Method of CNC automatic programming for gear hobbing based on standard template and expression driving

An expression-driven, standard template technology, applied in simulators, program control, instruments, etc., can solve problems such as low efficiency, high technical requirements for workers, long processing cycles, etc., to reduce technical requirements, improve programming efficiency, and benefit normalized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

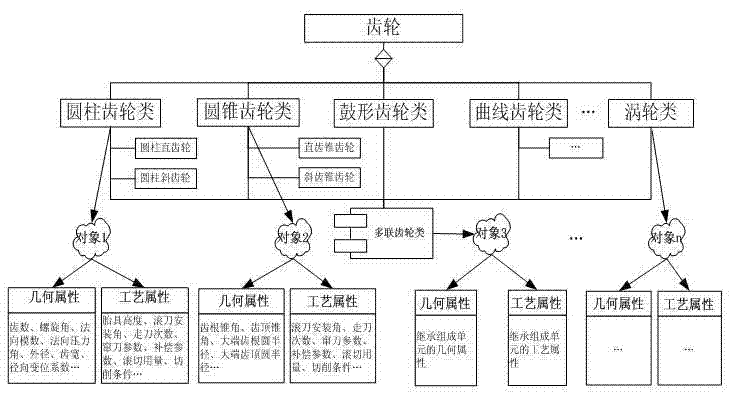

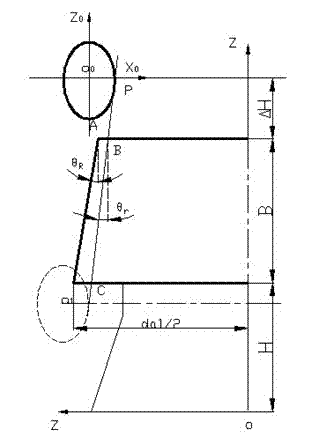

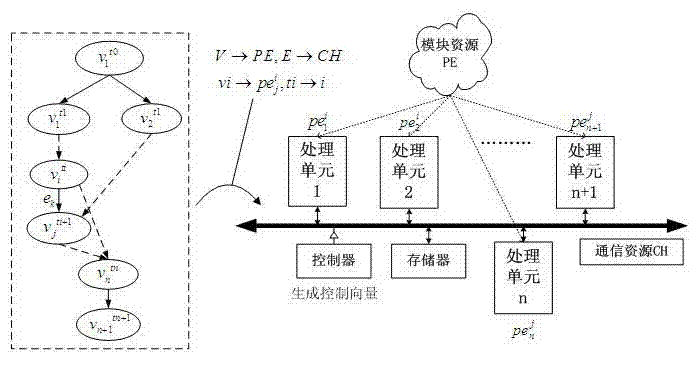

[0020] The idea of the present invention is: use the principle of group technology to establish a gear mathematical model according to the similarity of the geometric features of the gears, preset the NC standard template structure according to the similarity of the gear processing process features, and preset the modules according to the similarity of the NC codes , by setting the necessary processing parameters through the man-machine interface, the process parameters and NC standard template of gear hobbing can be determined, and the expression-driven algorithm is used to complete the instantiation of the standard template and generate the NC code file.

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0022] The gear hobbing CNC automatic programming method driven by standard templates and expressions of the present invention comprises the following steps:

[0023] Step 1, through the human-computer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com