Laser drilling device used for machining hard and brittle substrate

A laser drilling and substrate technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as cracks in the hole wall of alumina ceramic substrates, precision instruments, adverse environmental effects, and laser drilling track deviation. , to achieve the effect of small single pulse energy, avoid a large amount of dust, and avoid offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

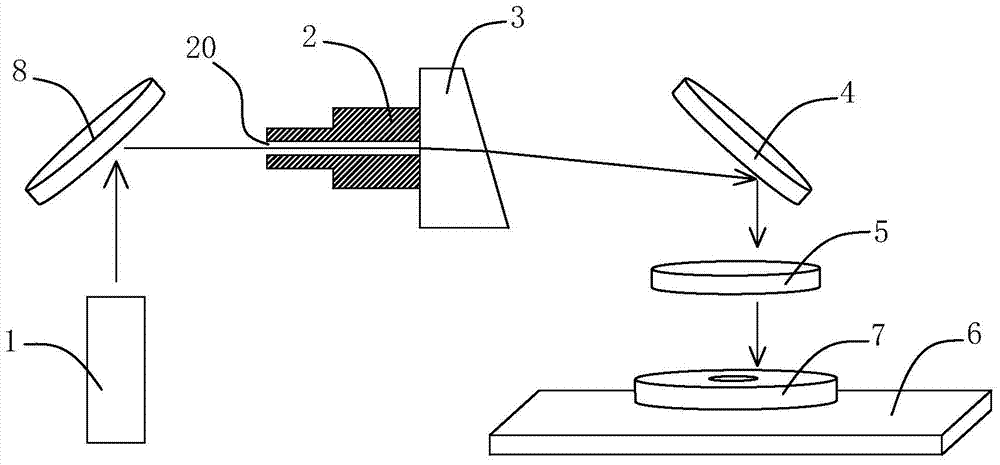

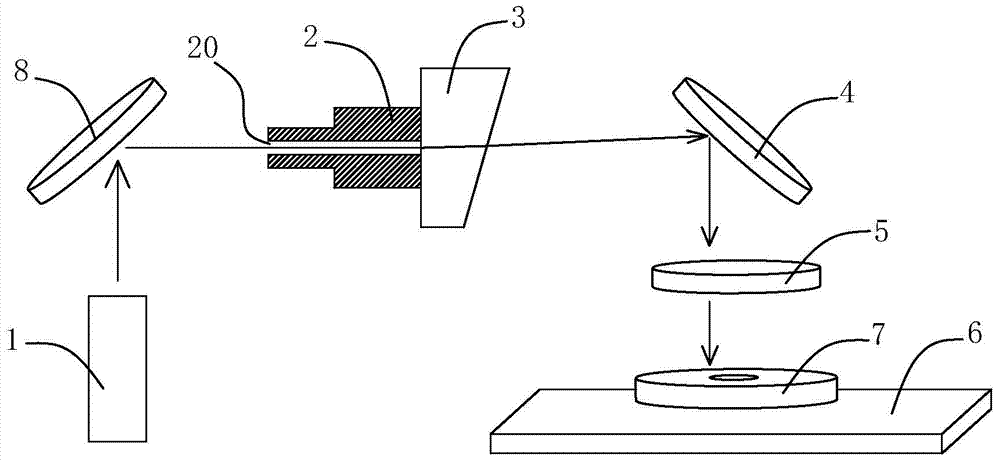

[0014] The invention discloses a laser drilling device for processing hard and brittle substrates, which combines figure 1 with figure 2 As shown, it includes a laser head 1, a drive device 2, a wedge prism 3, a first reflector 4, a focusing mirror 5 and a stage 6 are arranged in sequence along the transmission direction of the laser pulse emitted by the laser head 1, and a hard and brittle substrate 7 is placed on the stage 6, the laser head 1 is a Q-switched laser, that is, a Q-switched narrow pulse width, short-wavelength ultraviolet diode-pumped solid-state laser, the wedge prism 3 is fixedly connected to the driving device 2, and the wedge prism 3 The light emitting surface is an inclined surface, and the driving device 2 is provided with a light guide hole 20. Driven by the drive device 2, the wedge-angle prism 3 rotates around the axis o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com