ABS (acrylonitrile butadiene styrene) material used for 3D (three dimensional) printing and manufacturing process thereof

An ABS material and 3D printing technology, applied in the field of 3D printing, can solve problems such as easy breakage, insufficient product strength, cracking, etc., and achieve the effects of enhancing strength, improving uniform mixing, and good material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

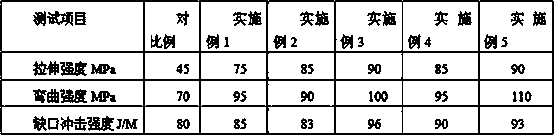

Embodiment 1

[0023] The ABS material includes 50kg of ABS resin, including: 50kg of bulk ABS with a rubber particle size of 0.8-1.0μm; 10kg of glass fiber with a monofilament diameter of 3-10μm and an aspect ratio L / D=5; Sodium 8kg; Ethylene bis stearic acid amide 3kg; Ethyl acetate 5kg;

[0024] The above-mentioned components are mixed and stirred in a mixer at room temperature for 10 minutes, and then extruded through a twin-screw extruder with a length-to-diameter ratio (L / D) of 1 / 25. The reaction temperature is: 200°C in the rear section , 200 ° C in the middle section, 210 ° C in the front section, and the screw speed is 120 rpm.

Embodiment 2

[0026] ABS materials include 65 kg of ABS resin, including 35 kg of bulk ABS with a rubber particle size of 0.8-1.0 μm, 30 kg of bulk ABS with a rubber particle size of 0.1-0.2 μm; =15 glass fiber 15kg; sodium methylene dinaphthalene sulfonate 8kg; ethylene bis stearic acid amide 4kg; ethyl acetate 7kg;

[0027] The above-mentioned components are mixed and stirred for 20 minutes in a mixer at room temperature, and then extruded through a parallel twin-screw extruder with a length-to-diameter ratio (L / D) of 1 / 36. The reaction temperature is: 190°C, 210°C in the middle section, 220°C in the front section, and the screw speed is 180rpm.

Embodiment 3

[0029] ABS materials include 70kg of ABS resin, including 30kg of bulk ABS with a rubber particle size of 0.8-1.0μm, 15kg of bulk ABS with a rubber particle size of 0.1-0.2μm, and 25kg of bulk ABS with a rubber particle size of 1.5-3.0μm; 20kg of glass fibers with a diameter of 3-5μm and an aspect ratio L / D=10; 7kg of sodium methylene bis-naphthalene sulfonate; 5kg of ethylene bis-stearic acid amide; 10kg of ethyl acetate;

[0030] The above-mentioned components are mixed and stirred for 40 minutes in a mixer at room temperature, and then extruded through a parallel twin-screw extruder with a length-to-diameter ratio (L / D) of 1 / 36. The reaction temperature is: 210°C, middle stage 210°C, front stage 230°C, screw speed 160rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com