Novel ceramic zinc pot and electrical heating arrangement method

An arrangement method and electric heating technology, applied in the direction of ohmic resistance heating parts, heating elements, heating element shapes, etc., can solve the problems of high temperature insulation, limited range of plating parts, electric heating breakdown and other problems, and achieve the reduction of zinc Consumption, energy saving, electricity cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

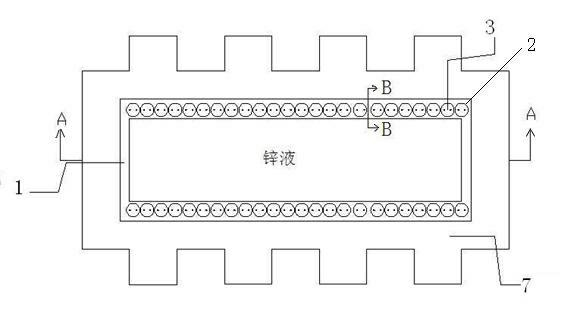

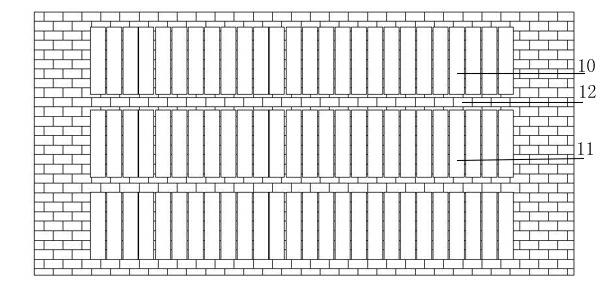

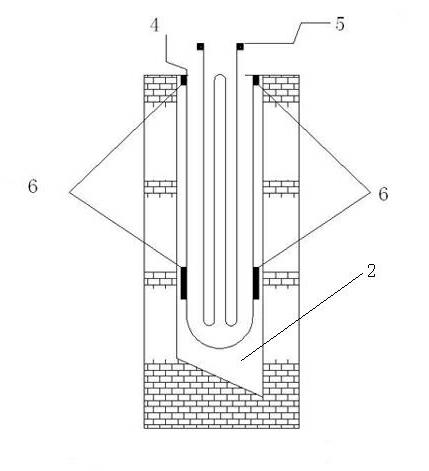

[0036] Such as figure 1 As shown, the novel ceramic zinc pot of the present invention includes a zinc pot body 1 made of refractory ceramic bricks, and also includes a zinc pot body 7 connected to the zinc pot body 1 . Wherein, the side wall of the zinc pot body 1 is provided with a plurality of placement positions 2 perpendicular to the bottom surface of the zinc pot body, the placement positions 2 are sequentially extended along the length of the side wall, and the placement position is provided with a heating unit 3; In this embodiment, the zinc pot body 1 adopts a cuboid with a length of 12m, a width of 1.2m, and a height of 2m. Of course, as long as it does not d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com