Processing method of fine micro-nano glass structure

A technology of nano glass and processing method, which is applied in the direction of microstructure technology, microstructure device, manufacturing microstructure device, etc. It can solve the problems of inability to apply glass micro-nano size structure processing, mask material compatibility, etc., to achieve processing and improve Processing efficiency, the effect of large processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

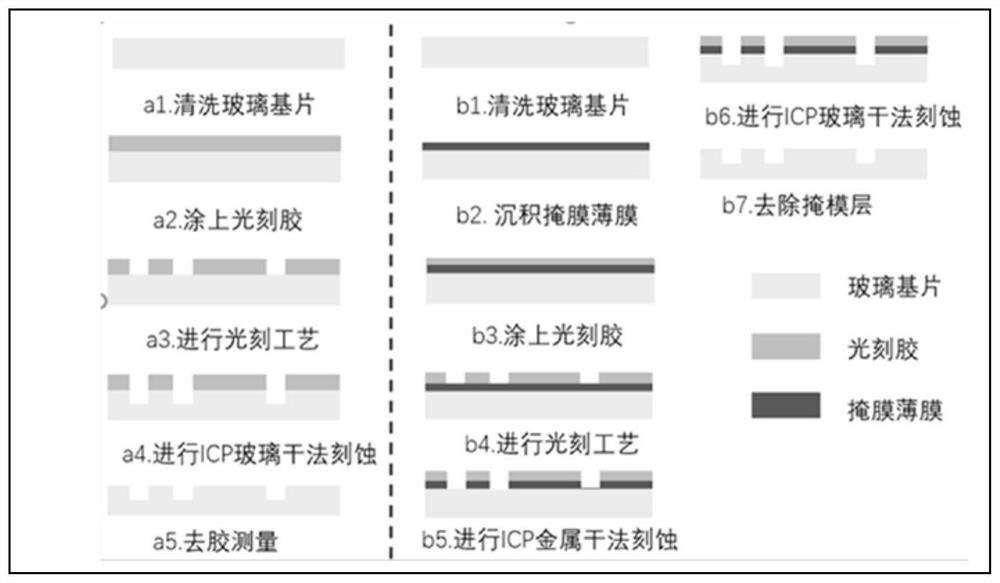

[0045] This embodiment 1 relates to a preparation method for finely processing a micro-nano glass structure, wherein the minimum size of the structure to be processed is 2 microns, and the preparation method of the micro-nano glass structure includes the following steps:

[0046]Clean the 1mm thick 4inch quartz substrate; deposit a layer of Cr film with a thickness of 130nm; then coat the photoresist on the Cr film, and make the grid structure by photolithography by ultraviolet exposure; use inductively coupled reactive ion etching Technology to etch Cr film and quartz substrate; the process parameters of etching Cr film are etching power 400W, bias RF power 40W; gas and flow rate are chlorine gas 55sccm, pressure 10mTorr. The process parameters of etching quartz substrate are etching power 1400W, bias RF power 400W; etching temperature is 58°C; gas and flow rate are Ar (auxiliary gas) 35sccm, CHF 3 110sccm, the air pressure is 45mTorr;

[0047] Use acetone ultrasonic cleani...

Embodiment 2

[0051] This embodiment 2 relates to a preparation method for finely processing the micro-nano glass structure, wherein the minimum size of the structure to be processed is 200nm, and the preparation method of the micro-nano glass structure includes the following steps:

[0052] Prepare quartz glass with a substrate thickness of 600um, and perform inorganic standard cleaning on the quartz glass to be processed; apply photoresist with a thickness of 400nm on the glass surface; transfer the processed structure to the substrate by electron beam direct writing exposure On the photoresist on the surface; use inductively coupled reactive ion etching technology to etch quartz glass, the parameters are etching power 1200W, bias RF power 200W, Ar (auxiliary gas) 35sccm, CHF 3 110sccm, the gas pressure is 35mTorr; the etching temperature is 50°C.

[0053] The photoresist is removed by ultrasonic cleaning with acetone.

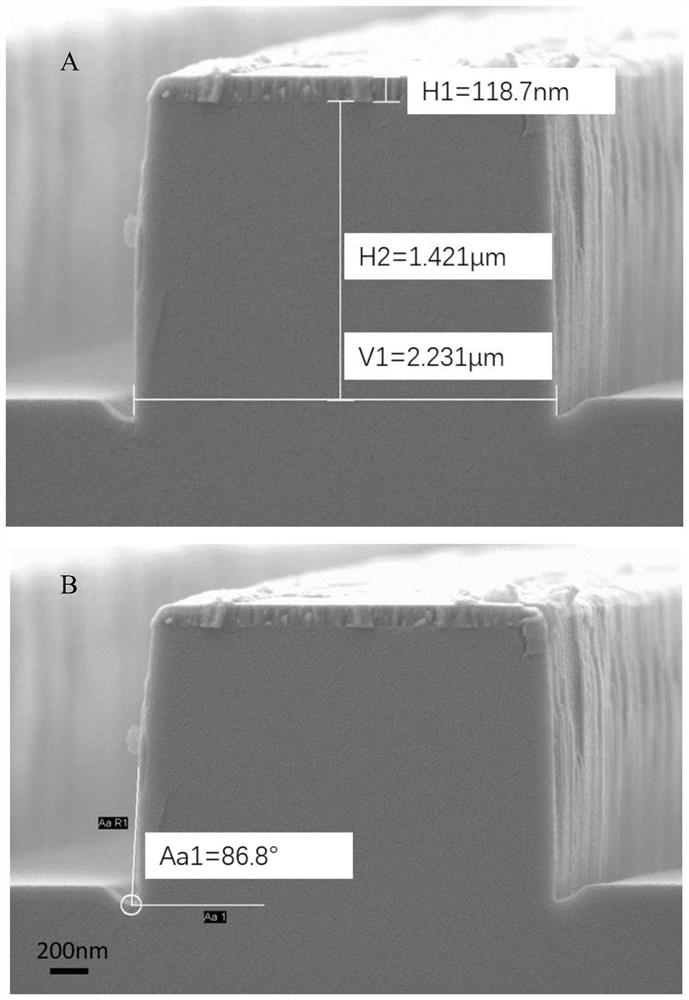

[0054] Using the preparation method of Example 2, the glass etchin...

Embodiment 3

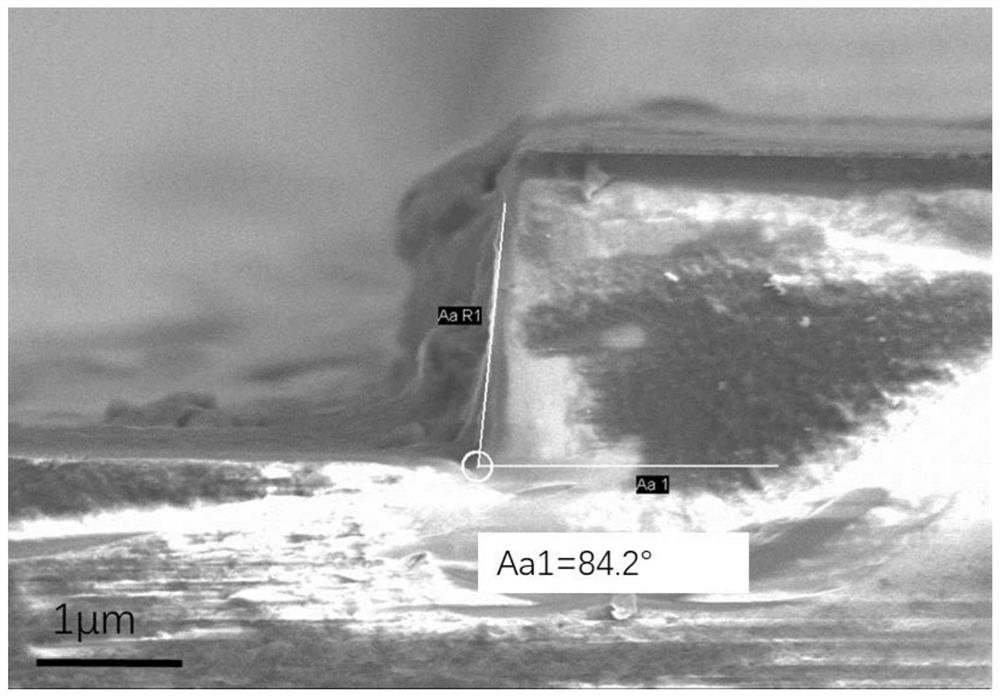

[0056] This embodiment is basically the same as Embodiment 1, the only difference is that: the Cr film and the quartz substrate are etched by inductively coupled reactive ion etching technology; the process parameters for etching the quartz substrate are etching power 800W, bias radio frequency power 500W; the etching temperature is 60°C, the gas and flow rate for etching the quartz substrate are Ar (auxiliary gas) 35sccm, CHF 3 200 sccm, the gas pressure is 120 mTorr; the gas and flow rate for etching the Cr film are 55 sccm chlorine gas, and the gas pressure is 10 mTorr.

[0057] Using the preparation method of this example, the glass etching efficiency is 350nm / min, the etching verticality is 91°, and the roughness is <50nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Etching power | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com