Air cylinder clamp

A cylinder block and fixture technology, applied in the directions of clamping, manufacturing tools, supports, etc., can solve the problems of increasing the complexity and manufacturing cost of the fixture, limited use of fixtures, and a relatively large impact on operability and convenience. Simple and reasonable, ensure the uniformity of wall thickness and the effect of precise processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment. It should be understood that the "upper", "lower", "left", "right", "front" and "reverse" mentioned in the following embodiments of the present invention are all based on the directions shown in the figures, These words used to limit the direction are only for convenience of description, and do not mean to limit the specific technical solution of the present invention.

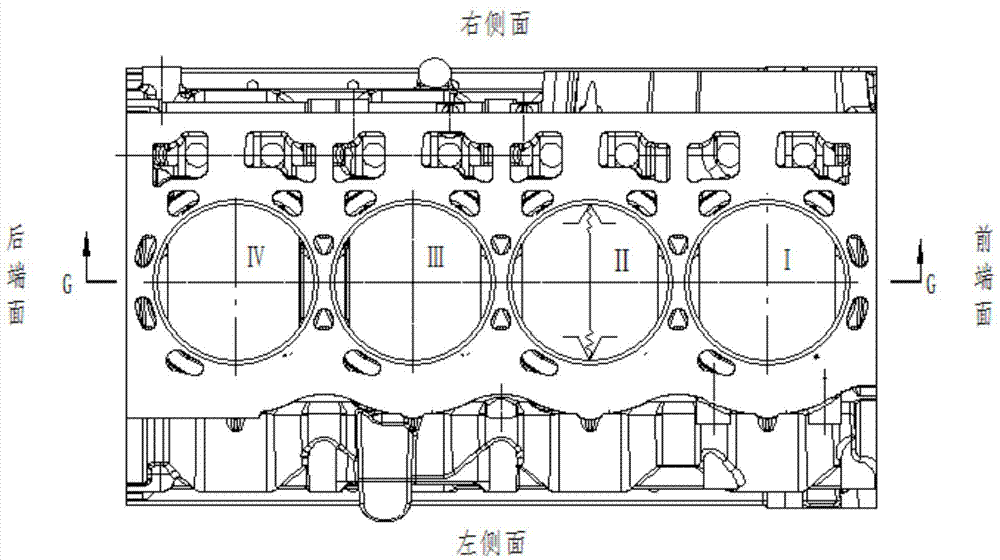

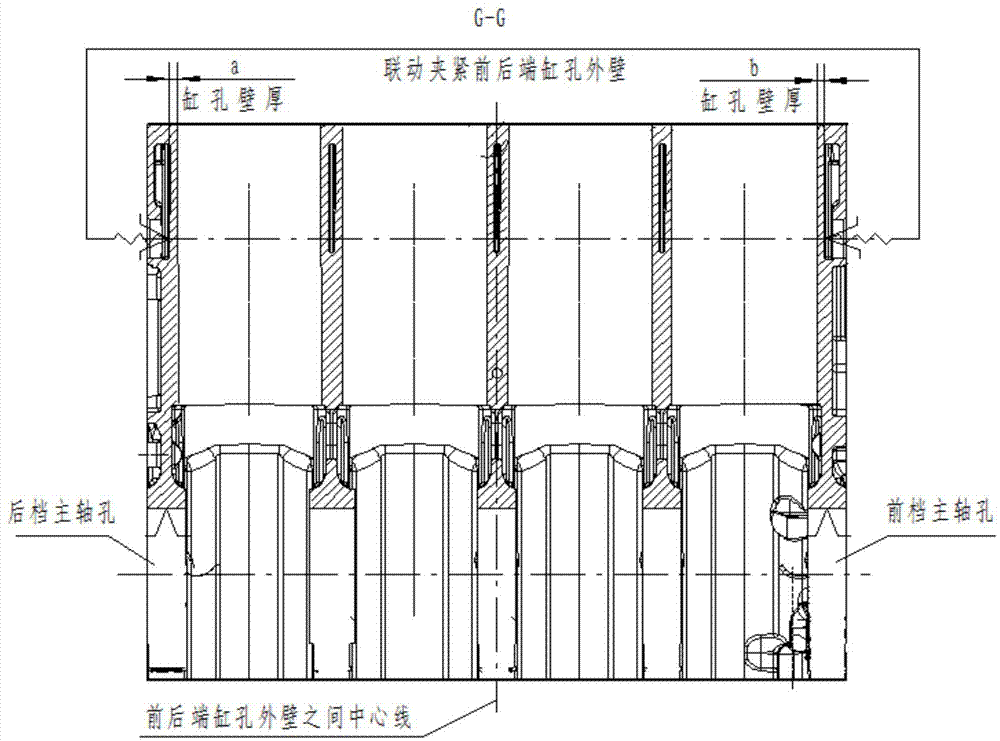

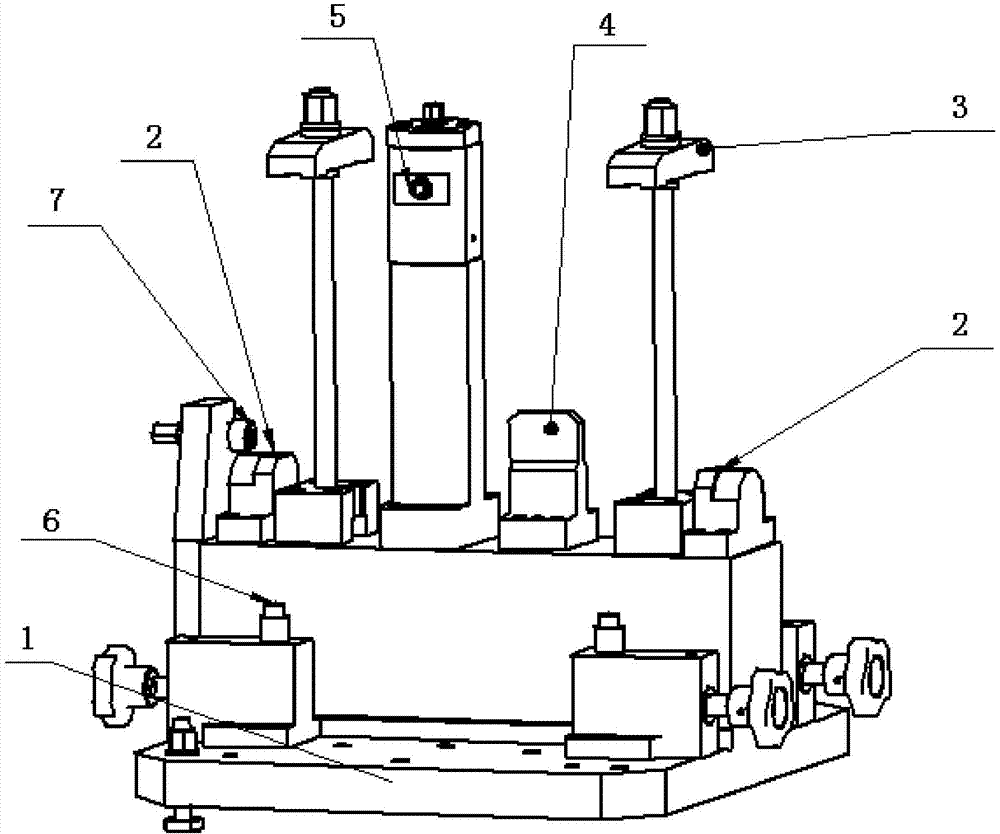

[0029] The structure of the cylinder block fixture of the present invention is simple and reasonable. The cylinder block is positioned by the semicircular holes of the front and rear gear spindles, the side of the middle gear bearing seat and the middle cylinder hole, the cylinder block is clamped from the end surface and the top surface, and the spindle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com