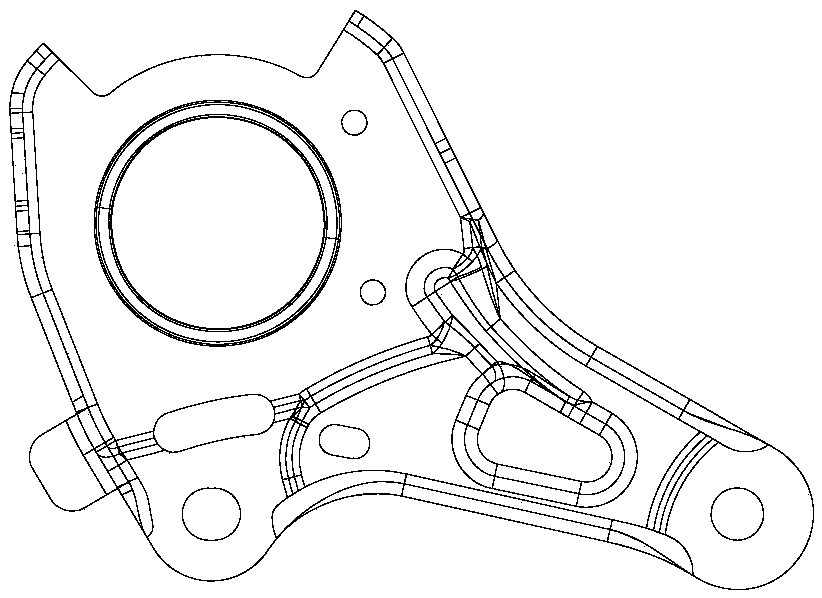

Automobile angle plate sheet continuous stamping die

A stamping die and stamping die technology are applied in the field of continuous stamping die and stamping for automobile angle plate material, which can solve the problems of complex processing procedures, high processing precision requirements, and low processing yield rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

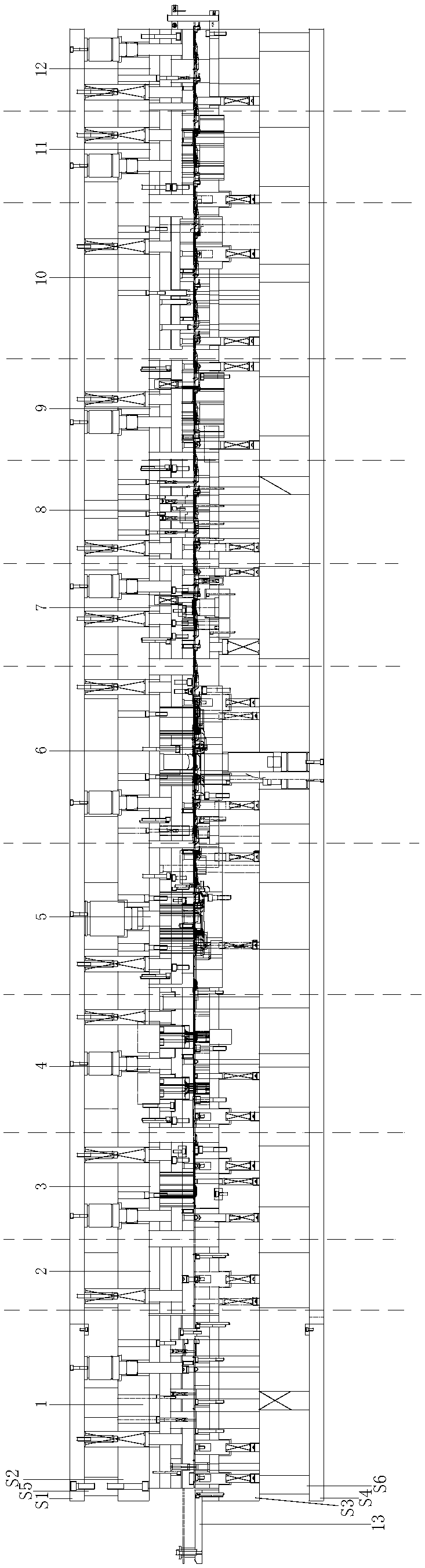

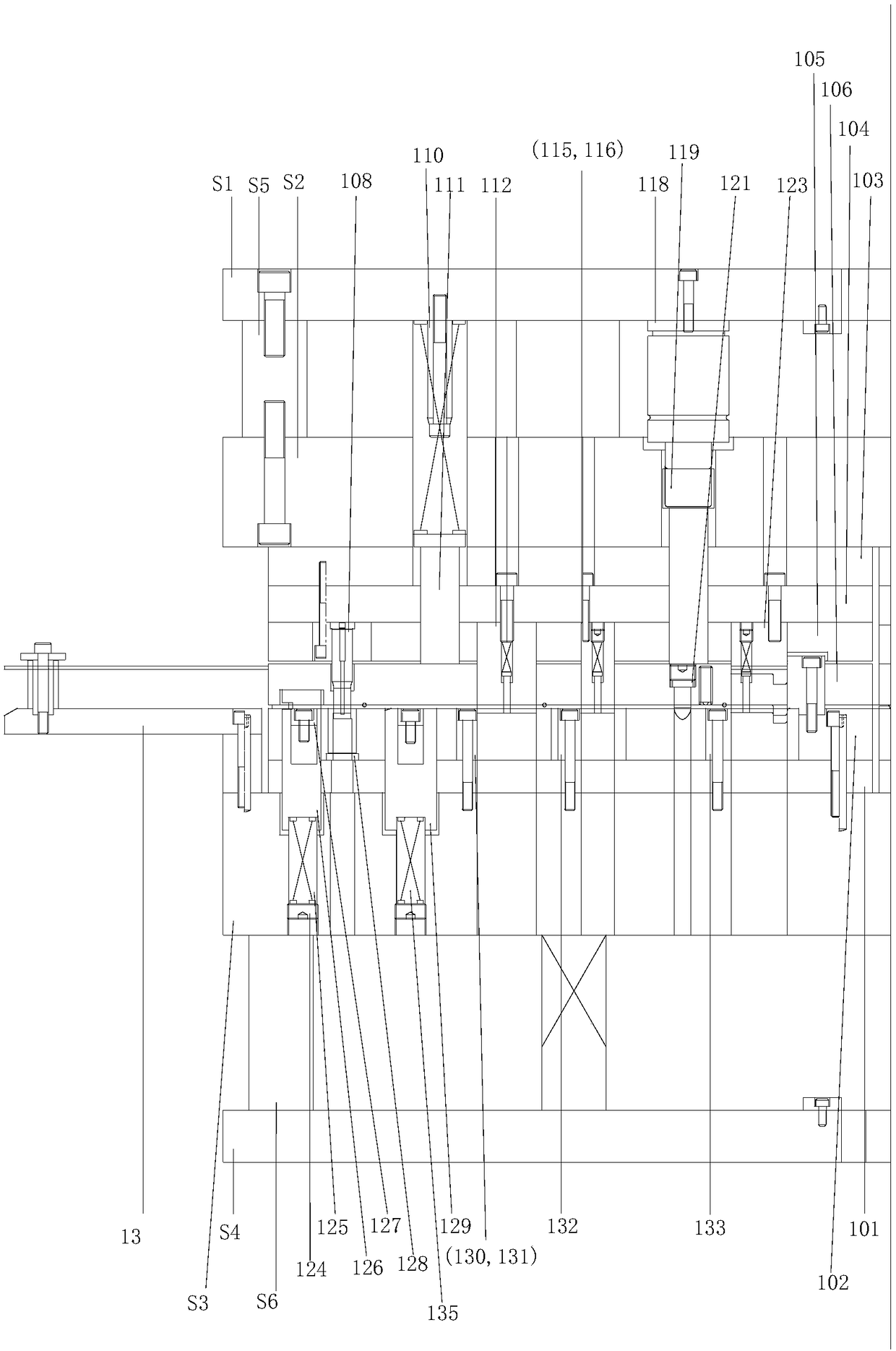

[0037] combine Figure 2 to Figure 14 , which describes a specific embodiment of the present invention in detail, but does not limit the claims of the present invention in any way.

[0038] like figure 2 As shown, a continuous stamping die for automobile corner sheet includes an upper positioning plate S1, an upper template S2, a lower template S3 and a lower positioning plate S4 arranged from top to bottom. An upper foot S5, a plurality of lower foot S6 is arranged between the lower formwork and the lower positioning plate, and a feeding plate 13, the first edge trimming, are arranged successively from left to right between the upper formwork 1-2 and the lower formwork 1-3 Process stamping die 1, chamfering process stamping die 2, forming process stamping die 3, embossing process stamping die 4, first flanging process stamping die 5, second flanging process stamping die 6, first shaping process Stamping die 7, second trimming process stamping die 8, second shaping process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com