Electric arc-laser composite additive manufacturing method

A technology of additive manufacturing and electric arc, which is applied in the field of additive manufacturing, can solve the problems of large internal stress, no improvement in the stress distribution of the forming structure, and coarse grains, so as to reduce anisotropy, improve dimensional accuracy and structural performance, and reduce The effect of martensitic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

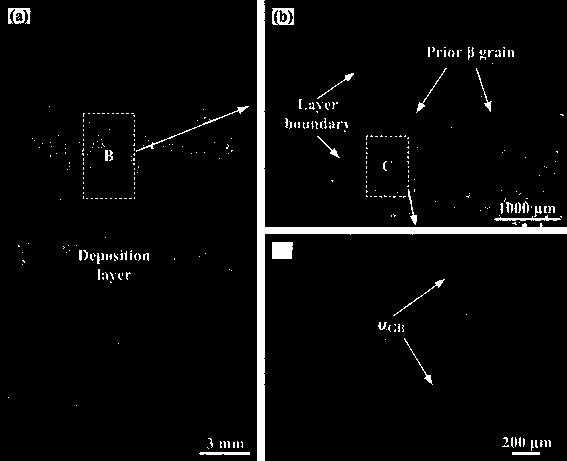

Image

Examples

Embodiment 1

[0025] An electric arc-laser composite additive manufacturing method, comprising the following steps:

[0026] (1) Cleaning: Mechanically polish the surface of the metal parts to be processed, use acetone and alcohol solvents to ultrasonically clean them to remove oil stains, dry them for use, and then measure the size of the cleaned metal parts to be processed and place them on the workbench. Fix it with a clamp and set it aside;

[0027] (2) Arc additive manufacturing: establish a 3D model of the metal parts to be processed, obtain the 3D model file, slice the file, obtain the processing path of arc additive, and set the process parameters of arc additive, in an inert gas Under the environment, the parts to be processed are deposited layer by layer by arc fuse;

[0028] (3) Laser heat treatment: According to the material of the processed metal parts and the effective wall thickness of the layer to be printed, through the simulation of the temperature field, the correspondin...

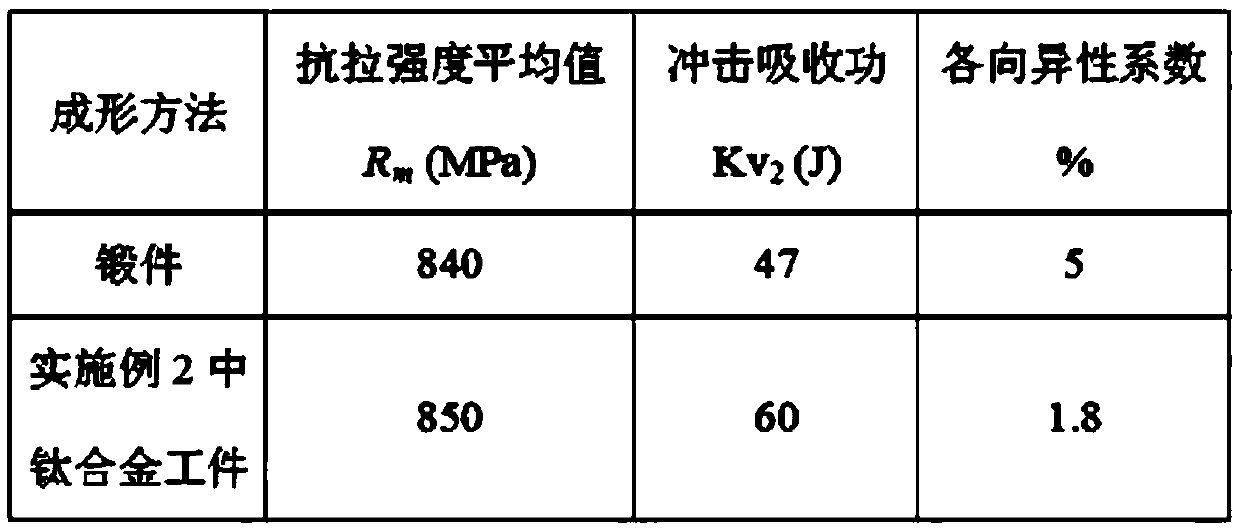

Embodiment 2

[0036] As another embodiment of the present invention:

[0037] The metal part to be processed is a titanium alloy, such as a Ti80 titanium alloy substrate, and the specification is According to the mass fraction, the Ti80 titanium alloy substrate includes the following chemical components: 5.5-6.5% Al, 2.5-3.5% Nb, 1.5-2.5% Zr, 0.6-1.5% Mo, 0.25% Fe, 0.15% Si, 0.10% of C, 0.05% of N, 0.015% of H, 0.15% of O, and the balance is Ti.

[0038] Mechanically polish the surface of the Ti80 titanium alloy substrate, use acetone and alcohol solvents to ultrasonically clean it to remove oil stains, dry it for use, then measure the size of the cleaned metal parts to be processed, place them on the workbench, fix them with fixtures, and set aside ;

[0039]Establish a 3D model of the metal part to be processed, obtain the 3D model file, slice the file, obtain the processing path of the arc additive material, and set the process parameters of the arc additive material, and adopt the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com