Multicolor three-dimensional forming device for 3D printer and forming method

A 3D printer and three-dimensional molding technology, applied in the field of 3D printers, can solve the problems that 3D printers do not have the function of multi-color product printing, and the color connection is not good at the color changing place, so as to achieve the effect of good connection and exquisite products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

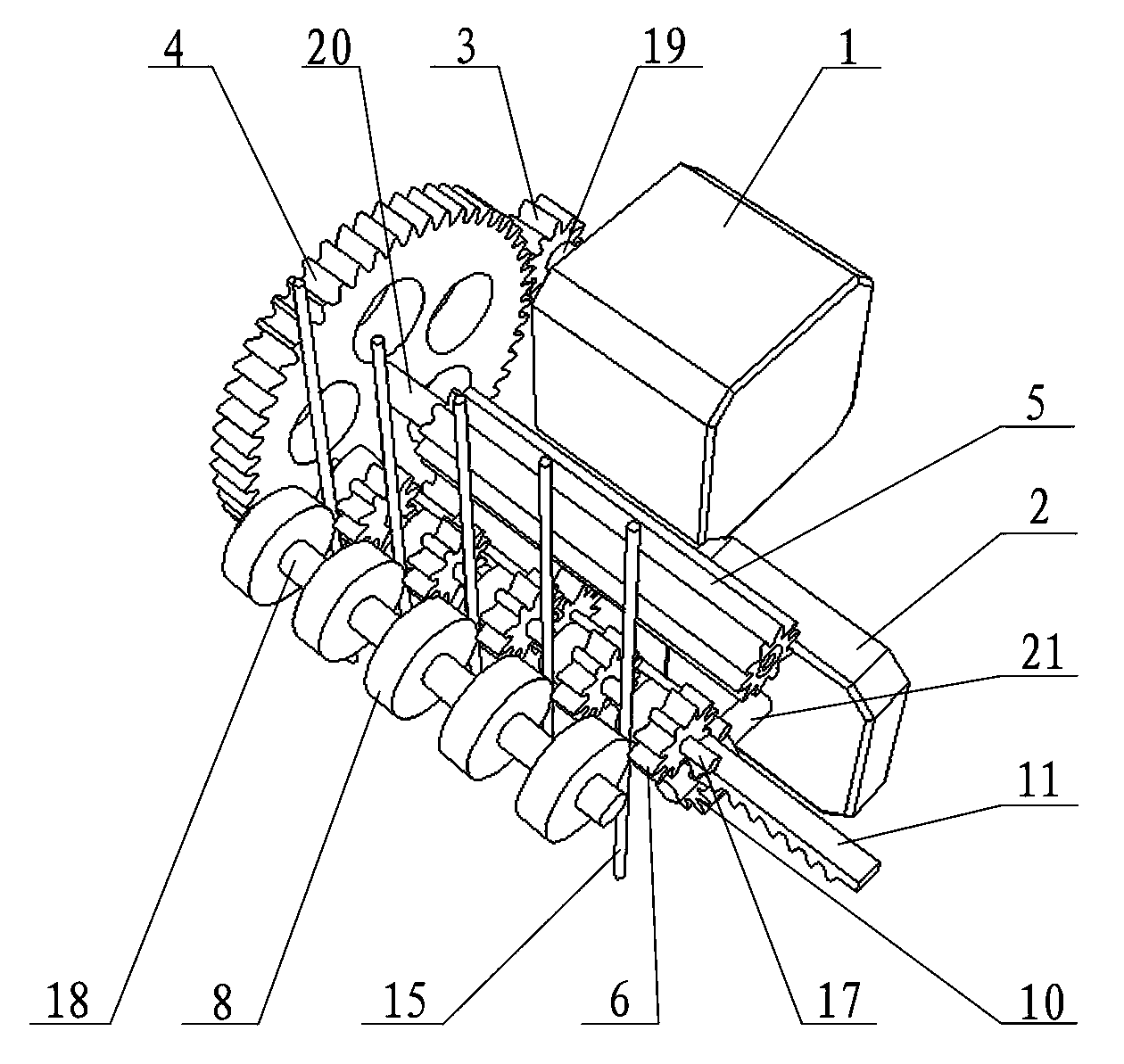

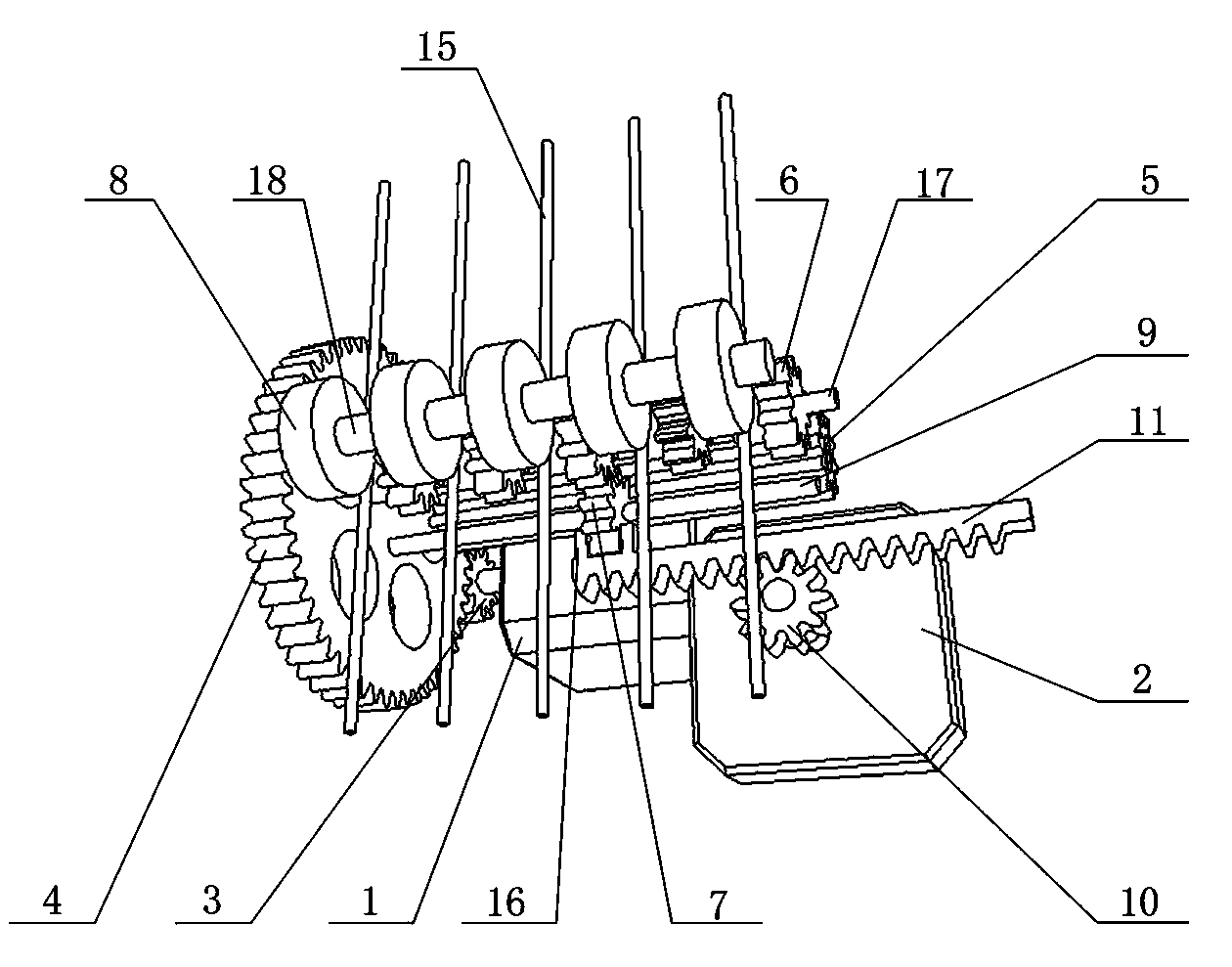

[0056] Embodiment 1: A 3D printer multi-color three-dimensional forming device.

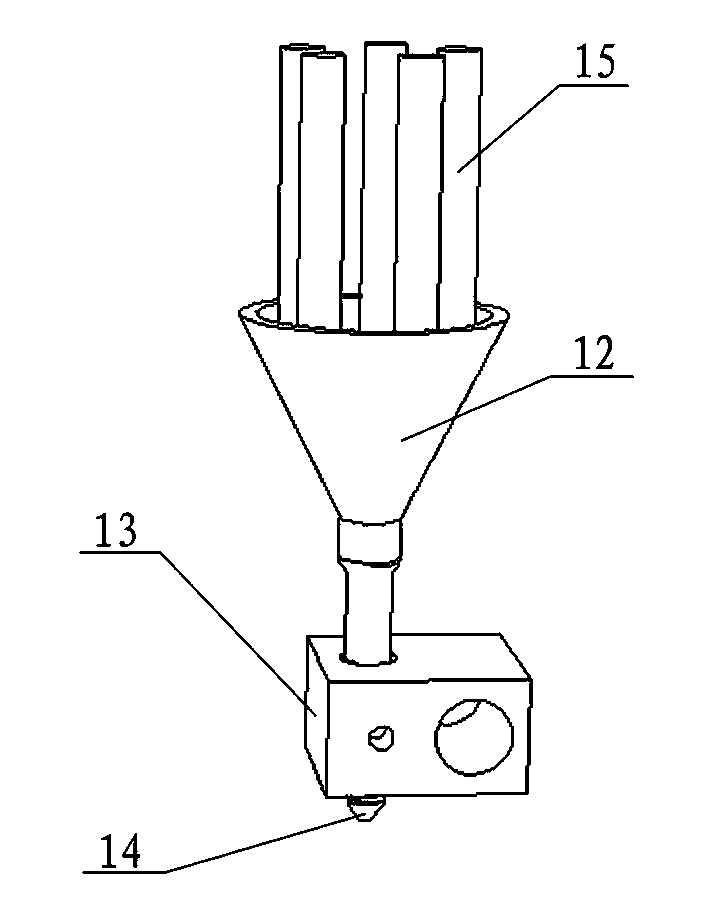

[0057] Such as Figure 1 ~ Figure 3 As shown, the 3D printer multi-color three-dimensional forming device in the present invention includes a frame (not shown in the figure) and a feeding mechanism installed on the frame (see figure 1 and figure 2 ) and discharge mechanism (see image 3 ).

[0058] Such as figure 1 and figure 2 As shown, the feeding mechanism includes a feeding motor 1, a refueling motor 2, a pinion shaft 5, a shifting gear 7, several feeding gears 6, several extrusion wheels 8 and a controller (not shown in the figure).

[0059] The feeding motor 1 is used to drive the pinion shaft 5 to rotate. In the embodiment of the present invention, the feeding motor 1 drives the pinion 5 through the first gear 3 and the second gear 4; the first gear 3 is installed on the first gear shaft 19, and the first gear shaft 19 is connected to the feeding motor 1 through a coupling The sec...

Embodiment 2

[0067] Embodiment 2: A method for multi-color three-dimensional molding of a 3D printer.

[0068] combine Figure 1 ~ Figure 3 , 3D printer multi-color three-dimensional molding method in the present invention comprises the following steps:

[0069] ① Set up the frame, and set the feeding mechanism on the frame (see figure 1 and figure 2 ) and discharge mechanism (see image 3 ).

[0070] The feeding mechanism includes a feeding motor 1, a refueling motor 2, a pinion shaft 5, a shifting gear 7, several feeding gears 6, several extrusion wheels 8 and a controller (not shown in the figure).

[0071] The feeding motor 1 is used to drive the pinion shaft 5 to rotate, and the pinion shaft 5 is meshed with the shifting gear 7 . The shifting gear 7 is freely installed on the smooth feeding shaft 9 , and the shifting gear 7 is driven by the refueling motor 2 and can move in a direction parallel to the axial direction of the pinion shaft 5 . Several feeding gears 6 are rotated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com