A clamping mechanism suitable for oil-edged materials and a method for clamping oil-edged materials

A clamping mechanism, oil edge technology, applied in the application, device for coating liquid on the surface, leather/skin/leather/hide chemical treatment equipment, etc. Meet the requirements of the leather oil edge market and other issues, and achieve the effect of stable movement, accurate positioning and opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

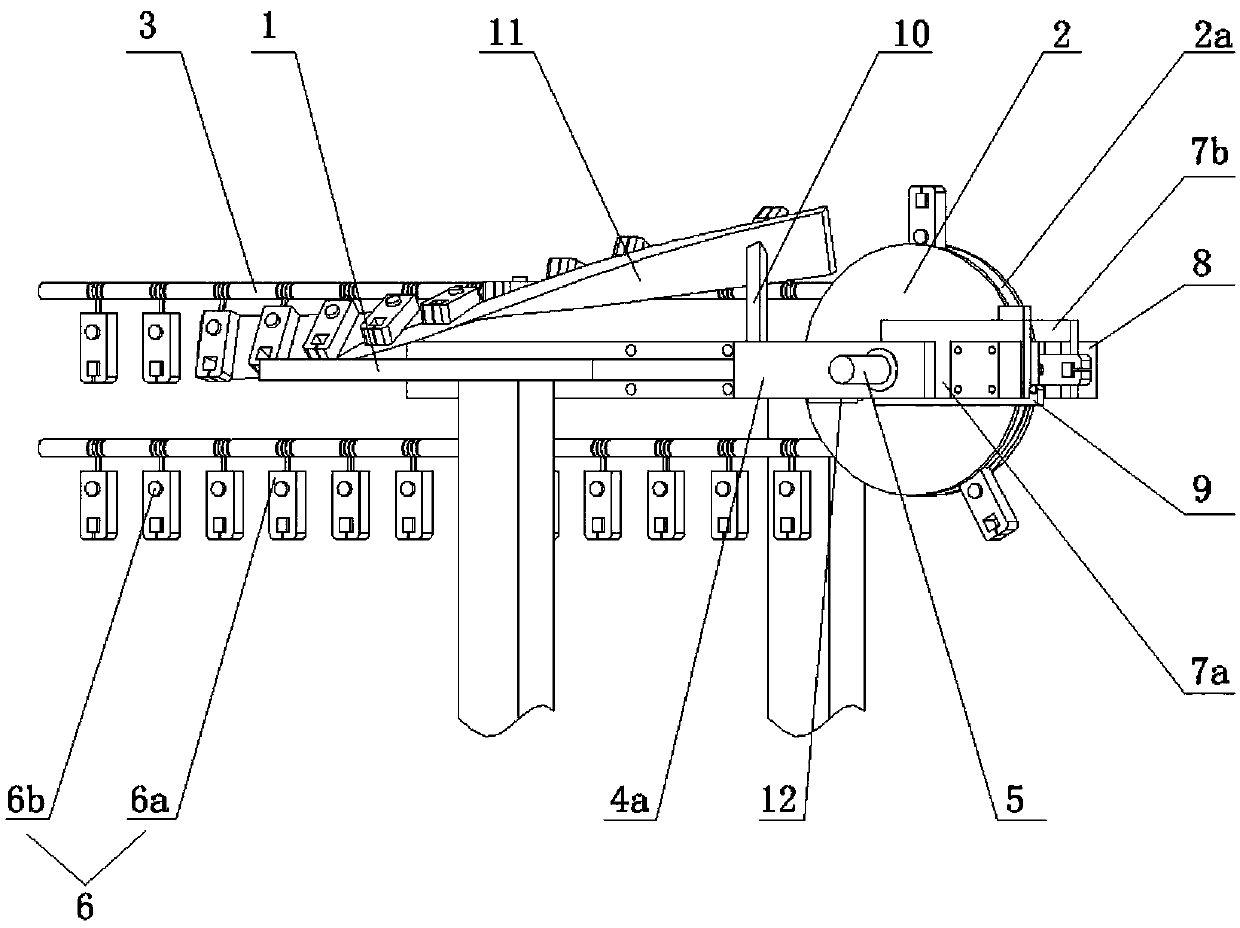

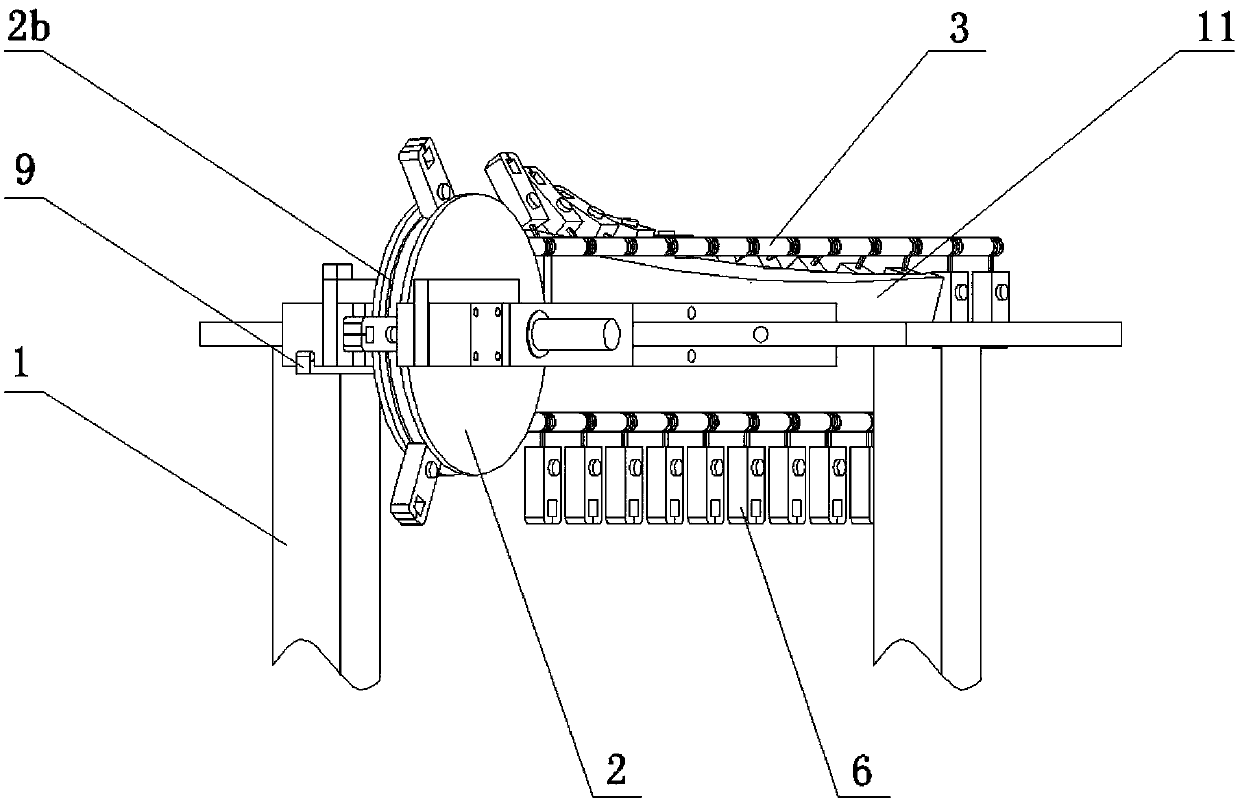

[0039] like figure 2 As shown, as the first embodiment of the present invention, the clip opening device is a clip opening cylinder 8, and the left and right sides of the turntable support frame 4 are respectively fixedly connected with a left support block 7a and a right support block 7b. The support block 7a is connected with a left open-clamp cylinder 8a, and the right support block 7b is connected with a right-open clamp cylinder 8b, which is a photoelectric induction cylinder; the side of the fixed chuck 2 is provided with the clamp detection device 9, The clip detection device 9 extends a certain distance to the front end of the fixed chuck 2. When the clip detection device 9 senses that the clip 6 moves to the middle position of the left-opening cylinder 8a and the right-opening cylinder 8b, the string-clamping rope 3 is stopped. At the same time, the left-clamping cylinder 8a and the right-clamping cylinder 8b open the clamps 6 .

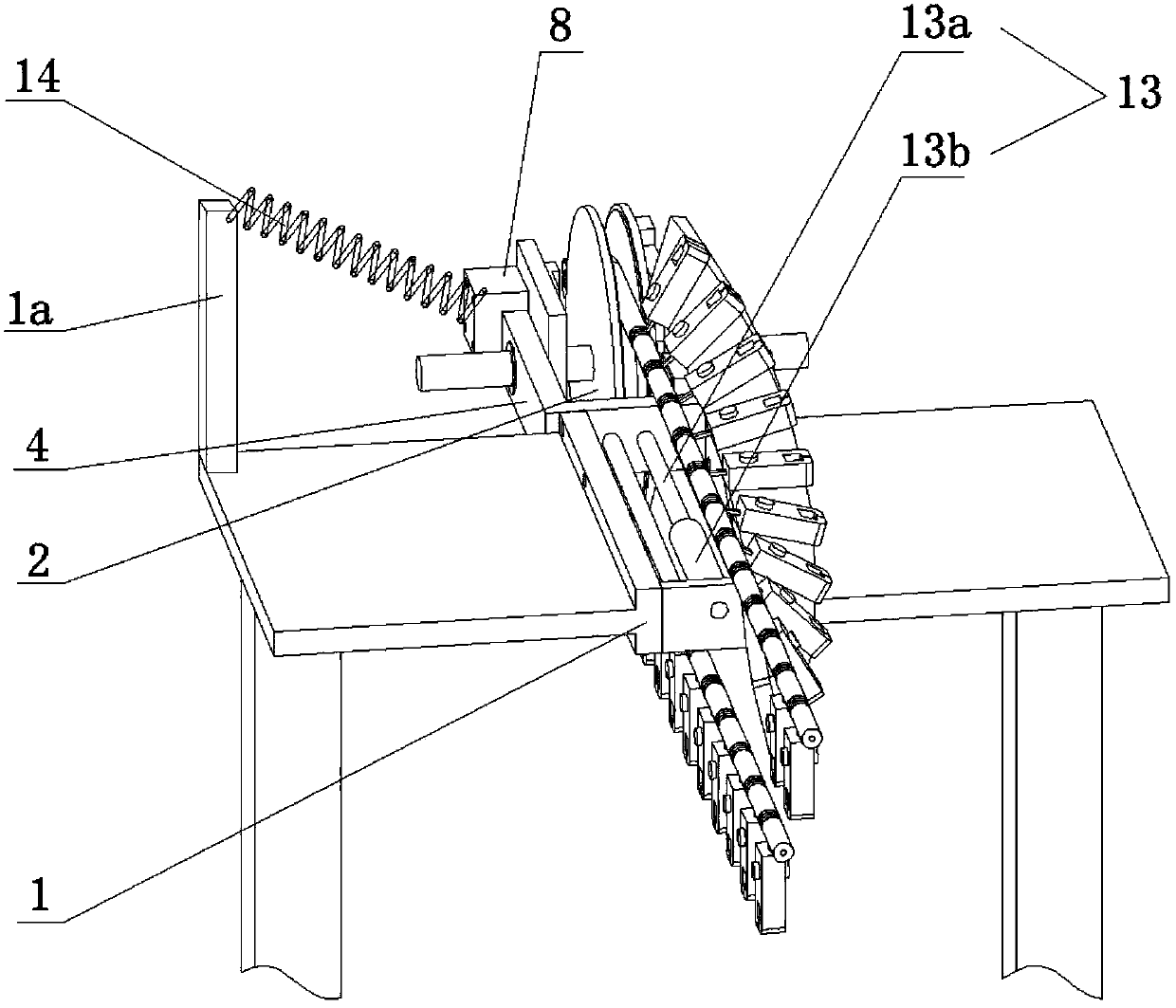

[0040] like image 3 As shown, as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com