High-carbon chromium bearing steel wire rod production method free of pickling after spheroidizing annealing

A high-carbon chromium bearing steel, spheroidizing annealing technology, applied in the direction of improving process efficiency, metal rolling, etc., can solve problems such as residues, and achieve the effect of reducing process costs and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

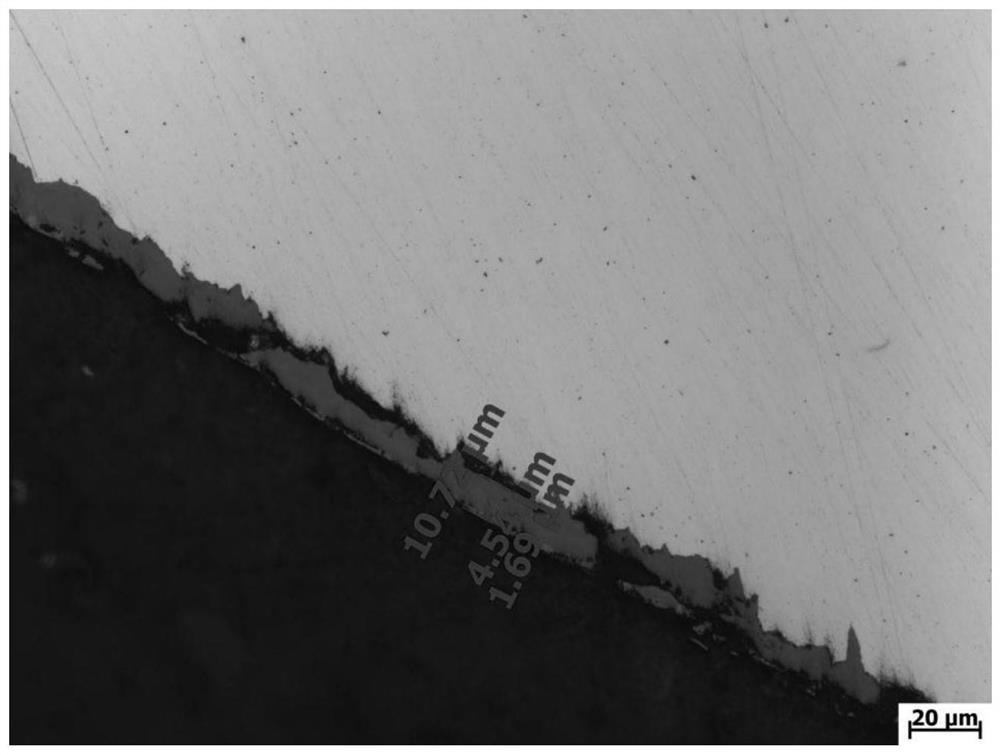

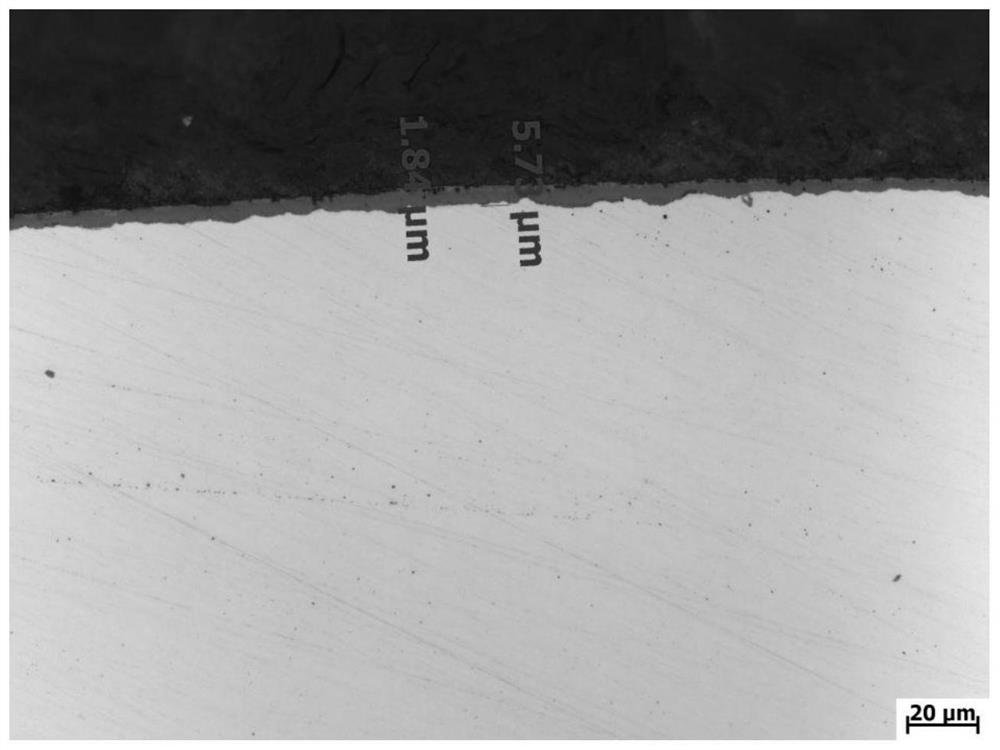

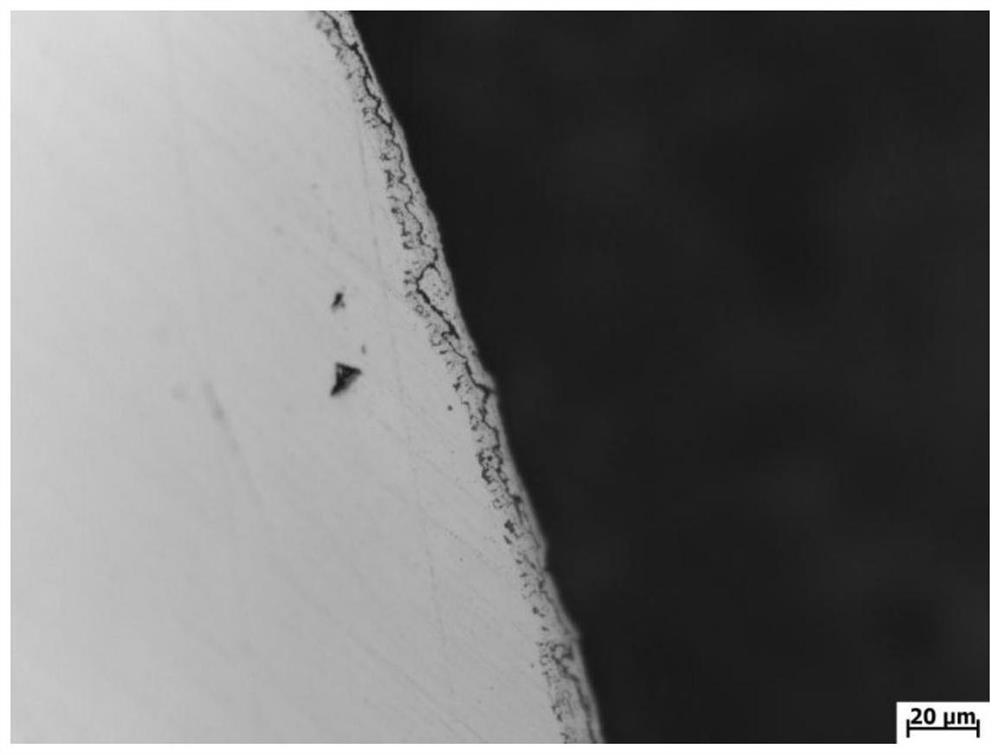

Image

Examples

Embodiment 1

[0048] Invention composition: C: 0.98%, Mn: 0.35%, Si: 0.24%, Cr: 1.47%, P: 0.010%, S: 0.002%, Ni: 0.02%, Cu: 0.02%, Mo: 0.03%, Al : 0.009%, Ti: 0.0015%, [O]: 0.0006%, Ca: 0.0001%, As: 0.004%, Pb: 0.0002%, Sn: 0.005%; the balance is Fe and unavoidable impurities.

[0049] The steps of the present invention: converter smelting, LF refining, VD vacuum treatment, continuous casting operation, to obtain 160 square continuous casting slabs; then the continuous casting slabs are slowly cooled in the heat preservation pit, heated in the heating furnace, dephosphorized by high-pressure water, controlled rolling, controlled cooling, collected and packaged , finishing and inspection, spheroidizing annealing, drawing.

[0050] (1) According to the control requirements of each component, through converter smelting, LF refining, VD vacuum treatment, and continuous casting operations, a 160-square-meter continuous casting billet was obtained;

[0051] (2) The continuous casting slab is dir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com