Automatic control system applicable to pipeline prefabricating production line

An automatic control and production line technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of large amount of maintenance, low welding quality, and short service life in the later period, so as to reduce labor intensity, Improve work efficiency and shorten working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

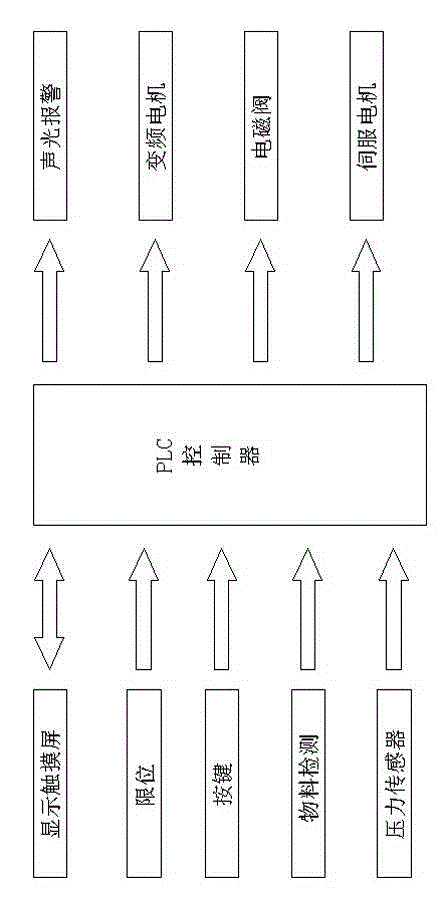

[0032] See attached figure 1 , this automatic control system is mainly used in the pipeline prefabrication production line. First, the wiring of the on-site pipeline is designed through the computer system, and then the pipeline is prefabricated in the factory, and then the prefabricated pipeline is connected through the flange at the construction site. This automatic control system mainly includes PLC controller and display touch screen. The PLC controller mainly completes the sampling, calculation, and precise control of the production line, and the action control programs of each auxiliary equipment are stored in the program memory of the PLC controller.

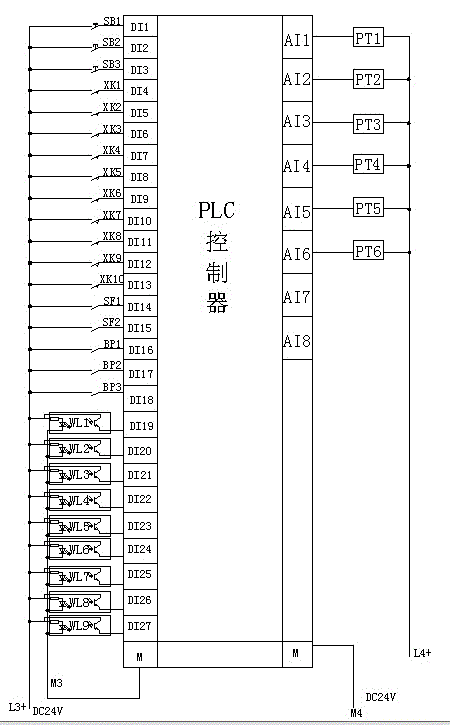

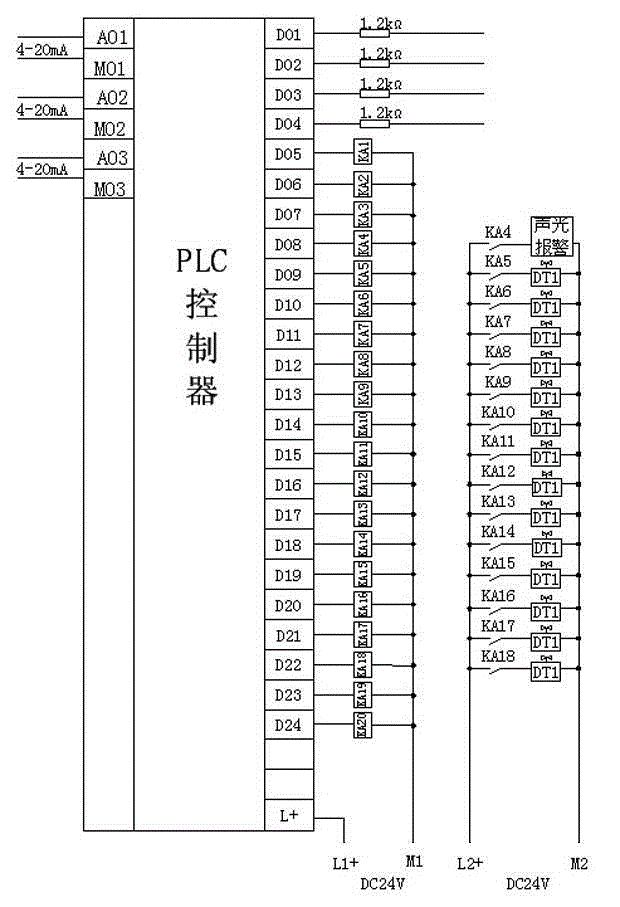

[0033] The interfaces of the PLC controller include digital input interface, analog input interface, digital output interface, analog output interface, high-frequency pulse interface, and MPI comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com