Preparation method of spherical titanium and nickel shape memory alloy for 3D (three-dimensional) printing

A memory alloy and 3D printing technology, applied in the field of 3D printing, can solve the problems of uneven distribution of elements and low powder sphericity, and achieve the effect of low non-metallic inclusion content, high powder sphericity, and ensuring consistency and uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

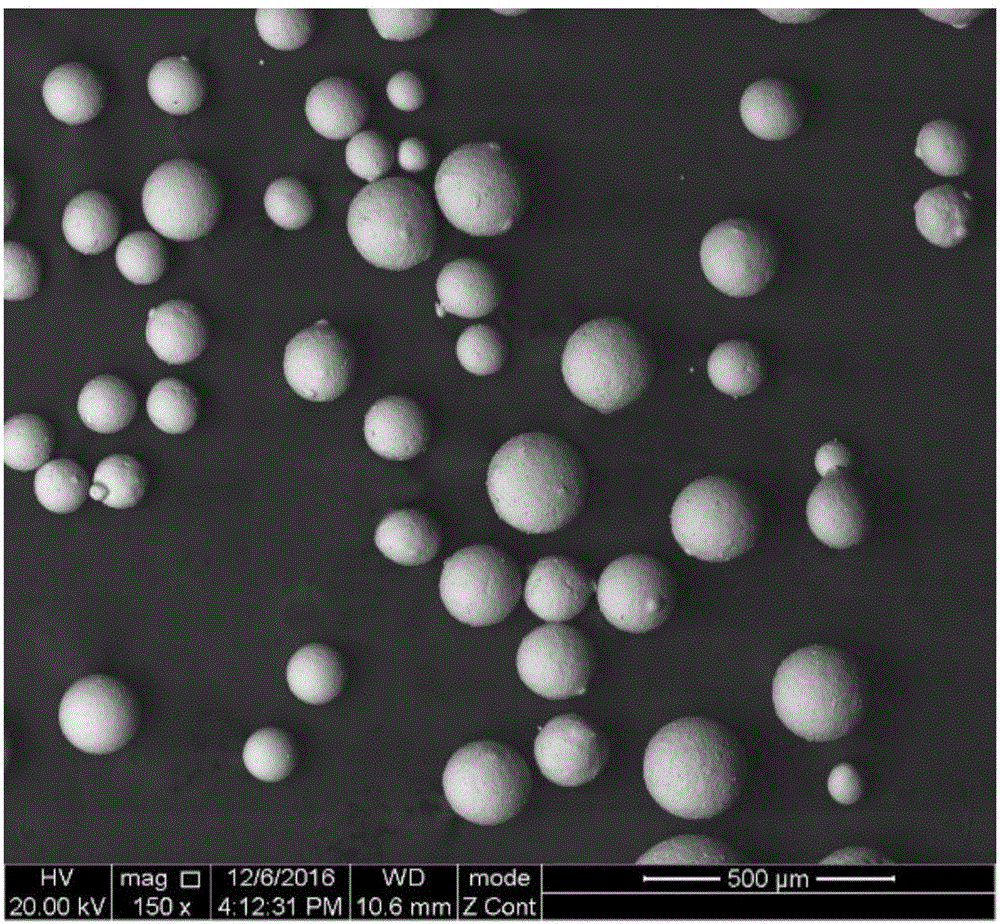

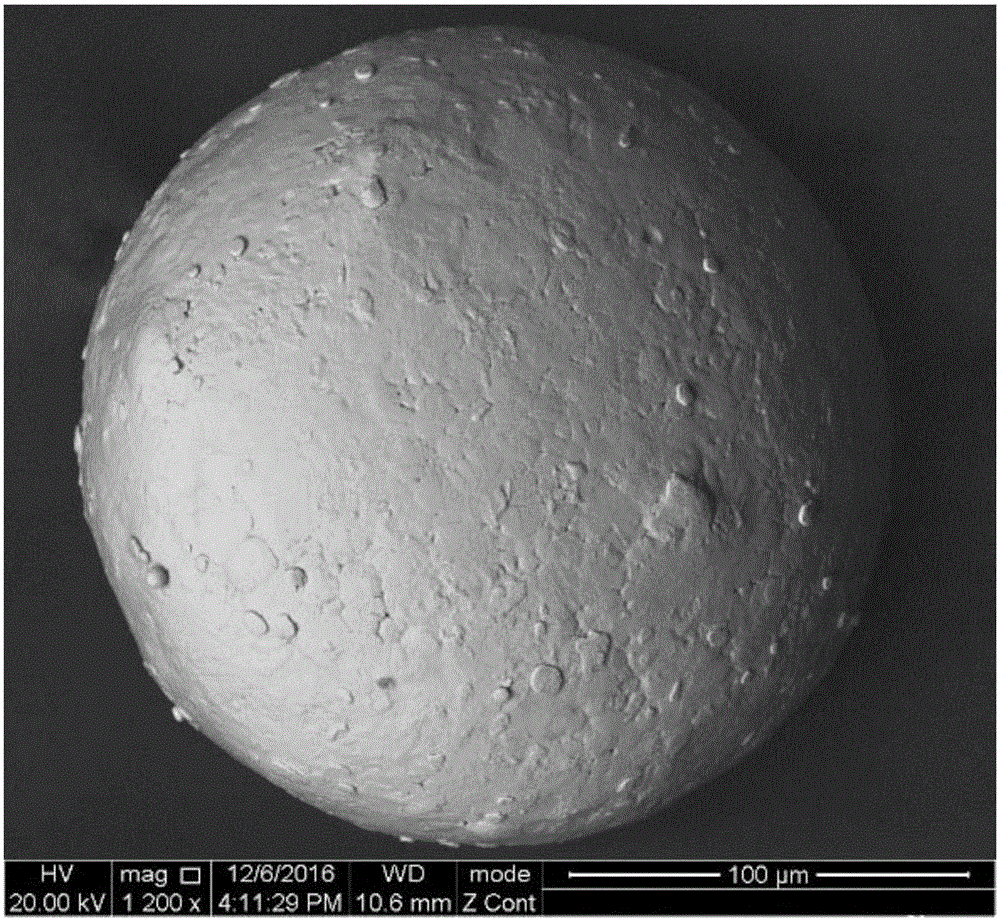

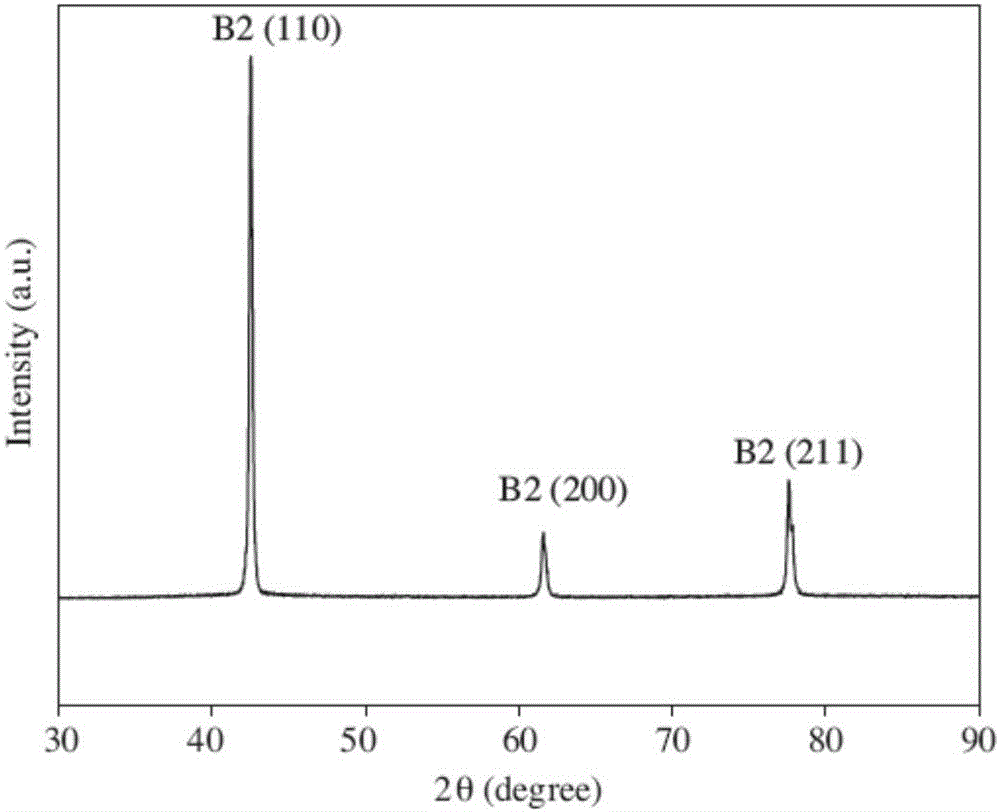

[0025] Process the titanium-nickel alloy into an electrode rod with a diameter of 50mm and a length of 600mm and install it on the feeding device, vacuumize the entire atomization device and fill it with argon protective gas; the electrode rod rotates at a speed of 140r / min and 80mm / min The falling speed of the rod enters the lower conical coil, and the tip of the bar is gradually melted by induction heating in the conical coil to form a melt flow. Under the action of gravity, the melt flow directly flows into the atomizer below the conical coil, and the high-pressure argon The gas enters the annular slit atomizer through the gas pipeline, and interacts with the metal liquid flow under the gas outlet. The liquid flow is broken into small droplets by the action of high-pressure gas, and the atomizing gas pressure is 3.5MPa. During the flight in the atomization chamber, the liquid droplets are spheroidized and solidified into metal powder by their own surface tension.

[0026] T...

Embodiment 2

[0028] The titanium-nickel master alloy with a diameter of 30mm and a length of 1000mm is used as the electrode rod. The electrode rod enters the lower conical coil at a rotation speed of 200rpm and a descending speed of 150mm / min. The tip of the rod is gradually melted by induction heating in the conical coil. The melt flow is formed, and under the action of gravity, the melt flow directly flows into the atomizer below the conical coil, and the high-pressure argon gas enters the atomizer through the gas pipeline, interacts with the metal liquid flow under the gas outlet, and passes through the high-pressure The gas action breaks the liquid flow into small droplets, and the atomization pressure is 3MPa. During the flight in the atomization chamber, the liquid droplets are spheroidized and solidified into metal powder by their own surface tension.

[0029] The particle shape of titanium-nickel powder prepared by electrode-induced gas atomization is spherical or nearly spherical...

Embodiment 3

[0031] The titanium-nickel master alloy with a diameter of 70mm and a length of 400mm is used as the electrode rod. The electrode rod enters the lower conical coil at a rotation speed of 50r / min and a descending speed of 40mm / min. The tip of the rod is heated by induction in the conical coil. Gradually melt to form a melt flow, and under the action of gravity, the melt flow directly flows into the atomizer below the conical coil, and the high-pressure argon enters the atomizer through the gas pipeline, and interacts with the metal flow under the gas outlet, The liquid flow is broken into small droplets by the action of high-pressure gas, and the atomization pressure is 4.5MPa. During the flight in the atomization chamber, the liquid droplets are spheroidized and solidified into metal powder by their own surface tension.

[0032] The particle shape of titanium-nickel powder prepared by electrode-induced gas atomization is spherical or nearly spherical, and there is basically no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com