Manufacture method for seamless steel tube

A manufacturing method and seamless steel pipe technology, which is applied in the manufacturing field of austenitic easy-cutting stainless acid-resistant steel, can solve the problems of lack of cutting performance and high-temperature bonding performance, and achieve simple process and high yield , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

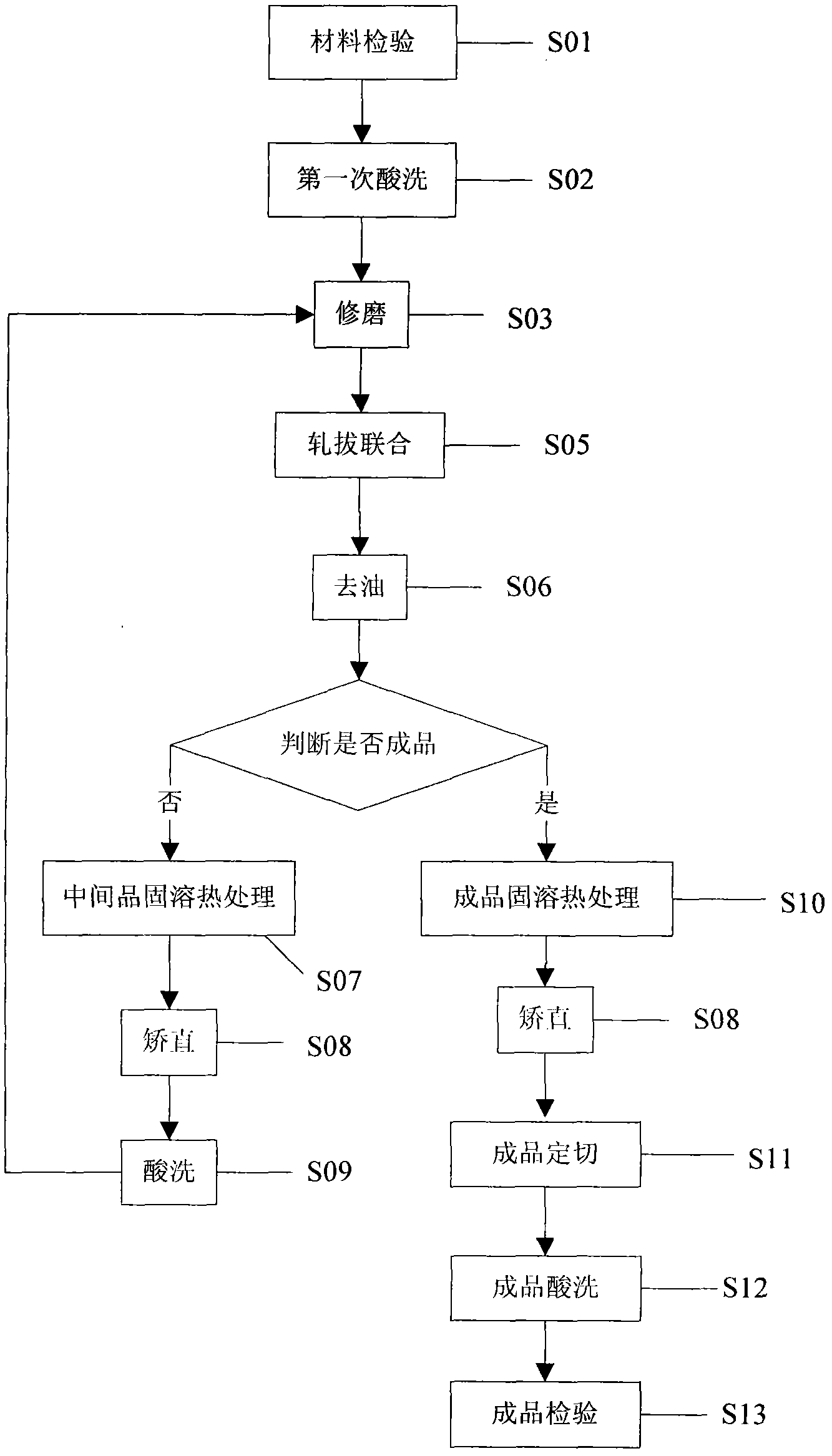

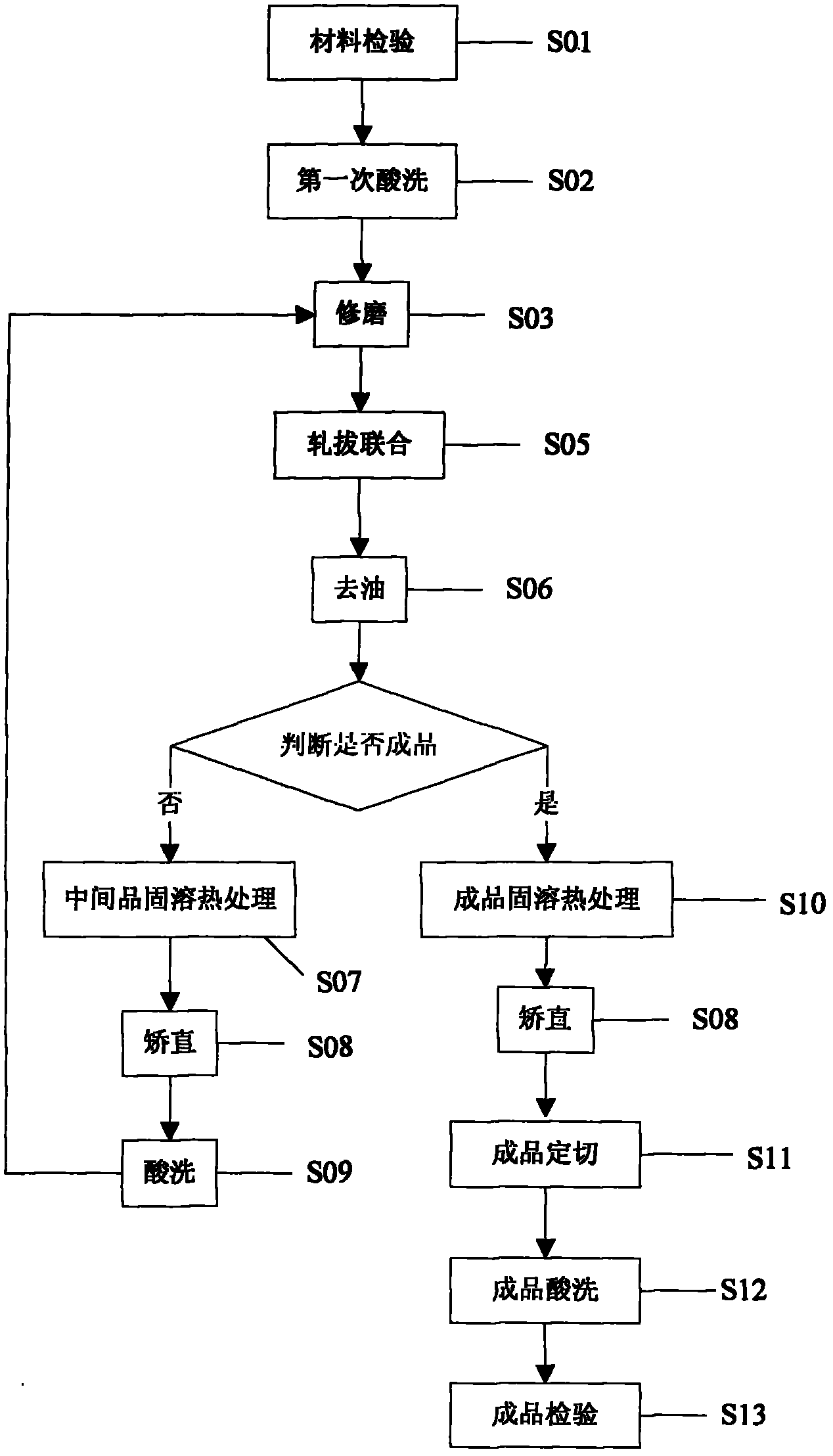

[0031] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0032] See attached figure 1 , Material inspection S01 refers to the inspection of raw materials, including dimensional inspection, surface inspection, quality inspection, chemical composition inspection, etc.

[0033] For the first pickling of S02, the pickling solution in the pickling process uses 8%-10% hydrofluoric acid and 17%-21% nitric acid, and the rest is water. The pickling temperature is controlled at 20-60°C. Pickling solution can completely remove the scale and rust on the steel surface, the surface quality is excellent, the surface roughness Ra can reach 1.00um, and a dense oxide protective film is formed inside and outside the stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com