Ultrasonic impact and deposition forming integrated device and technology for improving structure and performance of additive manufacturing metal component

A technology of ultrasonic shock and additive manufacturing, which is applied in the direction of additive processing, metal material coating technology, and energy efficiency improvement. It can solve the problems of microstructural defects, easy deformation and cracking of workpieces, and achieve the elimination of tissue defects and reduce stress concentration. , the effect of improving organizational performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

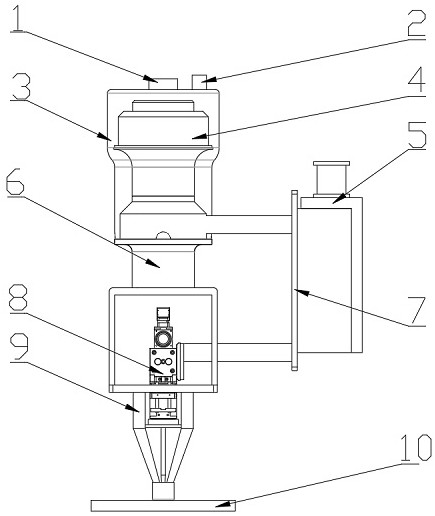

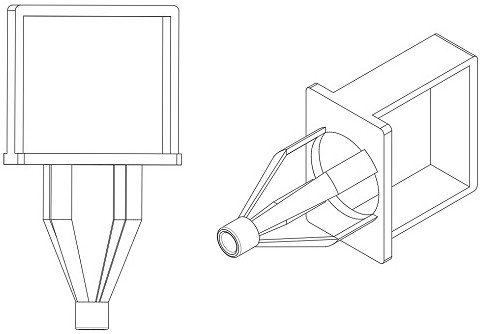

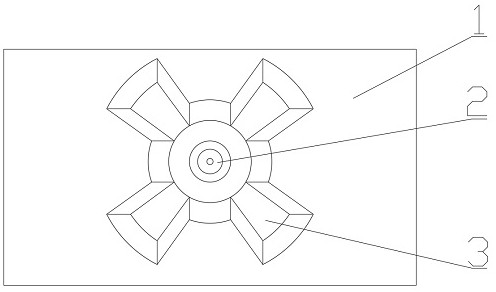

[0035] combine figure 1 , a new type of ultrasonic impact and laser deposition integrated composite technology and device for improving the metal structure and performance of additive manufacturing in the present invention, including: aviation plug 1, compressed air interface 2, transducer shell 3, transducer 4, Pneumatic sliding table 5, horn 6, pneumatic sliding table connecting frame 7, laser (or electric arc, electron beam, plasma) coaxial cladding head and connecting parts 8, embedded hollow ring tool head 9; The feature is that the aviation plug is used to connect the external ultrasonic generating device for signal transmission; the external cooling gas is connected with the transducer shell through the compressed air interface to realize the cooling of the transducer. The transducer, horn, and embeddable hollow ring tool head are all rigidly connected by screws to ensure that the frequency of the tool head acting on the surface of the workpiece really reaches the ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com