Laser shock assisted electric arc additive manufacturing method

An additive manufacturing and laser shock technology, applied in the field of additive manufacturing, can solve problems such as coarse grains, poor mechanical properties of components, and holes, and achieve the effects of inhibiting grain growth, improving performance, and accelerating bubble overflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

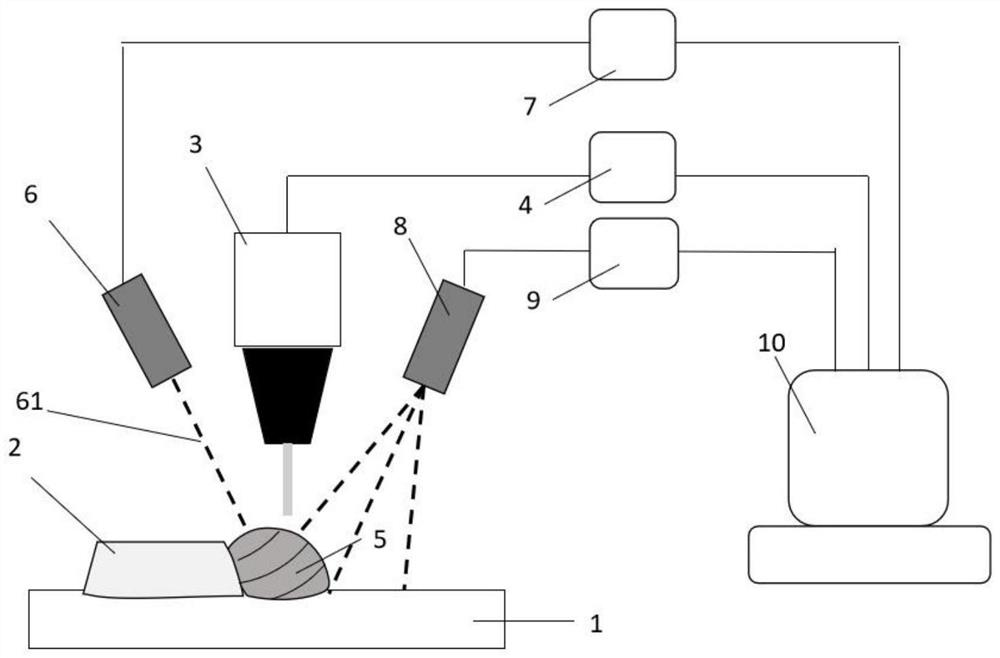

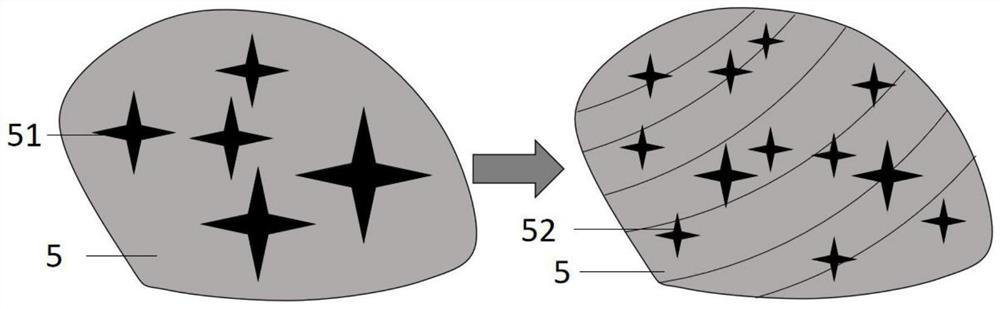

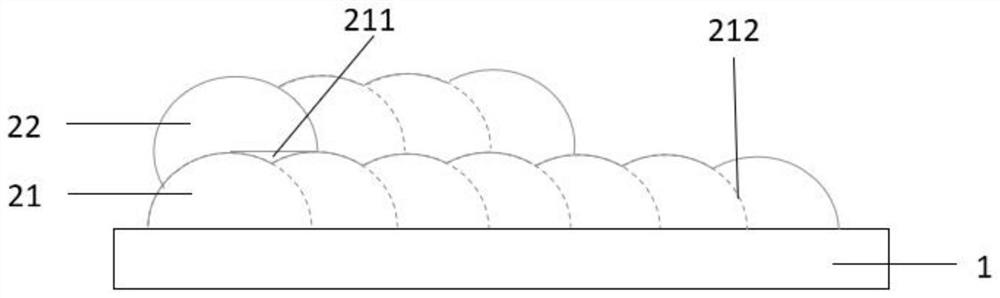

[0036] Such as Figure 1 to Figure 3 As shown, this embodiment provides a laser shock assisted arc additive manufacturing method, and the specific steps include:

[0037] Step 1: Establish a 3D model of the metal part to be processed, and design the arc additive processing path.

[0038] Specifically, according to the three-dimensional model of the metal part to be processed, the STL file of the three-dimensional model is obtained, and the STL file of the metal part is sliced by the rapid prototyping system software, and then the surface contour of the metal part is output, and then the contour is meshed. Thus filling the outline. According to the obtained slice shape, design arc additive processing path, square section adopts linear scanning filling path, circular section adopts contour scanning filling path, complex section adopts multiple cross scanning methods to determine filling path, and finally obtains arc additive part processing path.

[0039] Step 2: Obtain the ...

Embodiment 2

[0060] In order to make it easier for those skilled in the art to understand the technical solution of the present invention more clearly, the laser shock assisted arc additive manufacturing method of the present invention will be specifically described below by taking the additive material of a 5A06 aluminum alloy cuboid boss member as an example.

[0061] The size of the parts to be processed is 50mm (length) * 50mm (width) * 30mm (height), and the welding wire is made of 5B06 aluminum alloy.

[0062] The specific processing steps are as follows:

[0063] Step 1: Establish a three-dimensional model of the 5A06 aluminum alloy cuboid component, obtain the STL file of the three-dimensional model, and perform single-layer slice processing on the STL file.

[0064] Step 2: Use CMT+P mode (pulse cold metal transition), obtain the required arc additive process parameters through process tests, and set the processing parameters. The welding wire adopts 5B06 aluminum alloy welding w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com