Preparation method and device thereof of surface structuration composite coating

A technology of surface structuring and composite coating, applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve the problems such as patents and research papers of surface structuring composite coating that have not yet been seen, and achieve high efficiency Composite coating deposition, innovative ideas, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

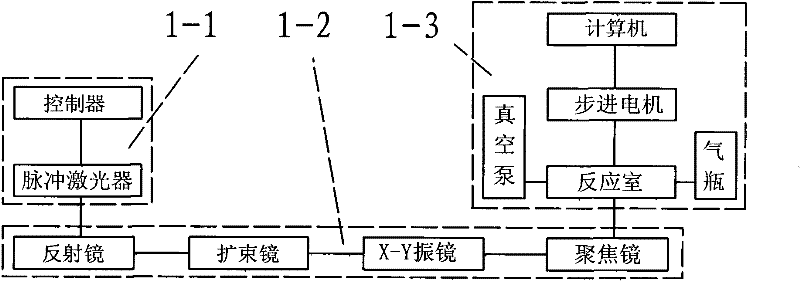

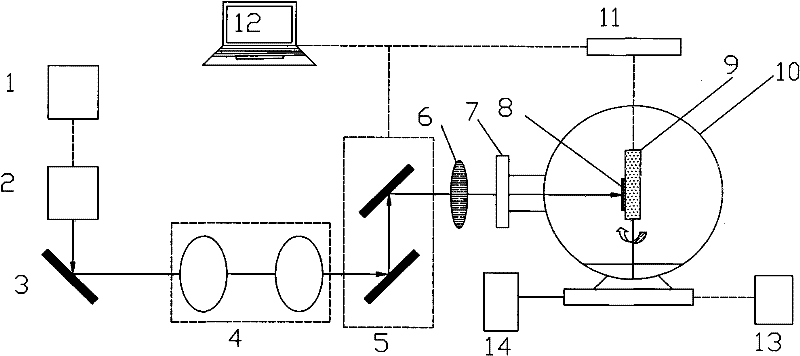

[0023] Embodiment 1: The special device used for the preparation method of surface structured composite coating is an ultraviolet pulse laser multifunctional surface treatment system device, and the ultraviolet pulse laser multifunctional surface treatment system device includes a pulse laser module 1-1, a precision scanning module 1- 2 and the environment control module 2-3, the pulse laser module 1-1, the precision scanning module 1-2 and the environment control module 1-3 are sequentially connected.

[0024] The pulsed laser module includes a controller 1 and a pulsed laser 2, the controller 1 and the pulsed laser 2 are connected in sequence, and the pulsed laser module is a commercially available product.

[0025] The precision scanning module includes a mirror 3, a beam expander 4, an X-Y vibrating mirror 5 and a focusing mirror 6, and the mirror 3, a beam expanding mirror 4, the X-Y vibrating mirror 5 and the focusing mirror 6 are sequentially connected, and the X-Y vibra...

Embodiment 2

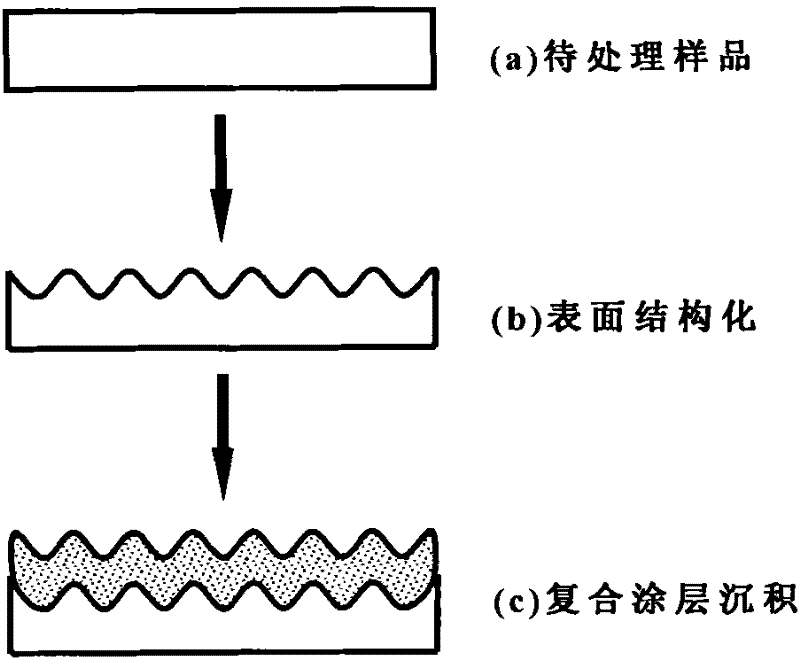

[0036] Embodiment 2: the present invention is realized according to the following steps: preliminary preparation, surface structuring, composite coating deposition and post-treatment;

[0037] 1. Preliminary preparation: first prepare the samples for surface structured composite coating preparation, reaction gas and establish the ultraviolet pulse laser multifunctional surface treatment system device, and prepare the three major modules required for the establishment of the ultraviolet pulse laser multifunctional surface treatment system device Components, the three major module components are the pulse laser module, the precision scanning module, and the environment control module, which are connected in sequence according to the pulse laser module, precision scan module, and environment control module; the reaction gas uses SiH 4 / NH 3 Combination, the purity is not less than 99.9%; the background gas uses N 2 , the purity is not less than 99%;

[0038] 2. Surface structur...

Embodiment 3

[0043] Embodiment 3: the present invention is realized according to the following steps: preliminary preparation, surface structural treatment, composite coating deposition and post-treatment;

[0044] 1. Preliminary preparation: first prepare the samples for surface structured composite coating preparation, reaction gas and establish the ultraviolet pulse laser multifunctional surface treatment system device, and prepare the three major modules required for the establishment of the ultraviolet pulse laser multifunctional surface treatment system device Components, the three major module components are the pulse laser module, the precision scanning module, and the environment control module, which are connected in sequence according to the pulse laser module, the precision scan module, and the environment control module; the reaction gas uses Si 2 h 6 / O 2 Combination, the purity of the two gases is not less than 99.9%; the background gas uses SF 6 and N 2 mixed gas, the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com