Novel metal welding method

A new type of metal welding technology, applied in welding equipment, metal processing equipment, resistance welding equipment, etc., can solve the problems of high cost, complicated process, narrow application range, etc., and achieve prolonging life, flexible and convenient operation, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

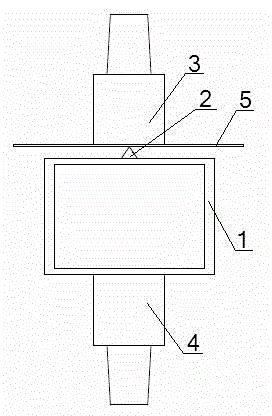

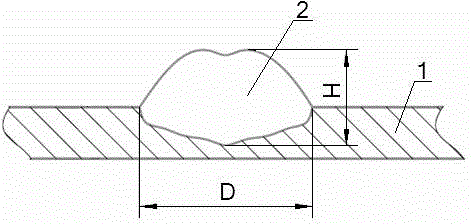

[0038] see figure 1 , figure 2 , a novel metal welding method, which includes the following processes in sequence:

[0039] Protrusion prefabrication process: first determine the welding method used for the prefabricated protrusions according to the size and accuracy requirements of the protrusion 2 as arc welding, and then select welding material 1 according to the materials of arc welding and No. 1 metal material 1 and No. 2 metal material 5 The materials of No. 1 metal material 1 and No. 2 metal material 5 are selected to match the welding consumables, and then an arc welding machine is used to arc-weld the protrusion 2 on the position to be welded of No. 1 metal material 1, wherein No. 1 metal material 1 is The size is a rectangular tube of 40mm×30mm×1.5mm, the second metal material 5 is a thin plate with a thickness of 1mm, the penetration depth of the protrusion 2 is 0.8mm, the penetration rate is 53%, the height H is 1.8mm, and the bottom diameter is D 5mm;

[0040]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com