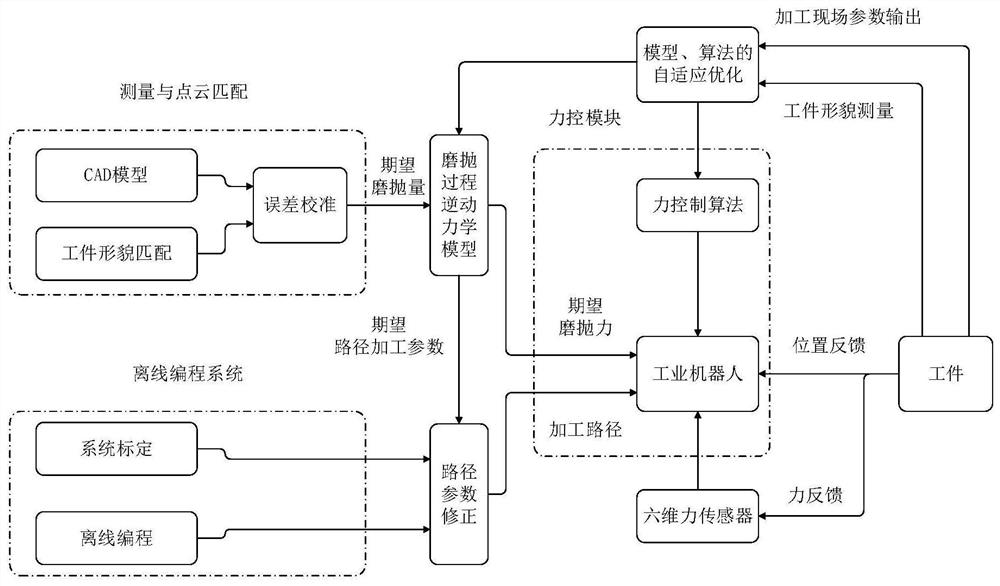

Active control method for grinding and polishing machining contact force of robot

A technology of active control and robotics, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of dependence on response speed and difficult control, so as to improve force tracking effect, processing accuracy and tracking effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

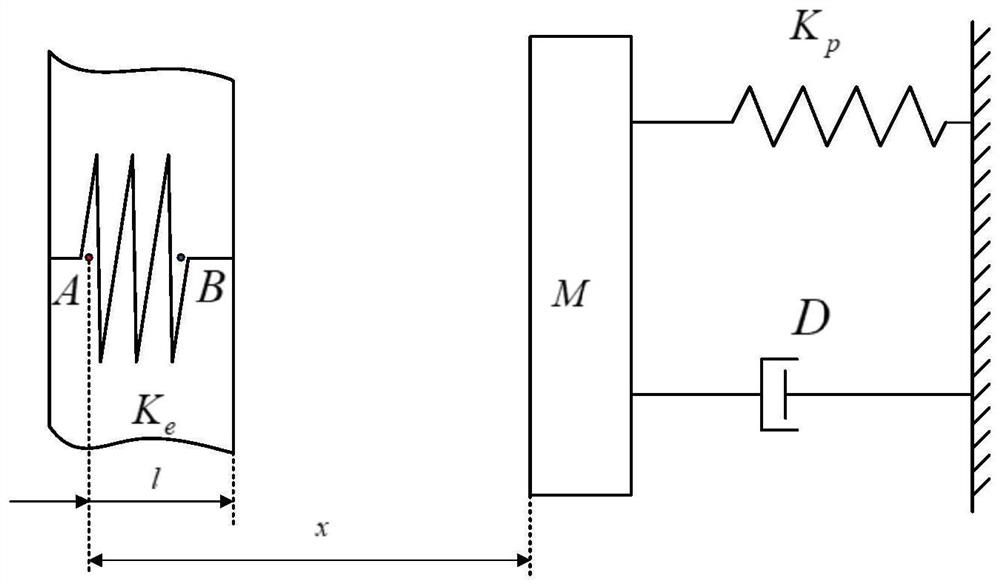

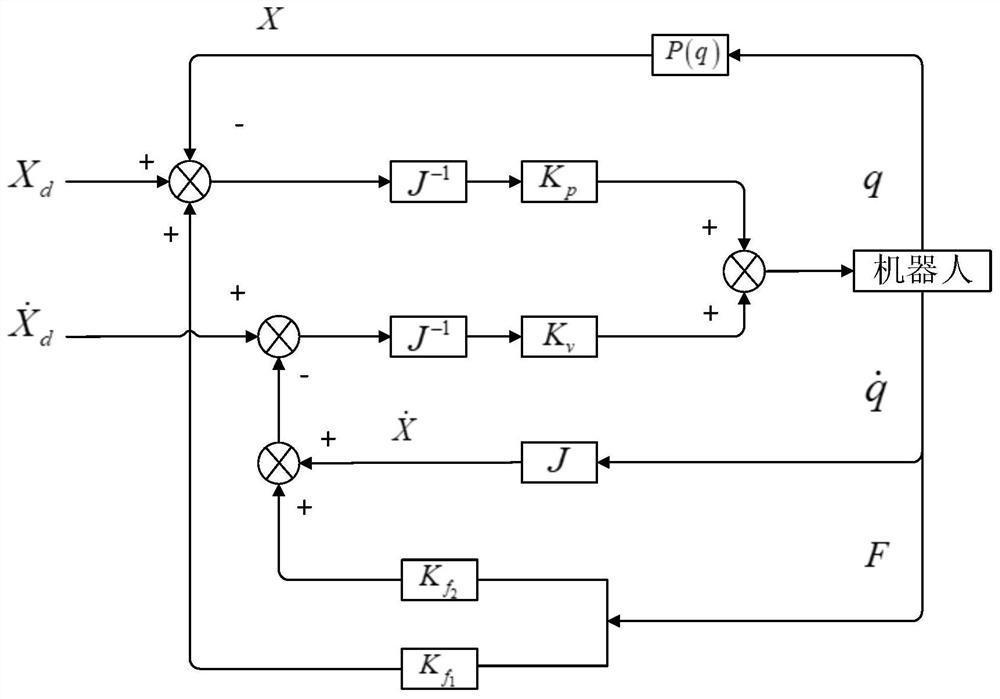

[0095] An active control method for contact force of robot grinding and polishing in an embodiment of the present invention is used to improve the tracking effect of impedance control on the expected force, improve the processing effect of the grinding and polishing system and the surface quality of the workpiece, and specifically includes the following steps:

[0096] (1) Perform off-line programming and simulation of the blade model in RobotStudio software, and complete the calibration of sensors such as robots, workpiece coordinate systems, scanners, and six-dimensional force sensors on site;

[0097] (2) Use the robot motion under non-impedance control to obtain the coordinate value of the robot in the z direction of the tool coordinate system, and perform polynomial fitting on the obtained position points to determine the key parameters in the objective function, thereby determining the primary constraints Objective function:

[0098]

[0099] In the formula, N is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com