Preparation method of polymer film containing nano fullerene

A nano-fullerene and fullerene technology, which is applied in the field of material doping and modification, can solve the problems of affecting the heat resistance of polymer materials, lowering the thermal decomposition temperature, and not having universal applicability, so as to achieve good storage stability , Inhibit viscosity decrease, improve storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

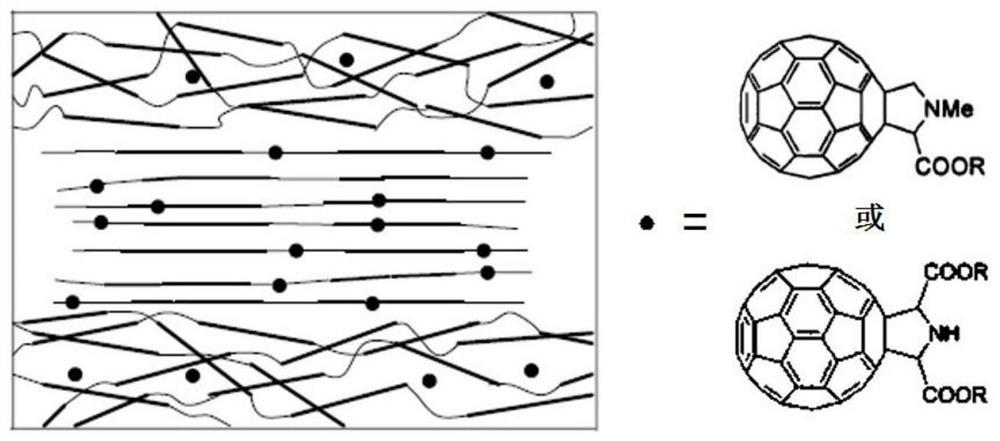

Image

Examples

Embodiment 1

[0027] Embodiment 1 polyimide / fullerene hybrid film PI / AC 60 -0.5%

[0028] Step (1): In a three-neck flask equipped with mechanical stirring, nitrogen inlet and outlet, and a thermometer, add 10.81 grams (0.10 moles) of p-phenylenediamine (p-PDA) and 160 grams of N-methyl-2-pyrrolidone, Stir under nitrogen protection until completely dissolved; add 29.42 grams (0.10 moles) of 3,3',4,4'-biphenyltetracarboxylic dianhydride (s-BPDA), stir until completely dissolved, and react at 20°C After 12 hours, a polyamic acid solution with a solid content of about 20 wt % was obtained.

[0029] Step (2): Weigh 0.18 g of methyl carbamate-modified C60 fullerene, add it into the above polyamic acid solution, and stir rapidly until the mixture is uniform.

[0030] Step (3): After filtering the above-mentioned polyamic acid / fullerene precursor solution and vacuum defoaming, it is coated on a glass plate or a stainless steel plate with a flat surface. Under nitrogen atmosphere, bake at 80°C f...

Embodiment 2

[0031] Embodiment 2 polyimide / fullerene hybrid film PI / AC 60 -1.0%

[0032] Step (1): In a three-necked flask equipped with mechanical stirring, nitrogen inlet and outlet, and a thermometer, add 10.81 grams (0.10 moles) of p-phenylenediamine (p-PDA) and 230 grams of N,N-diethylacetamide , stirred under nitrogen protection until completely dissolved; added 29.42 g (0.10 moles) of 3,3',4,4'-biphenyltetracarboxylic dianhydride (s-BPDA), stirred until completely dissolved, at 25°C React for 16 hours to obtain a polyamic acid solution with a solid content of about 15 wt%.

[0033] Step (2): Weigh 0.36 g of methyl carbamate-modified C60 fullerene, add it into the polyamic acid solution, and stir rapidly until the mixture is uniform.

[0034] Step (3): After filtering the above-mentioned polyamic acid / fullerene precursor solution and vacuum defoaming, it is coated on a glass plate or a stainless steel plate with a flat surface. Under nitrogen atmosphere, bake at 60°C for 2 hours, ...

Embodiment 3

[0035] Embodiment 3 polyimide / fullerene hybrid film PI / AC 60 -2.0%

[0036] Step (1): In a three-neck flask equipped with mechanical stirring, nitrogen inlet and outlet, and a thermometer, add 10.81 grams (0.10 moles) of p-phenylenediamine (p-PDA) and 230 grams of N,N-dimethylacetamide , stirred under nitrogen protection until completely dissolved; added 29.42 grams (0.10 moles) of 3,3',4,4'-biphenyltetracarboxylic dianhydride (s-BPDA), stirred until completely dissolved, at 15°C React for 24 hours to obtain a polyamic acid solution with a solid content of about 15 wt%.

[0037] Step (2): Weigh 0.72 g of methyl carbamate-modified C60 fullerene, add it to the above polyamic acid solution, and stir rapidly until the mixture is uniform.

[0038] Step (3): After filtering the above-mentioned polyamic acid / fullerene precursor solution and vacuum defoaming, it is coated on a glass plate or a stainless steel plate with a flat surface. Under nitrogen atmosphere, bake at 80°C for 1 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com