Method for processing Fery prism

A technology of a Ferri prism and a processing method, which is applied in the field of optical device manufacturing, can solve the problems affecting the imaging quality of an optical system, difficult system assembly and adjustment, etc., and achieves the effects of saving materials, good stability of the optical axis angle error, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment one: a kind of processing method of curved prism Ferry prism, comprises the following steps:

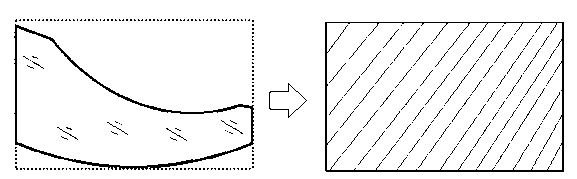

[0025] (1) According to the initial structure of the curved prism Ferry prism that needs to be processed, calculate the initial structure, see figure 1 As shown, its initial structure is processed into a cylinder, the diameter of which is equal to the diameter of the first curved surface of the Ferry prism, and the two end faces are circular planes perpendicular to the axis of the cylinder; the processed curved prism Ferry The initial structure of the prism, the initial structure is a cylinder, and the length of the cylinder is slightly greater than the maximum length of the workpiece on the optical axis of the first curved surface of the Ferry prism;

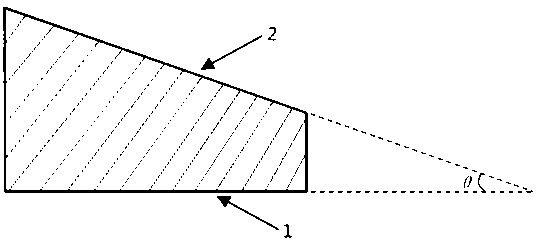

[0026] (2) Process the wedge-shaped cylindrical structure of the curved prism Ferry prism, see figure 2 As shown, taking one of the circular end faces 1 of the initial structure cylinder as the datum plane, a wedge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com