Metal surface treatment anti-sticking agent

A technology for metal surface treatment and anti-adhesive agent, applied in the field of anti-adhesive agent, can solve the problems of affecting the surface quality of copper strips, corrosion of chemical components, low content of active ingredients, etc., achieve good ecological safety and compatibility, and improve stability. and uniformity, the effect of improving the anti-sticking effect

Inactive Publication Date: 2015-09-16

黄琳

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For the rolled metal strip, due to the tension before and after the rolling process, there is a large internal stress between the layers of the metal strip, and the activity of the metal between the layers increases while annealing at a certain temperature , it is easy to cause adhesion between metal layers and affect the subsequent processing of metal strips. Therefore, it is necessary to solve the technical problem of metal strip adhesion

[0003] Application publication number is CN102560036A, and the Chinese invention patent of CN1024179056A has introduced anti-adhesive agent for copper tape, but there are two problems in it: the one, because use the particle that is 0.1-2 micron particle, particle size is too small, can't be very good To prevent the adhesion between the copper strip layer and the layer; second, the chemical composition used is easy to cause corrosion on the surface of the copper strip, which affects the surface quality of the copper strip; at the same time, the chemical composition content is high, and it is easy to form impurities on the surface of the copper strip

The content of active ingredients in this patent is very low, and the good effect of anti-sticking cannot be achieved, and the function is single, and the comprehensive performance is poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

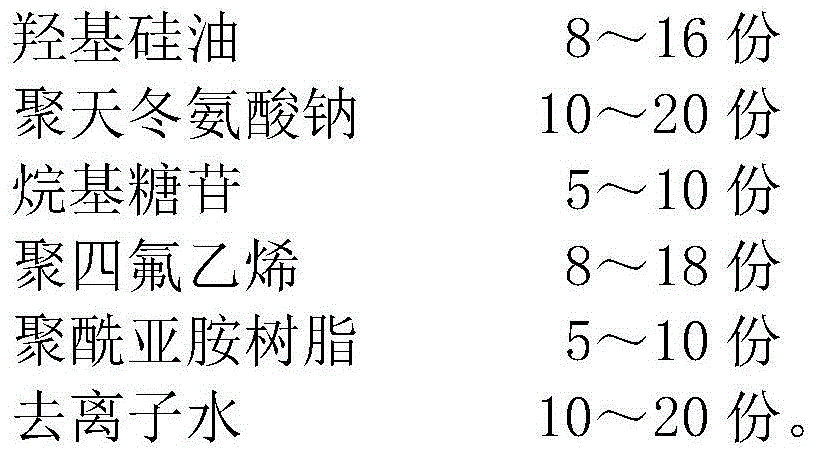

Embodiment 1

[0020] Weigh the raw materials according to the following parts by weight, and fully stir them evenly:

[0021]

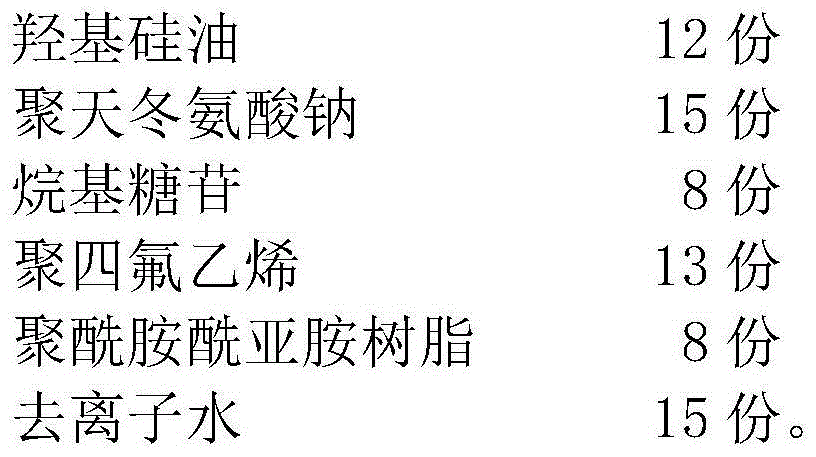

Embodiment 2

[0023] Weigh the raw materials according to the following parts by weight, and fully stir them evenly:

[0024]

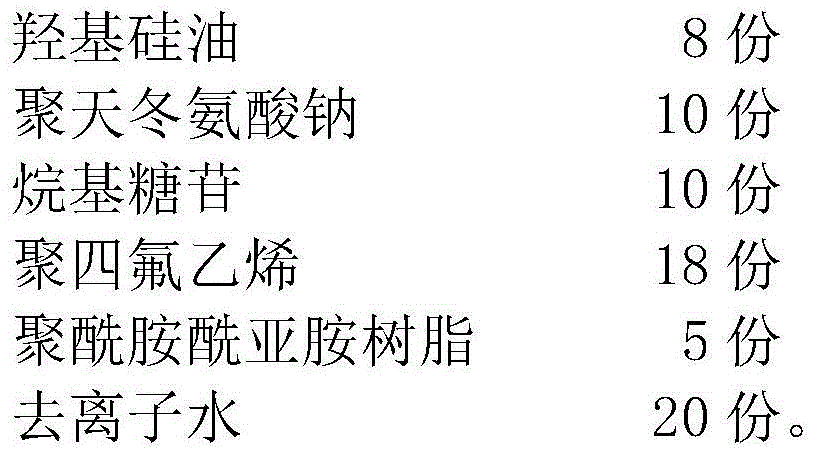

Embodiment 3

[0026] Weigh the raw materials according to the following parts by weight, and fully stir them evenly:

[0027]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to the anti-sticking agent technical field, and particularly relates to a metal surface treatment anti-sticking agent prepared from the following raw materials in parts by weight: 8-16 parts of hydroxyl silicone oil, 10-20 parts of polyaspartic acid, 5-10 parts of alkyl glycoside, 8-18 parts of polytetrafluoroethylene, 5-10 parts of polyamideimide resin, and 10-20 parts of deionized water. The metal surface treatment anti-sticking agent is reasonable in composition, obvious in effect and stable in chemical properties, can effectively prevent adhesion between layers of a metal strip, and also has the function of corrosion resistance; the metal product surface quality is bright and clean; and the anti-sticking agent has good levelling property and thixotropy, meets processing at various temperatures, and can be used for a long time.

Description

technical field [0001] The invention relates to the technical field of anti-adhesive agents, in particular to an anti-adhesive agent for metal surface treatment. Background technique [0002] Rolling is a commonly used processing method in metal processing. Rolling passes the metal billet through the gap between a pair of rotating rolls. Due to the compression of the rolls, the cross-section of the material is reduced and the length is increased. After rolling, the metal will undergo work hardening, that is, the plasticity of the metal will deteriorate, and subsequent processing will be more difficult, requiring annealing. For the rolled metal strip, due to the tension before and after the rolling process, there is a large internal stress between the layers of the metal strip, and the activity of the metal between the layers increases while annealing at a certain temperature , it is easy to cause adhesion between metal layers and affect the subsequent processing of the meta...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21D1/68

Inventor 黄琳

Owner 黄琳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com