Wrought magnesium alloy with nanostructure characteristics and preparation method thereof

A technology for deforming magnesium alloys and magnesium alloys, applied in the field of metal materials and metallurgy, can solve the problems of low strength and poor plasticity of AZ series magnesium alloys, and achieve the effects of improving stability, small vehicle sales and smooth surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

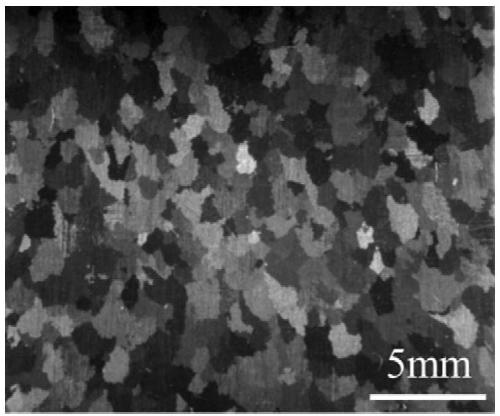

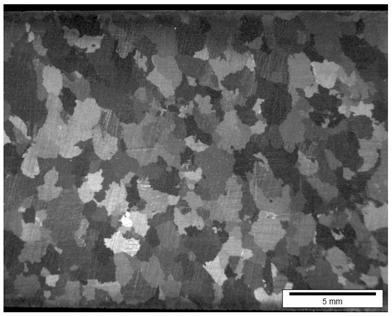

Image

Examples

Embodiment 1

[0036] The composition of the deformed magnesium alloy is Al: 0.8%, Zn: 2.5%, Ca: 0.15%, Mn: 0.2%, Gd: 0.3%, Mg is the balance, and the impurity Fe content is controlled below 0.003%.

[0037] (1) Under the protection of No. 5 flux, the resistance melting furnace is used to smelt the raw materials according to the mass percentage of the deformed magnesium alloy. The Mg ingot is heated to 720°C to melt, and the Al ingot and Zn ingot are added to the melted magnesium liquid. Refining with flux for 20 minutes, when the temperature rises to 730°C, add Mg-25%Gd master alloy and stir evenly to obtain Mg-Al-Zn-Gd melt;

[0038] (2) Cooling and iron removal treatment: Mg-Al-Zn-Gd melt is cooled to 660°C and MnCl is added 2 Perform double iron removal to ensure that the Fe content in the magnesium alloy is less than 0.003%;

[0039](3) Add Mg-30%Ca master alloy when the melt temperature rises to 705°C after iron removal, carry out secondary refining for 10min, and the actual yield of ...

Embodiment 2

[0046] The composition of the deformed magnesium alloy is Al: 0.9%, Zn: 2.2%, Ca: 0.2%, Mn: 0.2%, Gd: 0.2%, Mg is the balance, and the impurity Fe content is controlled below 0.003%.

[0047] (1) Under the protection of No. 5 flux, the electric resistance melting furnace is used to smelt the raw materials according to the mass percentage of the deformed magnesium alloy, and the magnesium ingot is heated to 720°C to melt. According to the mass percentage of the deformed magnesium alloy, Al ingots and Zn ingots are added to the already In the molten magnesium liquid, refine with No. 5 flux for 20 minutes, when the temperature rises to 730°C, add Mg-25%Gd master alloy, stir evenly, and obtain Mg-Al-Zn-Gd melt;

[0048] (2) Low-temperature iron removal treatment: cool down the Mg-Al-Zn-Gd melt to 660°C and add MnCl 2 Perform double iron removal to ensure that the Fe content in the magnesium alloy is less than 0.003%;

[0049] (3) Add Mg-30%Ca master alloy when the melt temperatur...

Embodiment 3

[0056] The composition of the deformed magnesium alloy is Al: 1.2%, Zn: 1.9%, Ca: 0.3%, Mn: 0.3%, Gd: 0.2%, Mg is the balance, and the impurity Fe content is controlled below 0.003%.

[0057] (1) Under the protection of No. 5 flux, the electric resistance melting furnace is used to smelt the raw materials according to the mass percentage of the deformed magnesium alloy, and the magnesium ingot is heated to 720°C to melt. According to the mass percentage of the deformed magnesium alloy, Al ingots and Zn ingots are added to the already In the molten magnesium liquid, refine with No. 5 flux for 20 minutes, when the temperature rises to 730 ° C, add Mg-25% Gd master alloy, stir evenly, and obtain Mg-Al-Zn-Gd melt;

[0058] (2) Low-temperature iron removal treatment: cool the Mg-Al-Zn-Gd melt obtained in step (1) to 660°C and add MnCl 2 Double iron removal, Fe content in magnesium alloy is less than 0.003%;

[0059] (3) Add Mg-30%Ca master alloy when the melt temperature rises to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com