A CNC lathe with inclined bed, double spindles, double rows of cutters and automatic loading and unloading inside the machine

An automatic loading and unloading, CNC lathe technology, applied in automatic lathes/semi-automatic lathes, turning equipment, turning equipment and other directions, can solve the problems of troublesome adjustment of hydraulic lathes, affecting the accuracy of processed workpieces, and high degree of environmental pollution, achieving novel protective appearance, The effect of improving machining accuracy and concise protection design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

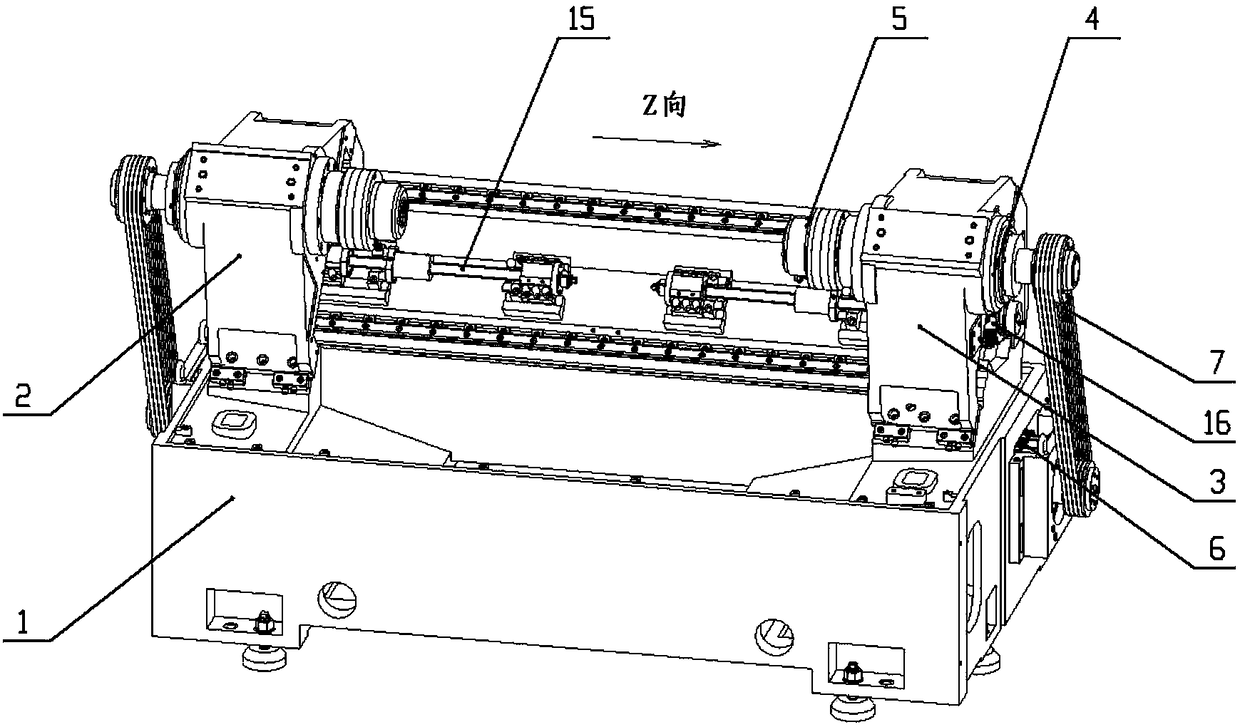

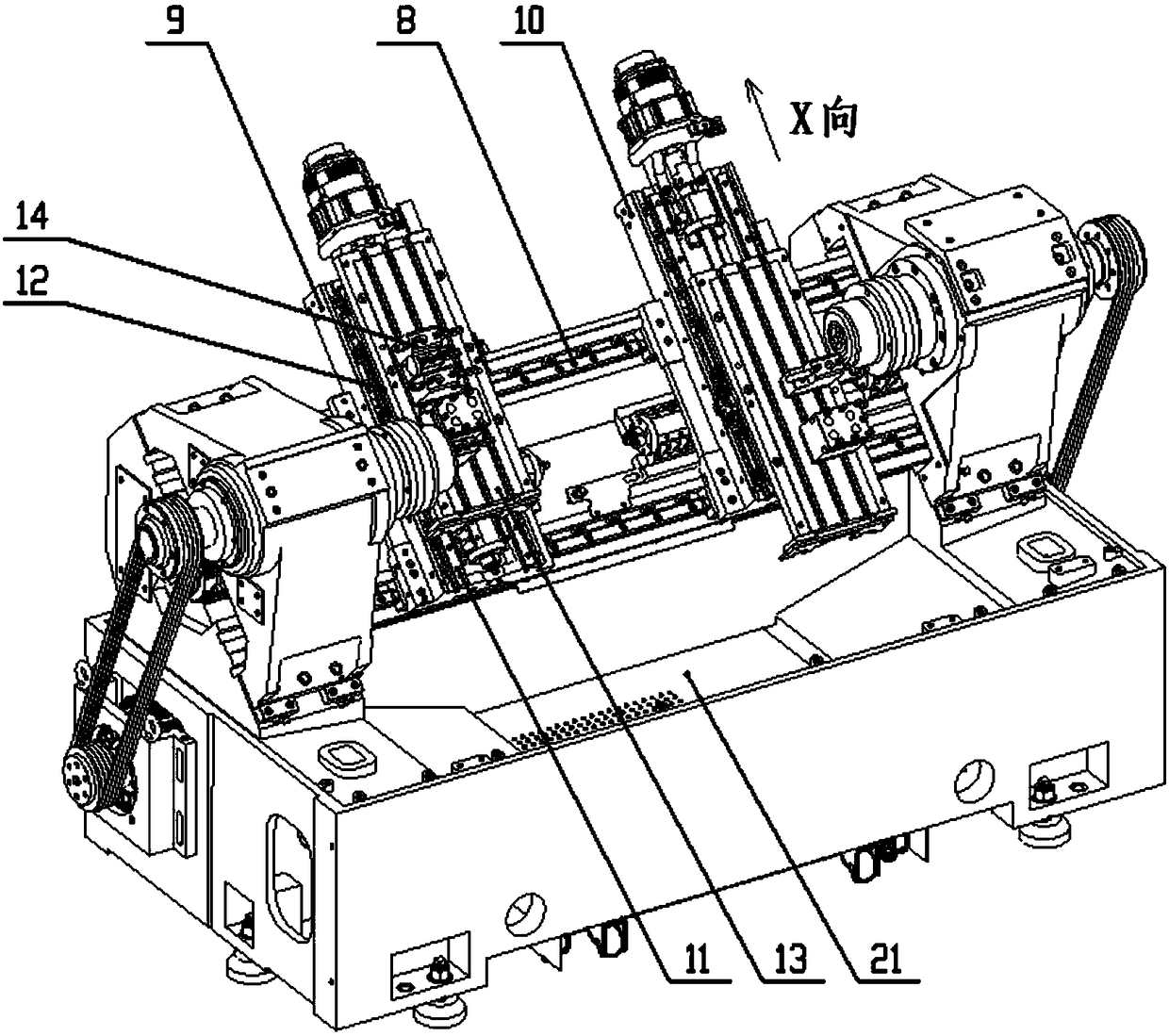

[0024] like figure 1 As shown, the bed 1 is provided with opposite spindle boxes 2 and 3, the spindle unit 4 is installed in the spindle box, the clamping device 5 is installed at the front end of the spindle unit, the spindle and the spindle power main motor 6 are connected by a belt 7, and the double spindle The boxes are respectively fixed with bolts and positioning pins, such as figure 2 As shown, the bed 1 adopts an integral casting inclined bed, and the inner cavity of the two Z-axis guide rails 8 is arranged with 5 horizontal ribs. The upper surface of the bed is funnel-shaped. The Z-axis guide rail supports the middle. This layout is compact and has strong torsion resistance and shock resistance.

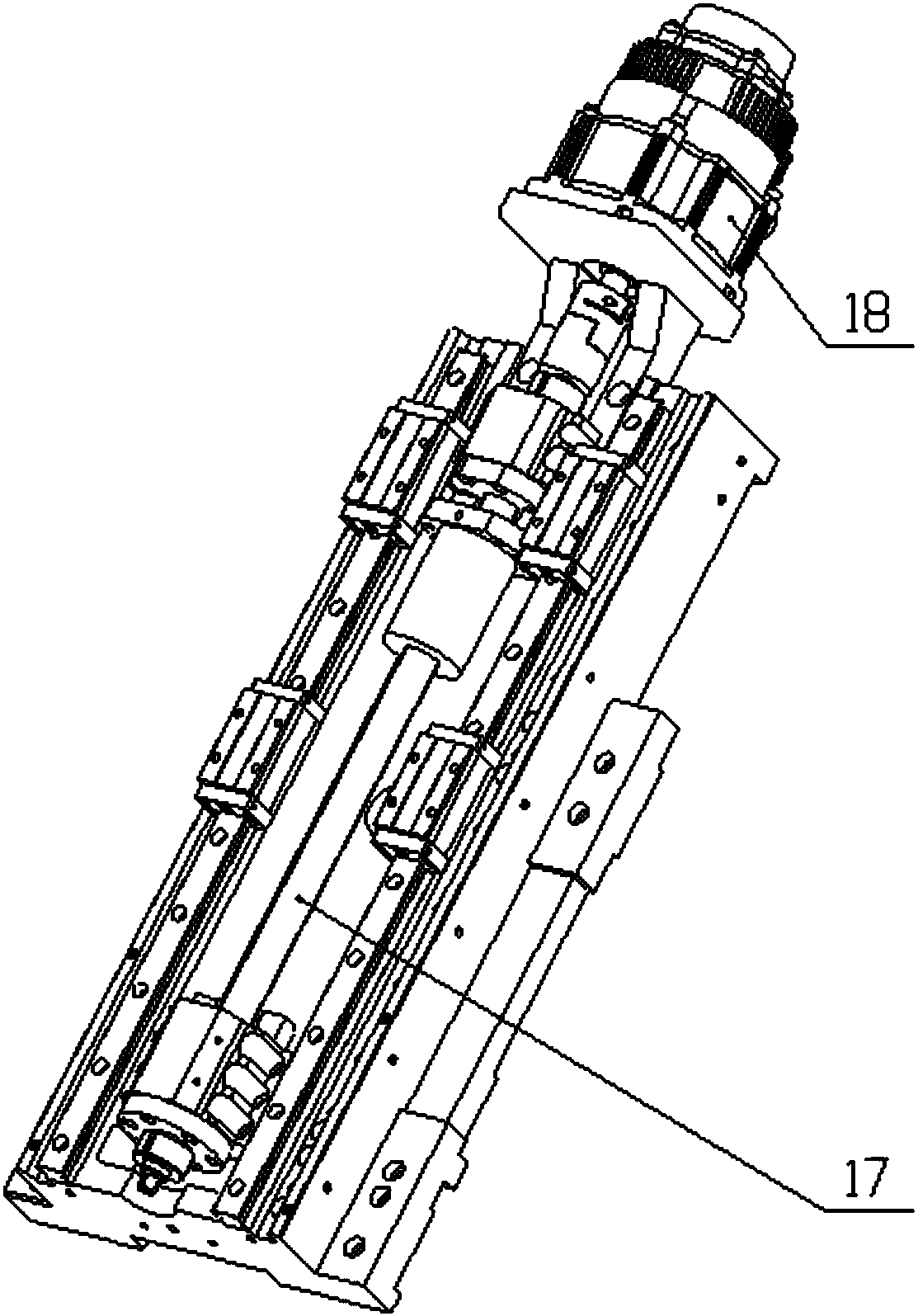

[0025] like figure 2 , image 3 As shown, two double saddles perpendicular to the spindle direction are placed on the bed.

[0026] Two Z-axis linear guides are placed on the bed, and the Z-axis linear guides contain 8 sliders. The left saddle 9 cooperates with the Z-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com