Variable-depth chamfering machining method for side edge of magnetic pole of spiral fan

A processing method and technology of helical fan, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve the problem of inability to provide variable depth chamfering graphics, the difficulty of precise processing of variable depth chamfering on the side of the magnetic pole of the helical fan, etc. problems, to achieve the effect of reducing asymmetry, improving accuracy, and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

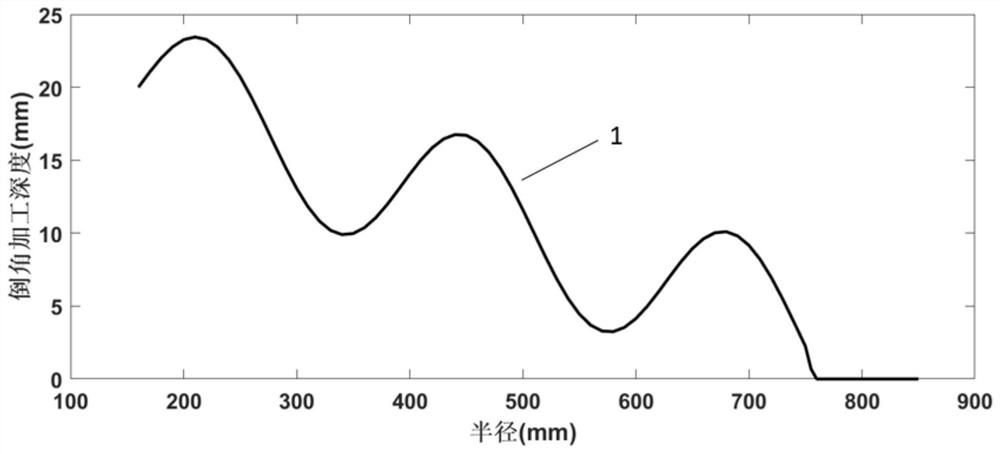

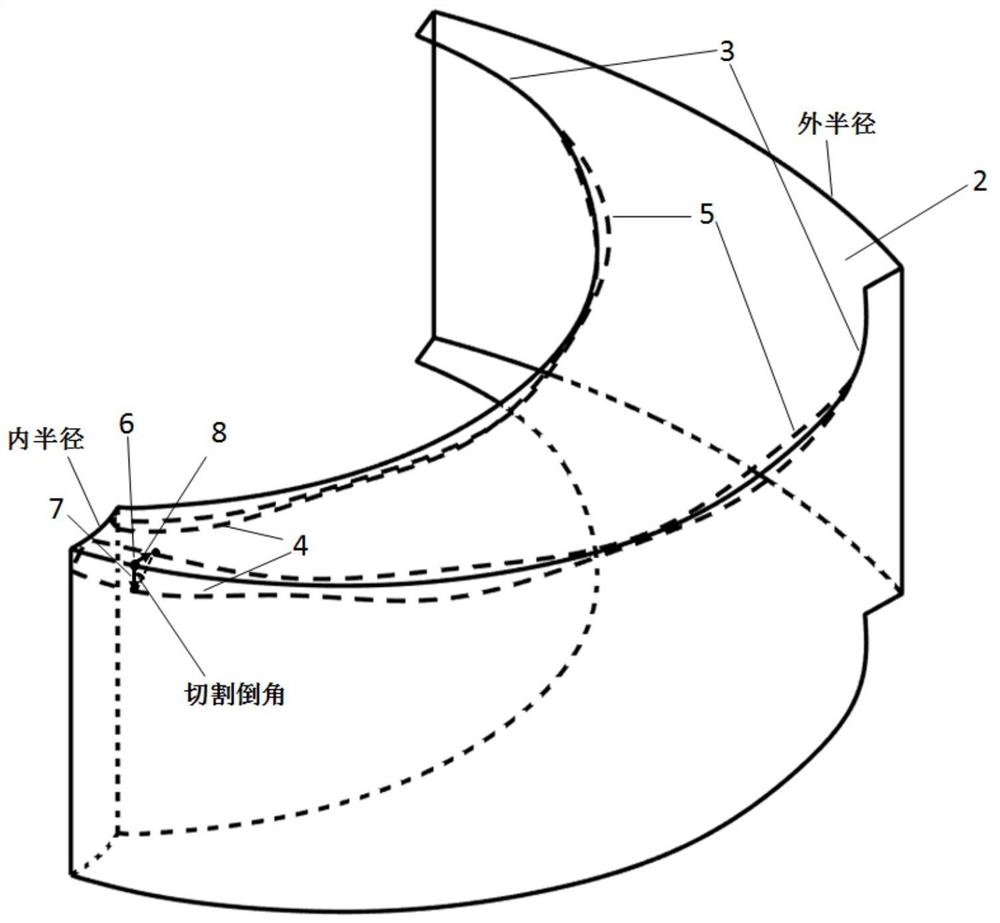

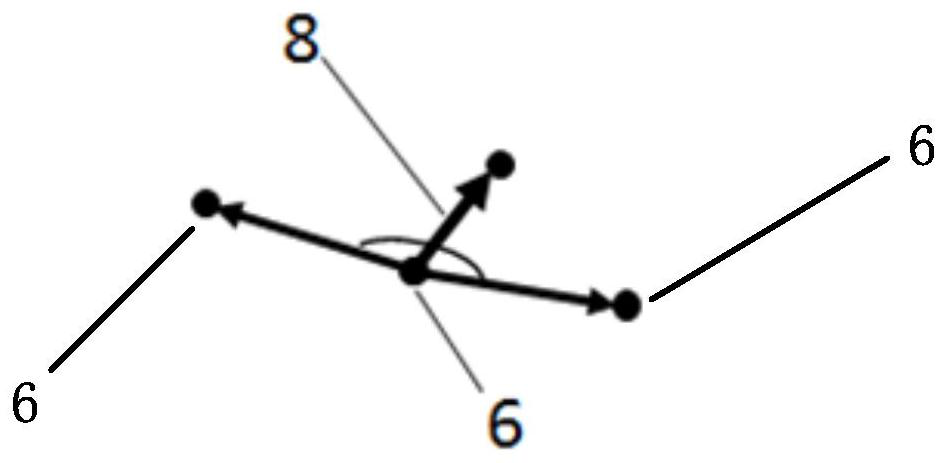

[0053] A 230MeV superconducting proton cyclotron adopts a four-fan spiral fan magnetic pole structure, with a total of 8 magnetic poles. The inner radius of each magnetic pole is 160mm, the outer radius is 850mm, and the two sides are spiral. The physical design requires magnetic poles The magnetic field is corrected by side chamfering, and the bevel angle of chamfering is 45 degrees. figure 2 As shown, the physical calculation gives a curve of chamfer depth changing with radius as figure 1 As shown, it is used for the processing of magnetic pole chamfering. 3D modeling software such as Solidwork cannot accurately give the cutting model of the chamfer depth changing with the radius. It is necessary to borrow the Boolean operation of the software to generate the cutting model. The steps are as follows:

[0054] Step 1. First calculate a shape body with variable depth chamfering on the side of the spiral fan magnetic pole as the cutting body;

[0055] Specifically:

[0056] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com