Non-instantaneous-pole envelope grinding method of spiral curved surface of superfine milling cutter

A micro-milling cutter, helical surface technology, applied in milling cutters, parts of grinding machine tools, grinding/polishing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

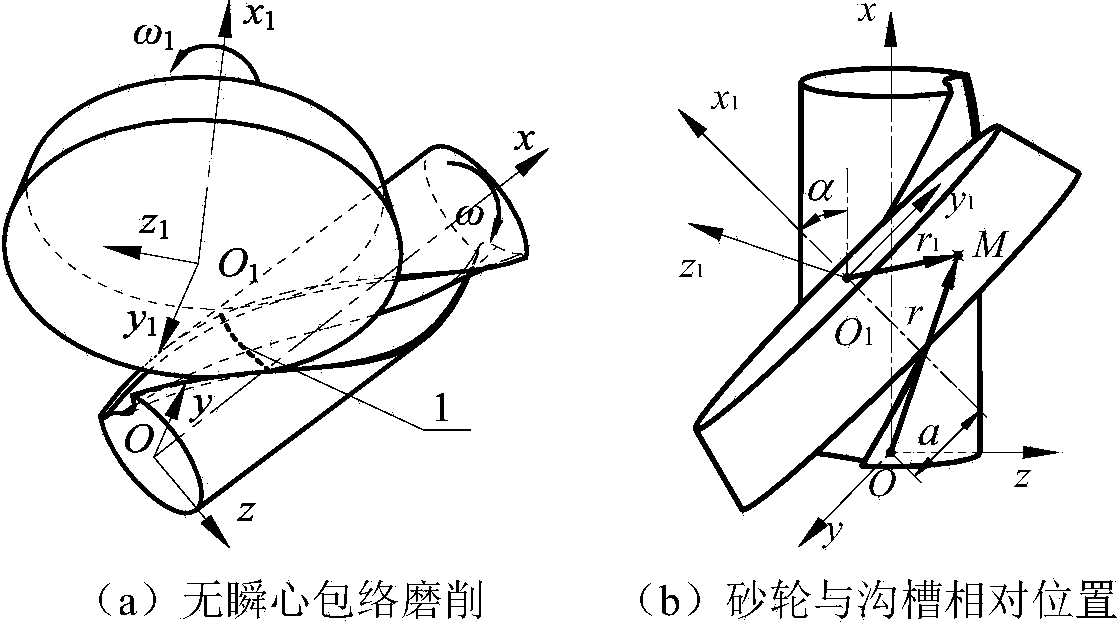

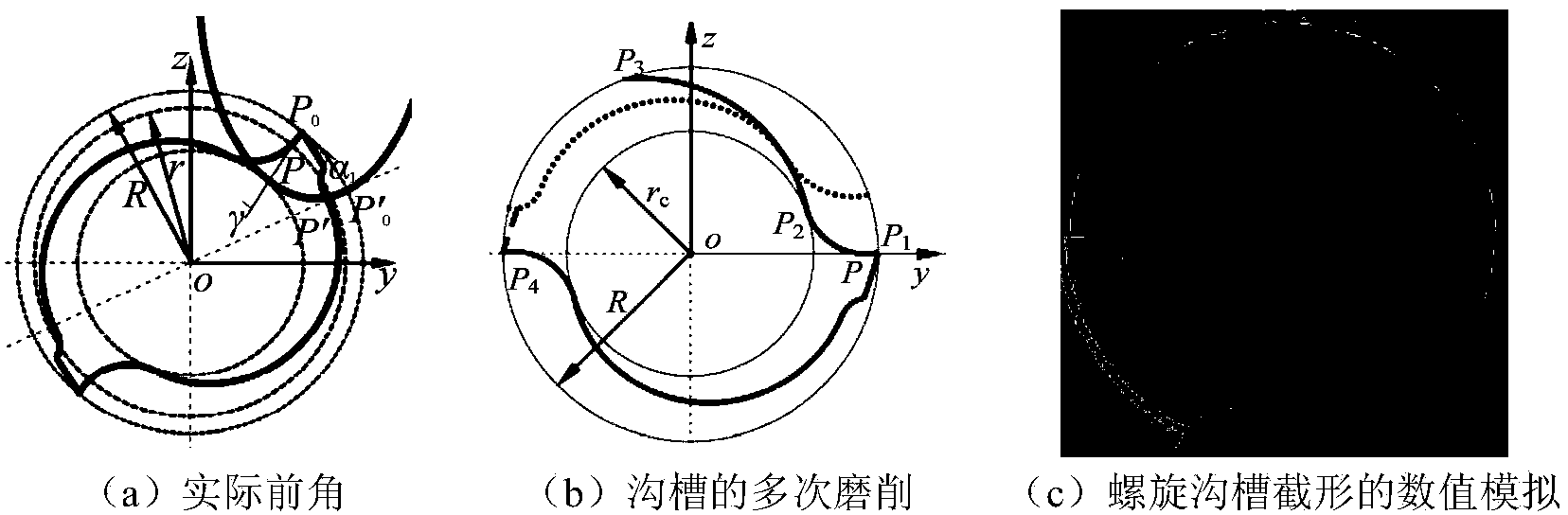

[0013] (1) According to the geometric angle parameters of the helical edge of the micro-milling cutter, the optimal geometry and installation angle of the grinding wheel are designed. Through numerical calculation, the non-instant center envelope of the simulated grinding wheel movement is developed into a helical surface section, and the grinding process is carried out. optimization.

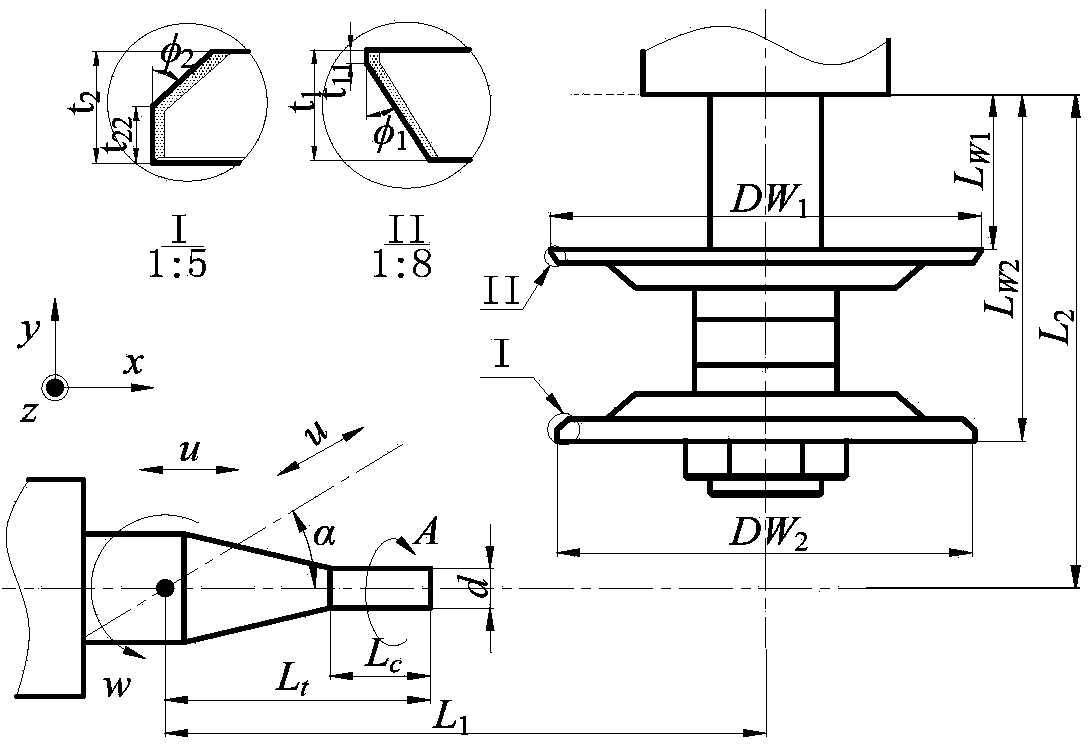

[0014] (2) When the groove is processed, the center of the large end of the grinding wheel moves from the origin position to the initial position C when the x, y, z and w axes move according to the positions in Table 1. The grinding wheel keeps rotating, and the workpiece performs a spiral motion. When the workpiece moves from the initial position to the end position along the u-axis and A-axis, the complete groove can be machined. In Table 1, θs and θf are the change angles of the A-axis rotation when machining the flank groove and the flank, respectively, compared to the machining of the chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com