Method for generating numerical control machining toolpath through triangular Bezier surface

A triangular and curved technology, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of long tool path length, low tool path accuracy, low processing efficiency, etc., to ensure the generation accuracy and shorten the tool path. Length, the effect of improving processing efficiency

Inactive Publication Date: 2011-06-15

SHANDONG UNIV OF TECH

View PDF3 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The efficiency and accuracy of tool path generation mainly depend on the intersection efficiency and calculation accuracy of the curved surface and the tool path section plane. When generating the finishing line cutting tool path, the boundary point calculation is cumbersome and unstable, and the tool path generation efficiency is low.

To sum up, the existing methods for generating tool paths for NC machining of triangular Bézier surfaces are usually implemented based on the method of cutting planes of tool paths, which obtains the intersection line between the triangular Bézier surface and the cutting plane of the tool path, and offsets each intersection point on the intersection line to generate line-cutting machining. Tool path, this method only considers the local curvature at the intersection point in the offset process, which cannot avoid the interference problem in the tool path, the accuracy of the tool path is low, and the tool positions of each row of the generated tool path are not in the same section, Large rail length and low processing efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

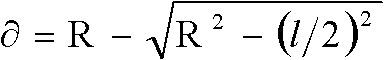

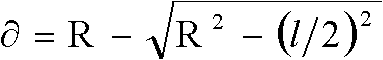

The invention provides a method for generating a numerical control machining toolpath through a triangular Bezier surface, which is characterized by comprising the following steps of: planning tool location drive points according to model characteristics of a triangular Bezier surface model, acquiring an instantaneous machining area based on dynamic indexes of the triangular Bezier surface, calculating a tool location point corresponding to each triangular Bezier surface in the instantaneous machining area through iteration, taking a tool location point with the highest projection position in a tool shaft direction as a current tool location point, performing interference-free tool location point calculation on the tool location drive points one by one, detecting a limit machining error between adjacent tool location points, controlling the toolpath accuracy by adopting a binary interpolation method, and generating the numerical control machining toolpath which meets the accuracy requirement. Experiments prove that the method is quick in toolpath generation and high in accuracy, and is suitable for generating a numerical control machining ball toolpath through a complicated triangular Bezier surface.

Description

Tool path generation method for NC machining of triangular Bézier surfaces technical field The invention provides a method for generating a tool track for numerically controlled machining of a triangular Bézier curved surface, which belongs to the field of computer-aided manufacturing. Background technique In product reverse engineering, the triangular Bézier surface can be effectively used to solve the problem of fast and accurate surface reconstruction of complex point cloud data due to its advantages of flexible configuration and good boundary adaptability. At present, the digital model of the product represented by the triangular Bézier surface cannot be compatible with the mainstream CAD / CAM system, and it is difficult to perform CNC machining. It is of great significance to study the generation method of NC toolpath on triangular Bézier surface and directly generate NC toolpath through triangular Bézier surface to improve product development efficiency and manufactur...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23Q15/013

Inventor 孙殿柱康新才李延瑞孙永伟

Owner SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com