G code generation method for pulse laser 3D printing

A 3D printing and pulse laser technology, applied in the field of 3D printing, can solve the problem that the 3D printing G code generation method is not suitable for pulse laser 3D printing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

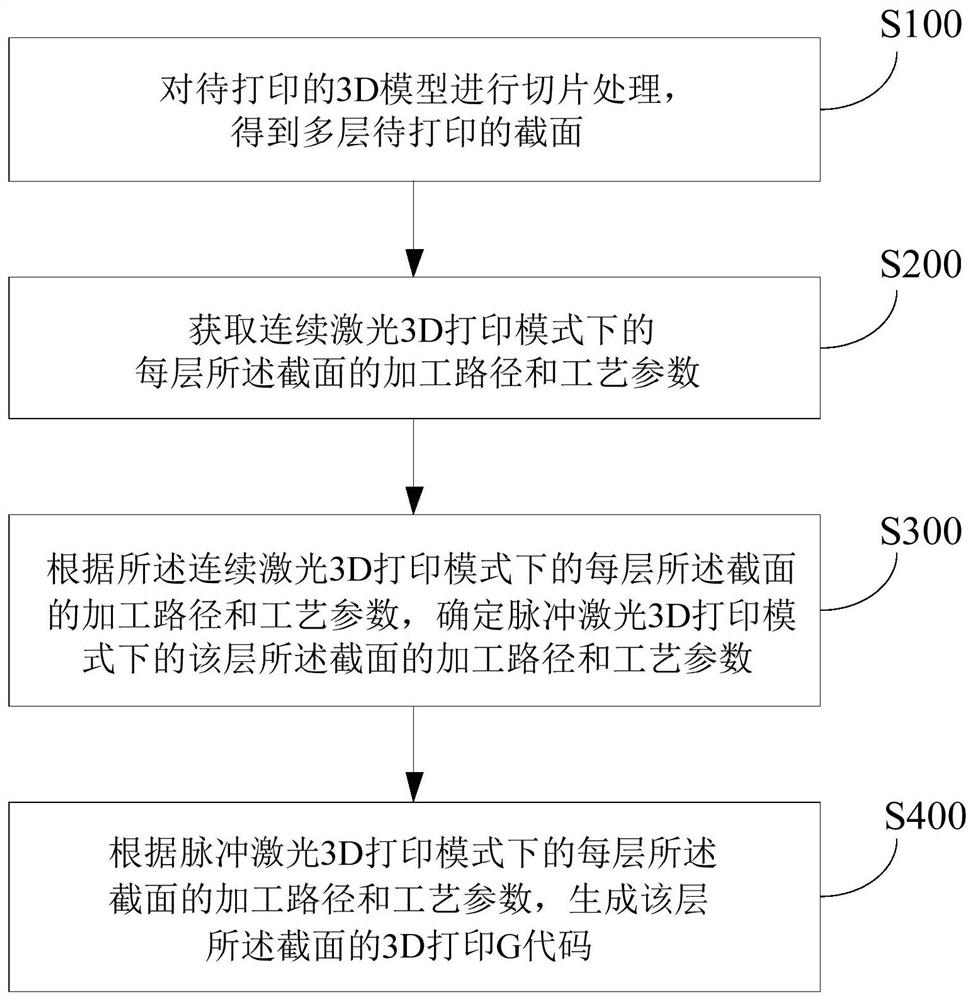

[0047] Example: figure 1 It shows the flow chart of the implementation of the G-code generation method for pulsed laser 3D printing according to the embodiment of the present invention. refer to figure 1 , the G code generation method for pulsed laser 3D printing of the present embodiment includes the following steps:

[0048] S100. Slicing the 3D model to be printed to obtain multi-layer cross-sections to be printed;

[0049] S200. Obtain the processing path and process parameters of the cross-section of each layer in the continuous laser 3D printing mode;

[0050] S300. According to the processing path and process parameters of the cross-section of each layer in the continuous laser 3D printing mode, determine the processing path and process parameters of the cross-section of the layer in the pulsed laser 3D printing mode;

[0051] S400. Generate a 3D printing G code for the section of each layer according to the processing path and process parameters of the section in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com