Hot-working die surface multipoint combination type bionic machining device and strengthening repair method

A technology of hot work die and processing equipment, applied in metal processing equipment, welding equipment, laser welding equipment and other directions, can solve the problems of reduced cold and heat fatigue resistance, mold brittle fracture, etc., to achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

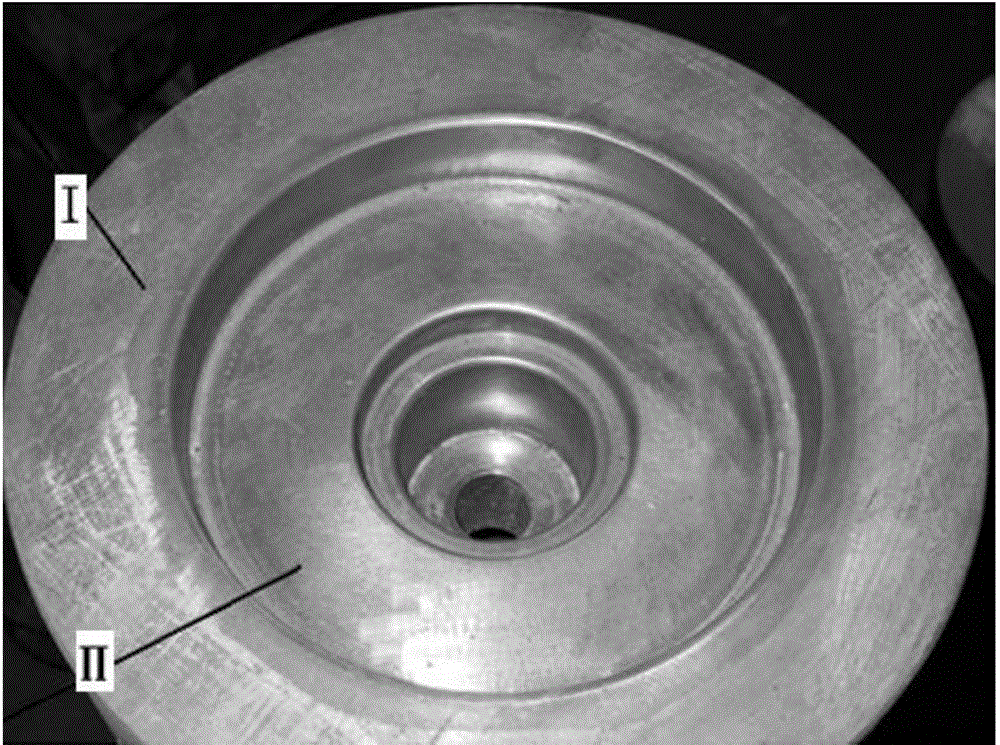

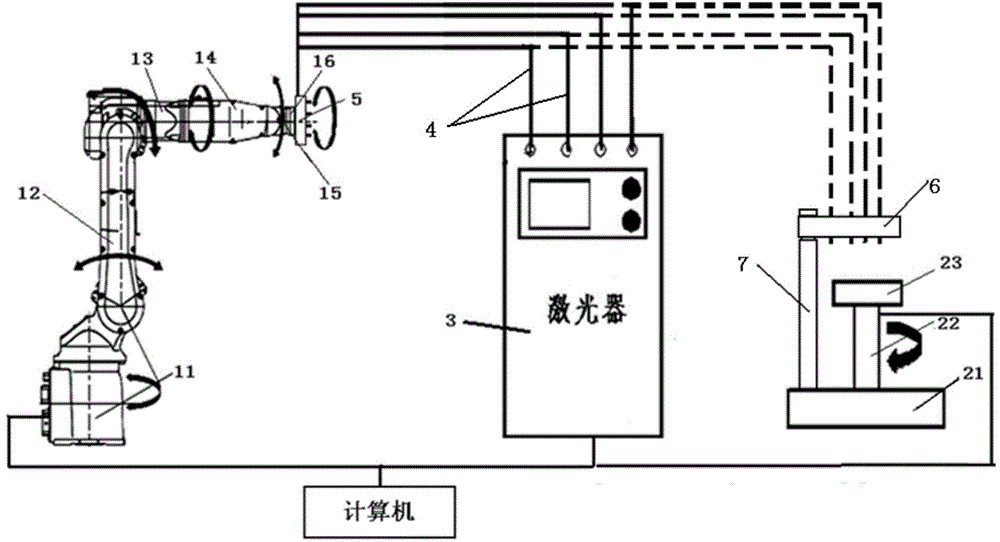

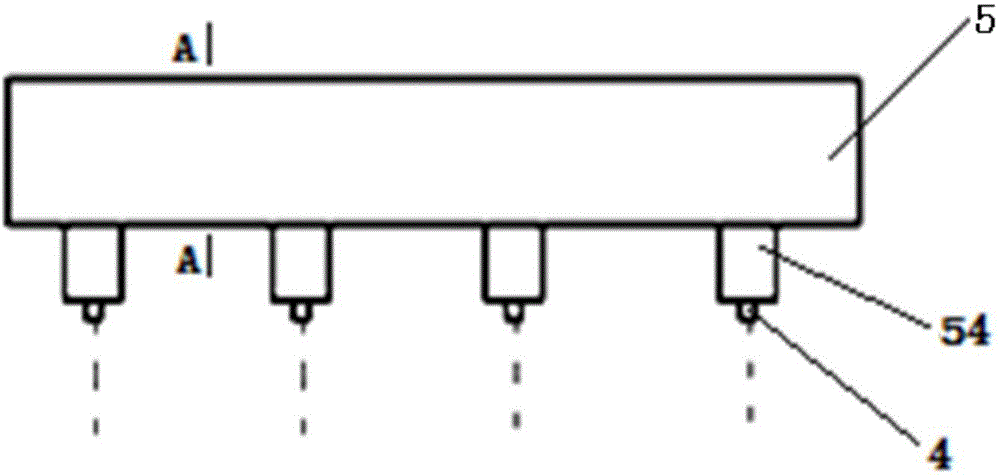

[0064] According to the distribution of working stress and thermal fatigue on the surface of the hot working mold, the surface laser bionic strengthening is carried out on the parts prone to wear when the device embodiment of the present invention manufactures the hot working mold with the bionic reinforced unit body on the surface. Such as Figure 6 Shown is a set of forging dies for the production of an automobile part. On its surface, we conduct bionic laser treatment on five parts on its surface according to its stress and failure mode. The position of area I in the figure is mainly affected by mild impact wear and thermal fatigue. Therefore, the number of optical fiber laser output channels is selected as 1 during processing. The fiber laser head is clamped on the first laser head splint 5, and the mold can be placed on the ground. On or on the workbench 23 (the workbench 23 is still during processing), the selected parameters are current 100A, pulse width 10ms, frequency...

Embodiment 2

[0067] According to the distribution of working stress and thermal fatigue on the surface of the hot working mold, the surface laser bionic strengthening is carried out on the parts prone to wear when the device embodiment of the present invention manufactures the hot working mold with the bionic reinforced unit body on the surface. Figure 7 The mold in the forging mold is a typical automobile disc-shaped part production mold in the forging mold. According to the summary data of the experiment, a single-point energy density of 350J with a current of 120A, a pulse width of 8ms, a frequency of 4HZ, and a defocus of 5.5mm is used to vertically Scan the surface of the guide rail, the 3-way fiber laser head is clamped on the second laser head splint 6, the mold is placed on the workbench 23, the relative speed between the fiber laser head and the workbench is about 0.7mm / s, the distance between the fiber laser head and the mold The surface distance is 110mm; the formed unit body ha...

Embodiment 3

[0070] According to the distribution of working stress and thermal fatigue on the surface of the hot working mold, the surface laser bionic strengthening is carried out on the parts prone to wear when the device embodiment of the present invention manufactures the hot working mold with the bionic reinforced unit body on the surface. Figure 8 The mold in the forging mold is used to manufacture the automotive connecting rod parts in the forging mold. From the figure, it can be seen that the part that needs to be processed is divided into 4 parts, the positions are different, and the heights are also quite different. The force and wear of the four parts are also different. During processing, process according to the following steps:

[0071] 1. According to the damage mode of the parts, four areas are selected as the treatment areas for laser processing, which are the areas I, II, III, and IV shown in the figure. According to the different wear modes of the 4 areas, the paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com