Bridge cutting and water jet cutter integrated equipment

A water jet and bridge cutting technology, applied in stone processing equipment, metal processing equipment, used abrasive processing devices, etc., can solve the problems of inability to cut curves, inability to cut the turning position of pot holes, and low processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

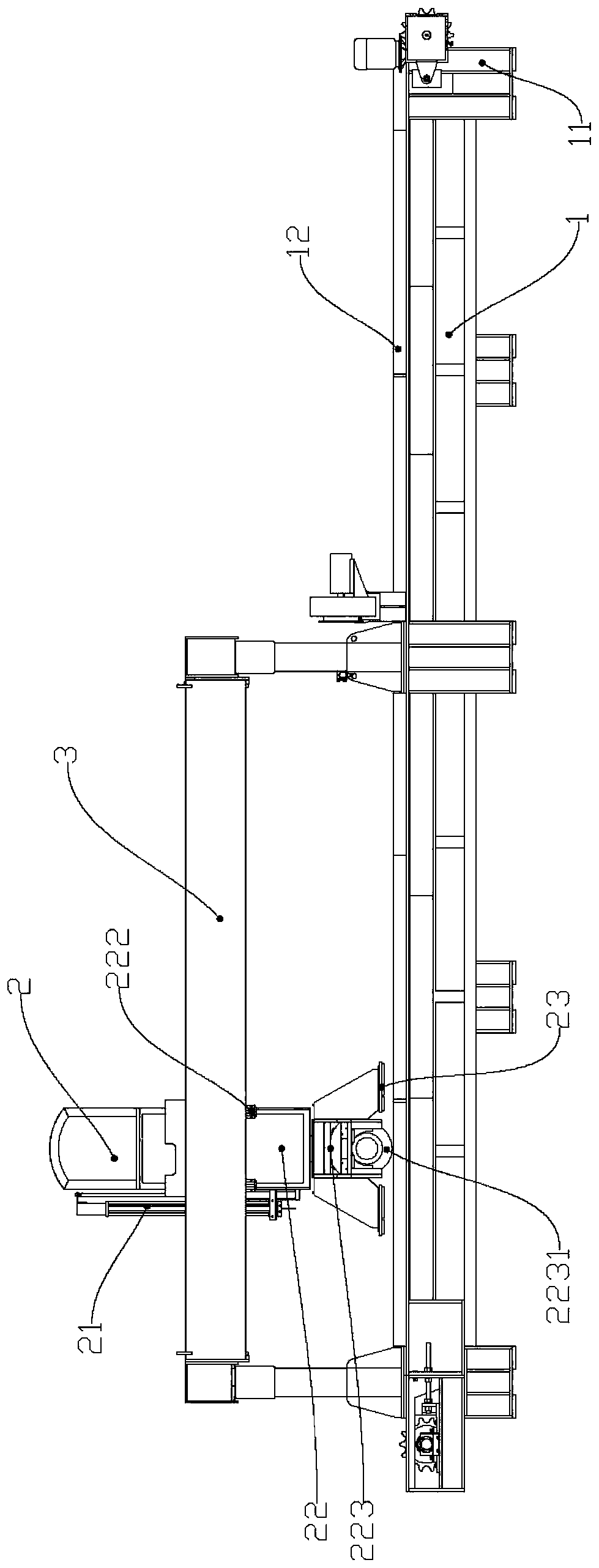

[0023] A kind of bridge cutting water knife integrated equipment of this embodiment, such as figure 1 As shown, it includes a transmission device 1, a cutting device 2 and a moving frame 3;

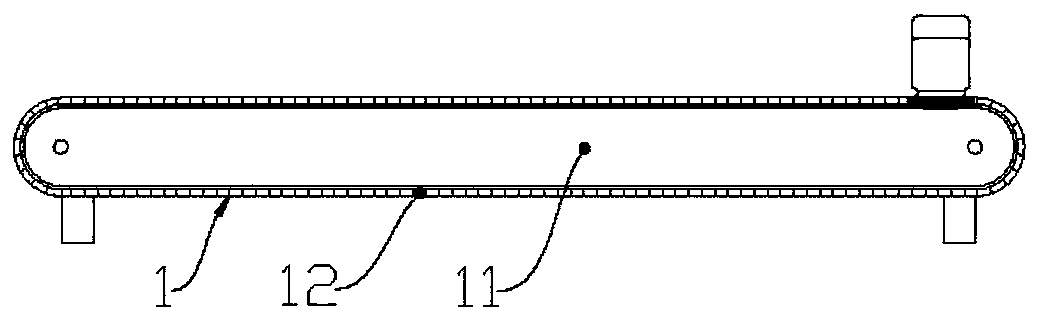

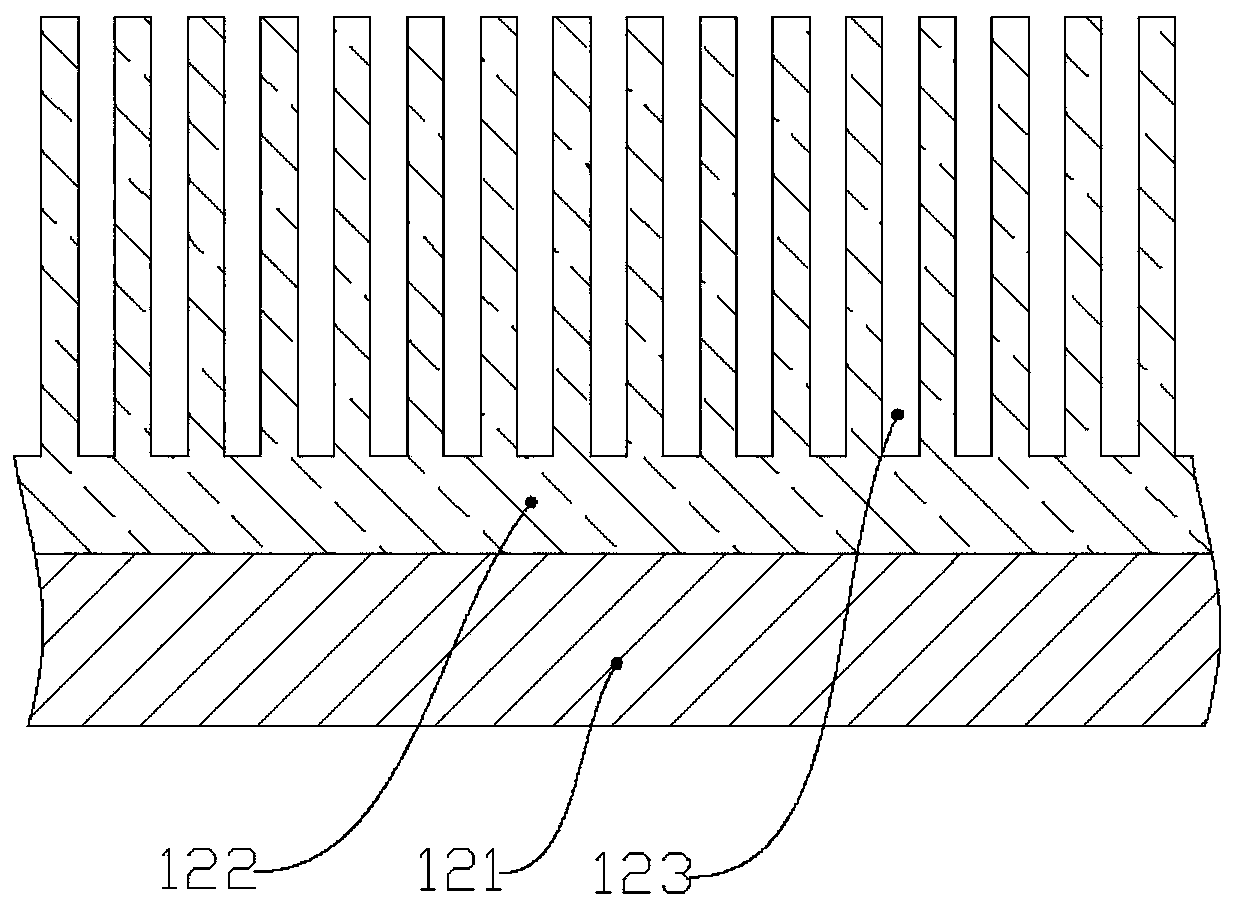

[0024] like figure 2 As shown, the transmission device 1 includes a frame 11 and a conveyor belt 12, the conveyor belt 12 is longitudinally arranged on the outside of the frame 11, and rotates around the frame 11, and the conveyor belt 12 is used for carrying and transporting plates ;

[0025] like figure 1 and 4 As shown, the cutting device 2 includes a water knife assembly 21 and a saw blade bridge cutting assembly 22. The water knife assembly 21 is arranged on one side of the saw blade bridge cutting assembly 22. The water jet assembly 21 or the saw blade bridge cutting assembly 22 cuts the plate place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com