Production method of cold rolling thin slab with size of 2.75->0.165*1000mm

A technology of cold-rolled sheet and production method, which is applied in metal rolling and other directions, can solve the problems of increasing production cost, affecting the yield of finished products, and low yield of finished products, and achieves the effects of improving production efficiency, reducing production cost and high cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

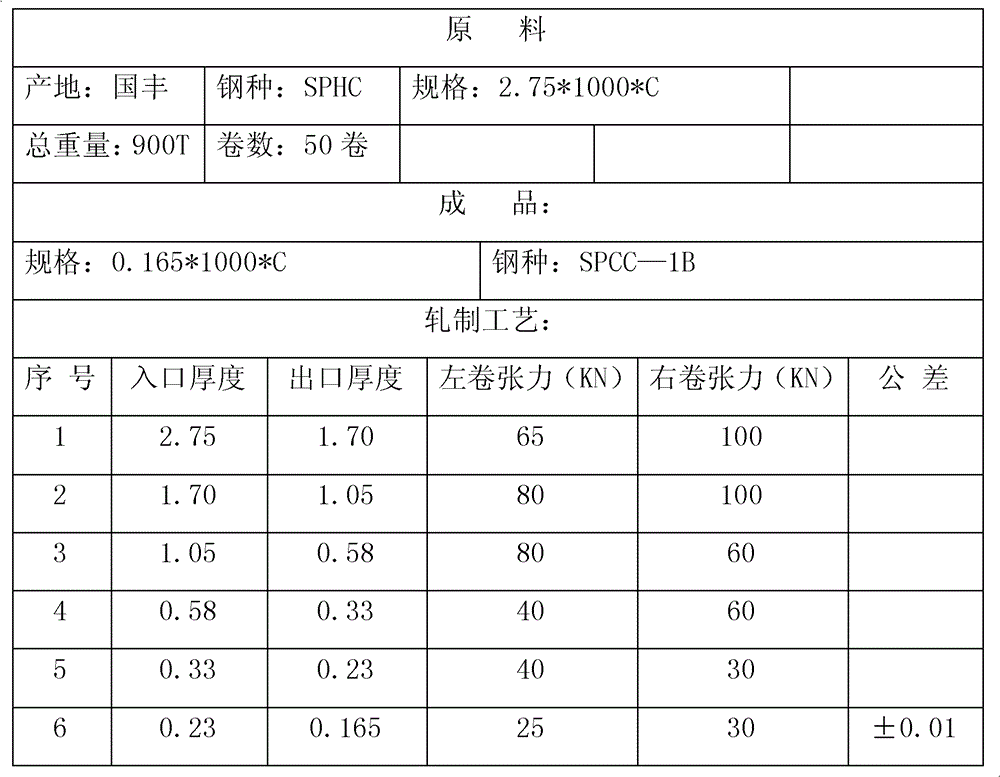

[0018] The production method of the 2.75->0.165*1000mm cold-rolled sheet of the present invention will be described in conjunction with the examples.

[0019] The production method of 2.75->0.165*1000mm cold-rolled sheet of the present invention, the method comprises the following steps:

[0020] ①Arrange specification production according to working conditions

[0021] According to the supply requirements, check the working conditions of the rolling mill, that is, whether the equipment is running normally, whether the roll system has out-of-tolerance runout, etc. After each roll change, first arrange 2 rolls of cold-rolled sheets with a specification of ≥0.35*1000mm, and then arrange cold-rolled sheets with a specification of ≤0.165-1000mm;

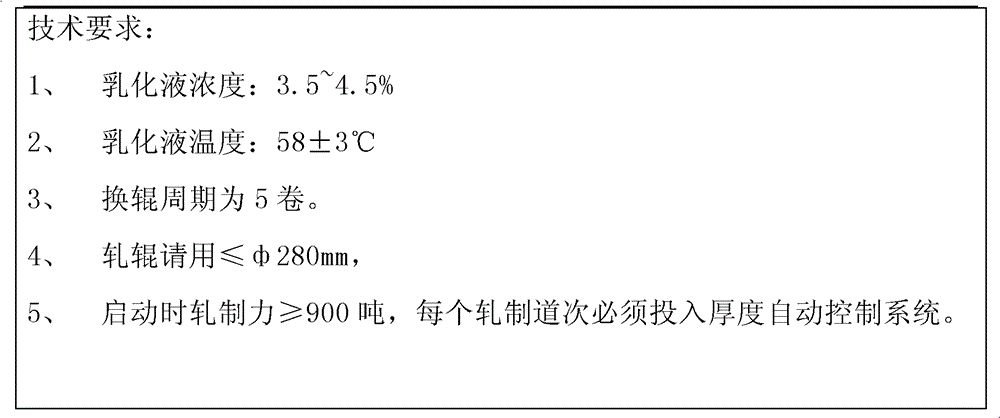

[0022] ②Adjust the technical parameters of rolling oil during rolling

[0023] During the rolling process, the concentration of rolling oil is controlled between 3.5-4.5%, the temperature is 57-60°C, and the pH value is 5.5-6.2;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com