Rapid prototyping SLA 3D printer and printing method thereof

A printer, fast technology, applied in the rapid prototyping SLA3D printer and its printing field, can solve the problems of equipment cost, maintenance cost, high material cost, toxicity of photosensitive resin raw materials, etc., and achieve the effect of simple structure, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

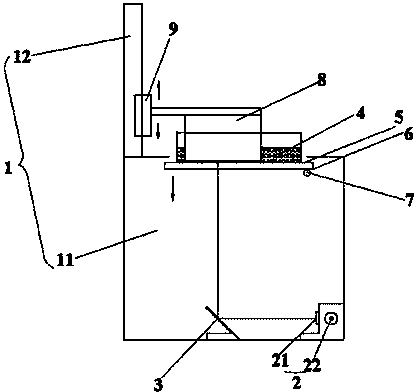

[0033] Such as figure 1 As shown, a rapid prototyping SLA3D printer includes a SLA3D printer body 1, the SLA3D printer body 1 includes a hollow cabinet 11 and a bracket 12 extending upward along one side of the cabinet, the cabinet 11 A laser scanning device 2 is provided at the front end of the bottom surface, a reflector 3 is provided at the center of the bottom surface of the cabinet 11, a resin tank 4 is provided directly above the reflector 3, and a high-transmittance quartz is fixed on the bottom surface of the resin tank 4. Glass 5, the high-transmittance quartz glass 5 is fixed on the iron plate 6, the iron plate 6 is fixedly connected with the motor 7 arranged on the bottom surface of the cabinet body 11, and a suspension is provided directly above the resin tank 4 platform 8, the support 12 is provided with a vertical slide rail 9, and the suspension platform 8 slides up and down along the vertical slide rail 9. Wherein, the motor 6 is preferably a through-type step...

Embodiment 2

[0046] Compared with Embodiment 1, the only difference is that the laser scanning galvanometer 22 is U-shaped, which can improve the scanning positioning accuracy. The bottom surface of the resin tank 4 is provided with an anti-adhesive layer, the anti-adhesive layer is a release film anti-adhesive layer or a Teflon anti-adhesive layer, it can also be a polydimethylsiloxane anti-adhesive layer, a release film Any combination of anti-adhesive layer or Teflon anti-adhesive layer; when used, it can be used alone or in combination.

[0047] Compared with the prior art, the rapid prototyping SLA3D printer and printing method thereof of the present invention have the following beneficial effects:

[0048] 1. The rapid prototyping SLA 3D printer of the present invention adopts laser curing, and the forming speed is fast;

[0049] 2. The rapid prototyping SLA 3D printer of the present invention includes a pull-down mechanical structure that eliminates vacuum force, greatly improving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com