Femtosecond laser precision removal method for thermal barrier coating of turbine blade

A thermal barrier coating, femtosecond laser technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of thermal barrier coating failure, damage, high cost, etc., and achieve the effect of high-precision removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

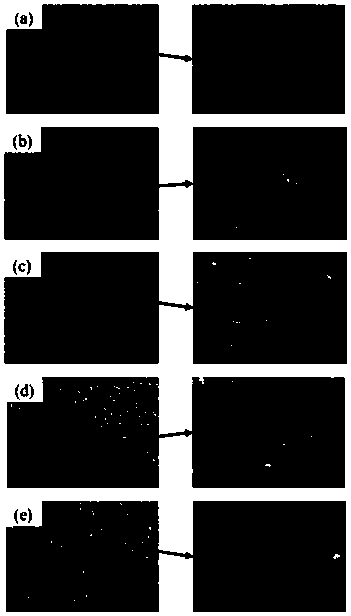

[0049] This embodiment mainly studies the influence law of laser power, and the specific process is:

[0050] The first step, before processing the workpiece, install the workpiece to be processed on the workbench, and set the parameters of the laser, among which, the wavelength is 1064nm, the pulse width is 290fs, the repetition frequency is 1000kHz, and the laser working power is 5, 10W, 15W, 20W;

[0051] The second step is to use CAD software to set the processing path, and use the laser marking control software to set specific processing conditions, where the spot diameter is 30 μm, the scanning speed is 1000 mm / s, the number of scanning times is 10, and the scanning line spacing is 0.04mm;

[0052] In the third step, when the processing starts, the ultrashort pulse laser beam is emitted from the laser source, the beam is expanded and straightened by the beam transmission adjustment system, and then reflected by the scanning galvanometer, and finally parallel focused by t...

Embodiment 2

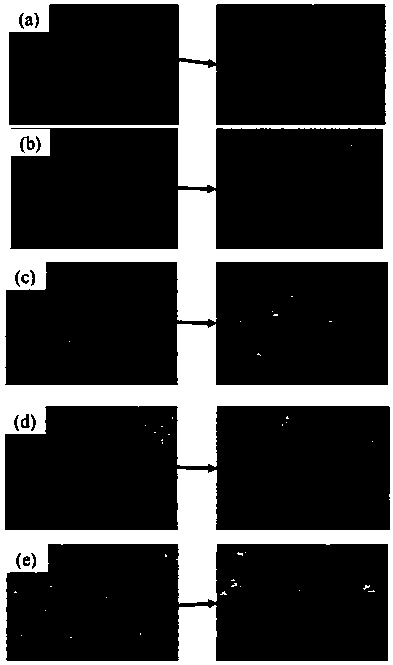

[0056] This embodiment mainly studies the influence law of the laser repetition frequency, and the specific process is:

[0057] The first step, before processing the workpiece, install the workpiece to be processed on the workbench, and set the laser parameters, among which, the wavelength is 1064nm, the pulse width is 290fs, the repetition frequency is 100KHz, 250KHz, 500KHz, 1000KHz, and the laser working power is 20W;

[0058] The second step is to use CAD software to set the processing path, and use the laser marking control software to set specific processing conditions, where the spot diameter is 30 μm, the scanning speed is 1000 mm / s, the number of scanning times is 10, and the scanning line spacing is 0.04mm;

[0059] In the third step, when the processing starts, the ultrashort pulse laser beam is emitted from the laser source, the beam is expanded and straightened by the beam transmission adjustment system, and then reflected by the scanning galvanometer, and finall...

Embodiment 3

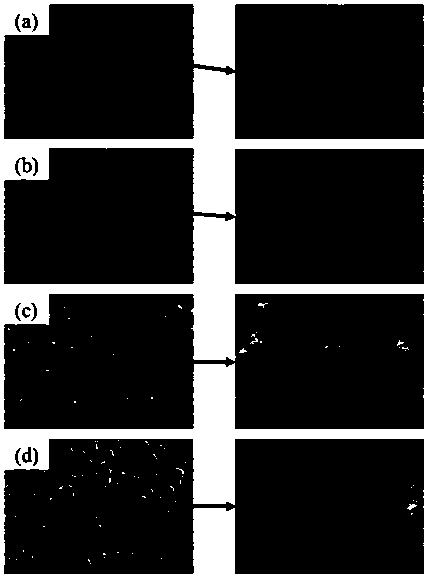

[0063] This embodiment mainly studies the influence law of the number of laser scans, and the specific process is:

[0064] The first step, before processing the workpiece, install the workpiece to be processed on the workbench, and set the parameters of the laser, among which, the wavelength is 1064nm, the pulse width is 290fs, the repetition frequency is 1000KHz, and the working power of the laser is 20W;

[0065] The second step is to use CAD software to set the processing path, and use the laser marking control software to set specific processing conditions. Among them, the diameter of the spot is 30 μm, the scanning speed is 1000 mm / s, and the number of scanning is 1, 10, and 50 times. Scanning line spacing is 0.04mm;

[0066] In the third step, when the processing starts, the ultrashort pulse laser beam is emitted from the laser source, the beam is expanded and straightened by the beam transmission adjustment system, and then reflected by the scanning galvanometer, and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com