Abrasion-resistant adhesive tape

A technology of adhesives and tapes, applied in the direction of adhesive types, adhesives, polyurea/polyurethane adhesives, etc., can solve problems such as no open tapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

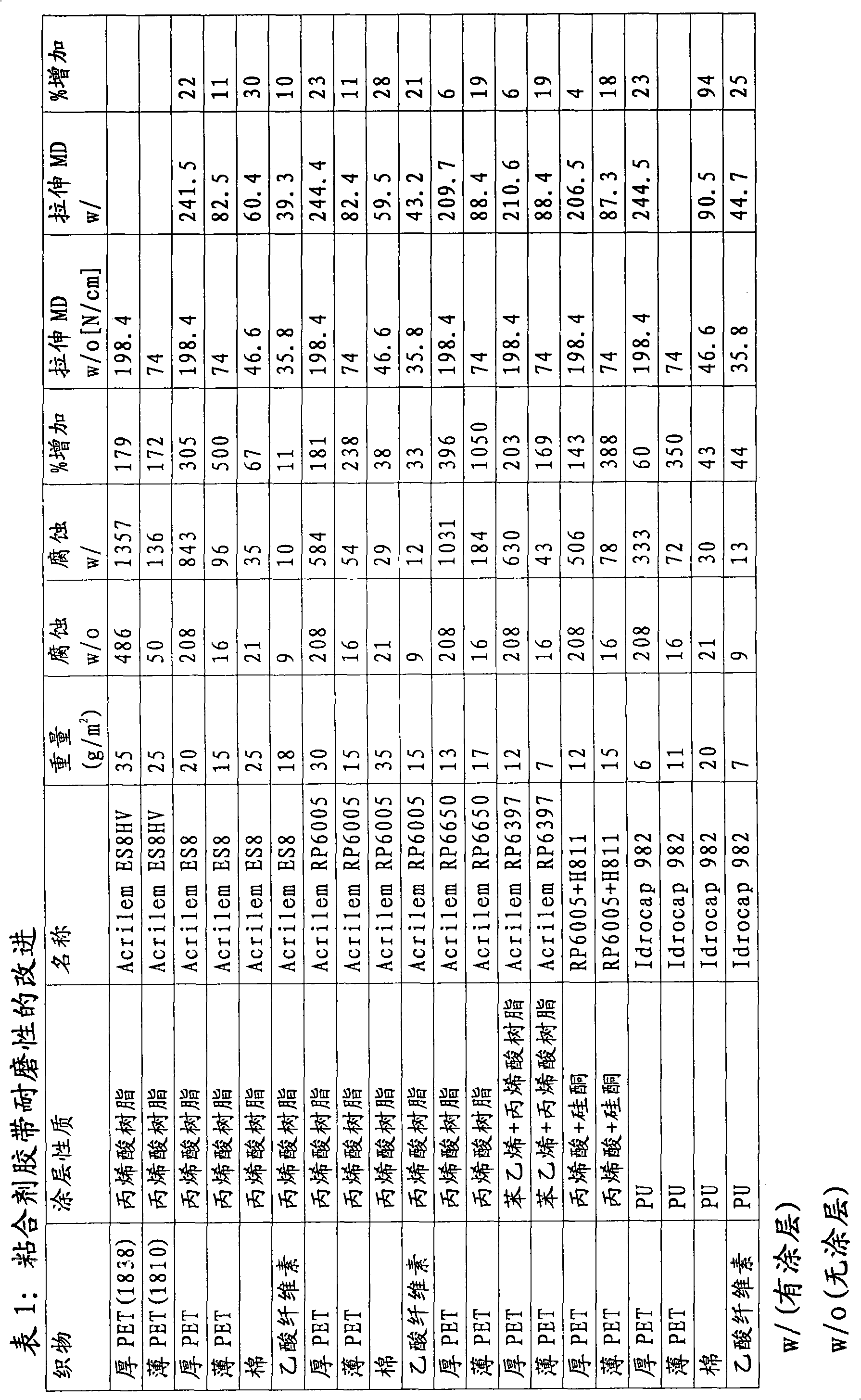

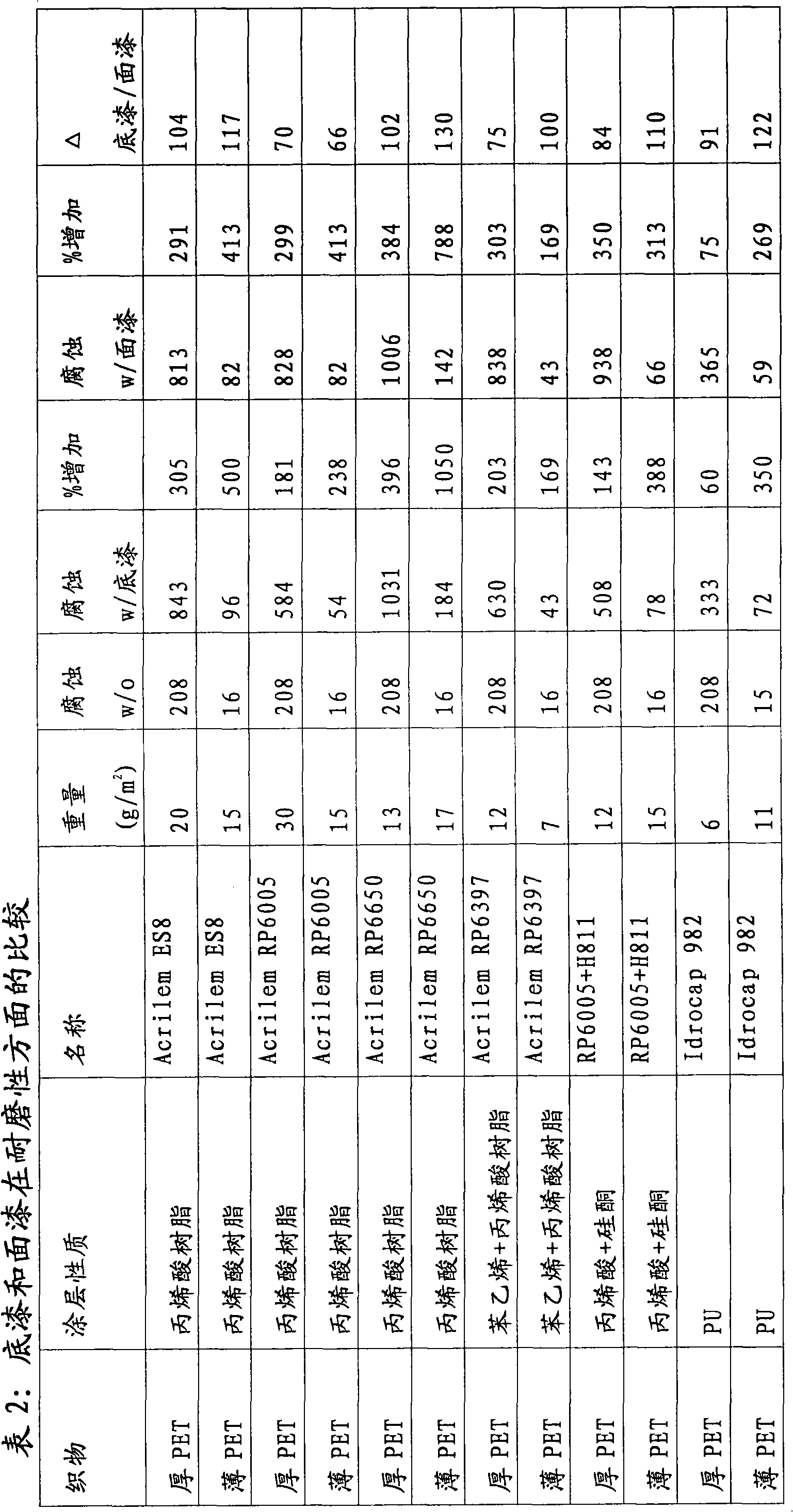

Examples

Embodiment

[0054] The examples provided herein were prepared using the following textile coating formulations. All starting materials used here were obtained from ICAP-Sira.

[0055] Coating polymer 100g aq.

[0056] Defoamer, Icawet N 1 drop

[0057] Ammonia 1% 1g

[0058] Thickener Acrilem 36630 3g, up to 15000mPas

[0059] The coating polymer can be polyurethane, acrylic, styrene-acrylic or silicone polymers. In the examples where silicone additives were used, 5% wetting agent was added.

[0060] A typical laboratory procedure for producing samples is described below. The polymer dispersion formulation listed above was applied to a sheet of polyester fabric held in a clamping device approximately A4 in size. Hand coating is done using an air knife process followed by drying by any standard process known in the art. Use roll-on-roll coating head, adopt 40g / m 2 A solvent based acrylic adhesive, such as Durotak 1104 available from National Starch & Chemical, applies the adhesive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com