Combined type aluminum alloy formwork system and application method thereof

A technology of aluminum alloy formwork and application method, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, which can solve the difficulty of disassembly and assembly and the inconvenience of wood formwork. Waterproof, running pulp and other problems, to achieve the effect of convenient processing and manufacturing, improve construction quality, and smooth surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

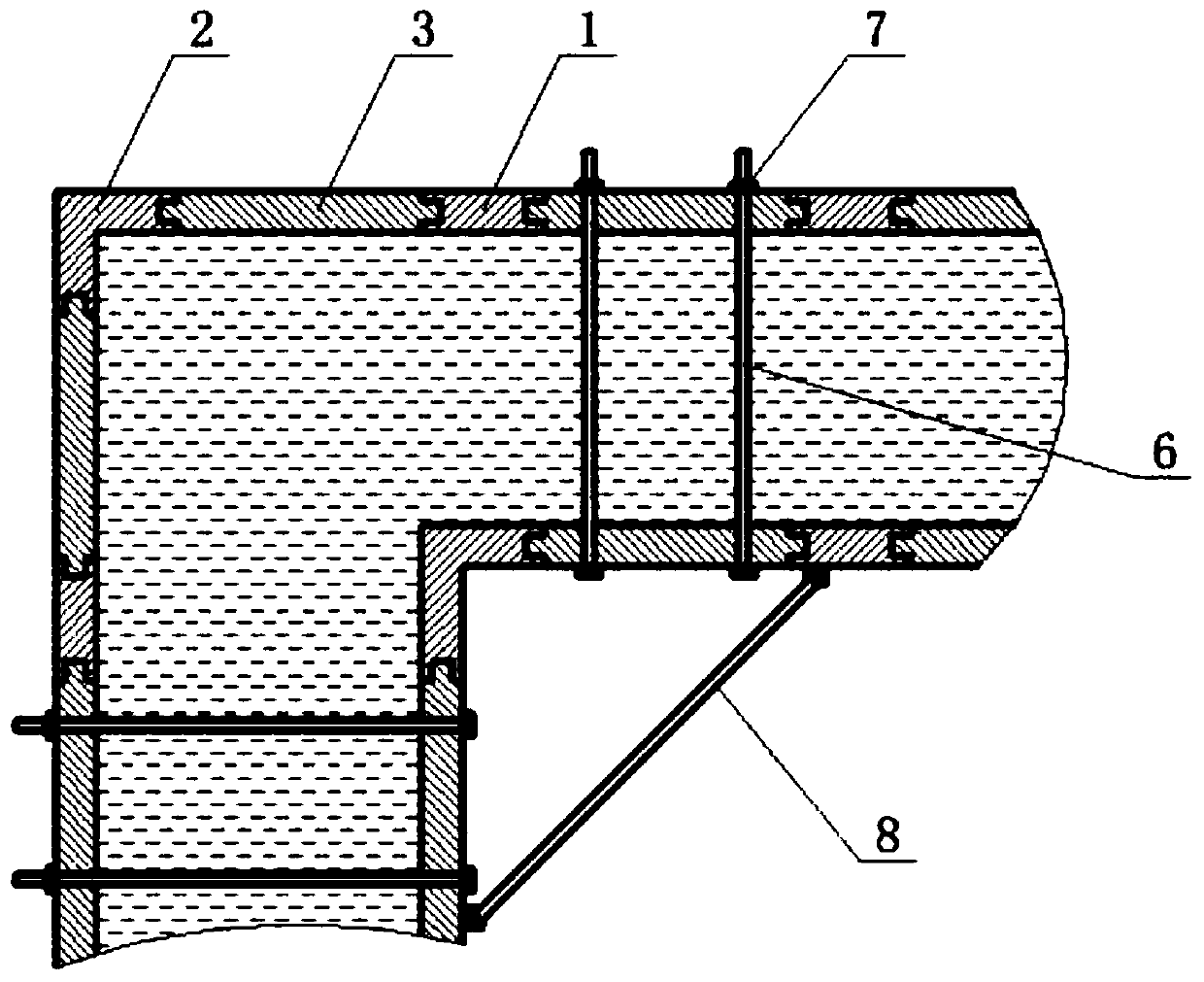

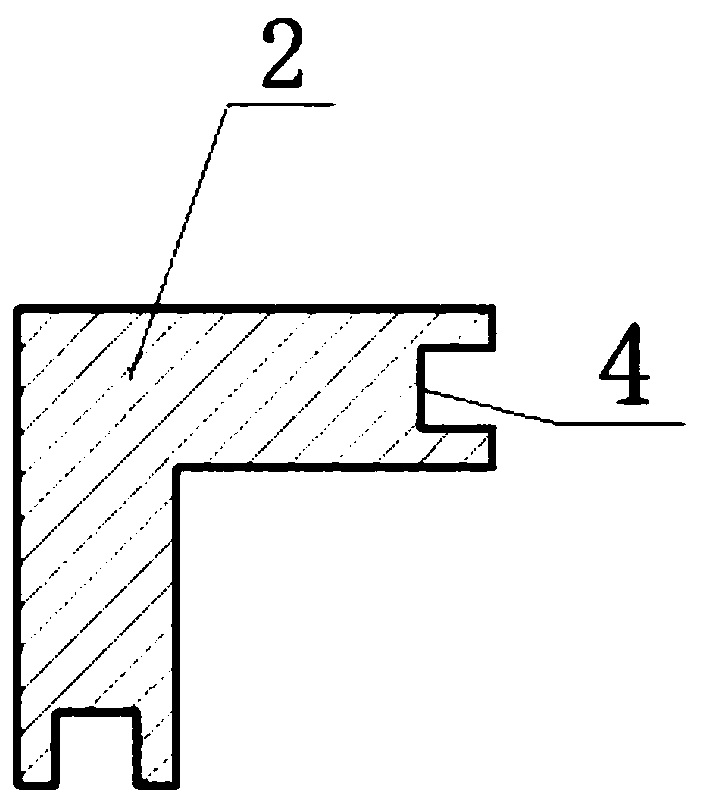

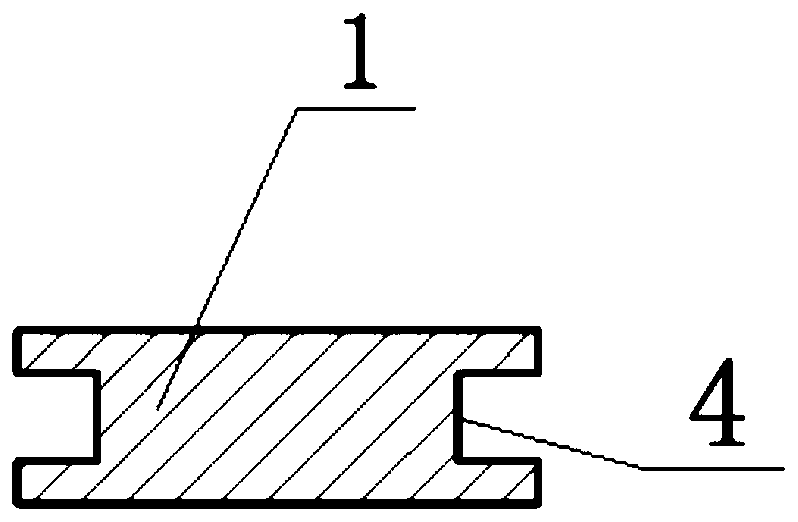

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention provides a combined aluminum alloy formwork system, including a plurality of vertical formwork columns 1, a plurality of corner formwork columns 2 and a plurality of wall formwork 3, vertical formwork columns 1, corner formwork columns 2 and wall formwork 3 is made of aluminum alloy. One end of the vertical mold column 1 and the corner mold column 2 is erected on the ground, and the other end extends upward along the vertical direction. Both ends of the vertical mold column 1 and the corner mold column 2 are provided with tenon grooves 4. The left and right sides of the wall formwork 3 are provided with corresponding tenons 5. Through the cooperation between the tenon grooves 4 and the tenons 5, multiple wall formworks 3 are stacked and de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com