Robot curved surface machining track optimization generation method, system and terminal

A curved surface processing and trajectory optimization technology, applied in general control systems, control/adjustment systems, instruments, etc., can solve the problems of work efficiency and curved surface processing quality, and achieve the effects of improving efficiency, high versatility, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

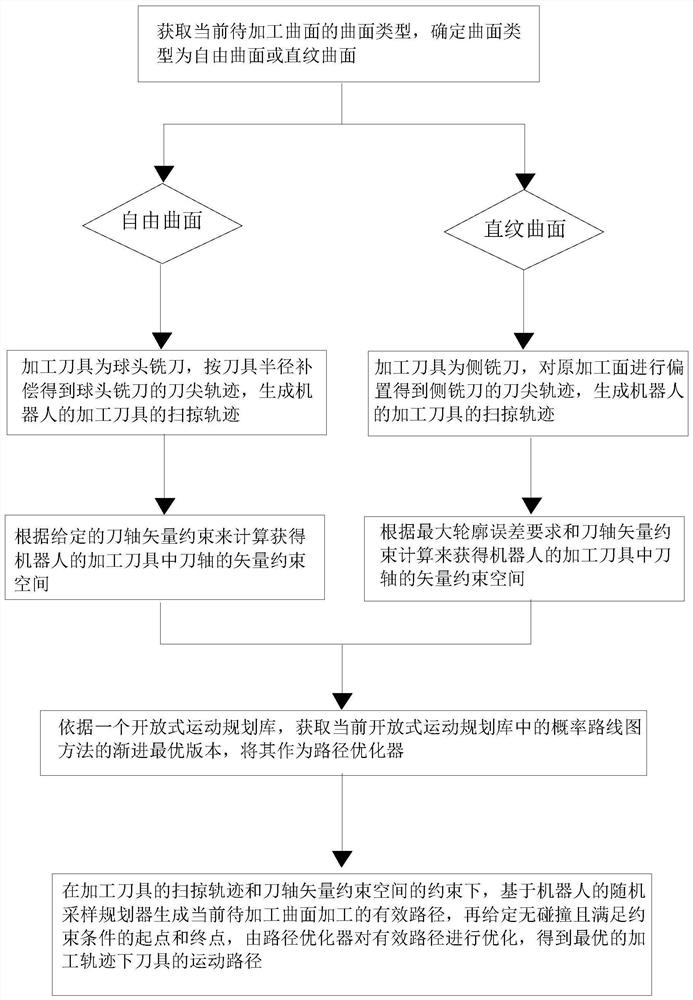

[0121] Such as figure 1 As shown, the present embodiment provides a method for optimizing and generating a robot curved surface processing trajectory, which is designed based on a random sampling algorithm and includes the following steps:

[0122] A method for optimizing and generating a robot curved surface machining trajectory, the method comprising the following steps:

[0123] S1: Obtain the surface type of the current surface to be processed, and determine whether the surface type is a free-form surface or a ruled surface;

[0124] S2: According to the surface type of the current surface to be processed, generate the sweep trajectory of the corresponding robot's processing tool, where:

[0125] (1) When the surface type to be processed is a free-form surface, the processing tool is a ball end milling cutter. At this time, the tool tip trajectory of the ball end milling cutter is obtained according to the tool radius compensation, and the sweeping trajectory of the robo...

Embodiment 2

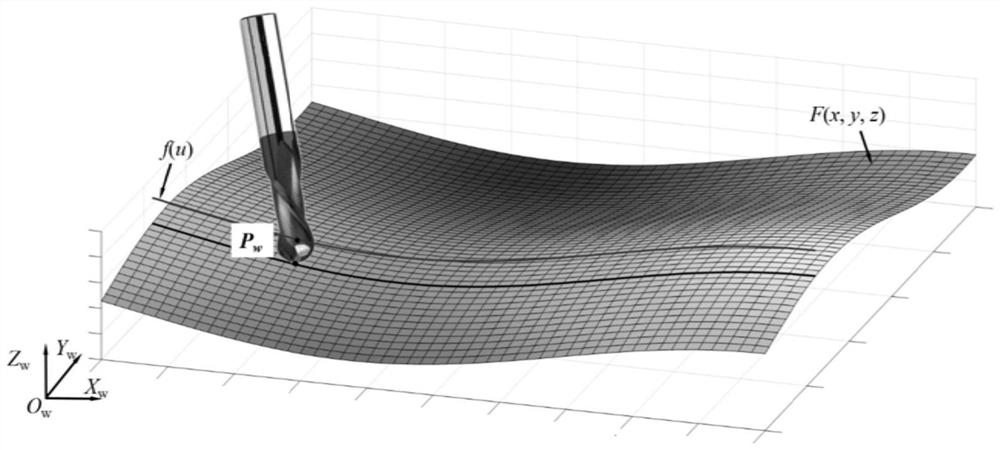

[0223] This embodiment is a kind of simulation experiment of the method that embodiment 1 provides, in this example, such as figure 2 As shown, the processed curved surface tested in this embodiment is a free curved surface.

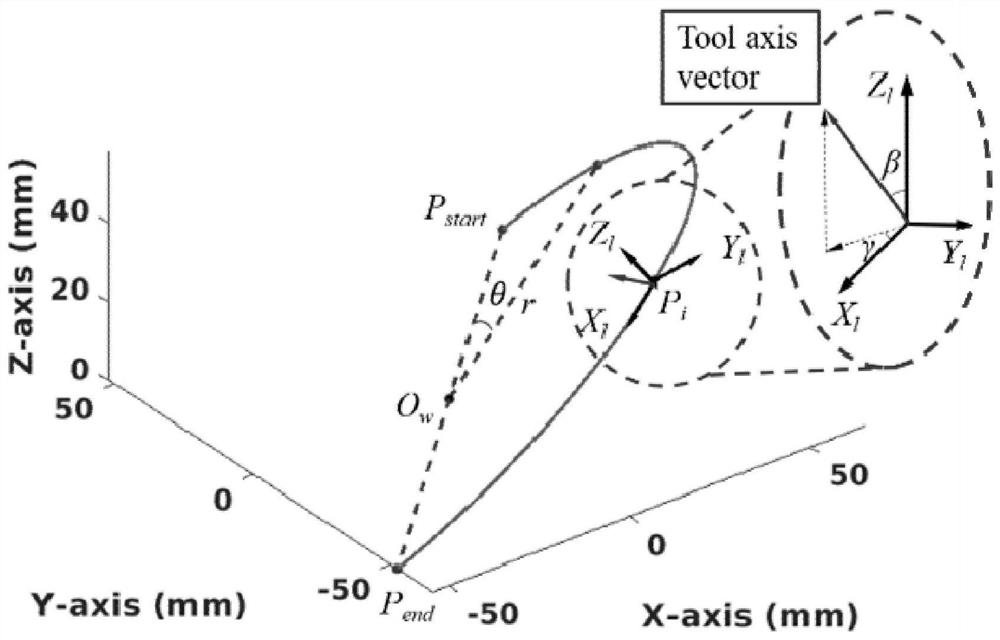

[0224] In this embodiment, an oblique semicircle tool path is used as the tool nose to follow and constrain the entire tool path, such as image 3 Shown, the circle radius r = 75mm. The parametric equation of the curve is:

[0225]

[0226] f(θ)=R z (θ z )*R x (θ x )*C(θ)

[0227] In the above formula, 0≤θ≤π, R z (θ z ) and R x (θ x ) is the rotation matrix around the Z and X axes, θ x = θ z =π / 4, f(θ) is the function of the tool path curve that the tool nose should follow.

[0228] The tool nose should strictly follow the tool nose trajectory curve, and the tool nose trajectory curve is:

[0229] P w =f(θ)

[0230] The position of the point on the tool in the workpiece space is:

[0231] P w =F(J)

[0232] In the above formula, P ...

Embodiment 3

[0265] This embodiment is a kind of simulation experiment of the method that embodiment 1 provides, in this example, such as Figure 10 As shown, the processed curved surface tested in this embodiment is a ruled curved surface.

[0266] In this embodiment, the tool trajectory curve of the side milling ruled surface of the elfin5 robot is planned with a sampling-based planner. Two directrix curves f expressed by third-order B-splines on the tool-swept surface 1 (u) and f 2 (u).

[0267] For a certain parameter u 0 , the tool axis movement curve is:

[0268] l(v)=f 1 (u 0 )+v*(f 2 (u 0 )-f 1 (u 0 ))

[0269] 0≤v≤1

[0270] The points on the surface are:

[0271] P(u 0 ,v 0 ) = f 1 (u 0 )+v 0 *(f 2 (u 0 )-f 1 (u 0 ))

[0272] The tool nose should follow the alignment curve, and the tool nose trajectory curve is:

[0273] P 1,w = f 1 (u)

[0274] In the above formula, P 1,w is the point of the tool axis in the workpiece space.

[0275] Therefore, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com