Electromechanical brake control system and automobile

An electromechanical brake and control system technology, applied in the automotive field, can solve problems such as failure to monitor faults in real time, driver discomfort, slow brake response, etc., to improve vehicle driving safety, improve operating comfort, control Motion control for flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

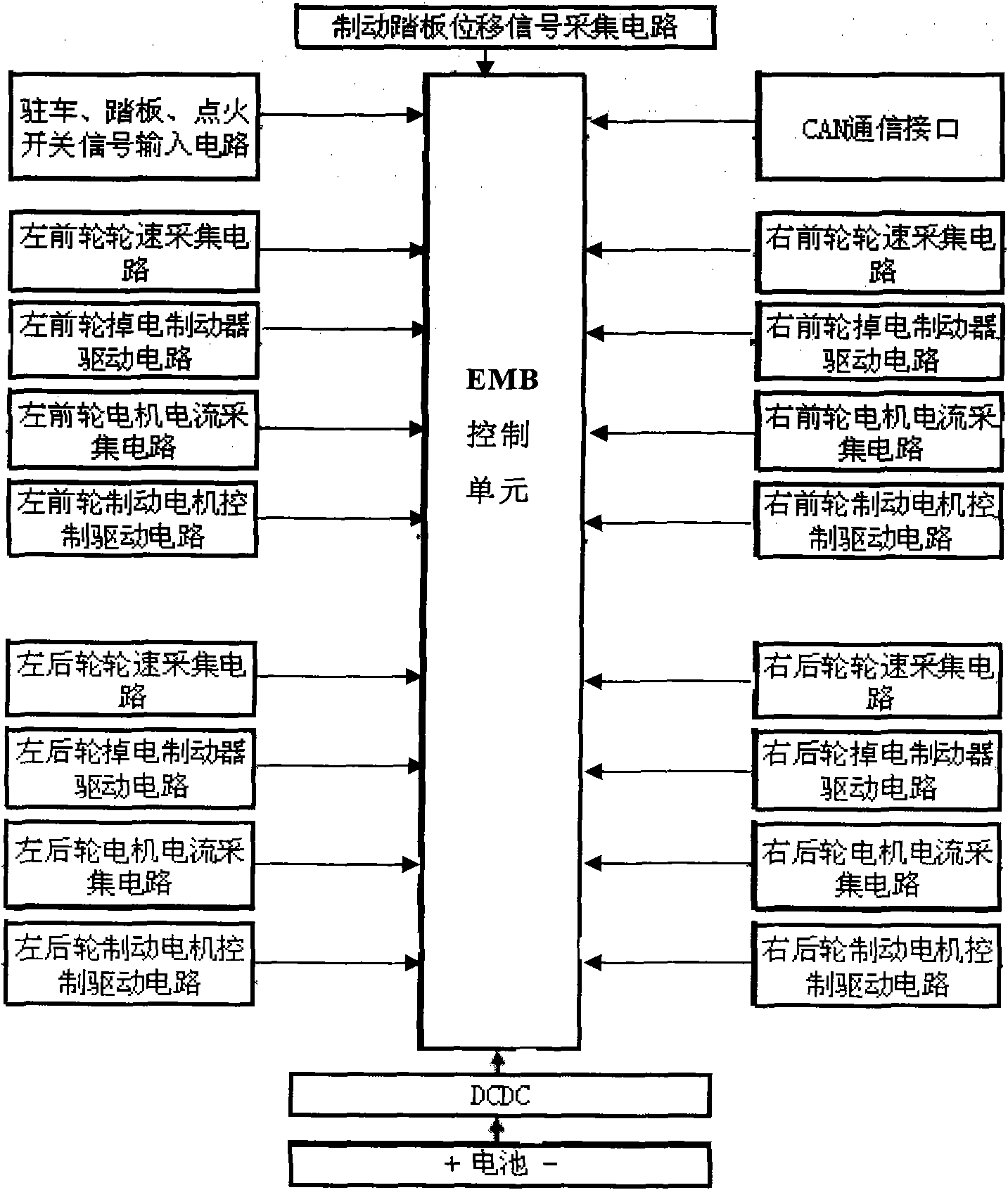

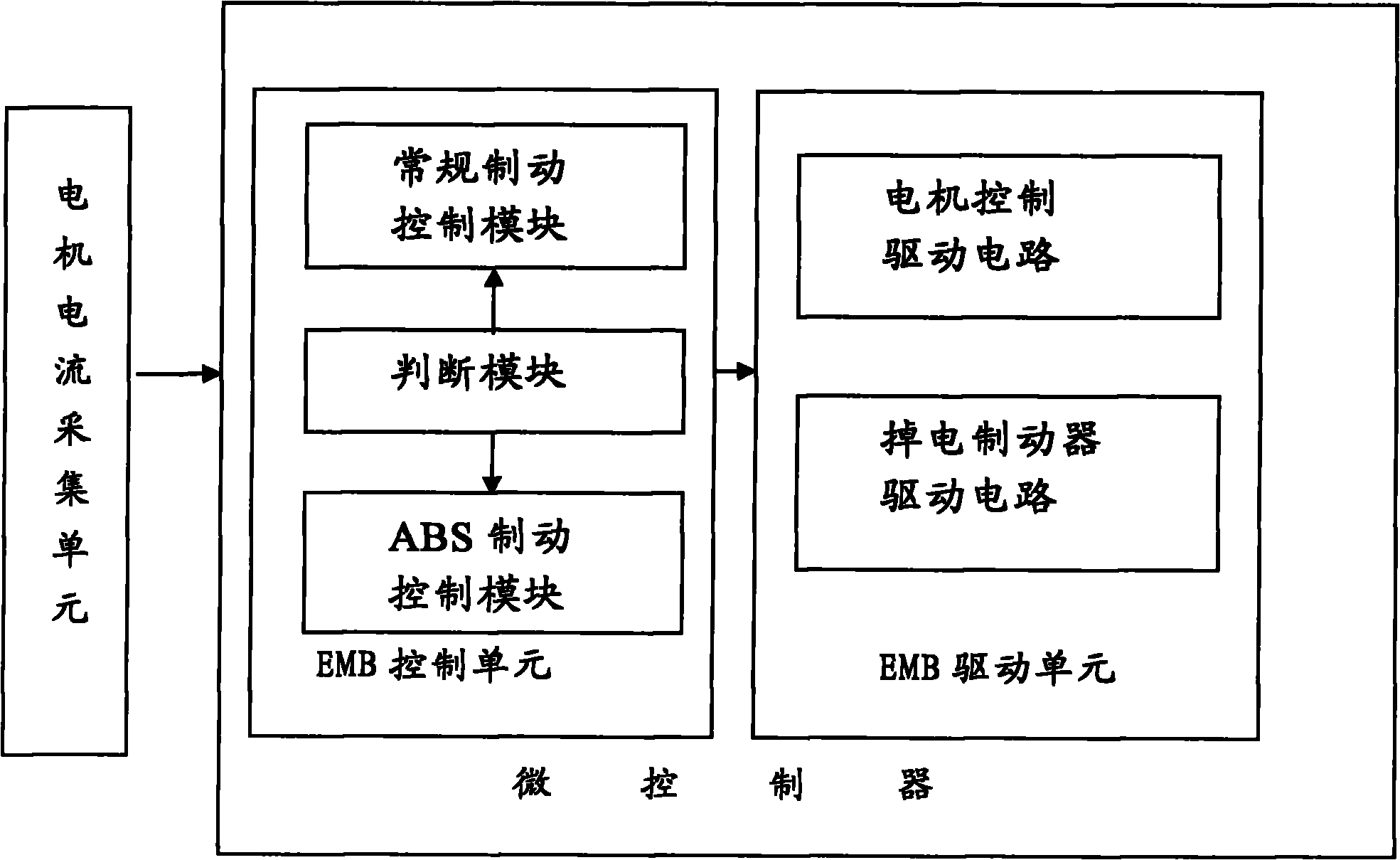

[0048] Such as figure 1 As shown, in this embodiment, the electromechanical braking system includes a braking signal acquisition unit, a microcontroller, a wheel speed acquisition unit, and an electromechanical brake.

[0049] In this embodiment, the electromechanical braking control system is applied to a four-wheeled vehicle, and an electromechanical brake is configured for each wheel of the four-wheeled vehicle, that is, the electromechanical brake in the electromechanical braking system uses four , respectively, the left front wheel electro-mechanical brake, the right front wheel electro-mechanical brake, the left rear wheel electro-mechanical brake, the right rear wheel electro-mechanical brake. By configuring an electro-mechanical brake for each wheel, the electro-mechanical braking system can independently control and real-time adjust the braking torque of each wheel, making the distribution and control of the braking force of the braking system more flexible; Moreove...

Embodiment 2

[0098] The difference between this embodiment and Embodiment 1 is that this system does not have the fault detection unit.

[0099] Other structures in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com