Bending-straightening machine for a long workpiece, device for feeding in and removing said workpiece and method for bend-traightening long workpieces

A technology for outputting equipment and long workpieces, applied in the field of straightening machines, can solve problems such as elastic recovery obstacles, and achieve the effect of simple connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

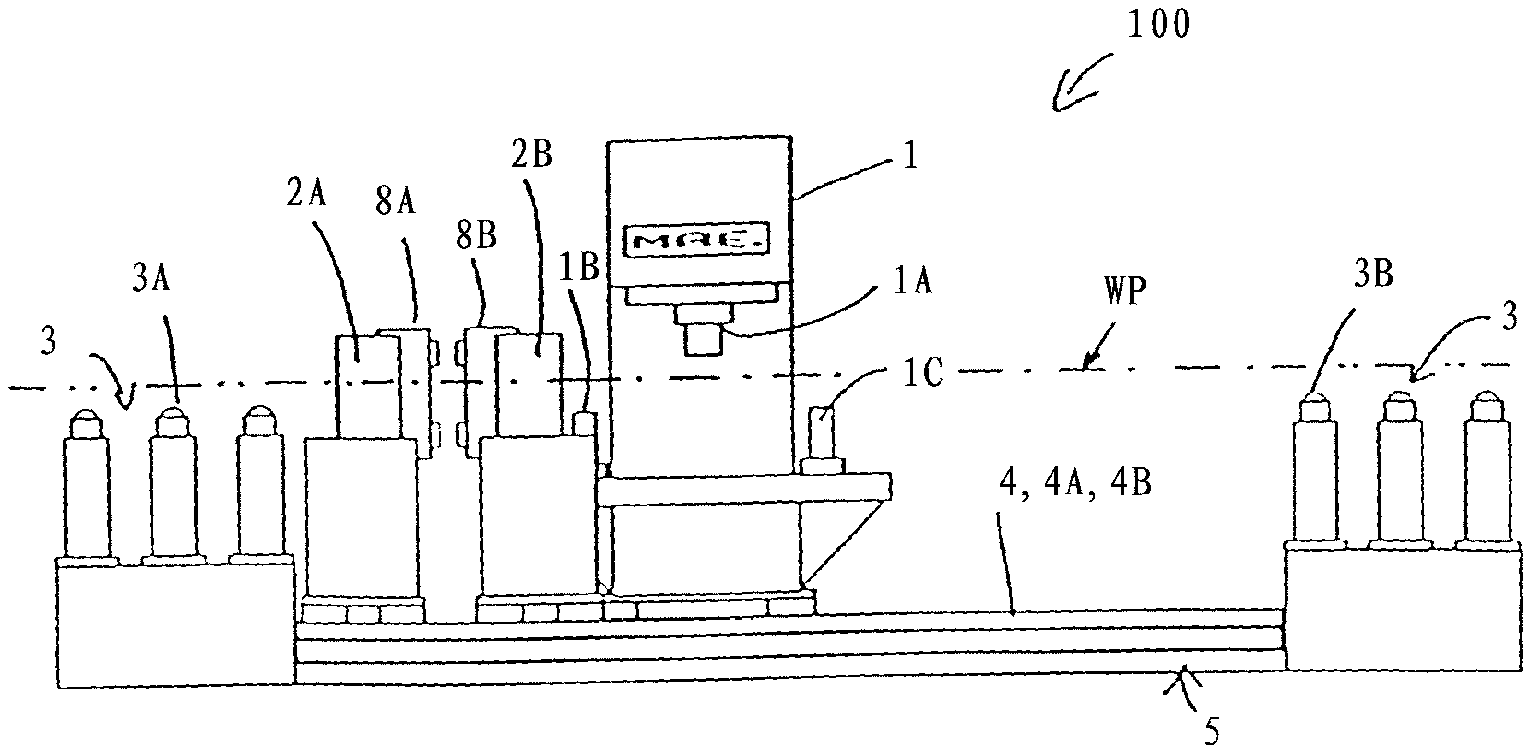

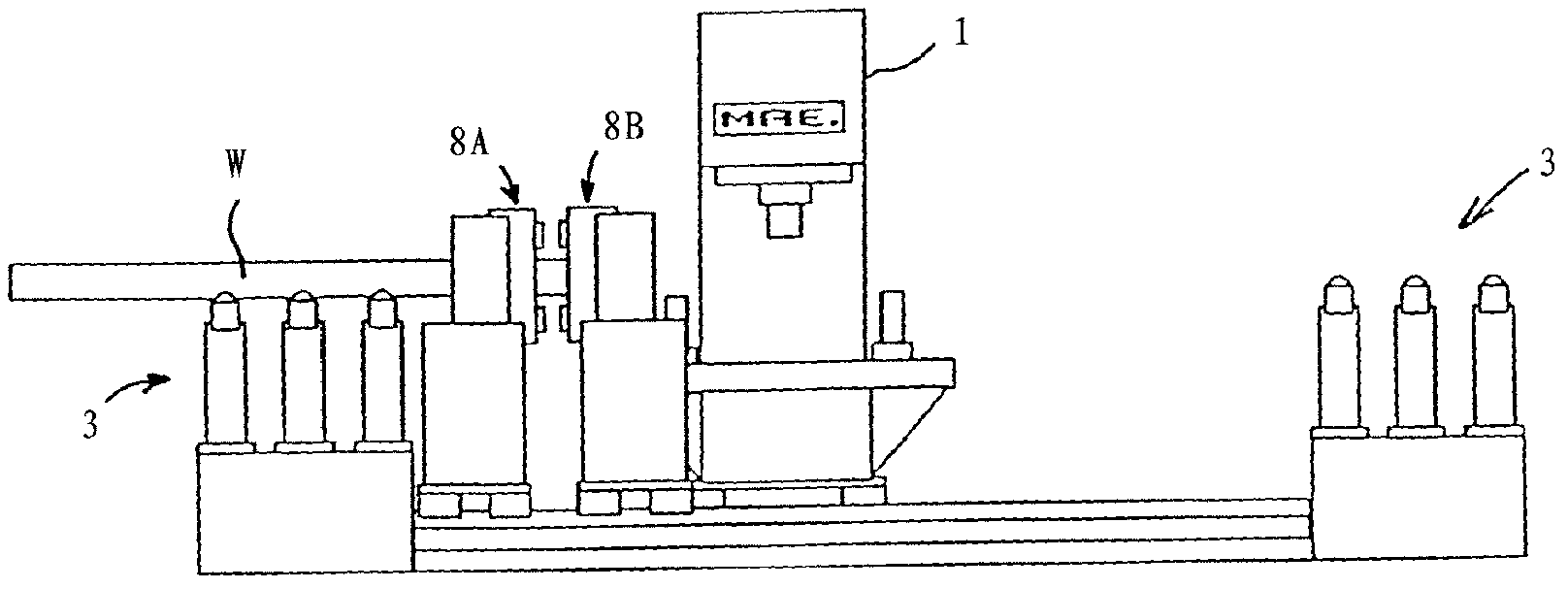

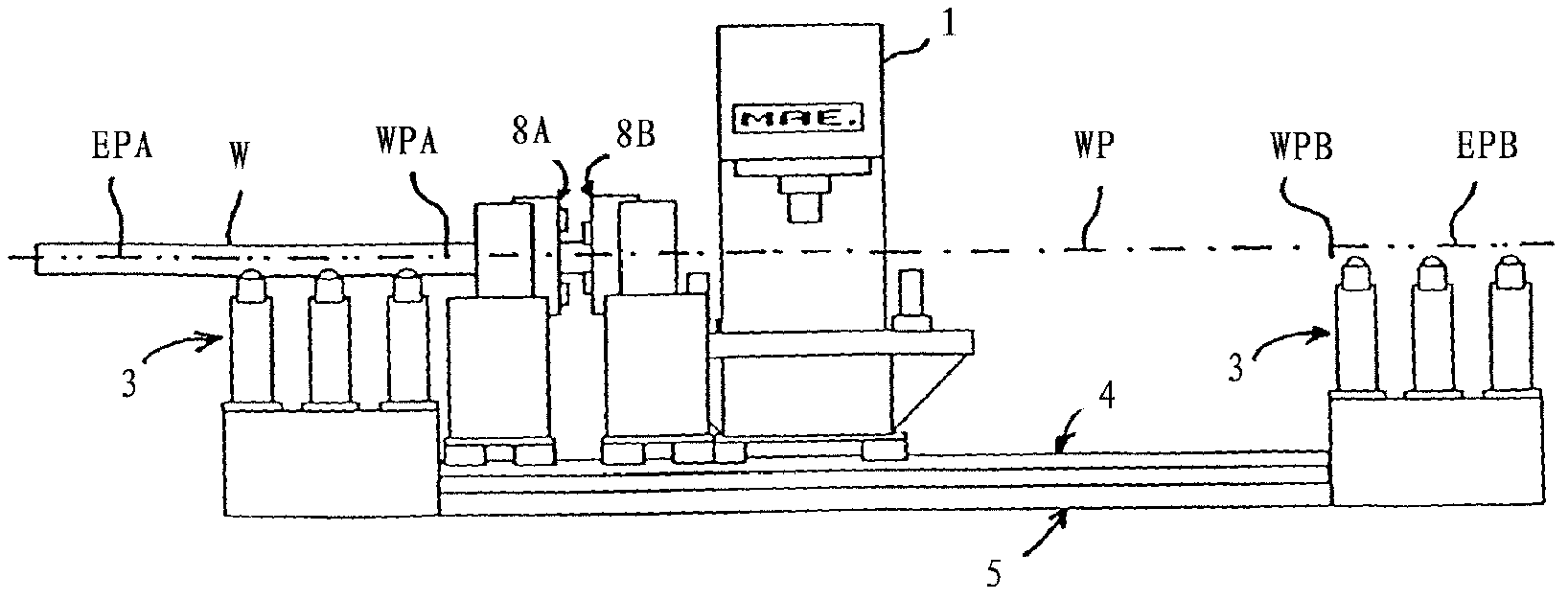

[0020] as in figure 1 Clearly visible in , the straightening machine marked as a whole with 100 comprises a press frame 1 movable horizontally along guide rails 4, 4A, 4B, said press frame having straightening heads 1A acting vertically and spacing Variable vertically acting straightening anvils 1B, 1C. Like the press frame 1 , the two clamping devices 2A, 2B are motor-driven longitudinally displaceable along the guide rails 4 , 4B of the machine bed 5 . Alternatively, it can be provided that the press frame 1 is fixedly arranged, which is not shown in the figures.

[0021] The clamping devices 2A and 2B together with the straightening head 1A and the straightening anvils 1B and 1C define a machining path WP shown in dotted lines, which coincides with the workpiece W clamped for machining ( Figure 3A -C). Accordingly, the working area delimited by the straightening head 1A and the straightening anvils 1B, 1C is a subpath of the working path WP. Due to the movability of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com