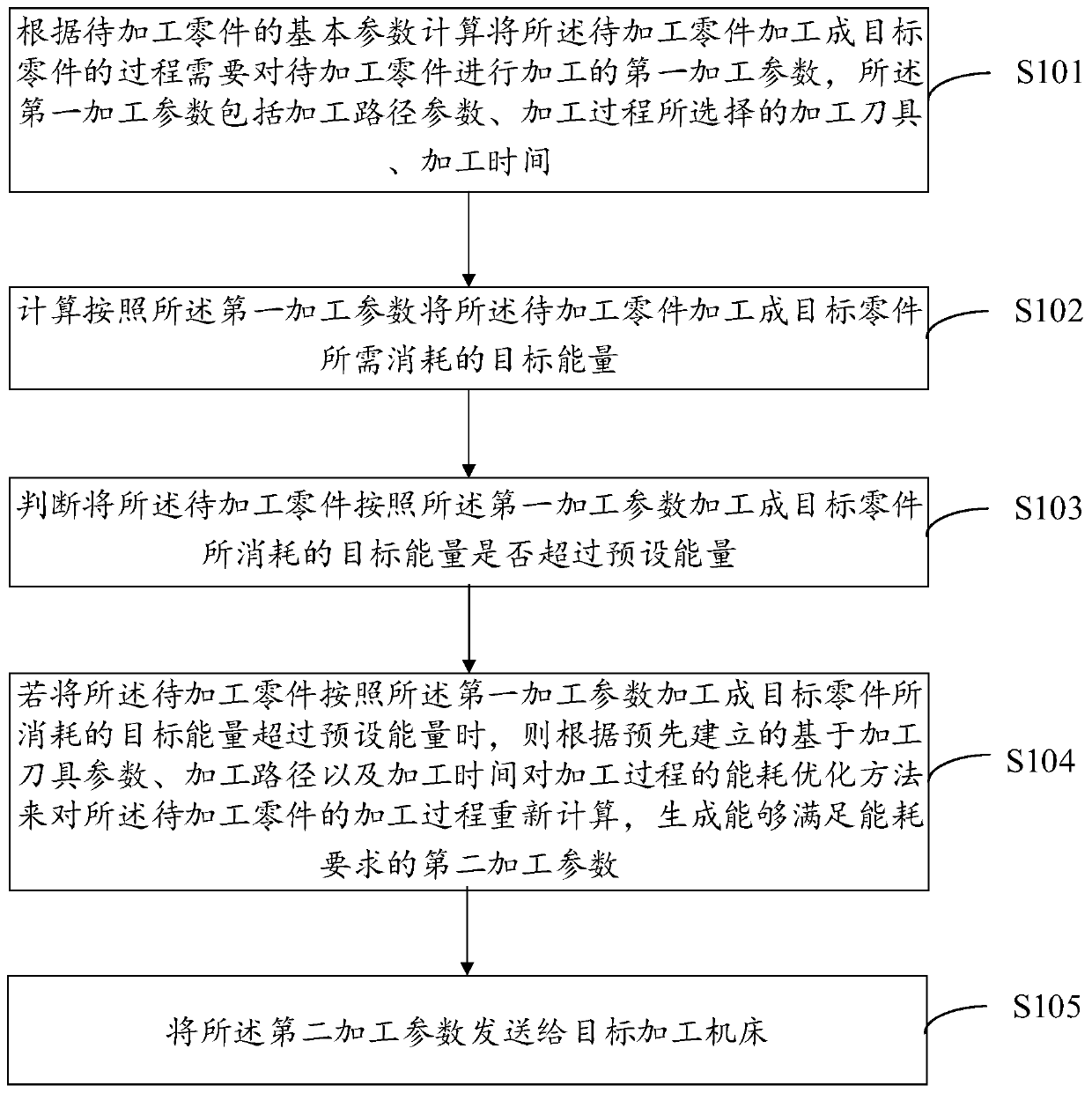

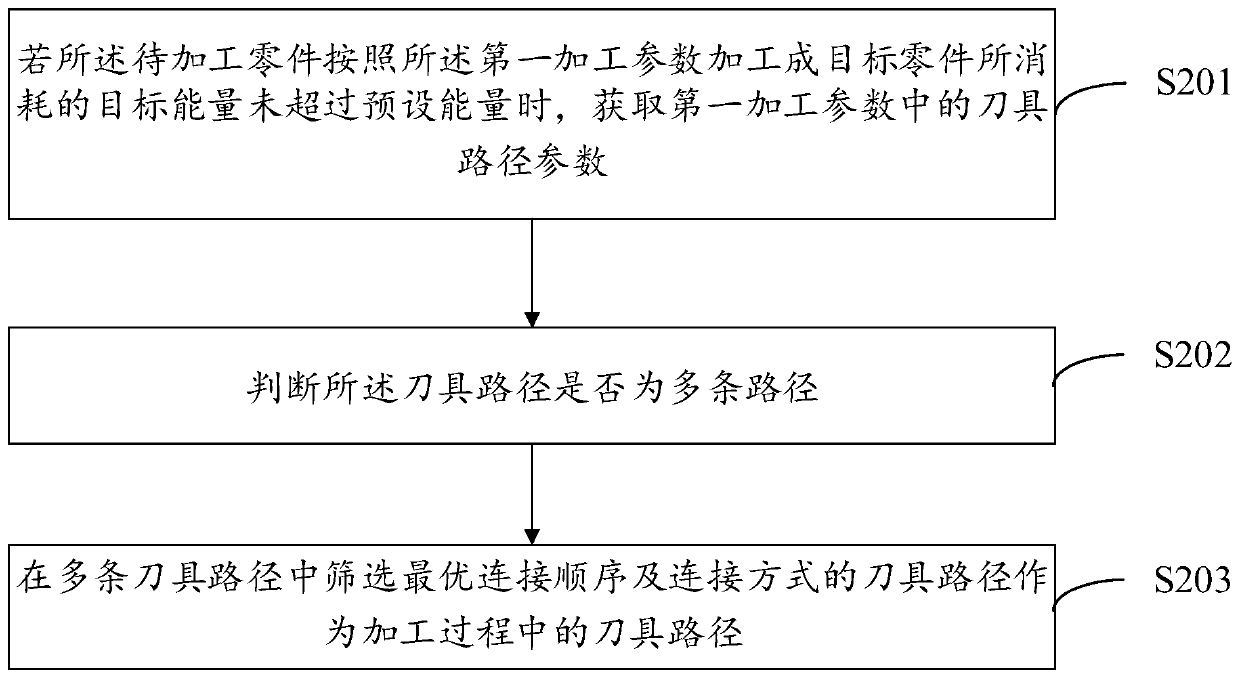

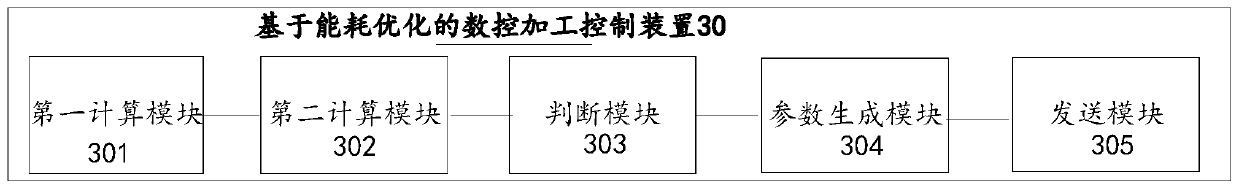

Numerical control machining control method and device based on energy consumption optimization and electronic equipment

The embodiment of the invention provides a numerical control machining control method and device based on energy consumption optimization and electronic equipment, and belongs to the technical field of machining. The method comprises the steps: calculating a first machining parameter for machining of a to-be-machined part in the process of machining the to-be-machined part into a target part according to the basic parameters of the to-be-machined part; calculating target energy required to be consumed for machining the to-be-machined part into the target part according to the first machining parameter; judging whether target energy consumed for machining the to-be-machined part into the target part according to the first machining parameter exceeds preset energy or not; if so, recalculating to generate a second machining parameter capable of meeting the energy consumption requirement; and sending the second machining parameter to a target machining machine tool. By means of the scheme,the energy consumption of the machined part before machining is estimated, a proper cutter and a proper machining path are selected according to the estimated energy consumption so as to reduce the energy consumption in the machining process, and thus the part machining energy consumption is reduced.

Owner:HUNAN INST OF TECH

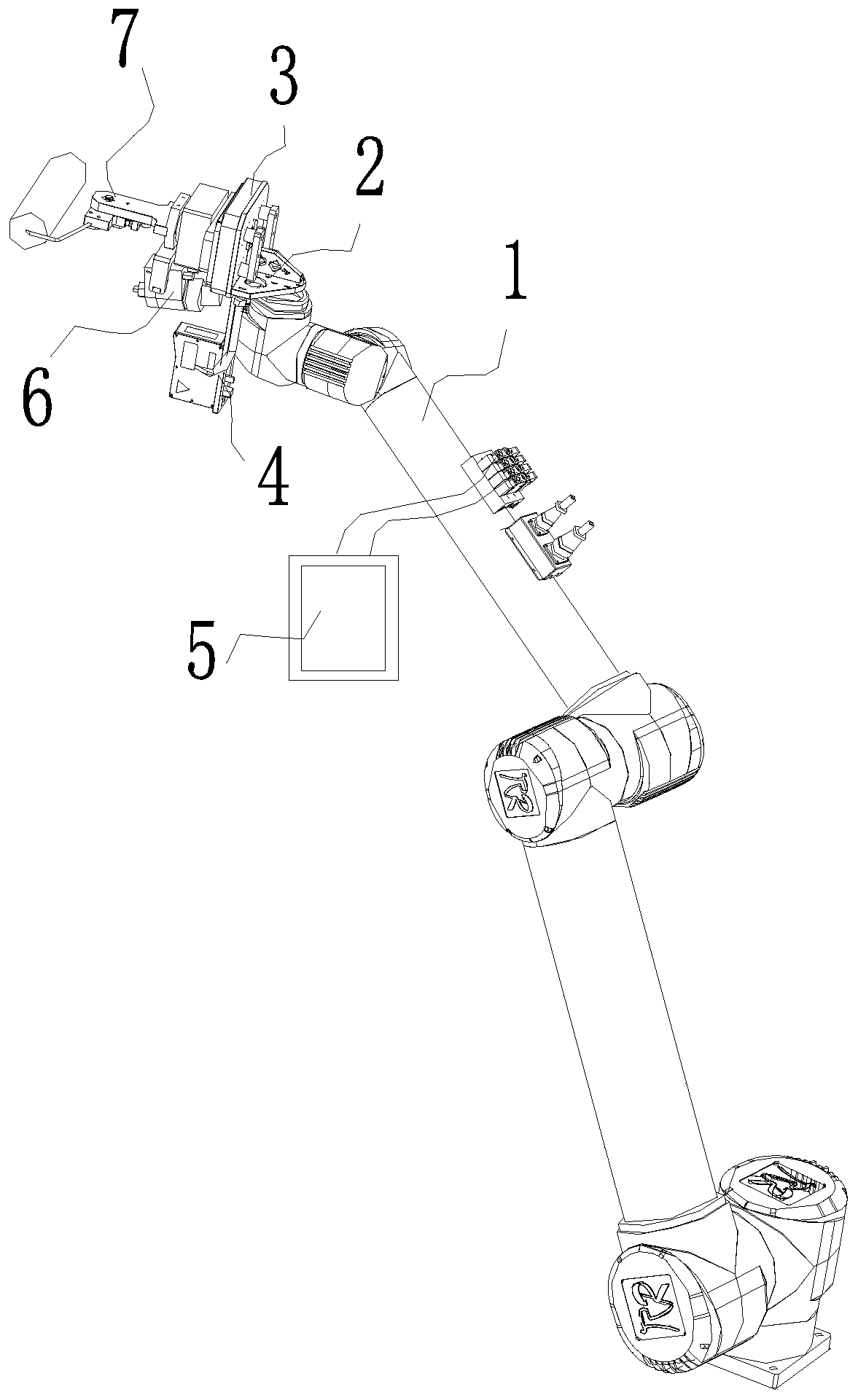

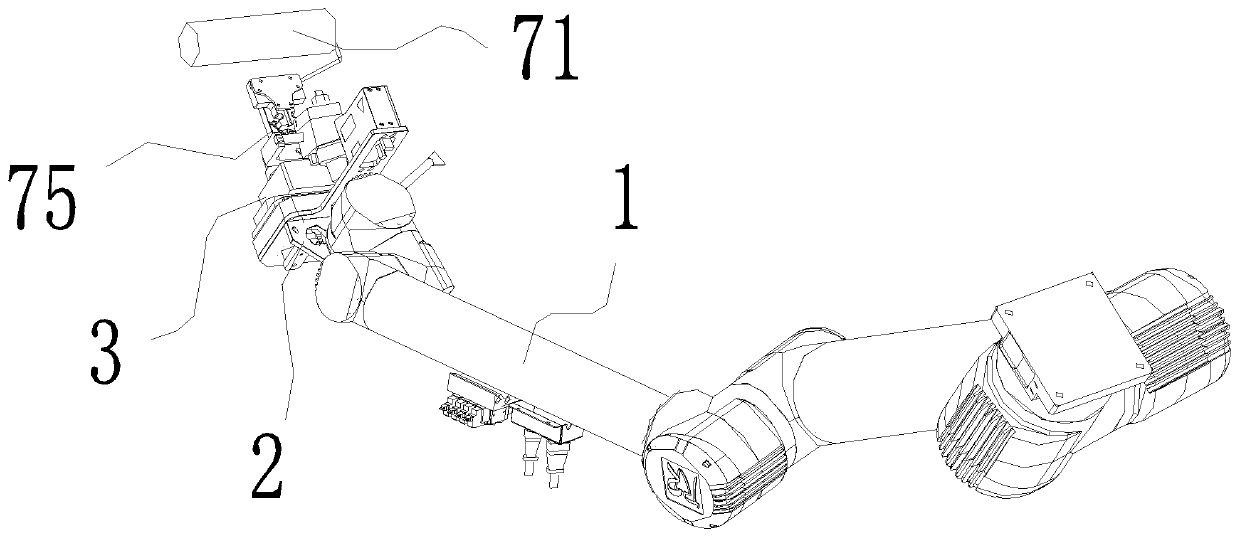

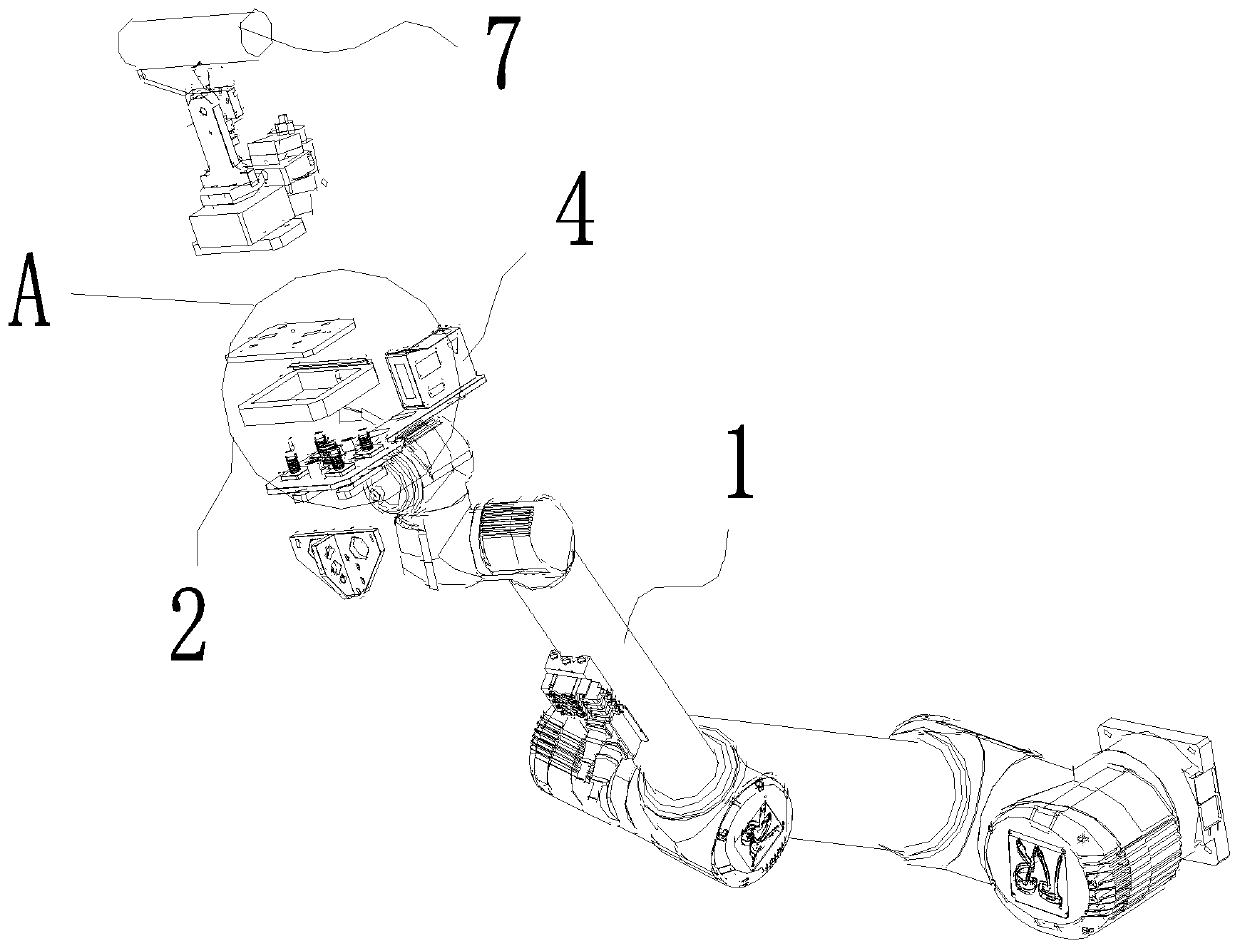

Indoor intelligent spraying and rolling coating dual-purpose machine for robot

The invention relates to an indoor intelligent spraying and rolling coating dual-purpose machine for a robot, and elates to the technical field of building automatic processing equipment. The indoor intelligent spraying and rolling coating dual-purpose machine is characterized by comprising an automatic mechanical arm, an adaptive force control device, a visual detection device, and a controller;the tail end of the arm of the automatic mechanical arm is connected with a base; the adaptive force control device is connected with the base, the adaptive force control device is provided with a pressure sensor; the visual detection device is used for detecting wall surface depth and contour data; the controller receives the wall surface depth and contour data returned by the visual detection device in real time and the flatness state of the processed wall in real time, and instructs the spraying and rolling coating actuators through the real-time processing radial force condition returned by the pressure sensor, so that the roller acts according to the processing path with the appropriate contact pressure and contact area. The structure is firm and simple, batch production is easy to realize, freedom degree and flexibility of operation space is good, thus effectively improving construction quality and construction quality.

Owner:珠海心怡科技有限公司

Hot-working die surface multipoint combination type bionic machining device and strengthening repair method

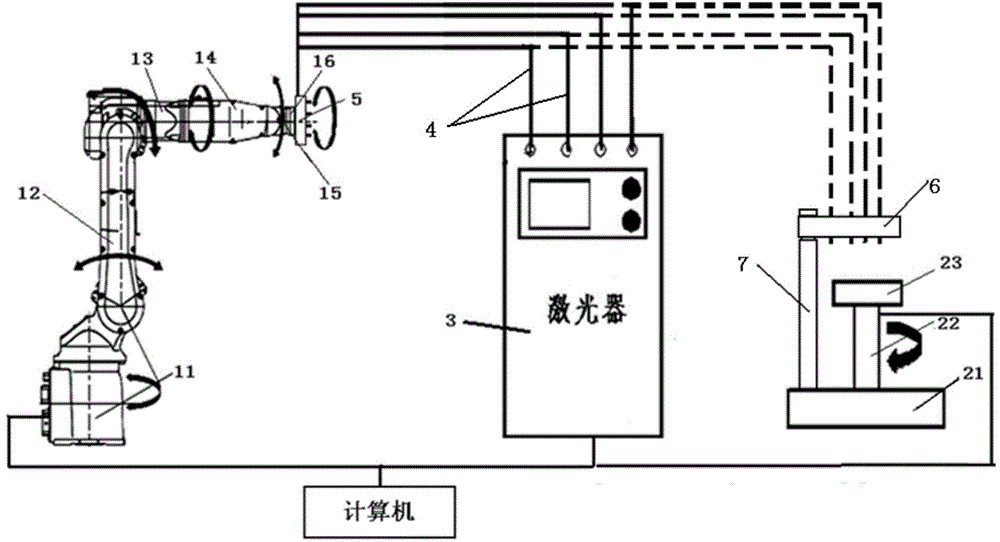

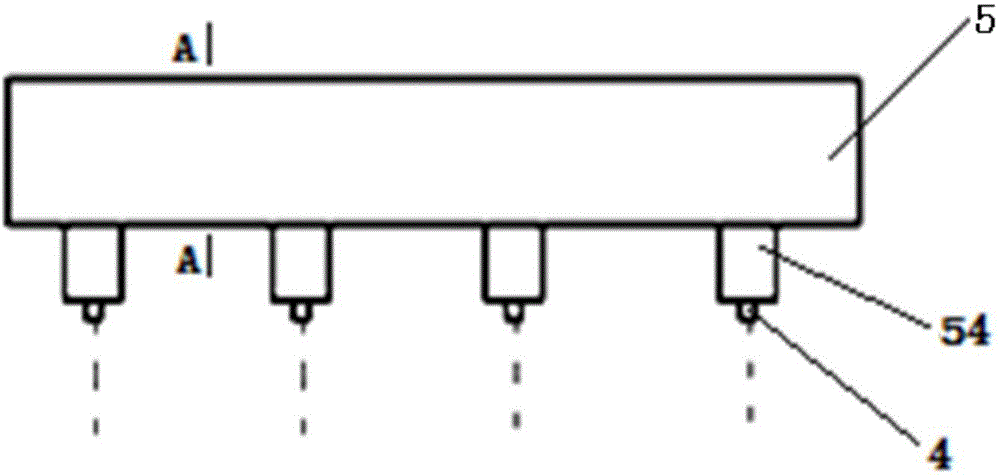

ActiveCN104668778AConvenient laser processingImprove processing efficiencyLaser beam welding apparatusEngineeringHot working

The invention relates to a hot-working die surface multipoint combination type bionic machining device. A computer of the device is connected with a servo control system of a six-degree-of-freedom robot, a laser and a rotary serve device of a rotary workbench; the laser comprises a plurality of optical fiber laser heads; a first laser head clamp plate is fixedly mounted on the rotating head of the six-degree-of-freedom robot; a second laser head clamp plate is mounted above the rotating workbench. Working modes of the rotating workbench and movement curves of the laser heads can be arranged according to the shape and area of a to-be-machined area on a die, and laser parameters, number of laser paths, light splitting modes and the like are designed according to strength requirements on surface materials; output energy of laser as well as the number of output light paths are combined with the movement curves, complexity of processing paths is guaranteed, and requirements of different positions and different energy during machining are guaranteed; the workbench or the die on the ground can be independently machined, two dies can be machined simultaneously, efficiency is improved, and cost is saved.

Owner:江苏拜欧尼克智能科技有限公司

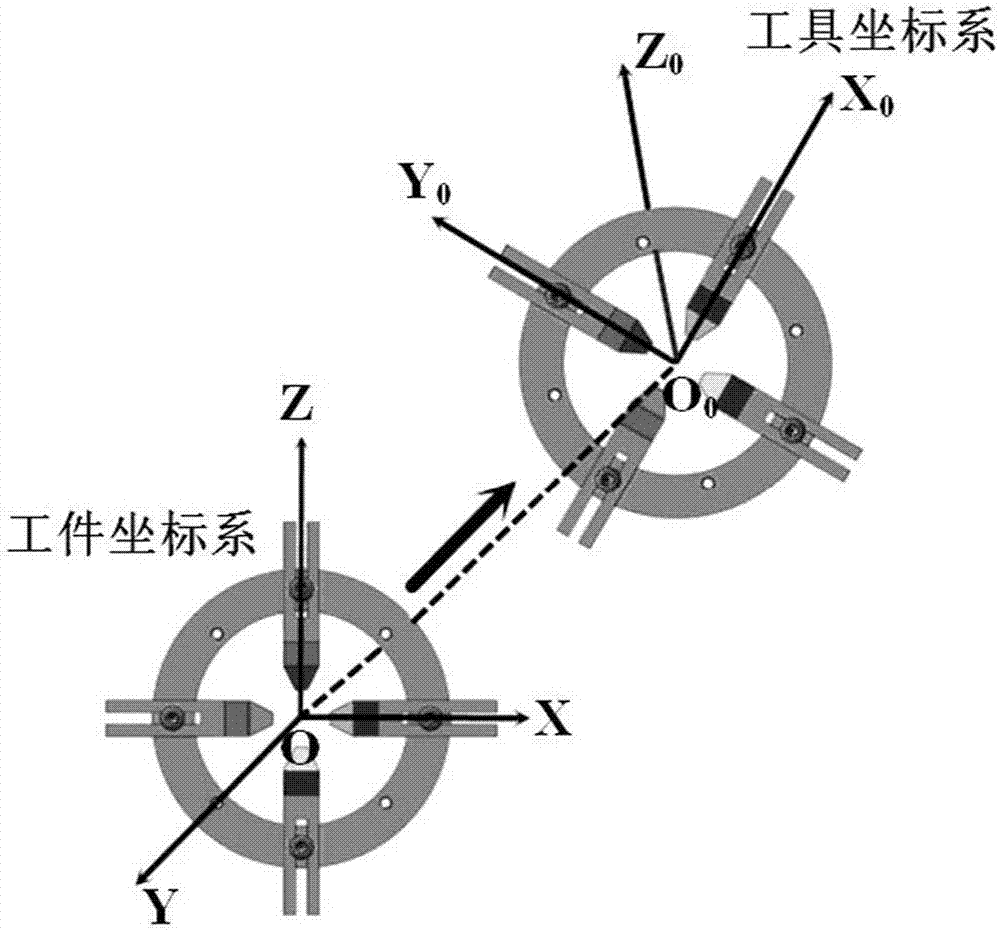

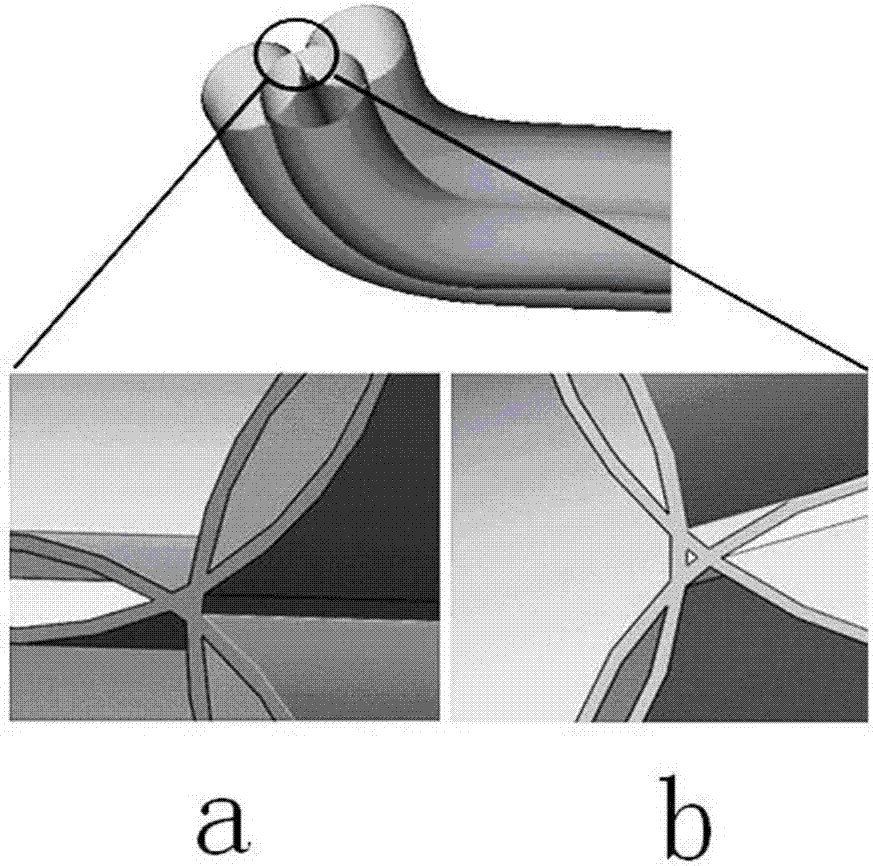

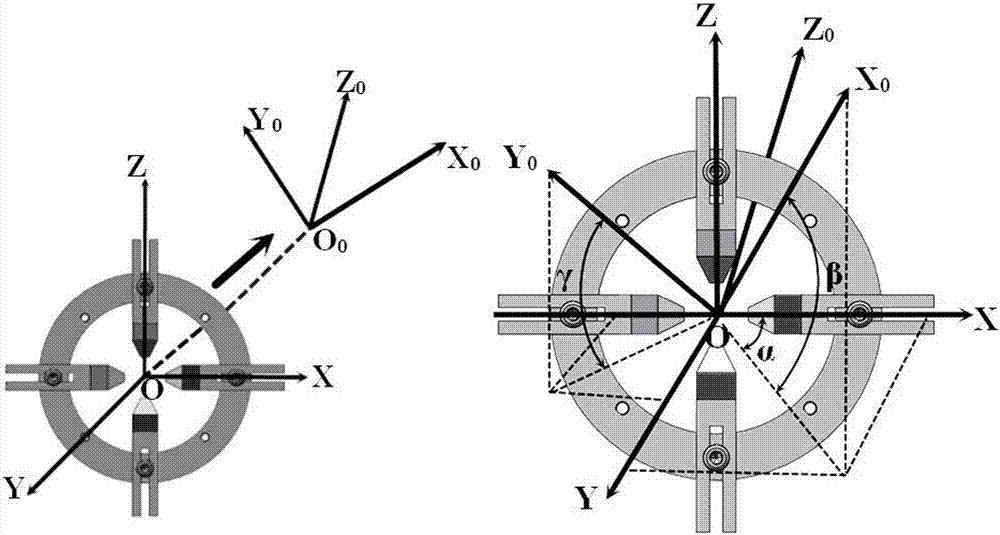

Method for generating inner surface polishing path of spatial bend pipe by c reconstruction

ActiveCN107422693AImprove work efficiencyLess preparationNumerical controlPoint cloudRectangular coordinates

The invention belongs to the technical field of magnetic grinding, and especially relates to a method for generating an inner surface polishing path of a spatial bend pipe by center line reconstruction. The method is characterized by comprising the following steps: step 1, obtaining outer contour point cloud of a spatial bend pipe; step 2, through curve fitting, obtaining three contour lines; step 3, generating a spatial bend pipe by using the fit outer contour line through a cross section intersection method; step 4, performing point discretization on the generated bend pipe center line and the outer contour line generated by measurement; step 5, establishing a space rectangular coordinate system O0X0Y0Z0, setting the rectangular coordinate system as a robot tool coordinate system; step 6, through translation and rotation, transforming a workpiece coordinate system to the tool coordinate system; step 7, through conversion of a homogeneous coordinate transformation matrix on the coordinate system, obtaining a pose coordinate in a processing path at the processing moment; step 8, obtaining a final machine polishing path. The method can accurately determine a processing path of a complex spatial bend pipe, and improves working efficiency.

Owner:UNIV OF SCI & TECH LIAONING

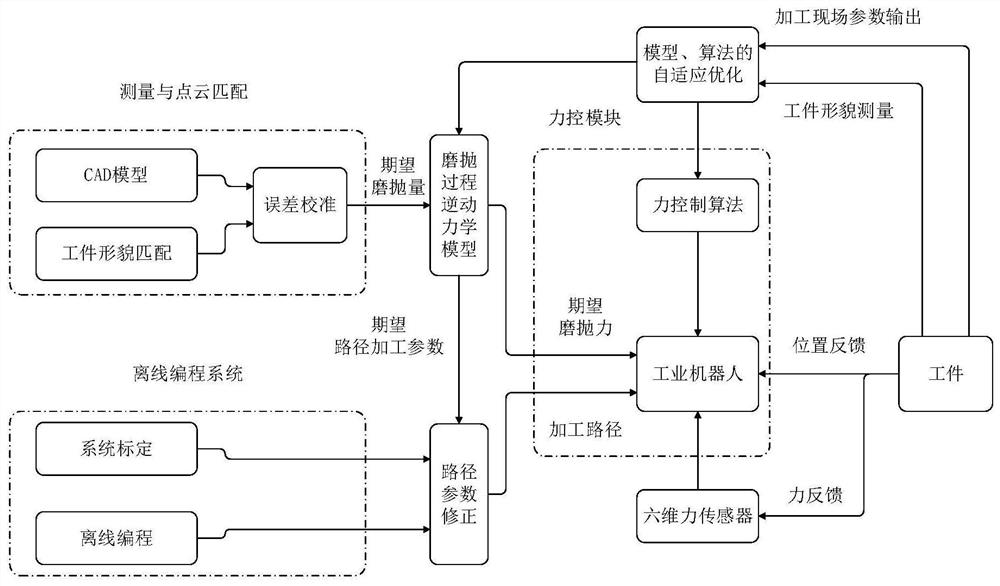

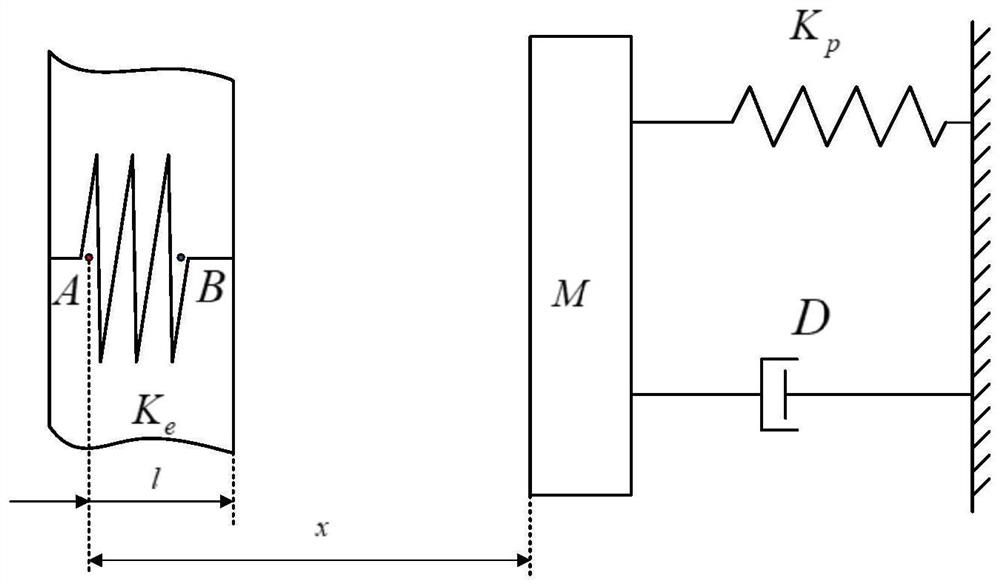

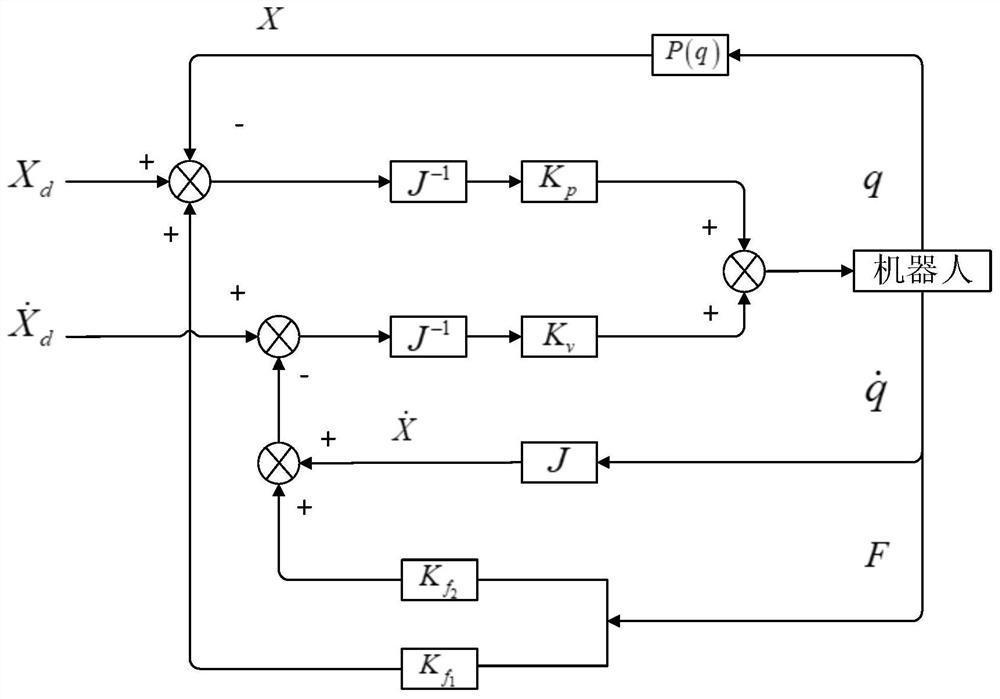

Active control method for grinding and polishing machining contact force of robot

PendingCN112666831ARealize active controlGuaranteed Surface ConsistencyAdaptive controlGrindingMachining toolpath

The invention belongs to the field of robot machining, and particularly discloses an active control method for grinding and polishing machining contact force of a robot. The method comprises the following steps: calculating the expected grinding and polishing amount of robot grinding and polishing machining, and generating a machining path, an expected pose and expected grinding and polishing force in the robot grinding and polishing machining process; obtaining a plurality of position points of the robot in the Z direction of the workpiece coordinate system in the process of moving along the machining path, and constructing a target function according to the position points and the impedance control key parameters; constructing constraint conditions of the key parameters, and obtaining an optimal solution of the key parameters by adopting a weight improved particle swarm algorithm; and updating and adjusting the grinding and polishing pose and the grinding and polishing force of the robot in real time to make the force tracking error of the robot for grinding and polishing along the machining path minimum. According to the method, the tracking effect of impedance control on expected force is effectively improved, the machining precision of robot grinding and polishing machining is improved, and the surface consistency and good surface roughness of machined workpieces are guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH

Electric arc additive manufacturing method with adjustable laser shock

PendingCN112329161AReduce residual stressOptimum Laser Shock Working ParametersGeometric CADDesign optimisation/simulationEngineeringShock treatments

The invention belongs to the field of electric arc additive manufacturing, and particularly relates to a laser shock adjustable electric arc additive manufacturing method. The method comprises the following steps: (1) obtaining a machining path of an electric arc additive; (2) setting a temperature threshold; (3) obtaining the stress field distribution of the electric arc additive manufacturing component in real time by adopting a numerical simulation method; (4) setting a laser impact path and setting laser beam parameters; (5) setting technological parameters of arc additive manufacturing, and carrying out layer-by-layer wire arc manufacturing; (6) repeating the steps (3) and (4), and carrying out laser shock treatment on the weld bead to eliminate residual stress; and (7) repeating thestep (5) and the step (6) until the electric arc additive manufacturing component is machined. Numerical simulation and laser shock are combined and applied to electric arc additive manufacturing, sothat residual stress conditions of different areas correspond to laser shock parameters, the optimal laser shock working parameters are adjusted and maintained in real time, and the forming precisionis effectively controlled.

Owner:NANJING UNIV OF SCI & TECH

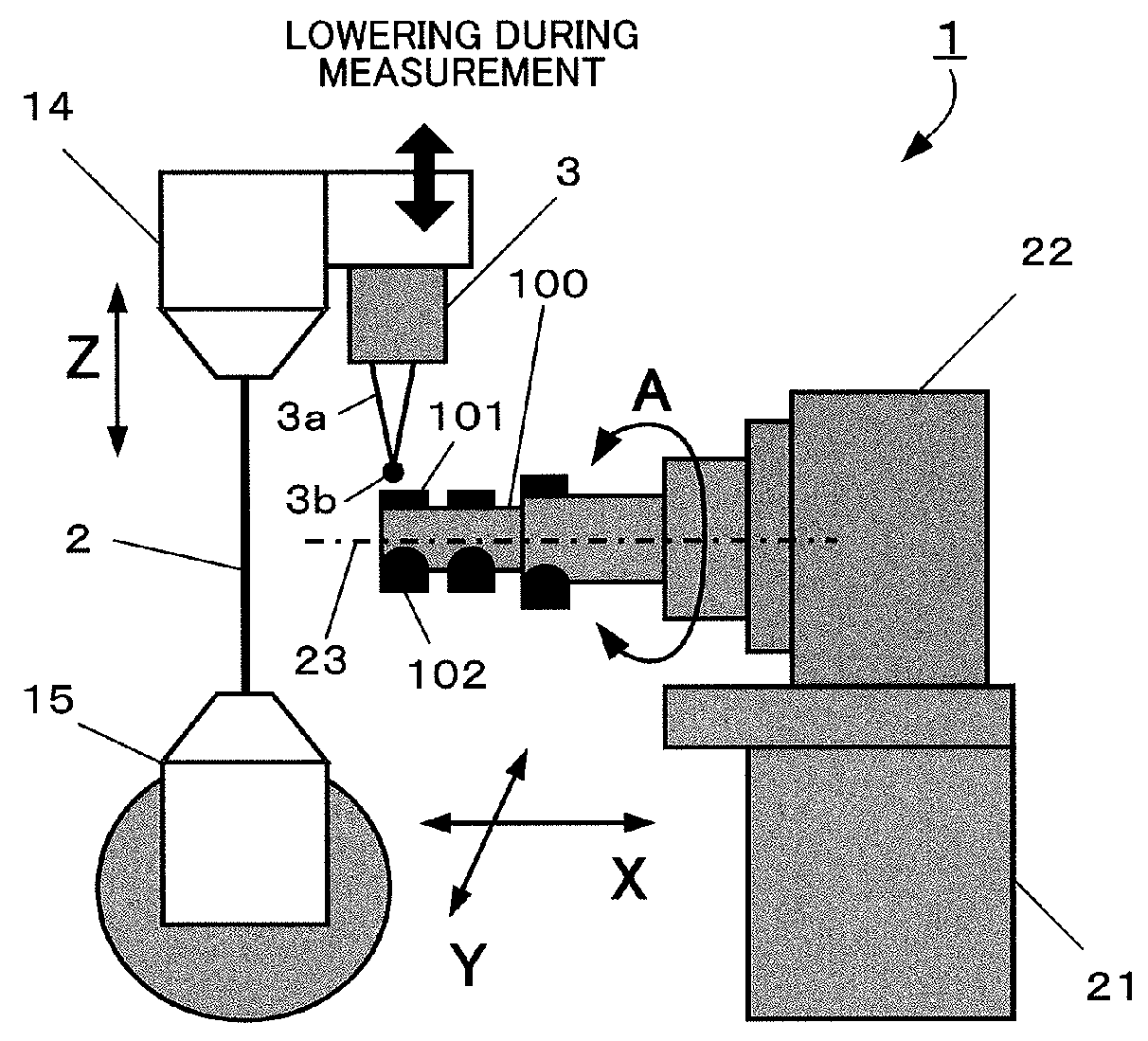

Wire electric discharge machining method and wire electric discharge machine for machining tool that uses ultra-hard material and is mounted to rotating shaft

ActiveUS9381589B2Improve accuracyReduce measurement errorProgramme controlElectric circuitsRotational axisElectric discharge

An ultra-hard material fixed to a cutting tool is formed into a cutting blade by electric discharge machining. The wire electric discharge machine has a rotating shaft to which the cutting tool is mounted, and has a touch sensor mounted to an upper wire guide. A measurement program is generated on the basis of a machining path instructed by the machining program. A machining program is regenerated from rotating shaft coordinate information and path coordinate position information obtained at measurement points, on the basis of the measurement program. As a result, a rake face position of the cutting tool can be accurately measured and a wire electrode can be positioned accurately with respect to that position during machining.

Owner:FANUC LTD

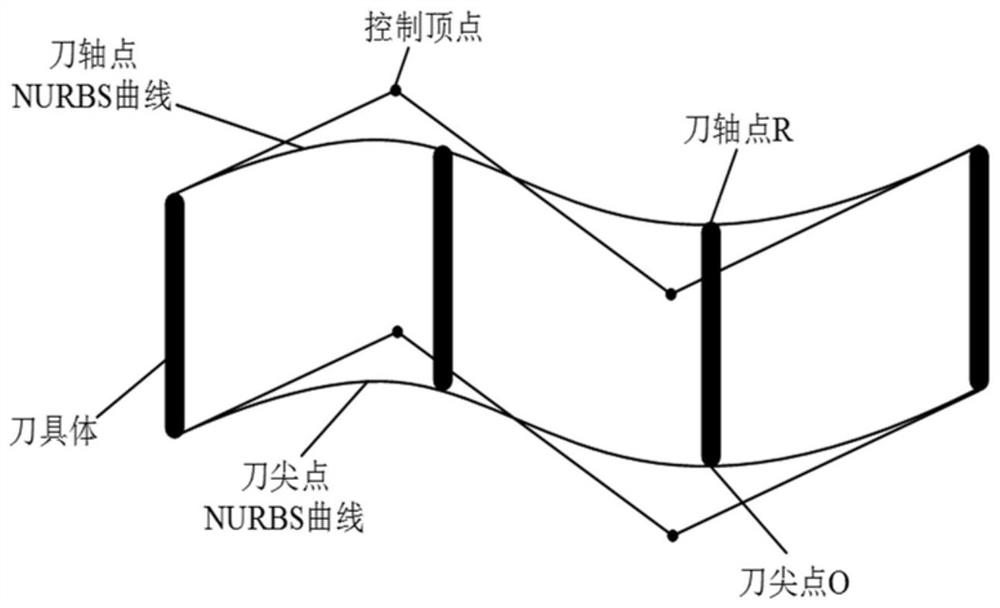

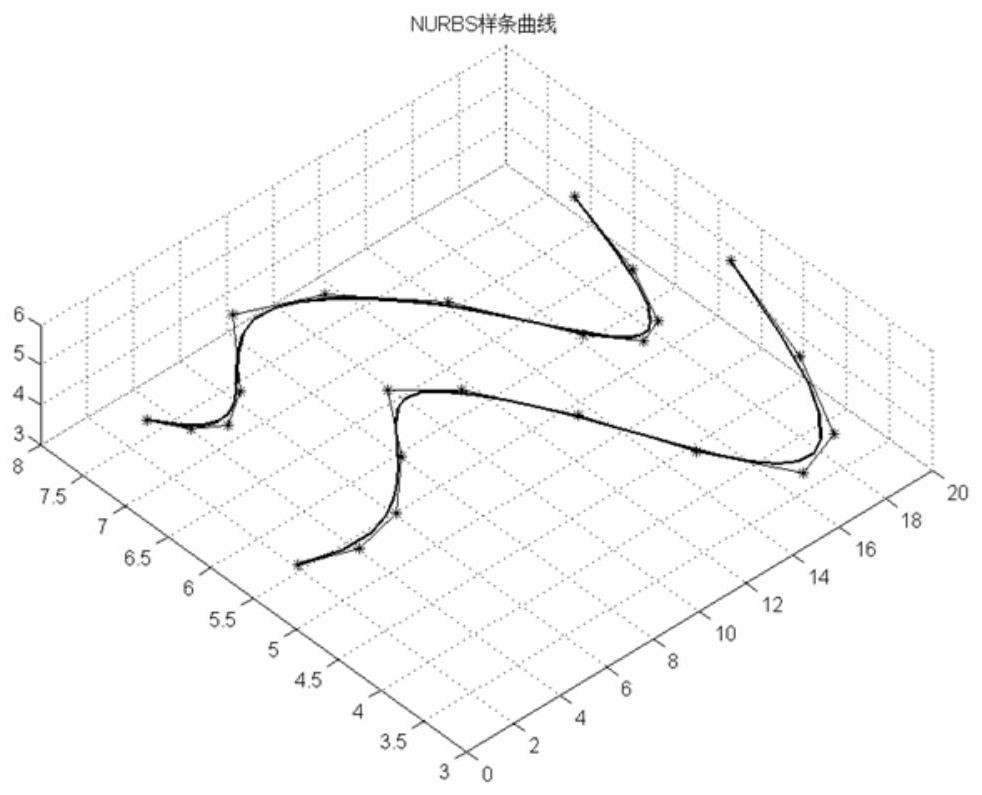

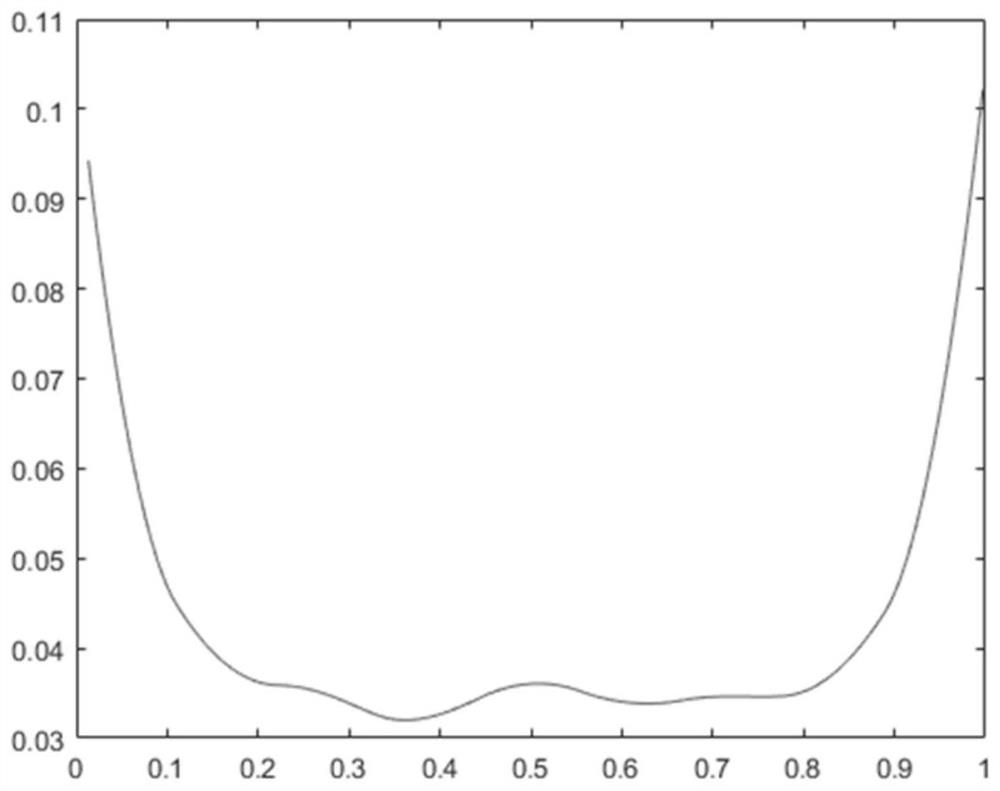

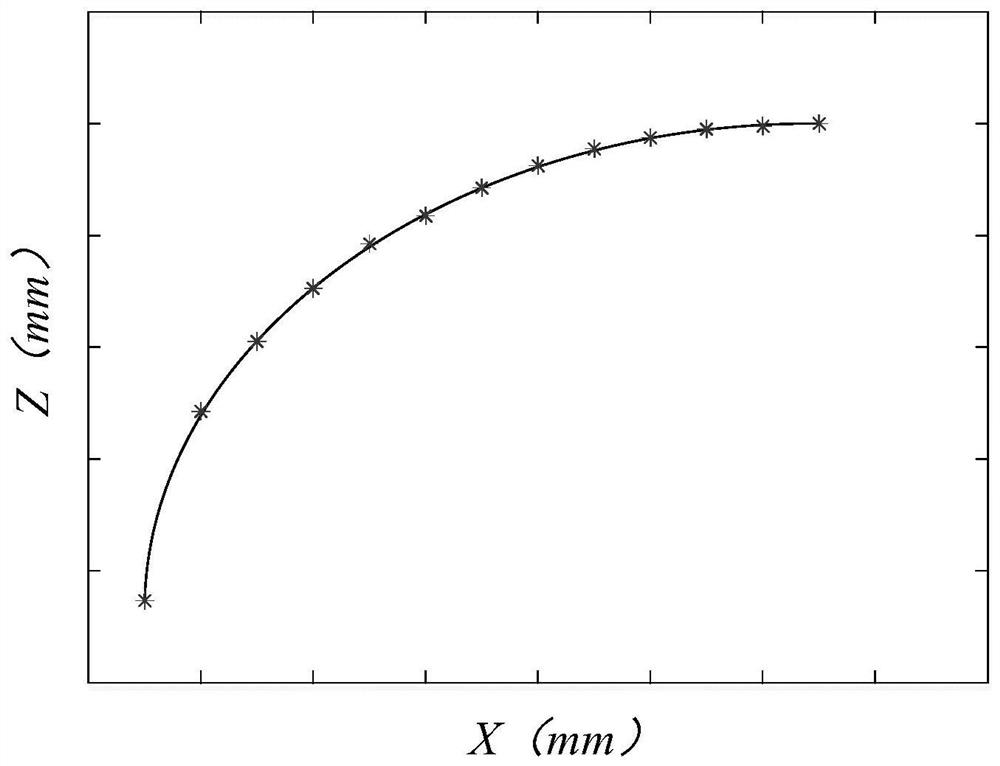

Method for calculating limit speed of double NURBS paths in free-form surface machining

PendingCN111736537AImprove machining accuracyGuaranteed stabilityNumerical controlGeometric errorKinematics

The invention discloses a method for calculating the limit speed of a double NURBS path in free-form surface processing. The method comprises the following steps: (1) calculating a control vertex anda node vector of an NURBS curve according to data points of a known discrete tool nose file, defining a fitting curve of a tool nose point track, calculating data points (cutter axis points for short)participating in cutting in the cutter axis direction through a linear relation, and defining a fitting curve of a track of the point by using the same method, so as to generate the double NURBS path; and (2) solving the curve length of an interpolation road section on a definition domain by integrating a first-order guide vector function of a tool nose point NURBS fitting curve, traversing the whole processing path, and calculating a key point of which the curvature radius reaches a local extreme value under the limitation of geometric error constraint and kinematics constraint so as to obtain the limit speed at the key point.

Owner:TIANJIN UNIV

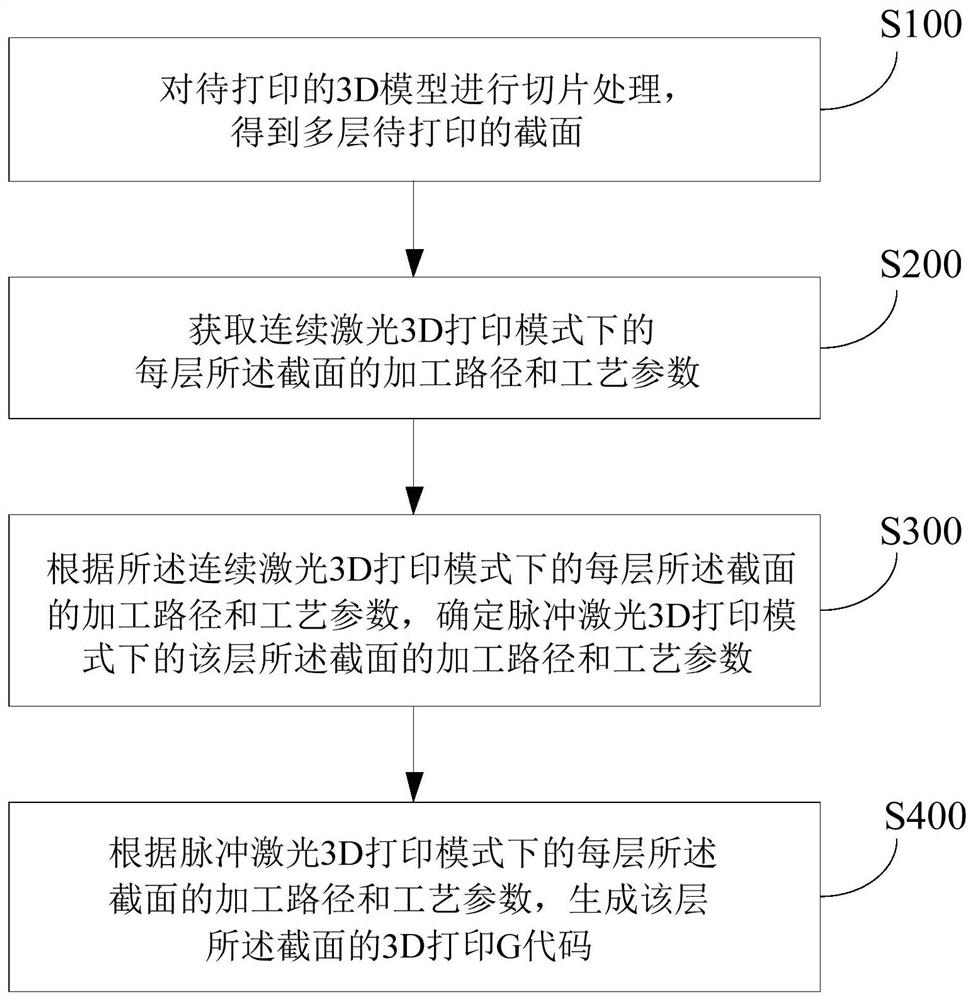

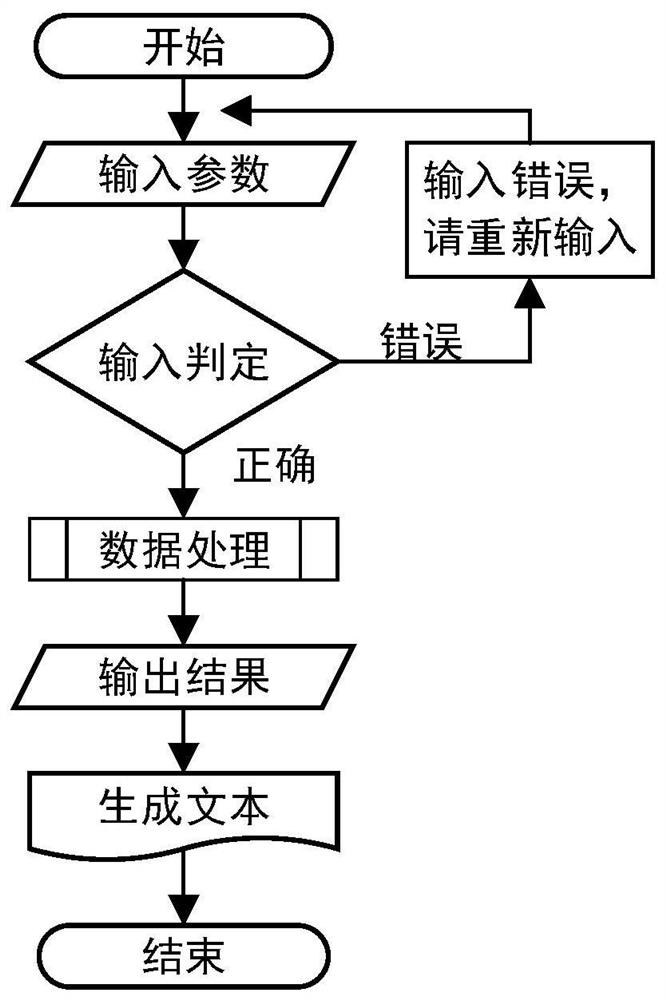

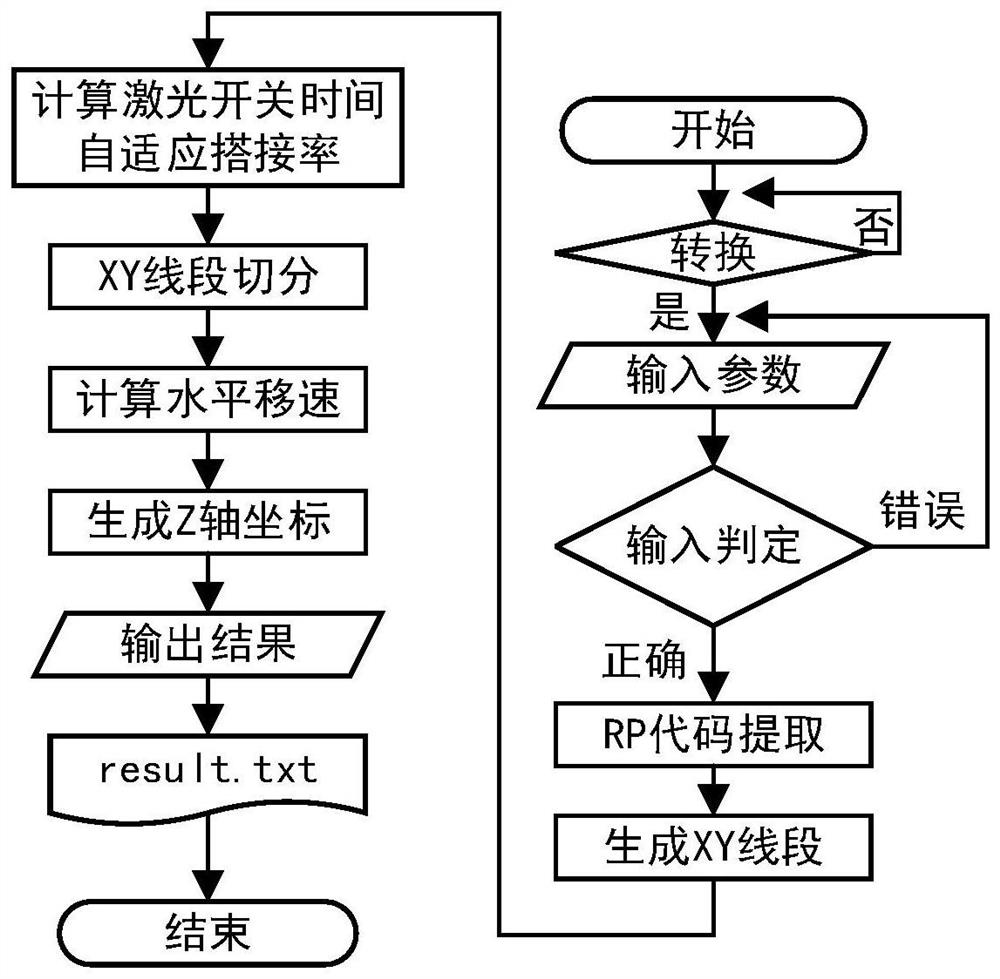

G code generation method for pulse laser 3D printing

ActiveCN112068840ASolve the problem that does not work with pulsed laser 3D printingAdditive manufacturing apparatusManufacturing data aquisition/processing3d printSoftware engineering

The invention discloses a G code generation method for pulse laser 3D printing, and the method comprises the steps: carrying out the slicing of a to-be-printed 3D model, and obtaining a plurality of to-be-printed sections; acquiring a processing path and process parameters of each layer of section in a continuous laser 3D printing mode; according to the machining path and the technological parameters of the section of each layer in the continuous laser 3D printing mode, determining the machining path and the technological parameters of the section of the layer in the pulse laser 3D printing mode; and generating a 3D printing G code of the cross section of the layer according to the processing path and the process parameters of the cross section of each layer in the pulse laser 3D printingmode. According to the invention, the method can effectively solve a problem that a conventional 3D printing G code generation method is not suitable for pulse laser 3D printing because of the designfor continuous laser 3D printing.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

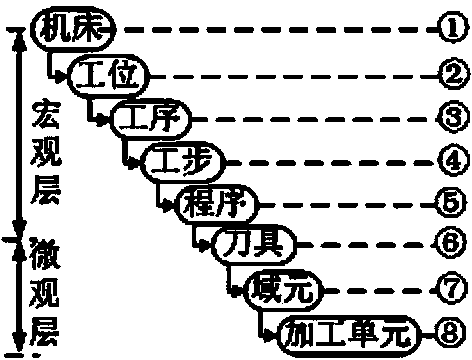

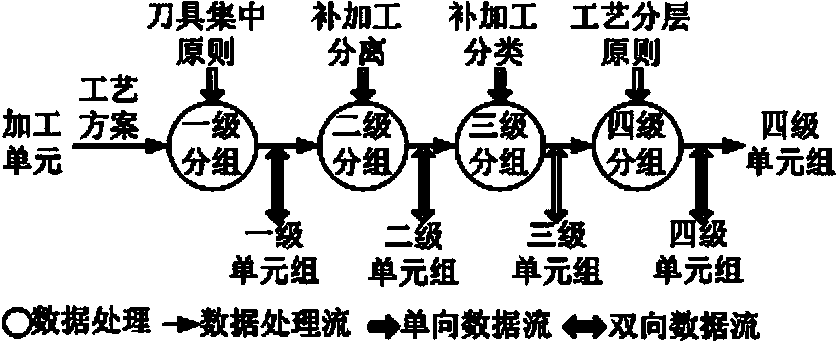

Method for optimally sorting aircraft structural part automatic programming processing units based on technological process

ActiveCN104007699AShorten the production cycleMeet the process requirementsNumerical controlMachining deformationProcess engineering

The invention provides a method for optimally sorting aircraft structural part automatic programming processing units based on a technological process. The method comprises the steps that the technological process is built, and the machining craft process of parts is built through the tree structure of the depth traversal process scheme according to an input technological scheme file; the machining units are grouped, a set of tool sequences is obtained according to a given technological scheme, the grouping rule of the machining units is built according to the machining units, target machining units and real-time make-up machining units with tools associated in the tool sequences, and the special requirements of different types of make-up machining units and technologies, and the machining units are divided into four groups; the machining units are sorted, an overall layering and a virtual layering method are adopted, rough machining deformation is reduced, and layered machining and sorting are achieved. According to the method, the sorting result conforms to the practical technological requirement, interference and excessive cutting in the machining process are effectively reduced, the machining path is short, and the machining efficiency is high.

Owner:SHENYANG AIRCRAFT CORP

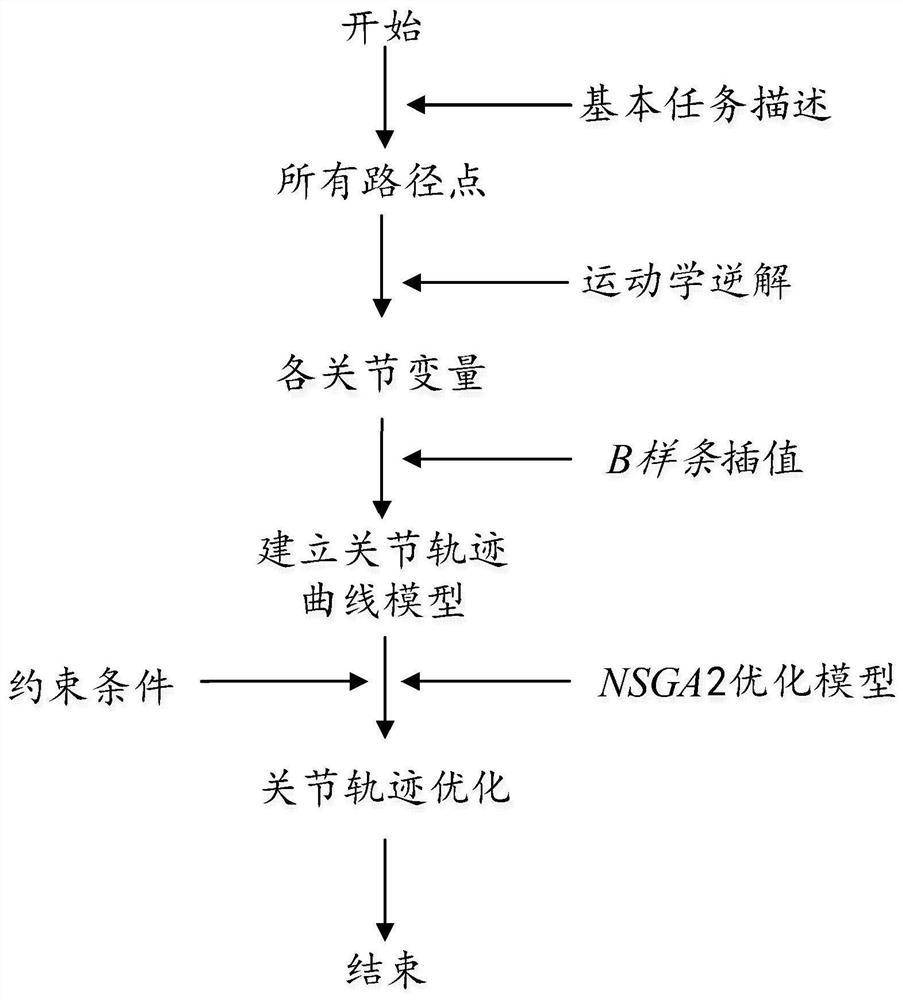

Multi-machine cooperative trajectory optimization method based on quintic non-uniform rational B-spline

InactiveCN113296407AAddress performance requirementsOvercoming the Runge phenomenonAdaptive controlAlgorithmMathematical model

The invention discloses a multi-machine cooperative trajectory optimization method based on a quintic non-uniform rational B-spline, and the method comprises the steps of firstly, carrying out discretization on a machining path of each robot after the respective motion trajectory of each robot is determined, carrying out inverse solution on the discrete points through the robots, and obtaining a series of joint position sequences in a joint space, interpolating the joint sequence by using a quintic non-uniform rational B spline mathematical model, and constructing a high-order continuous joint trajectory with designable end point motion parameters; adopting a non-dominated sorting genetic algorithm (NSGA2) with an elitist strategy, taking operation time and trajectory smoothnessas targets, taking time intervals serve as decision variables to optimize the motion trajectory of a mechanical arm, and obtaining a high-order continuous optimized trajectory. According to the method, a Runge phenomenon of polynomial interpolation caused by increase of the number of times is overcome, and the problem that a single-target optimization technology cannot meet the requirement of actual engineering on the comprehensive performance of the robot under the advanced manufacturing background is solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

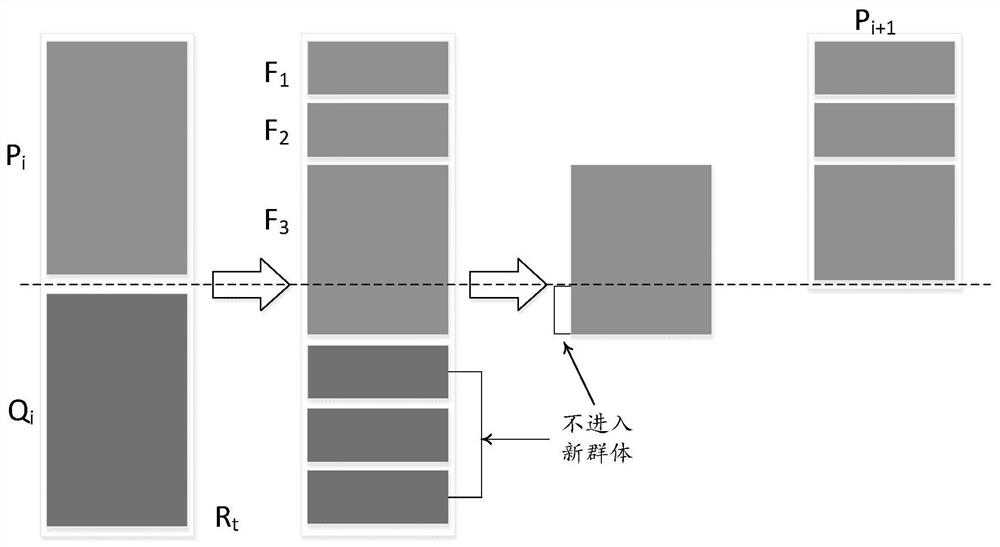

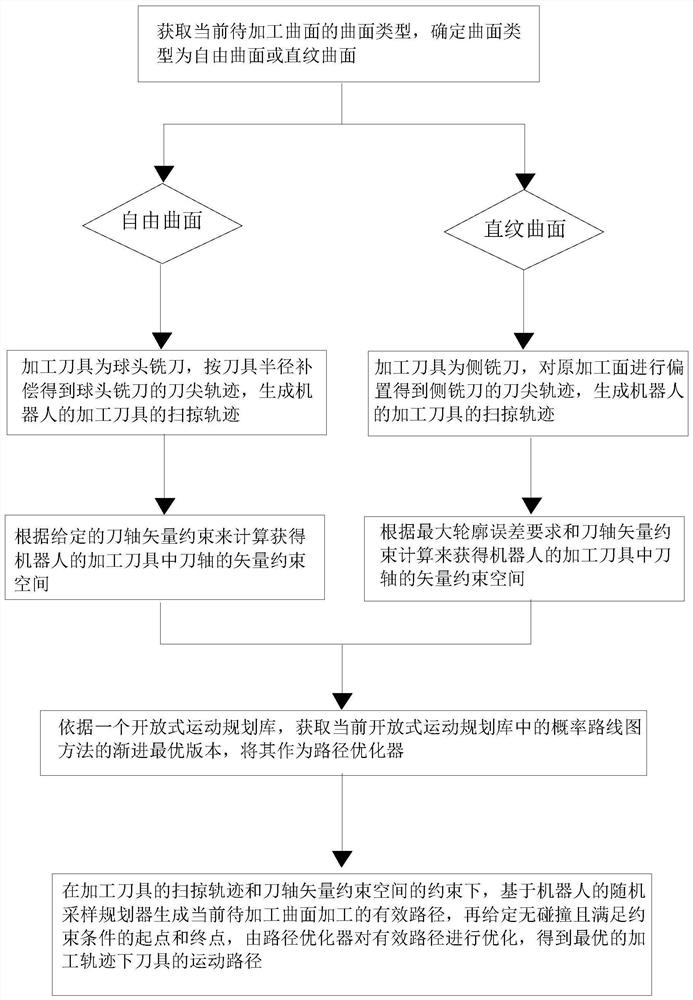

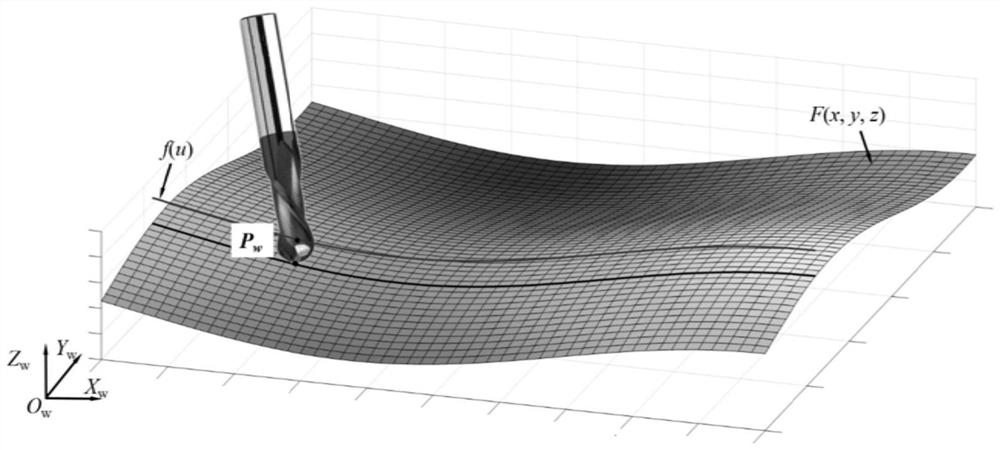

Robot curved surface machining track optimization generation method, system and terminal

InactiveCN112947298AImprove processing efficiencyQuality assuranceNumerical controlMachining toolpathProcess engineering

The invention belongs to the technical field of industrial robots, and particularly relates to a robot curved surface machining track optimization generation method, system and terminal. The method comprises the following steps: S1, obtaining the curved surface type of a current to-be-machined curved surface, and determining whether the curved surface type is a free-form curved surface or a straight-line curved surface; s2, generating a sweeping track of a machining tool of the corresponding robot; s3, calculating a vector constraint space of a cutter shaft of the robot; s4, obtaining a version with the optimal optimization performance in the probability route map method as a path optimizer; and S5, optimizing the effective path by a path optimizer under the constraint of the sweeping track of the machining tool and the tool axis vector constraint space to obtain an optimal machining track. The system comprises a curved surface type acquisition module, a sweeping trajectory generation module, a vector constraint space calculation module and a path planner module. According to the method, system and terminal, the problem that the working efficiency and the curved surface machining quality cannot be both considered in the curved surface machining path optimization process of a traditional method is solved.

Owner:HEFEI UNIV OF TECH

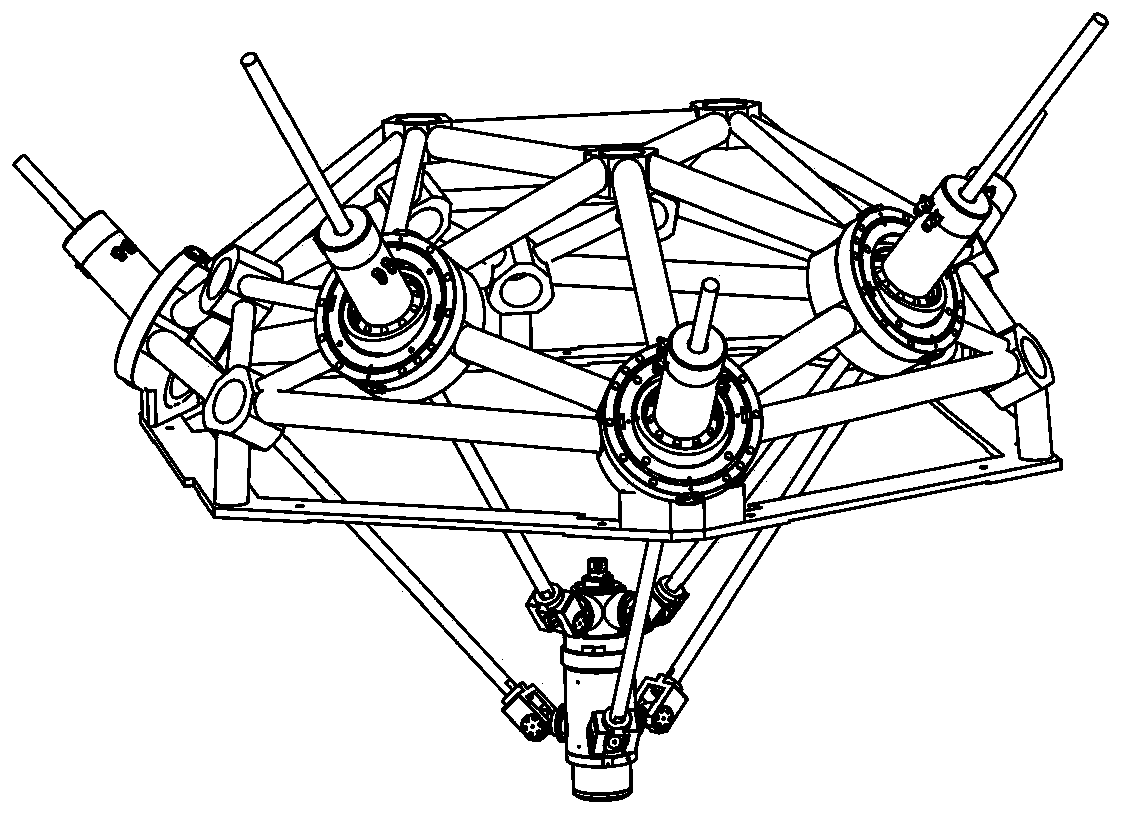

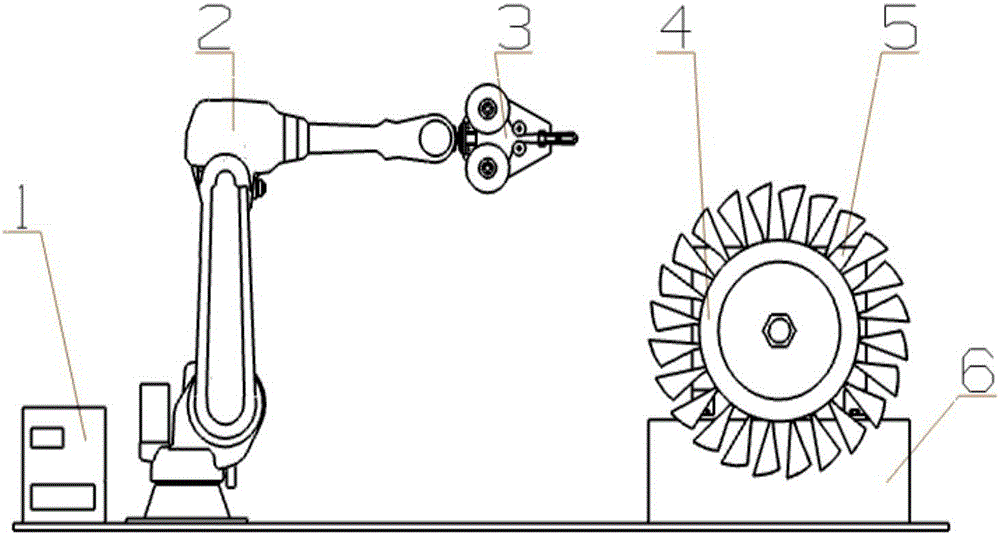

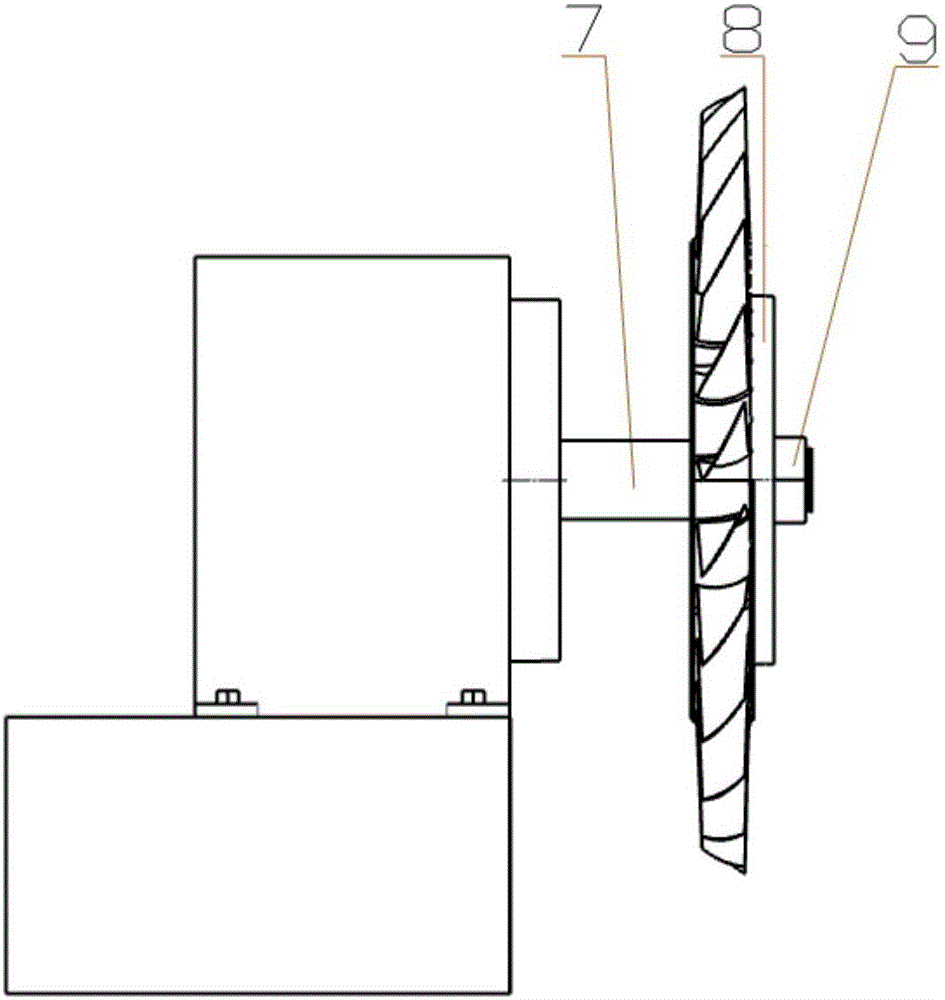

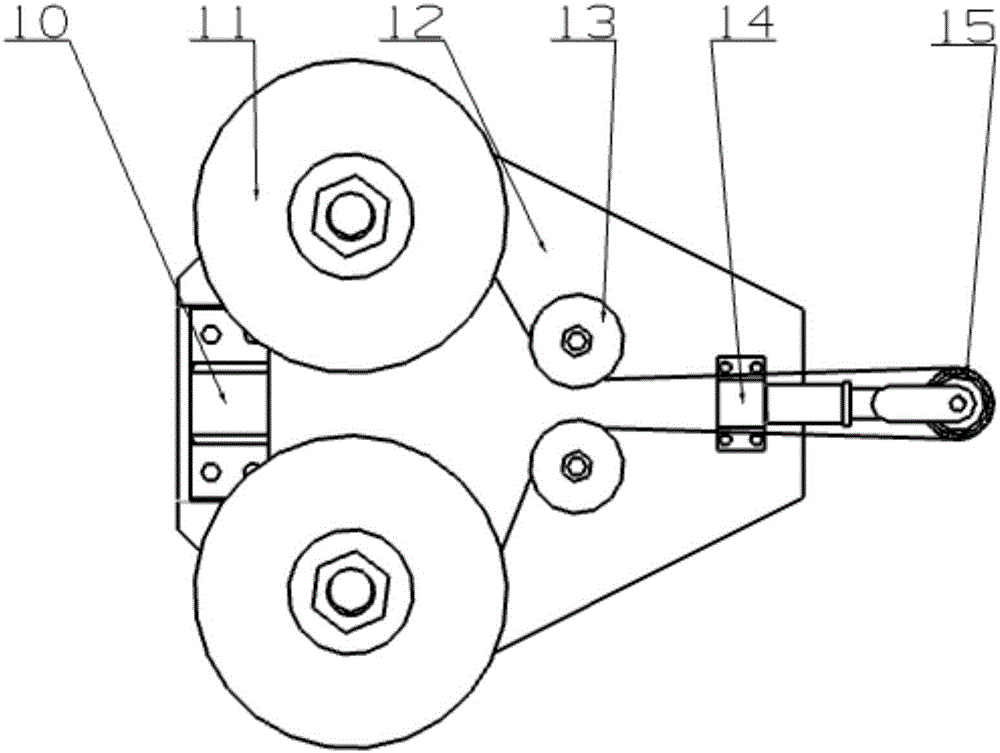

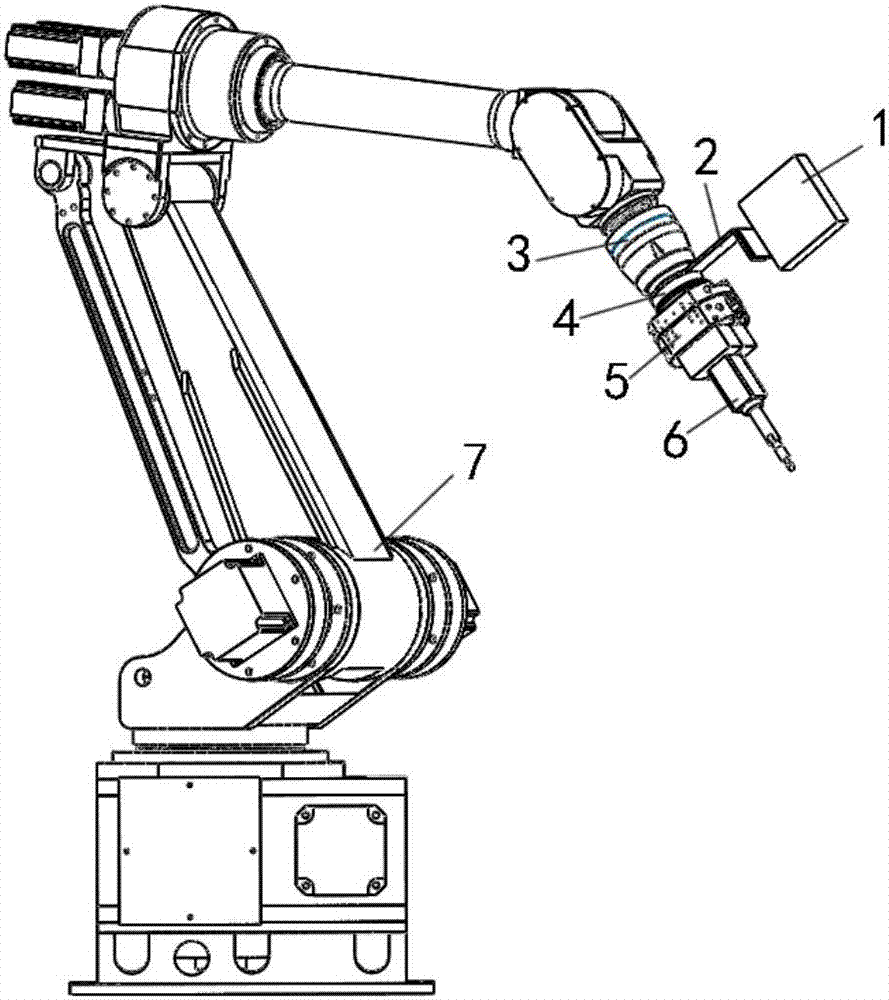

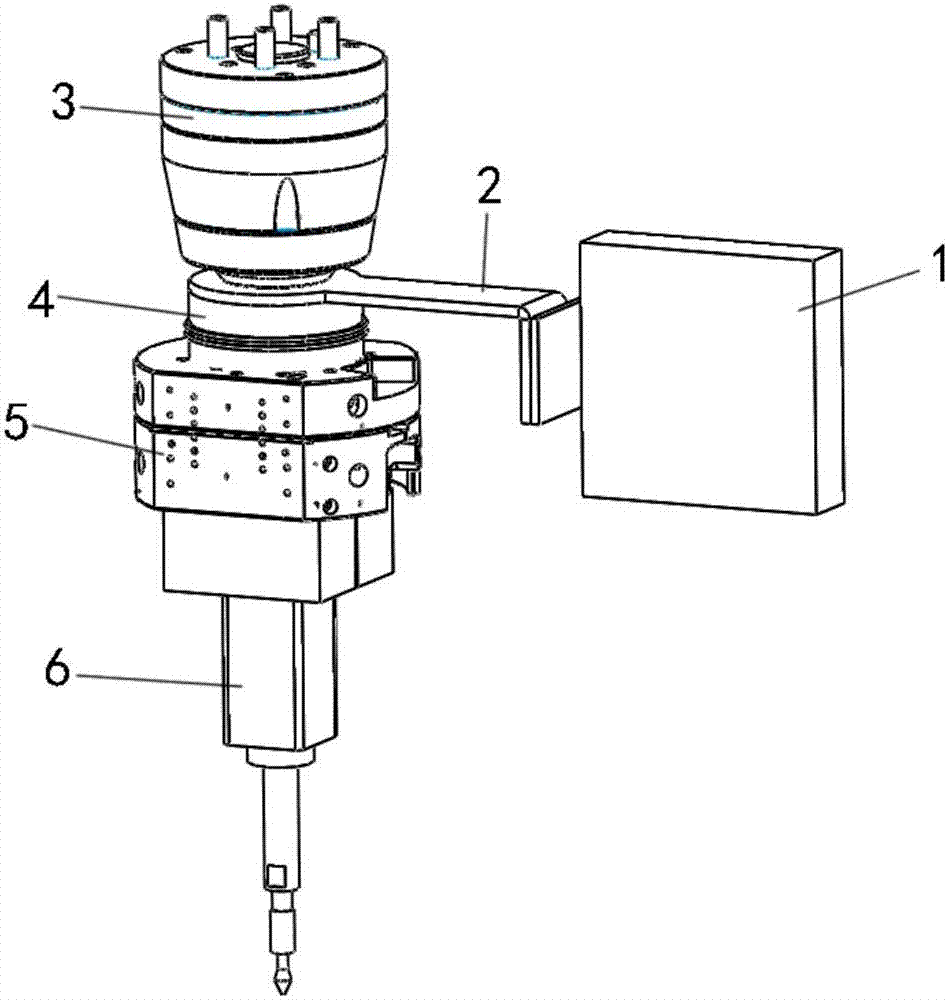

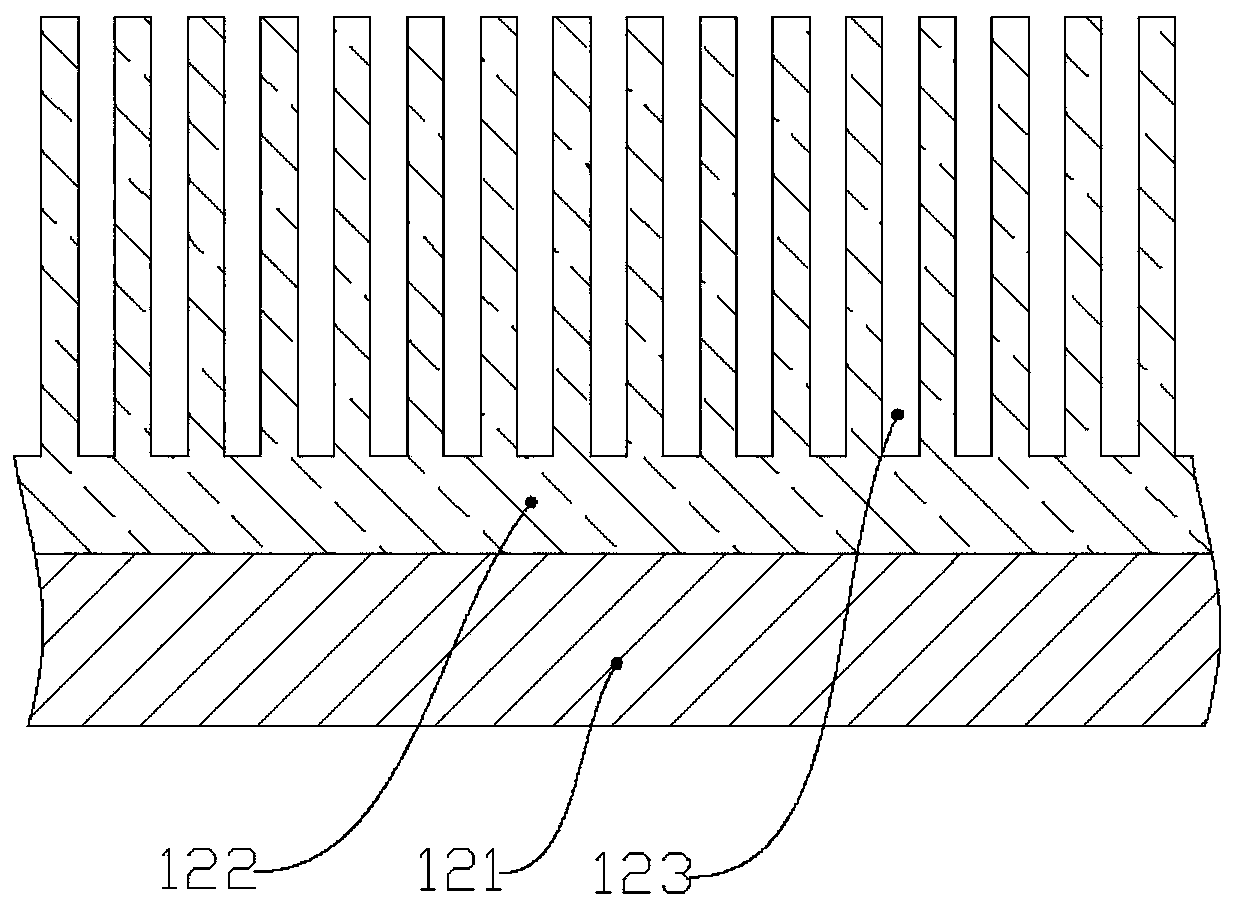

Integral leaf disc machining system and method

PendingCN106181687AReduce processing costsFlexible adjustmentGrinding carriagesGrinding machinesIndustrial roboticsMachining system

The invention discloses an integral leaf disc machining system and method, and aims to solve the problems such as low efficiency, unstable precision, great labor intensity and great dust harm due to the fact that an existing aero-engine leaf disc must adopt an artificial grinding and polishing process after being subjected to milling or electrolytic machining. The system comprises an industrial robot, a grinding device, a leaf disc, a rotary table and a control cabinet. An integral leaf disc machining path is planned and machining program is transmitted into a controller of the industrial robot; the industrial robot is started to drive an abrasive belt grinding device to enter an machining area; the industrial robot controls the grinding device to machine a target blade on the leaf disc according to the pre-planned grinding path; and the rotary table drives the leaf disc to rotate by certain angle, and the grinding and machining of each blade molded surface of the whole leaf disc are completed by repeating the process. The integral leaf disc machining system is delicate in structure, is high in grinding and machining efficiency, is flexible in working mode, is low in machining cost, eliminates potential hazards of artificial grinding operation, and has a relatively high practical value and a relatively high popularization value.

Owner:成都极致智造科技有限公司

Fully-automatic grinding and polishing device using two-dimensional laser displacement sensor

PendingCN107450470AEnsure safetyHigh precisionComputer controlSimulator controlControl systemEngineering

The present invention discloses a fully-automatic grinding and polishing device using a two-dimensional laser displacement sensor. The fully-automatic grinding and polishing device comprises the two-dimensional laser displacement sensor, a support, a quick cutter changing device, a cutter head and a robot; the robot is fixedly connected with the support; the two-dimensional laser displacement sensor and the quick cutter changing device are both mounted on the supporter; the cutter head is installed in the quick cutter changing device; the handle of the cutter head satisfies the holding requirements of the quick cutter changing device; the two-dimensional laser displacement sensor, the robot and the quick cutter changing device are all connected with a robot control system; the robot control system comprises a software control module; and the software control module includes an offline programming module for generating the machining path of a workpiece and an online correction module for correcting the machining path according to differences between the actual coordinates and standard coordinates of the workpiece. With the fully-automatic grinding and polishing device of the invention adopted, the problems of poor universality, low precision, mechanical arm vibration and wear-caused uneven cutter head output forces of a traditional robot can be solved, and the requirements of different polishing and grinding conditions can be satisfied.

Owner:四川海博达航空科技有限公司

Bridge cutting and water jet cutter integrated equipment

PendingCN111113684AWorking accessoriesAbrasive machine appurtenancesStructural engineeringWater jet cutter

The invention discloses bridge cutting and water jet cutter integrated equipment. The bridge cutting and water jet cutter integrated equipment comprises a transmission device, a cutting device and a moving frame, wherein the transmission device comprises a machine frame and a conveying belt, the conveying belt is longitudinally arranged on the outer side of the machine frame and rotates around themachine frame, and the conveying belt is used for carrying and transporting plates; the cutting device comprises a water jet cutter assembly and a saw blade bridge cutting assembly, the water jet cutter assembly is arranged on one side of the saw blade bridge cutting assembly, and the cutting device cuts the plates placed on the transmission device by alternatively using the water jet cutter assembly or the saw blade bridge cutting assembly; and the moving frame is arranged above the transmission device, the cutting device is connected with the moving frame, and the moving frame is used for driving the cutting device to move along a machining path in the horizontal direction. The bridge cutting and water jet cutter integrated equipment has the advantages of high production efficiency andgood product quality.

Owner:VEEGOO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com