Adjustable positioning table used for aluminum alloy machining and use method

An aluminum alloy, adjustable technology, applied in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve the problems of hidden safety hazards, inability to process, frequent contact of workers, etc., to protect aluminum alloy workpieces, improve processing accuracy, Improve the effect of fixed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

[0043] Among them, the drawings are only used for exemplary description, and they are only schematic diagrams rather than physical drawings, and cannot be understood as a limitation of the patent; in order to better illustrate the embodiments of the present invention, some parts of the drawings may be omitted, Enlargement or reduction does not represent the actual product size.

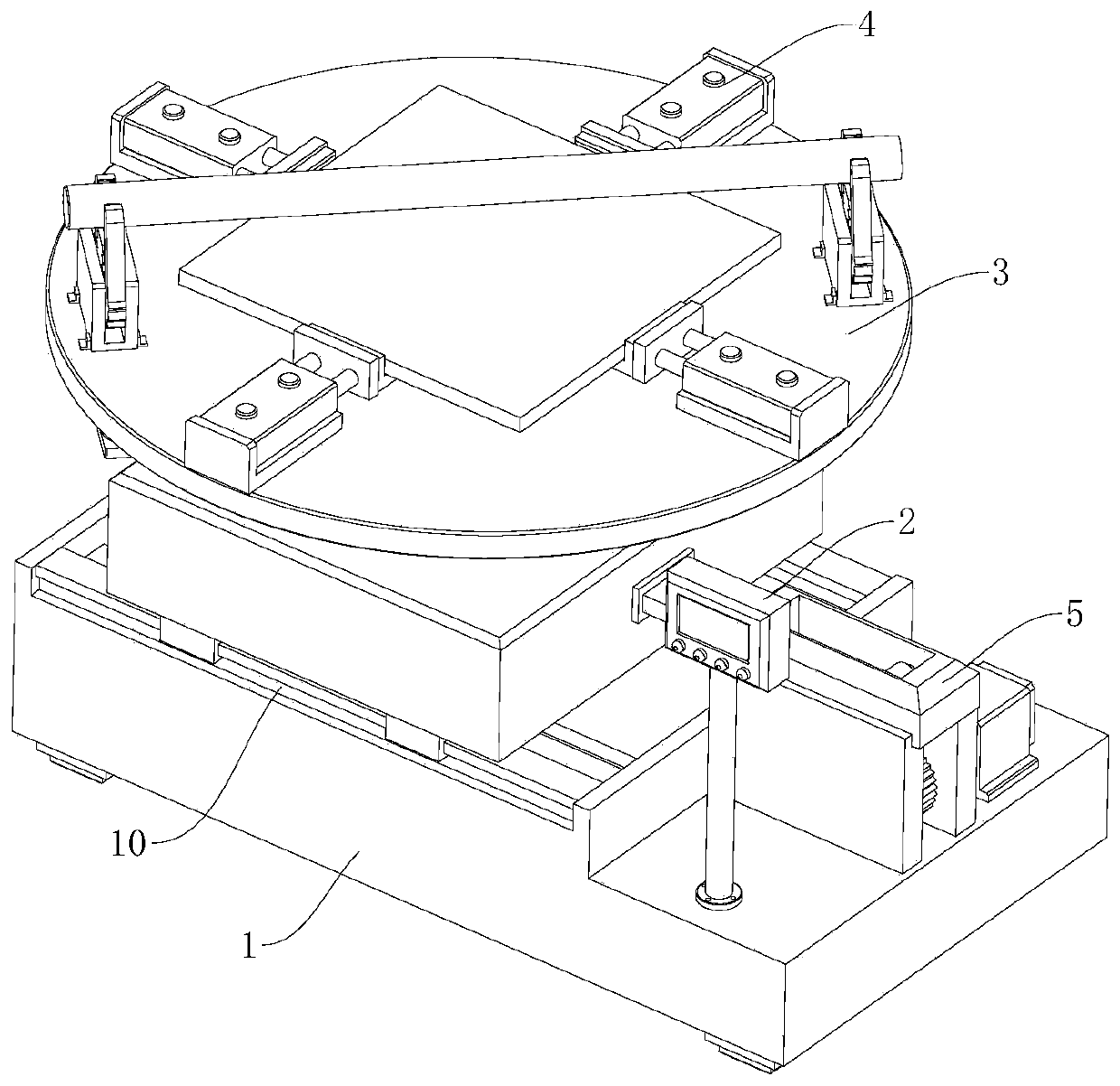

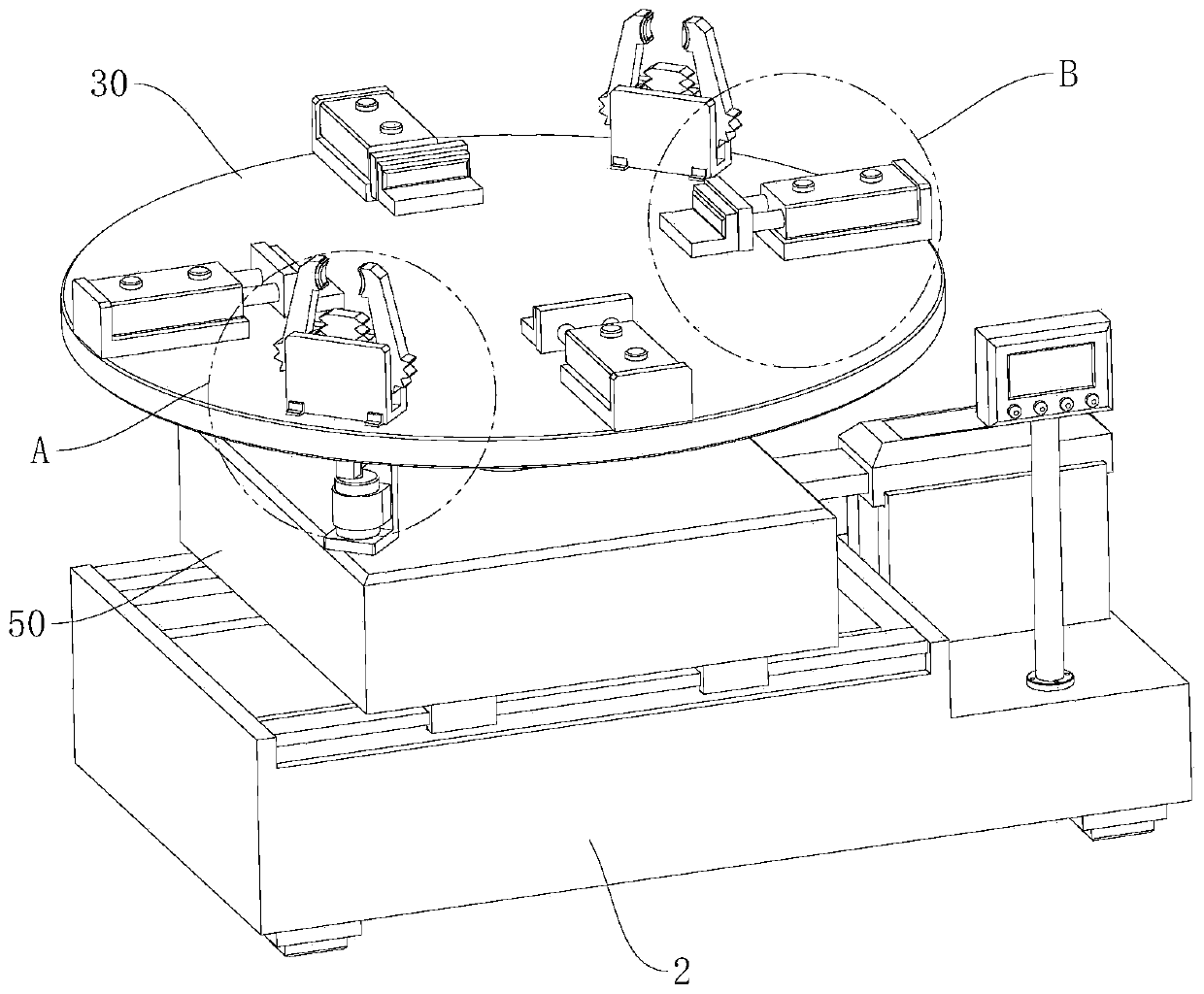

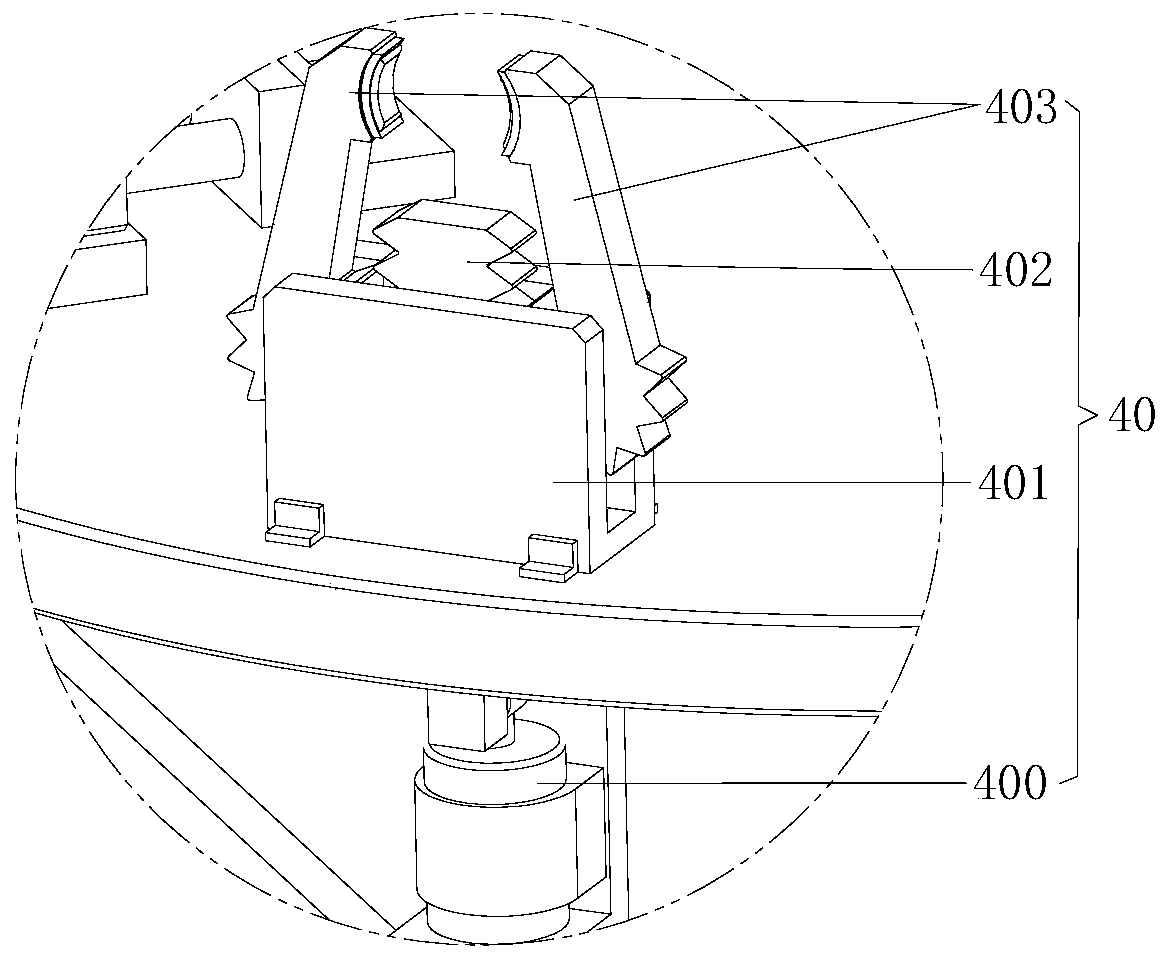

[0044] Reference Figure 1 to Figure 10 The illustrated adjustable positioning table for aluminum alloy processing includes a base 1, which is arranged horizontally, and also includes a controller 2, a rotating mechanism 3, a fixing mechanism 4, and a sliding mechanism 5, and the controller 2 is fixed. Set on the top of the base 1, the sliding mechanism 5 is set on the top of the base 1 to drive the aluminum alloy workpiece to slide. The sliding mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com